Beruflich Dokumente

Kultur Dokumente

Precast Plank Design

Hochgeladen von

arif_rubinCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Precast Plank Design

Hochgeladen von

arif_rubinCopyright:

Verfügbare Formate

VIKRAM UDYOGPURI LIMITED, UJJAIN, MADHYA PRADESH

10.0)

10.1)

SPML - OM METALS (JV)

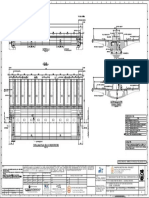

DESIGN OF Precast Concrete Plank as BEAM supported on column

The 50 mm thick precast Plank will be inserted in the 50mm wide spout in the column.

The column will be solid rectangular till ground level. The column above ground level will have 50/60mm thick x 35 mm deep groove for the Precast plank

insert. The bottom plank will be resting on the column having bearing of 30 mm on both side of column.

Total Number of Planks will be 7 of 300 mm depth.

Bottom Plank will act as simply supported beam resting on column and other 6 planks will be resting on bottom plank.

Bottom Plank is designed as simply supported beam and same design will be applied to all planks.

2.25

Effective span of Plank =

2.17

- 0.035

2.135 m

Design of Bottom Plank supporting other Planks above

Plank Thickness =

50 mm

Plank Depth =

300 mm

Plank Length =

2160 mm

=

=

2.625 kN/m

1.496 kNm

2.244 kNm

2.802 kN

4.203 kN

Uniform Load over Bottom Plank =

Maximum BM @ Midspan =

0.050

x 2.10

2.625 x 2.135 ^2

Ultimate Moment Mu =

1.50

x 1.496

Maximum Shear Force @ Support =

2.63

x 2.14

Ultimate Shear Force Vu =

1.50

x 2.802

Sanguine Infra Tech Pvt.Ltd., Mumbai

x 25

/8

/2

Page | 26

VIKRAM UDYOGPURI LIMITED, UJJAIN, MADHYA PRADESH

SPML - OM METALS (JV)

Design of Individual Plank for its self weight while lifting

Also each Panel shall be designed for its self weight while lifting at both end.

Uniform Load of one Plank due to self weight

Maximum BM @ Midspan =

0.050

0.375

x 0.30

x 2.16 ^2

Ultimate Moment Mu =

1.50

x 0.219

Maximum Shear Force @ Support =

0.38

x 2.16

Ultimate Shear Force Vu =

1.50

x 0.405

x 25

/8

/2

=

=

0.375 kN/m

0.219 kNm

0.328 kNm

0.405 kN

0.608 kN

10.2) Prestressing detail & Check for section :

Use

3 Nos.

of

3 mm

of

Allowable stress in Prestressing steel =

Total Prestressing steel area =

Total Prestressing force =

3

21.210

ultimate strength of

0.80

/4

1492

fy

x

3^2

1865

Mpa

1492

21.21

Mpa

mm2

31.65

kN

10.2.1 ) Losses due to pretension :

( As per IS : 1343-1980, Cl 18.5)

Stress in cable after prestress

Stress in concrete at CG of cable

10.2.1.1)

31650

Loss due to elastic shortening :

=

( 50

x 300 )

1492 N/mm2

2.110 N/mm2

(IS 1343:1980, Cl 18.5.2.4 b)

x modular ratio x avg. stress in concrete at c.g. of cable

2

Grade of concrete at the time of stressing

Ec

=

=

5700 x

31220 N/mm

210000 =

30

N/mm2

14.2

N/mm2

30

2

6.7

31220

Loss

Sanguine Infra Tech Pvt.Ltd., Mumbai

6.7

2.11

= 0.95 %

Page | 27

VIKRAM UDYOGPURI LIMITED, UJJAIN, MADHYA PRADESH

10.2.1.2)

Due to creep of concrete :

SPML - OM METALS (JV)

(IS 1343:1980, Cl 18.5.2.1)

Age of loading @ 28 days

Loss

10.2.1.3)

Take creep coefficient

=

1.6

2.1

6.7

1.6

22.7

N/mm2

= 1.52 %

44.0 N/mm

= 2.95 %

90.0 N/mm

= 6.03 %

171 N/mm2

= 11.46 %

Due to shrinkage of concrete : (IS 1343:1980, Cl 18.5.2.2)

Shrinkage strain =

0.0002/Log(t +2)

0.00021

Between 3 and 21 days

Loss

10.2.1.4)

@

0.00021

210000

Loss due to relaxation of H.T. steel at first stage loss :

0.800 UTS

(IS 1343:1980, Cl 18.5.2.3)

Total loss due to elastic shortening, creep , shrinkage & relaxation :

=

14.2

22.7

44.0

31.65

88.54 %

1000

90.0 =

10.2.2 ) Prestress after Losses :

Prestressing force after losses =

Stress due to prestressing force =

28.02

Permissible Compressive stresses =

0.34 fck =

10.2 N/mm2

Permissible Tensile stresses =

/

0.0 N/mm

( 50

x 300 )

28.02 kN

1.87 MPa

(Refer IS 1343, Cl. 22.7.1(b) & Fig 7)

(Refer IS 1343, Cl. 22.7.1 Type - 2)

10.2.3 ) Check of Section

A. Section Check for Stress

Section Moment b

(kN-m)

Bottom Plank 1.50

Midspan

Individual Plank 0.22

Midspan

Moment Cg of NA Cg of NA Sect ModulusSect Modulus Bending stress M/Z

Stress due to Resultant stress

RemZ

Z

of Inertia from Top from Bottom

@ Top @ Bottom Initial Prestress

@ Top

@ Bottom ark

TOP

BOTTOM

4

(mm)

(mm )

(m )

50

300

0.000113

0.15

0.15

0.00075

N/mm

N/mm

Compressive Tensile

(i)

(ii)

0.00075

1.99

-1.99

300

50

0.000003

0.025

0.025

0.00013

0.00013

Sanguine Infra Tech Pvt.Ltd., Mumbai

(m )

(mm)

1.75

-1.75

N/mm

N/mm

N/mm

Compressive Compressive Compressive

(iii)

(i) + (iii)

(ii) + (iii)

1.87

3.86

-0.13

Unsafe

1.87

3.62

0.12

Safe

Page | 28

VIKRAM UDYOGPURI LIMITED, UJJAIN, MADHYA PRADESH

SPML - OM METALS (JV)

B. Section Check for Limit State of Collapse

The ultimate strenght of cross section is calculated according to the recommendattions of IS 1343, Appendix B

Section

Mult.

Bottom Plank

2.244 kN-m

2

fck

Concrete grade

30

Depth of Section

0.300

0.050

=

=

0.050

0.150

m

m

0.300

0.025

m

m

0.150

0.025

Area of compression zone

0.0014

Depth of compression zone

Ultimate Moment capacity under concrete failure

=

=

0.0143

2.33

kN-m

Area of Prestressing steel

21.21

mm

B

c.g.st

Width of Section

Depth of cg of prestressing steel from top of section

db = D-cgst or cgst Effective depth to cg of steel from top

Ac

cg1

Mult. conc.

As

N/mm

Individual Plank

0.328

kN-m

30

0.0024

2

2

0.39

kN-m

21.21

mm

1865

N/mm

1865

(Ref IS 1343, T-11)

(Ref IS 1343, T-11)

=

=

0.088

0.088

1.000

1.000

(Ref IS 1343, T-11)

0.191

0.191

fpu

1623

1623

Xu

0.029

Ultimate tensile strength of prestressing steel

(Ap fp) / (b d fck)

fpu/(0.87fpu

Xu/d

Ast

Non Prestressing steel

Mult. Due to yielding of steel

=

=

Mult. Capacity of section

Remark

N/mm

0.005

4.748

0.791

2.332

kN-m

0.389

kN-m

m

mm2

kN-m

safe

mm

kN-m

0.0014

fp

N/mm

safe

C. Check for Limit State of Shear

Sanguine Infra Tech Pvt.Ltd., Mumbai

Page | 29

VIKRAM UDYOGPURI LIMITED, UJJAIN, MADHYA PRADESH

Section Shear

Force

(kN) (mm)

SPML - OM METALS (JV)

clear

Shear

Ast prov.

(mm)

cover

(mm)

(mm)

stress

2

v (N/mm )

dia

(mm)

Pt %

Shear

capacity

provided

of

2

c (N/mm )

Remark.

IS1343, T-6

Bottom Plank

Midspan

Individual Plank

4.20

50

300

25

274

0.307

3 mm

3 Nos.

0.155

0.370

Shear Reinf

Not Required

0.61

300

50

25

25

0.081

3 mm

3 Nos.

0.283

0.370

Shear Reinf

Not Required

Midspan

10.3) Check for Bearing strength on concrete column bearing area due to reaction from planks:

Reaction at one end of column 1.5 x 2.625 x 2.16 / 2

Bearing Area =

30

x 50

Bearing Stress on column

4250 / 1500

Permissible bearing strength on concrete 0.45 fck =

Sanguine Infra Tech Pvt.Ltd., Mumbai

4.25 kN

2

1500 mm

2.83 N/mm2

13.5 Mpa

Safe

(Ref IS 456:2000, Cl 34.4)

Page | 30

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Costing - 2021-2022 - 28.072023Dokument804 SeitenCosting - 2021-2022 - 28.072023arif_rubinNoch keine Bewertungen

- MBC - NAVEEN - RETURNWALL - 004 - 01102021-Concrete ProfileDokument1 SeiteMBC - NAVEEN - RETURNWALL - 004 - 01102021-Concrete Profilearif_rubinNoch keine Bewertungen

- Composite CheckDokument1 SeiteComposite Checkarif_rubinNoch keine Bewertungen

- Schedule of Bearing Load (31M Span & R 420M)Dokument1 SeiteSchedule of Bearing Load (31M Span & R 420M)arif_rubinNoch keine Bewertungen

- Vup 002 R0Dokument1 SeiteVup 002 R0arif_rubinNoch keine Bewertungen

- Tuglakabad Corridor Load Test ReportDokument8 SeitenTuglakabad Corridor Load Test Reportarif_rubinNoch keine Bewertungen

- Technical Data Sheet For The HSA Stud Anchor Technical Information ASSET DOC 2027424Dokument9 SeitenTechnical Data Sheet For The HSA Stud Anchor Technical Information ASSET DOC 2027424SupervitalikNoch keine Bewertungen

- Vup 001 R0Dokument1 SeiteVup 001 R0arif_rubinNoch keine Bewertungen

- DBR VupDokument15 SeitenDBR Vuparif_rubinNoch keine Bewertungen

- PileLatLoadCap1500 10mDokument7 SeitenPileLatLoadCap1500 10marif_rubinNoch keine Bewertungen

- Spine Girder QtyDokument1 SeiteSpine Girder Qtyarif_rubinNoch keine Bewertungen

- AASHTO Hook DetailDokument1 SeiteAASHTO Hook Detailarif_rubinNoch keine Bewertungen

- JV of Shirish Patel & Associates Consultants PVT Limited & Indus Consultrans PVT LTDDokument540 SeitenJV of Shirish Patel & Associates Consultants PVT Limited & Indus Consultrans PVT LTDarif_rubin100% (1)

- Yfc Project PVT Ltd. DMRC: JV of Shirish Patel & Associates Consultants PVT Limited & Indus Consultrans PVT LTDDokument2 SeitenYfc Project PVT Ltd. DMRC: JV of Shirish Patel & Associates Consultants PVT Limited & Indus Consultrans PVT LTDarif_rubinNoch keine Bewertungen

- Design of 4L 31.25m SpanDokument1 SeiteDesign of 4L 31.25m Spanarif_rubinNoch keine Bewertungen

- 31.25m 4L Concrete Dime DRG - 1Dokument1 Seite31.25m 4L Concrete Dime DRG - 1arif_rubinNoch keine Bewertungen

- 4L BOx Girder Concrete Dimension DRGDokument1 Seite4L BOx Girder Concrete Dimension DRGarif_rubinNoch keine Bewertungen

- 31.25m 4L Concrete Dime DRG - 1Dokument1 Seite31.25m 4L Concrete Dime DRG - 1arif_rubinNoch keine Bewertungen

- Nagpur Metro Rail Project: Systra-Aecom-Egis-RitesDokument1 SeiteNagpur Metro Rail Project: Systra-Aecom-Egis-Ritesarif_rubinNoch keine Bewertungen

- Nagpur Metro Rail Project: Systra-Aecom-Egis-RitesDokument1 SeiteNagpur Metro Rail Project: Systra-Aecom-Egis-Ritesarif_rubinNoch keine Bewertungen

- Appendix BDokument95 SeitenAppendix Barif_rubinNoch keine Bewertungen

- 4L BOx Girder Concrete Dimension DRGDokument1 Seite4L BOx Girder Concrete Dimension DRGarif_rubinNoch keine Bewertungen

- Appendix EDokument51 SeitenAppendix Earif_rubinNoch keine Bewertungen

- 4L BOx Girder Concrete Dimension DRGDokument1 Seite4L BOx Girder Concrete Dimension DRGarif_rubinNoch keine Bewertungen

- Appendix A: Dead Load & Sidl Load Calculation: SPAN-1 SPAN-2Dokument2 SeitenAppendix A: Dead Load & Sidl Load Calculation: SPAN-1 SPAN-2arif_rubin50% (2)

- Appendix BDokument95 SeitenAppendix Barif_rubinNoch keine Bewertungen

- Superstructure design drawing of a 4 lane flyoverDokument1 SeiteSuperstructure design drawing of a 4 lane flyoverarif_rubinNoch keine Bewertungen

- Ground Water Table Value As Per CGWB Data: (Refer Appendix A)Dokument1 SeiteGround Water Table Value As Per CGWB Data: (Refer Appendix A)arif_rubinNoch keine Bewertungen

- Appendix DDokument63 SeitenAppendix Darif_rubinNoch keine Bewertungen

- Appendix CDokument18 SeitenAppendix Carif_rubinNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Car Booking Using JavaDokument21 SeitenCar Booking Using JavaTechBonker AdiNoch keine Bewertungen

- ORACLE UCM OrderDokument17 SeitenORACLE UCM OrderMohinder SinghNoch keine Bewertungen

- Lte Radio Protocol Architecture PDFDokument2 SeitenLte Radio Protocol Architecture PDFjamos200Noch keine Bewertungen

- 3G FundamentalDokument46 Seiten3G FundamentalkunprdNoch keine Bewertungen

- On MIX DesignDokument27 SeitenOn MIX DesignGaurav naddaNoch keine Bewertungen

- Zigbee Technology: "Wireless Control That Simply Works.": Submitted byDokument24 SeitenZigbee Technology: "Wireless Control That Simply Works.": Submitted byAnonymous nNyOz70OHpNoch keine Bewertungen

- Doosan DBC130II Installation ManualDokument122 SeitenDoosan DBC130II Installation ManualDarryl Hardt100% (1)

- Mac Operating SystemDokument12 SeitenMac Operating SystemMaham100% (1)

- How To Restore Rman Backups On A Different Node When The Directory Structures Are DifferentDokument5 SeitenHow To Restore Rman Backups On A Different Node When The Directory Structures Are Differentalok_mishra4533Noch keine Bewertungen

- Pneumatic StructuresDokument7 SeitenPneumatic StructuresMicah EuropaNoch keine Bewertungen

- Manual Funciones Alternantes stm32f7Dokument227 SeitenManual Funciones Alternantes stm32f7erika salinasNoch keine Bewertungen

- Glasgow Library Facade OverhaulDokument9 SeitenGlasgow Library Facade OverhaulSubhishasri A K VNoch keine Bewertungen

- Spring Webflow ReferenceDokument92 SeitenSpring Webflow Referencemenna_moustafaNoch keine Bewertungen

- EHEIM Product RangeDokument10 SeitenEHEIM Product RangeLeoRualesNoch keine Bewertungen

- Translation of Architecture, Production of Babel - Mark WigleyDokument17 SeitenTranslation of Architecture, Production of Babel - Mark Wigleytadija5Noch keine Bewertungen

- System I Architecture OverviewDokument70 SeitenSystem I Architecture OverviewecorradiNoch keine Bewertungen

- WSM West Salem MachineryDokument7 SeitenWSM West Salem Machinerymostafa sherifNoch keine Bewertungen

- Dywidag Threadbar Properties - Dywidag Threadbar - Reinforcing Steel Hardware DimensionsDokument1 SeiteDywidag Threadbar Properties - Dywidag Threadbar - Reinforcing Steel Hardware DimensionsMangisi Haryanto ParapatNoch keine Bewertungen

- Introduction To VRF Systems PDFDokument12 SeitenIntroduction To VRF Systems PDFeimrehNoch keine Bewertungen

- Practical-1: CPU (Central Processing Unit)Dokument33 SeitenPractical-1: CPU (Central Processing Unit)programmerNoch keine Bewertungen

- The Humanizing of ArchitectureDokument4 SeitenThe Humanizing of ArchitectureRafaelaAgapitoNoch keine Bewertungen

- BS 8204-4-1993-In-Situ Floorings-Code of Practice For TerrazDokument22 SeitenBS 8204-4-1993-In-Situ Floorings-Code of Practice For Terrazgops1963100% (1)

- Medicinal PlantsDokument5 SeitenMedicinal PlantsPRINTDESK by DanNoch keine Bewertungen

- SME PPT TCU02 Technical DescriptionDokument23 SeitenSME PPT TCU02 Technical DescriptionabhinavNoch keine Bewertungen

- Install and service instructions for Themaclassic combination and system boilersDokument60 SeitenInstall and service instructions for Themaclassic combination and system boilersbettyanghelNoch keine Bewertungen

- Thermal Staking Design Guide Pgs PDFDokument4 SeitenThermal Staking Design Guide Pgs PDFdiego_mtzNoch keine Bewertungen

- Peb Brochure SteelDokument40 SeitenPeb Brochure SteelChamila RajapakshaNoch keine Bewertungen

- Project ScheduleDokument2 SeitenProject ScheduleanandpurushothamanNoch keine Bewertungen

- How To Build Clam Antivirus RPM Package For Fedora Core 1Dokument3 SeitenHow To Build Clam Antivirus RPM Package For Fedora Core 1Mahir EfendiyevNoch keine Bewertungen

- BricksDokument94 SeitenBricksCool 198Noch keine Bewertungen