Beruflich Dokumente

Kultur Dokumente

Engro

Hochgeladen von

HaseebPirachaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Engro

Hochgeladen von

HaseebPirachaCopyright:

Verfügbare Formate

IFC INCLUSIVE BUSINESS MODEL CASE STUDY

May 2014

Inclusive Business Case Study: ENGRO FOODS LIMITED (EFL)

Location: Pakistan

Sector: Dairy

IFC Investment: Up to $50 million in long-term debt financing

COMPANY BACKGROUND

Launched in 2005, EFL manufactures, processes, and sells dairy products,

juice, ice cream, and frozen desserts in Pakistan. It is the second largest

producer of processed milk in the country. EFL has state-of-the-art processing

plants and an ice cream factory in the province of Punjab, as well as its own

dairy farm in the province of Sindh. The company employs more than 1,700

people, including 200 staff in rural areas.

EFL is a majority-owned (87%) subsidiary of Engro Corporation Limited (ECL),

one of Pakistans largest conglomerates with seven businesses in a wide

range of industries. Other shareholders include individuals, employees, and

institutional investors. EFL is listed on two stock exchanges in Pakistan.

EFLS Inclusive Business Model

EFL seeks to build strong, long-term relationships with small dairy farmers to ensure

the company has a stable and secure supply of milk. However, the nature of the dairy

sector in Pakistan presents formidable challenges. First, EFL has to engage farmers

in the informal sector. Less than 1 million of the approximately 8 million farming

households sell milk to companies; the rest are in the informal sector. Second, EFL

has to procure milk from farmers who are dispersed over a large geographic area.

Dairy farming is small-scale in nature in Pakistan. Households on average rear two

to five cows or buffaloes that yield three to five liters of milk per day. The more than

72 million dairy animals in the country are spread over hundreds of thousands of

square kilometers at these very small farms. Third, EFL has to help farmers improve

milk yields and quality, which are sub-optimal due to weak feeding patterns, lack of

modern farming techniques, and poor access to veterinary services.

To overcome these challenges, EFL has developed a system that combines a vast

village-level procurement infrastructure, transparency through technology, and

technical training and agri-services for farmers. EFLs value-proposition to small

farmers has three elements:

Direct Sourcing through Village-Level Infrastructure: EFL procures milk directly from

farmers in rural areas through a three-pronged approach.

First, the company has set up over 1,800 Milk Collection Centers (MCCs) to

reach 85% of EFLs supplier base of 300,000 farmers. Run by an EFL contractor,

an MCC is typically a 300-sq.ft shop with a chilling tank, basic laboratory,

and geyser. Equipment runs on electricity or a generator in off-grid areas.

Centers are on average within two kilometers of farmers homes so are walking

distance or a short ride by local transport. Each center collects around 400

liters of milk per day.

Second, farmers who are far from an MCC can sell milk to Village Milk Collectors

(VMCs) hired by EFL. The company has hired over 1,700 VMCs including Female

Village Milk Collectors (FVMCs). EFL trains them in milk testing, handling, and

hygiene practices. The company provides VMCs with basic equipment such

as collection utensils, a testing kit, and record keeping register; those who

collect large quantities are given coolers and generators. VMCs collect milk

regularly from dairy farmers in their villages at the company-set price and after

conducting the required tests. They receive commissions based on volumes

collected.

Third, EFL uses contractors and dodhis who purchase milk from farmers and

transport it to an MCC where it is tested. Dodhis are village-level door-to-door

milk collectors who purchase and sell milk to a number of buyers. Contractors

may have their own milk collection networks of dodhis. In general, purchase

prices are mutually agreed, farmers may receive cash advances, and tests are

not conducted at the time of purchase.

More than 360 trucks with insulated tanks then transport milk from MCCs to EFL

regional hubs and thereafter to the milk processing plants.

Transparency and Efficiency through Technology: EFL has created a management

information system to collect, transmit, and monitor real time data from its MCCs

called the Engro Milk Automation Network (EMAN). This name evokes the Urdu word

iman, meaning faith, and signifies the trust-based, fair, and transparent relationship

that EFL seeks to build with its suppliers.

Milk is tested and measured at an MCC at the time of delivery. After acceptance, a

unique magnetic card assigned to the farmer is swiped at a point-of-sale terminal to

enter the transaction in EMAN. Using a GPRS connection, data is transmitted to EFL

staff to so they can monitor gains and losses in the value chain, optimize logistics,

and advise on improvements among other areas. EMAN is finally used to facilitate

payment via direct deposit to suppliers or to MCCs that pay farmers in cash. Payment

schedules can be customized based on farmers needs.

Improved Yields through Training and Access to Inputs: EFL has established 40 agriservice units staffed with 87 veterinarians and agrarians who the company trains to

serve MCC clusters. Each unit serves an average of 25 farmers. Vets provide practical

training and guidance in areas such as vaccination, hygiene, and feeding practices.

EFL is about to launch shops for dairy and agri-inputs for farmers at its 22 field offices.

The companys projects with USAID and CARE Inc. USA are creating livelihood

opportunities for women by training them in livestock and dairy management. These

Female Livestock Extension Workers (FLEW) provide services to women dairy farmers

including those in EFLs network. FVMCs are also trained through these programs.

In partnership with the Asian Development Bank and a local bank, EFL plans to

extend 12-month working capital finance and longer-term finance for purchase of

cows and other assets. Farmers loan repayments will be deducted from weekly milk

payments from EFL.

IFCs Inclusive Business Models Group

www.ifc.org/inclusivebusiness

IFC INCLUSIVE BUSINESS MODEL CASE STUDY

Inclusive Business Case Study: ENGRO FOODS LIMITED (EFL)

Location: Pakistan

Sector: Dairy

IFC Investment: Up to $50 million in long-term debt financing

DRIVERS FOR EFLS Inclusive Business MODEL

A majority of dairy farmers in Pakistan rear 2-5 cows; engaging and strengthening small farmers underpins EFLs ability to secure its milk supply

Improving and maintaining milk quality requires training and deeper engagement with small farmers

Need to expand domestic milk procurement rather than milk imports as EFL grows

Over 92% of milk is produced by small farmers in Pakistan. These farmers rear two to

five cows that produce between 3-5 liters per day as against the world benchmark

of 25-30 liters per day. Small farmers are dispersed over hundreds of thousands of

kilometers in rural areas with poor or limited access to markets, transportation, and

other infrastructure. This results in a high rate of milk spoilage or loss of 15%. Further,

farmers rely on middlemen to sell milk and receive unfair prices and high interest

rates for credit. Companies pay transaction fees to middlemen and receive milk of

inconsistent quality. A primary business driver, therefore, for EFLs inclusive business

model is the need to engage small farmers directly for raw milk supply.

Second, EFL recognizes that procuring milk through middlemen will not help the

company improve quality. Instead, it needs to invest in farmer training to procure

quality milk to deliver high quality products. Third, growing demand for EFLs products

requires the company to ramp-up its milk supply. To ensure stability and security of

milk supply in the medium- to long-term EFL requires a strong system to expand

domestic procurement.

RESULTS OF EFLS Inclusive Business MODEL

Total revenues of $370 million and gross profits of $8.5 million in 2013

Procuring milk from 300,000 small dairy farmers

More than 1,800 milk collection centers covering around 15,000 villages

EFL began operations in 2006 with a processing capacity of 234,000 liters of milk per

day, which has increased to over 1.8 million liters per day as of 2013. The companys

total revenues grew from $16.5 million in 2006 to $370 million in 2013. The company

became profitable in 2010, and its gross profits increased from $2 million in 2010 to

$8.5 million in 2013.

the companys dairy farm. A small dairy farmer supplies an annual average of 1,000

liters of milk to EFL, earning approximately $450 in sales revenue. The company has

also established a vast procurement infrastructure with a field force, 40 agri-service

units, and over 1,800 milk collection centers across 200,000 square kilometers to cover

around 15,000 villages.

The companys supplier base of small dairy farmers more than doubled between 2008

and 2013 to reach 300,000. During the same period, the total value of milk procured

grew from $55 million to $90 million. In 2013, EFL procured 200 million liters of milk

or 95% of its total supply from small farmers, while the balance was sourced from

In 2012, EFL received the G20 Challenge on Inclusive Business Innovation Award. In

2013, the Computerworld Honors Program, which recognizes visionary applications

of information technology to promote positive social, economic and educational

change, recognized EFL as a laureate for its EMAN system.

IFCS ROLE AND VALUE-ADD

IFC and Engro Corporation Ltd. (ECL), the parent company of EFL, have a long

relationship that spans over two decades, enabling the company to diversify

into important sectors of the economy

In 2009, IFC provided a subordinated loan of up to $50 million to help ECL

meet its financing needs

Play a counter cyclical role, financing ECL at an important time in the

companys growth trajectory as well as in difficult market conditions for

financing

IFCs Inclusive Business Models Group

www.ifc.org/inclusivebusiness

IFCs Investment:

Up to $50 million in long-term debt financing

Investment Year:

2009

Das könnte Ihnen auch gefallen

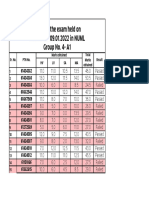

- Result of The Exam Held On 08.01.2022-09.01.2022 in NUML Group No. 4-A1Dokument2 SeitenResult of The Exam Held On 08.01.2022-09.01.2022 in NUML Group No. 4-A1HaseebPirachaNoch keine Bewertungen

- Result of The Exam Held On 08.01.2022-09.01.2022 in NUML Group No.5-A1Dokument1 SeiteResult of The Exam Held On 08.01.2022-09.01.2022 in NUML Group No.5-A1HaseebPirachaNoch keine Bewertungen

- Result of The Exam Held On 08.01.2022-09.01.2022 in NUML A2Dokument2 SeitenResult of The Exam Held On 08.01.2022-09.01.2022 in NUML A2HaseebPirachaNoch keine Bewertungen

- Result of The Exam Held On 18.12.2021-19.12.2021 in Lahore B2Dokument1 SeiteResult of The Exam Held On 18.12.2021-19.12.2021 in Lahore B2HaseebPirachaNoch keine Bewertungen

- b2 Karachi Result 21.01.2022Dokument1 Seiteb2 Karachi Result 21.01.2022HaseebPirachaNoch keine Bewertungen

- Result of The Exam Held On 08.01.2022-09.01.2022 in NUML B2: HV LV SA MA 1 2 3 4 5 Sr. No. PTN No. Marks ObtainedDokument1 SeiteResult of The Exam Held On 08.01.2022-09.01.2022 in NUML B2: HV LV SA MA 1 2 3 4 5 Sr. No. PTN No. Marks ObtainedHaseebPirachaNoch keine Bewertungen

- b2 Karachi Result 21.01.2022Dokument1 Seiteb2 Karachi Result 21.01.2022HaseebPirachaNoch keine Bewertungen

- Result of The Exam Held On 18.12.2021-19.12.2021 in Lahore B2Dokument1 SeiteResult of The Exam Held On 18.12.2021-19.12.2021 in Lahore B2HaseebPirachaNoch keine Bewertungen

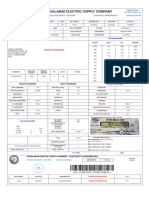

- Fesco Online Bill January 2Dokument1 SeiteFesco Online Bill January 2HaseebPirachaNoch keine Bewertungen

- b2 Karachi Result 21.01.2022Dokument1 Seiteb2 Karachi Result 21.01.2022HaseebPirachaNoch keine Bewertungen

- Result of The Exam Held On 08.01.2022-09.01.2022 in NUML B2: HV LV SA MA 1 2 3 4 5 Sr. No. PTN No. Marks ObtainedDokument1 SeiteResult of The Exam Held On 08.01.2022-09.01.2022 in NUML B2: HV LV SA MA 1 2 3 4 5 Sr. No. PTN No. Marks ObtainedHaseebPirachaNoch keine Bewertungen

- Result of The Exam Held On 08.01.22-09.01.2022 in NUML B1Dokument2 SeitenResult of The Exam Held On 08.01.22-09.01.2022 in NUML B1HaseebPirachaNoch keine Bewertungen

- Result of The Exam Held On 23.10.2021-25.10.2021 in Lahore B1Dokument2 SeitenResult of The Exam Held On 23.10.2021-25.10.2021 in Lahore B1HaseebPirachaNoch keine Bewertungen

- Result of The Exam Held On 08.01.2022-09.01.2022 in NUML B2: HV LV SA MA 1 2 3 4 5 Sr. No. PTN No. Marks ObtainedDokument1 SeiteResult of The Exam Held On 08.01.2022-09.01.2022 in NUML B2: HV LV SA MA 1 2 3 4 5 Sr. No. PTN No. Marks ObtainedHaseebPirachaNoch keine Bewertungen

- Fesco Online Bill January 1Dokument1 SeiteFesco Online Bill January 1HaseebPirachaNoch keine Bewertungen

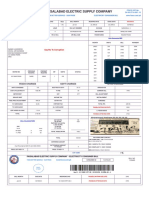

- FESCO GST No. Bill DetailsDokument1 SeiteFESCO GST No. Bill DetailsHaseebPirachaNoch keine Bewertungen

- Fesco Online Bill January 1Dokument1 SeiteFesco Online Bill January 1HaseebPirachaNoch keine Bewertungen

- FESCO GST No. Bill DetailsDokument1 SeiteFESCO GST No. Bill DetailsHaseebPirachaNoch keine Bewertungen

- Ausschreibung Helmut-Schmidt-Programm enDokument7 SeitenAusschreibung Helmut-Schmidt-Programm enGemechuNoch keine Bewertungen

- Fesco Online Bill January 1Dokument1 SeiteFesco Online Bill January 1HaseebPirachaNoch keine Bewertungen

- Fesco Online BillDokument2 SeitenFesco Online BillHaseebPirachaNoch keine Bewertungen

- FESCO GST No. Bill DetailsDokument1 SeiteFESCO GST No. Bill DetailsHaseebPirachaNoch keine Bewertungen

- Fluid Mechanics 101: Calculators & ToolsDokument11 SeitenFluid Mechanics 101: Calculators & ToolsHaseebPirachaNoch keine Bewertungen

- Fesco Online Bill January 2Dokument1 SeiteFesco Online Bill January 2HaseebPirachaNoch keine Bewertungen

- Fesco Online Bill January 2Dokument1 SeiteFesco Online Bill January 2HaseebPirachaNoch keine Bewertungen

- Complete Postcode List For Pakistan: Listed in Postcode Order From 10010 To 97320Dokument38 SeitenComplete Postcode List For Pakistan: Listed in Postcode Order From 10010 To 97320allah ditta shafiNoch keine Bewertungen

- Faisalabad Electric Supply Company: Say No To CorruptionDokument2 SeitenFaisalabad Electric Supply Company: Say No To CorruptionHaseebPirachaNoch keine Bewertungen

- Faisalabad Electric Supply Company: Say No To CorruptionDokument2 SeitenFaisalabad Electric Supply Company: Say No To CorruptionHaseebPirachaNoch keine Bewertungen

- Complete Postcode List For Pakistan: Listed in Postcode Order From 10010 To 97320Dokument38 SeitenComplete Postcode List For Pakistan: Listed in Postcode Order From 10010 To 97320allah ditta shafiNoch keine Bewertungen

- Fesco Online Bill January 2Dokument1 SeiteFesco Online Bill January 2HaseebPirachaNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 2017-06-10 SUU MongoliaDairy ResearchReportDokument25 Seiten2017-06-10 SUU MongoliaDairy ResearchReportByambadorj SaranzayaNoch keine Bewertungen

- Australian and New Zealand Standard Industrial Classification guideDokument11 SeitenAustralian and New Zealand Standard Industrial Classification guideverdadro1Noch keine Bewertungen

- 5 Dairy Processing - Clarification and Cream SeparationDokument6 Seiten5 Dairy Processing - Clarification and Cream SeparationSPMUSER9ANoch keine Bewertungen

- TVL - BPP11 - Q2 - M18Dokument6 SeitenTVL - BPP11 - Q2 - M18Jenice F. DinizNoch keine Bewertungen

- Distribution Channel Management AmulDokument41 SeitenDistribution Channel Management AmulGaganpreetmultani9860% (5)

- Wuletaw Belayneh Agri. Economics - Jan 2007Dokument111 SeitenWuletaw Belayneh Agri. Economics - Jan 2007mulejimmaNoch keine Bewertungen

- Cadbury Dairy - The Brand: "A Glass and A Half of Full Cream Milk in Every Half Pound"Dokument3 SeitenCadbury Dairy - The Brand: "A Glass and A Half of Full Cream Milk in Every Half Pound"Gaurav DedhiaNoch keine Bewertungen

- SPX Flow Technology OverviewDokument40 SeitenSPX Flow Technology Overviewluis penagosNoch keine Bewertungen

- Daftar Harga Fonterra 1 January 2020Dokument3 SeitenDaftar Harga Fonterra 1 January 2020AlloyMeinaPurnamasariNoch keine Bewertungen

- 5 Forces Model - Vinamilk - K20405CDokument19 Seiten5 Forces Model - Vinamilk - K20405CNga Nguyễn Thị HảiNoch keine Bewertungen

- Interpuls Novinki 2014Dokument64 SeitenInterpuls Novinki 2014BaklanovaSVNoch keine Bewertungen

- Retail Franchise ParloursgfgdfgdfDokument7 SeitenRetail Franchise Parloursgfgdfgdfshaikkhaleelmba10% (1)

- Strategies for Enhancing Food Production Through Animal HusbandryDokument19 SeitenStrategies for Enhancing Food Production Through Animal HusbandryMaitri RoyNoch keine Bewertungen

- KomulDokument72 SeitenKomulBharath IngleNoch keine Bewertungen

- Alexis Wolter ResumeDokument2 SeitenAlexis Wolter Resumeapi-610069547Noch keine Bewertungen

- WPC in Ice CreamDokument5 SeitenWPC in Ice CreamIvan MojsaNoch keine Bewertungen

- Jackie's Tips For Hardcore Homesteading... by Jackie ClayDokument5 SeitenJackie's Tips For Hardcore Homesteading... by Jackie ClayKOSTASPDFNoch keine Bewertungen

- SAGAR AVHAD HR PROJECT FinalDokument51 SeitenSAGAR AVHAD HR PROJECT Finalsurekha parasur0% (1)

- Vinamilk's Marketing Environment AnalysisDokument24 SeitenVinamilk's Marketing Environment AnalysisKunNguyen HuyNoch keine Bewertungen

- Loc Sua PDFDokument17 SeitenLoc Sua PDFthinnnhNoch keine Bewertungen

- DKS 2500-2021 Dairy Cattle Feed PremixDokument7 SeitenDKS 2500-2021 Dairy Cattle Feed PremixThanh Tâm TrầnNoch keine Bewertungen

- Sales & Distribution in Dairy Industry: A Study of Aanchal ProductsDokument57 SeitenSales & Distribution in Dairy Industry: A Study of Aanchal ProductsRohit KumarNoch keine Bewertungen

- Parag MilkDokument39 SeitenParag MilkSomnath KejriwalNoch keine Bewertungen

- Namaste IndiaDokument12 SeitenNamaste IndiaUtkarsh Pandey50% (2)

- Success Story of SUMULDokument17 SeitenSuccess Story of SUMULRagini ChopdaNoch keine Bewertungen

- Dairy industry contacts databaseDokument19 SeitenDairy industry contacts databaseFresh aliveNoch keine Bewertungen

- Hassan Co Operative Milk Producers Society Union Limited HASSANDokument63 SeitenHassan Co Operative Milk Producers Society Union Limited HASSANPrashanth PB80% (10)

- Omfed Dairy Supply ChainDokument9 SeitenOmfed Dairy Supply Chainfaltupila100% (2)

- Socio - Economic Profile and Constraints of Dairy Farmers in Cuddalore District of Tamil Nadu, IndiaDokument7 SeitenSocio - Economic Profile and Constraints of Dairy Farmers in Cuddalore District of Tamil Nadu, IndiaGopi MecheriNoch keine Bewertungen

- Alpro: Your Runway To Greater Control and Profi TabilityDokument14 SeitenAlpro: Your Runway To Greater Control and Profi TabilitytaraNoch keine Bewertungen