Beruflich Dokumente

Kultur Dokumente

Technical Problems of Mud Pumps On Ultra Deepwater Drilling Rigs

Hochgeladen von

Onur Deniz NarinOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Technical Problems of Mud Pumps On Ultra Deepwater Drilling Rigs

Hochgeladen von

Onur Deniz NarinCopyright:

Verfügbare Formate

Scientific Journals

Zeszyty Naukowe

Maritime University of Szczecin

Akademia Morska w Szczecinie

2013, 36(108) z. 2 pp. 1316

ISSN 1733-8670

2013, 36(108) z. 2 s. 1316

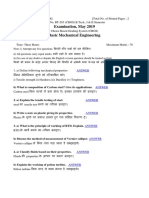

Technical problems of mud pumps on ultra deepwater

drilling rigs

Artur Bejger1, Tomasz Piasecki2

1

Maritime University of Szczecin

70-205 Szczecin, ul. Podgrna 52/53, e-mail: a.bejger@am.szczecin.pl

2

Maersk Drilling, e-mail: piaseckitomasz83@gmail.com

Key words: drilling rig, mud pumps, damage to mud pump valves

Abstract

The article presents selected technical issues relating to drilling performed by a drillship, one type of drilling

rigs. Basic problems encountered in the main function of such rigs drilling a well are failures of mud

pumps. The authors investigate these pumps in operational conditions, aiming at development of a system for

monitoring the technical condition of these pumps. Work on a diagnostic system is in progress that will permit to predict the condition of mud pump valves well in advance.

Introduction

which allow them to keep in position in varying

weather conditions (in waves up to 11 metres high

and wind speed to 26 m/sec). In extreme allowable

conditions, six azimuth thrusters, each with 5500

kW power output, keep the vessel in place.

Figures 2 and 3 depict drilling rigs and their

respective sea and subsea depth ranges.

A drillship is a vessel with own propulsion

and dynamic positioning systems. Equipped with

a characteristic derrick, it also has all auxiliary apparatus for drilling operations (Fig. 1). The equipment is capable of boring holes in rocky bottom of

the sea or ocean.

Drilling systems

Exploration of the seas in search of new mineral

deposits brings technical problems associated with

the construction and operation of drilling units. The

main challenge is that the whole process and tools

used have to satisfy the requirements at all times,

no matter what type of bottom is encountered. Well

drillers can reach increasingly deeper owing to

continuous advancements in drilling technologies,

including improvements in materials used. Drilling,

however, requires that special fluids have to be

used for cleaning the drill bits to carry away sediments and pieces of rock etc. The fluid presently

used is a chemically treated mud, whose composition depends on, among other things, nature of the

bottom where a well is being drilled. Mud is

pumped in by high pressure pumps, primary components of the high pressure mud system (Fig. 4).

Fig. 1. A ultra deepwater class drillship, under construction in

Samsung Heavy Industries shipyard, Korea [1]

The drillship referred to in this article is of ultra

deepwater class, which means it can make wells at

a water depth of 3,600 metres and up to 12,000

metres down into the seafloor. These ships are fitted with uptodate dynamic positioning systems,

Zeszyty Naukowe 36(108) z. 2

13

Artur Bejger, Tomasz Piasecki

Fig. 2. Types of drilling rigs [1]

Fig. 3. Types of drilling rigs and their water depth ranges [1]

Fig. 4. High pressure mud system used on drilling rigs [2]

14

Scientific Journals 36(108) z. 2

Technical problems of mud pumps on ultra deepwater drilling rigs

Mud pumps in drilling units

works. Modern drilling rigs usually have four

pumps to assure a stable drilling process. In case of

complex wells, three pumps work in parallel discharging mud into the drill pipe, while one is on

standby.

A mud pump is a high pressure piston pump of

high capacity. The pump referred to in this article is

a triplex pump with three single action pistons.

High pressure mud pumps are the main components of the high pressure mud supply system

(Fig. 7). Each High Pressure Mud Pump is charge

with mud from mud pits at around 0.81.0 MPa by

Super Charge Centrifugal Pump. On the suction

side, suction pressure transmitter is fitted. If suction

pressure is not detected HP Pump will be interlocked. Suction, discharge and pump stroke transmitters send signal to Driller cabin for constant

monitoring of all parameters. The suction manifold

on the pump has dampener and pressure safety

valve. Safety valve on suction manifold is set to

0.5 MPa (70psi). Discharge manifold has pulsation dampener designed to reduce damaging effects

of fluid flow pulsations. To avoid over pressurizing

the pump on the discharge side the special Titan

BX pressure relief valve is fitted. Titan valve will

open at 50 MPa (7500 psi) to release pressure and

give alarm. All High Pressure Mud Pumps has following interfaces:

MCS Mud Control System;

Potable water filling for mud pump auxiliary

cooling system;

Electrical power system;

Electrical instrumentation;

Instrument air system;

Seawater system.

Mud used in offshore drilling is a mixture of

liquid substances and chemicals. Mud returning

from the well to the pits undergoes a complex operation of cleaning, then it is pumped again down to

the bottomhole assembly. Pump elements suffer

damage when mud is insufficiently cleaned of cuttings. The frequency of failures strictly depends on

the chemical aggressiveness of fluids added to mud.

Chemicals improve mud parameters (viscosity,

density, ability to rinse out and dissolve contaminants etc.). Chemicals are essential for the well to

have the right standard and quality, but in most

cases they act agressively, particularly on elastomer

parts of the pumps, e.g. on valve faces (Fig. 8).

Typical faults in mud pumps include wear resulting in increased clearance between the cylinder

and piston and damage to suction and discharge

valves. The latter, while the drilling is intensive,

may become defective every hour or so.

The function of a mud pump used in drilling rigs

(Figs 5 and 6) is to exert a specific pressure on mud

while drilling is taking place. Mud, in turn, is used

for washing away bits of rock and sand produced in

the process of crushing caused by the rotation and

pressure of the drill bit on the well bottom. Thus

formed rock pieces, or cuttings, have to be continuously removed from the drill bit and transferred up

to the surface. The mud pump discharges mud under a high pressure through the drill pipe and

through a number of nozzles in the drill bit washes

away tiny rock pieces under the drill bit. Therefore,

the mud pump functions like the heart maintaining constant flow of mud under high pressure. Other essential functions of the mud are cooling and

lubricating, reducing the weight of the drill pipe,

and protecting the unit elements against corrosion.

Fig. 5. A view of the mud pumps section of a drilling rigs

power plant

Fig. 6. A view of a mud pump used on drilling rigs; triplex

14-P-220 mud pump made by NOV [3]

Smooth and failure-free operation of mud

pumps is crucial. Any stoppage caused by a failure

of a key component results in a stoppage of drilling

Zeszyty Naukowe 36(108) z. 2

15

Artur Bejger, Tomasz Piasecki

Fig. 7. A diagram of a mud pump installed on a drillship

Leakages due to worn out piston-cylinder units

have a symptom, namely contamination of water

cooling the cylinder liners (the symptom is visible

even if the damage is slight), because water flowing

in a closed circulation system returns to a cooling

water tank. Defective suction and discharge valves

are more difficult to identify, as leaks caused by

wash-out are not visible anywhere. They may be

detected only in an advanced stage of damage,

when maintaining constant discharge pressure

becomes difficult. In such cases a pump must be

stopped immediately and valve exchanged. The

difficulty, however, lies in identifying which valve

is damaged or works incorrectly. One of the methods of valve condition assessment include method

by listening. Unfortunately, these methods are far

from accurate, unreliable and require a comparison

of acoustic effects from different working units

approximately every quarter of an hour.

A mud pump works under a pressure of up

to 52 MPa (7500 psi), so this diagnostic method

involves risk of operators injury [4]. Besides, the

room with mud pumps also houses up to eight centrifugal pumps used for other purposes, mixing of

mud fluids, therefore, the noise inside the room

often makes leak detection impossible.

A failure of a mud pump due to a leaking valve

may cause a complete stoppage of the drilling operation, which is particularly dangerous when drilling

takes place in the so called hard segments. For

a drilling company an hour of suspended work

means loss of thousands of dollars.

Fig. 8. Damaged seat and head of a mud pump valve [5]

The authors are doing field research into issues

of mud pump valve failures aimed at developing

and implementing a system for diagnosing mud

pump valves by using high frequency elastic waves

of acoustic emission.

Preliminary results indicate with high probability that such system will be capable of detecting an

initial stage of valve damage, which will allow

pump operators to plan a prompt repair of the diagnosed pump without stopping the entire drilling

operation.

References

1. www.maersk-drilling.com

2. Dokumentacja Techniczna puczkowego systemu wysokiego cinienia firmy Maersk.

3. Maersk Drilling, Drillship 2018 Technical Manual 2nd

Draft, Jun 2013.

4. Age Kyllingstad, Pl Jacob Nessjen, A New Early Leak

Detection System for Mud Pumps, SPE/IADC Drilling

Conference and Exhibition, 13 March 2011, Amsterdam,

The Netherlands.

5. www.sine.ni.com, Valve Leakage Detection in Industrial

Pumps.

16

Scientific Journals 36(108) z. 2

Das könnte Ihnen auch gefallen

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsVon EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNoch keine Bewertungen

- KOSUN Hydrocyclone For Drilling Mud Desander and DesilterDokument4 SeitenKOSUN Hydrocyclone For Drilling Mud Desander and DesilterkosunlucyNoch keine Bewertungen

- DRAFT - Requirements For Pressure TestingDokument3 SeitenDRAFT - Requirements For Pressure TestingAdhie WaelacxhNoch keine Bewertungen

- Reservoir SimulationDokument3 SeitenReservoir SimulationEuler MendozaNoch keine Bewertungen

- Circulating System Moves Drilling FluidDokument6 SeitenCirculating System Moves Drilling FluidUsman Ahmed0% (1)

- RheologyDokument24 SeitenRheologyPercy Herrera Figueroa100% (1)

- Circulating System of Drilling MudDokument20 SeitenCirculating System of Drilling MudKadhim AdnanNoch keine Bewertungen

- Pre Recorded Imformation: Davis Family 1-42Dokument10 SeitenPre Recorded Imformation: Davis Family 1-42scrbdgharaviNoch keine Bewertungen

- Spe 196232 MSDokument18 SeitenSpe 196232 MShijoetigreNoch keine Bewertungen

- Mud Design by Using KCL Polymer To Reduce Swelling Shale Control 2015 h2Dokument5 SeitenMud Design by Using KCL Polymer To Reduce Swelling Shale Control 2015 h2Andi SusetioNoch keine Bewertungen

- Hydrocyclones: D-Sa N Der D-SilterDokument10 SeitenHydrocyclones: D-Sa N Der D-Siltersaa6383Noch keine Bewertungen

- Cougar DLLG Solutions FaqDokument5 SeitenCougar DLLG Solutions FaqLenis CeronNoch keine Bewertungen

- Uttaranchal Uni Annular Pressure ReportDokument26 SeitenUttaranchal Uni Annular Pressure ReportDhruv DasNoch keine Bewertungen

- Remedial Cementing TechniquesDokument4 SeitenRemedial Cementing TechniquesColor RougeNoch keine Bewertungen

- Hole CleaningDokument8 SeitenHole Cleaninganon_850924421Noch keine Bewertungen

- Well Control Data Sheet: Vertical WellsDokument2 SeitenWell Control Data Sheet: Vertical WellsscrbdgharaviNoch keine Bewertungen

- Drilling Fluid Compressibility ExplainedDokument1 SeiteDrilling Fluid Compressibility ExplainedLuisA.HarCórNoch keine Bewertungen

- Permian Basin Development WellsDokument8 SeitenPermian Basin Development WellsPesireron RoberthNoch keine Bewertungen

- Mongoose Pro Shaker BrochureDokument12 SeitenMongoose Pro Shaker BrochureOscar Rodrigo Andrade SilvaNoch keine Bewertungen

- BOP BoltsDokument5 SeitenBOP BoltsHadirah DunglahNoch keine Bewertungen

- Properties of drilling fluidsDokument3 SeitenProperties of drilling fluidsAnsell EwemeNoch keine Bewertungen

- Drilling Formulas Calculation Sheet Verson 1.5Dokument199 SeitenDrilling Formulas Calculation Sheet Verson 1.5Vidit GuptaNoch keine Bewertungen

- 5 Mud System-Lecture-5 PDFDokument26 Seiten5 Mud System-Lecture-5 PDFأبراهيم كريم كاظم100% (1)

- Optimization of Drilling Parameters With The Performance of Multilobe Positive Displacement Motor (PDM)Dokument8 SeitenOptimization of Drilling Parameters With The Performance of Multilobe Positive Displacement Motor (PDM)drilling moneytree100% (1)

- Directional DrillingDokument16 SeitenDirectional DrillingRajeev LochanamNoch keine Bewertungen

- Spe 128712 MS PDokument8 SeitenSpe 128712 MS Pb4rfNoch keine Bewertungen

- MudMaster HPHT Pistons Mud PumpDokument2 SeitenMudMaster HPHT Pistons Mud PumpifebrianNoch keine Bewertungen

- SPE-116364-Entrance Pressure of Oil Based Mud Into Shale Effect of Shale, WaterDokument19 SeitenSPE-116364-Entrance Pressure of Oil Based Mud Into Shale Effect of Shale, WaterwjawichNoch keine Bewertungen

- Mud Pumps 1Dokument2 SeitenMud Pumps 1John RongNoch keine Bewertungen

- Shale ProblemsDokument12 SeitenShale ProblemsShirley Hernandez JimenezNoch keine Bewertungen

- 26 Mill-EZ Composite Bridge PlugDokument2 Seiten26 Mill-EZ Composite Bridge PlugzbhdzpNoch keine Bewertungen

- Cementing: IntroductionDokument4 SeitenCementing: IntroductionanuNoch keine Bewertungen

- Introduction To Managed Pressure Drilling and Presuure Mud Cap DrillingDokument23 SeitenIntroduction To Managed Pressure Drilling and Presuure Mud Cap DrillingKunal GuptaNoch keine Bewertungen

- TUTORIAL 1 Drilling EngineerDokument4 SeitenTUTORIAL 1 Drilling EngineerAnonymous AkV8maWxGNNoch keine Bewertungen

- Cement and Cementing PDFDokument18 SeitenCement and Cementing PDFSadashiw Patil100% (1)

- ONGC Report First Pit Less Drilling in ONGC Scripts Success at RajahmundryDokument6 SeitenONGC Report First Pit Less Drilling in ONGC Scripts Success at RajahmundryPETROPATH FLUIDS INDIA PVT. LTD.Noch keine Bewertungen

- 3 KickDokument63 Seiten3 KickAmirah Razali100% (2)

- Rules of Thumb To Improve High-Angle Hole CleaningDokument29 SeitenRules of Thumb To Improve High-Angle Hole CleaningjalalNoch keine Bewertungen

- Drill Right Tools Motor ManualDokument55 SeitenDrill Right Tools Motor ManualsumsolcaggNoch keine Bewertungen

- CAD Product Brouchure 2010Dokument11 SeitenCAD Product Brouchure 2010jlmunozvNoch keine Bewertungen

- Drilling Fluids Selection Criteria FactorsDokument5 SeitenDrilling Fluids Selection Criteria FactorsMohamedElAbbasyNoch keine Bewertungen

- Geothermal Drilling Problems and SolutionsDokument38 SeitenGeothermal Drilling Problems and Solutionskrishnsgk100% (1)

- Chap 4Dokument43 SeitenChap 4adrien_ducaillouNoch keine Bewertungen

- AXON Drilling Products v2014.07.15 MtsDokument40 SeitenAXON Drilling Products v2014.07.15 MtsJuan Pablo Villazon Richter100% (1)

- SEI BasicDokument146 SeitenSEI BasicYuthia Aulia Riani100% (1)

- Effects of Thickening Time On The Application of Cement Slurry For High PressureDokument10 SeitenEffects of Thickening Time On The Application of Cement Slurry For High PressureAlexander DeckerNoch keine Bewertungen

- Well CompletionDokument82 SeitenWell CompletionFlorian Ananias ByarugabaNoch keine Bewertungen

- AB-09-01 Drawworks Auxiliary BrakeDokument2 SeitenAB-09-01 Drawworks Auxiliary BrakeAgohuvNoch keine Bewertungen

- Evaluation of Wellbore Stability in Open Hole Horizontal WellsDokument12 SeitenEvaluation of Wellbore Stability in Open Hole Horizontal WellsPeng TerNoch keine Bewertungen

- Testing of Drilling Fluids: Mud DensityDokument9 SeitenTesting of Drilling Fluids: Mud DensityMohammed Amin BenharkatNoch keine Bewertungen

- Drilling Fluid TreatmentDokument9 SeitenDrilling Fluid TreatmentKasper JensenNoch keine Bewertungen

- Drilling FLUIDDokument6 SeitenDrilling FLUIDsrikantaLeeNoch keine Bewertungen

- One Traxv1 5completepresentation 130102094233 Phpapp02Dokument259 SeitenOne Traxv1 5completepresentation 130102094233 Phpapp02NolanJohnsonNoch keine Bewertungen

- SPE-203603-MS Lessons Learned From Drilling A Long Open Hole Interval and Recovery From A Stuck Pipe IncidentDokument8 SeitenSPE-203603-MS Lessons Learned From Drilling A Long Open Hole Interval and Recovery From A Stuck Pipe IncidentKd FaNoch keine Bewertungen

- ENM210 Cementing Operations Lecture 2 - Stage Cementing - 1 StageDokument8 SeitenENM210 Cementing Operations Lecture 2 - Stage Cementing - 1 StageHamid Reza BabaeiNoch keine Bewertungen

- PETE 203 Drilling Engineering Laboratory Manual ExperimentsDokument98 SeitenPETE 203 Drilling Engineering Laboratory Manual ExperimentsFima Molly100% (1)

- Measurement While Drilling: Signal Analysis, Optimization and DesignVon EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNoch keine Bewertungen

- Fundamentals and Applications of Bionic Drilling FluidsVon EverandFundamentals and Applications of Bionic Drilling FluidsNoch keine Bewertungen

- Drilling Engineering Problems and Solutions: A Field Guide for Engineers and StudentsVon EverandDrilling Engineering Problems and Solutions: A Field Guide for Engineers and StudentsBewertung: 5 von 5 Sternen5/5 (1)

- Strain, Force, and PressureDokument22 SeitenStrain, Force, and PressureOnur Deniz NarinNoch keine Bewertungen

- Aade 11 Ntce 28Dokument8 SeitenAade 11 Ntce 28Onur Deniz NarinNoch keine Bewertungen

- Kistler - Pieozoelectric TheoryDokument12 SeitenKistler - Pieozoelectric TheoryOnur Deniz NarinNoch keine Bewertungen

- Schlumberger Engineer Guide (MWD/LWD)Dokument58 SeitenSchlumberger Engineer Guide (MWD/LWD)Onur Deniz Narin100% (10)

- Iadc Mud Equipment ManualDokument51 SeitenIadc Mud Equipment ManualOnur Deniz Narin100% (1)

- Amaco Solid Control Control Handbook Ch. 7Dokument5 SeitenAmaco Solid Control Control Handbook Ch. 7Onur Deniz NarinNoch keine Bewertungen

- 09 Bit Balling Summary GuidelinesDokument1 Seite09 Bit Balling Summary GuidelinesCerón Niño SantiagoNoch keine Bewertungen

- #.06 HydrocyclonesDokument47 Seiten#.06 HydrocyclonesOnur Deniz Narin50% (2)

- Beggs (SPE 5434) Estimating The Viscosity of Crude Oil SystemsDokument2 SeitenBeggs (SPE 5434) Estimating The Viscosity of Crude Oil SystemsOnur Deniz Narin100% (1)

- Bourdon Tube Pressure Gauge WithDokument15 SeitenBourdon Tube Pressure Gauge WithOnur Deniz NarinNoch keine Bewertungen

- Eikos A Simulation Toolbox For Sensitivity AnalysisDokument57 SeitenEikos A Simulation Toolbox For Sensitivity AnalysisOnur Deniz NarinNoch keine Bewertungen

- Chem 210 Lab Report 1Dokument6 SeitenChem 210 Lab Report 1Mxokzah Cmoh100% (1)

- YSI Model 55: Handheld Dissolved Oxygen and Temperature SystemDokument26 SeitenYSI Model 55: Handheld Dissolved Oxygen and Temperature Systemdwisdt9044Noch keine Bewertungen

- Steam Trap PerformanceDokument36 SeitenSteam Trap Performancenewnse2008Noch keine Bewertungen

- MOF Part 2-1-100Dokument100 SeitenMOF Part 2-1-100Tayyaba BibiNoch keine Bewertungen

- Data Sheet For Mixer M34Dokument5 SeitenData Sheet For Mixer M34bingminNoch keine Bewertungen

- HP 5973 Quick ReferenceDokument28 SeitenHP 5973 Quick ReferenceDavid ruizNoch keine Bewertungen

- Pipe Bends Specification PDFDokument4 SeitenPipe Bends Specification PDFToniNoch keine Bewertungen

- PhysRevD 99 052002 PDFDokument28 SeitenPhysRevD 99 052002 PDFBibhuprasad MahakudNoch keine Bewertungen

- BT 203 Basic Mechanical Engineering May 2019 PDFDokument2 SeitenBT 203 Basic Mechanical Engineering May 2019 PDFKunta PatleNoch keine Bewertungen

- IJCE v5n1p48 enDokument18 SeitenIJCE v5n1p48 enAslam HutagiNoch keine Bewertungen

- Weld StudsDokument24 SeitenWeld StudsDGWNoch keine Bewertungen

- Some Important Excipients Used in Tablet FormulationDokument6 SeitenSome Important Excipients Used in Tablet FormulationnanditakarmakarNoch keine Bewertungen

- Iso 02834-1-2006Dokument12 SeitenIso 02834-1-2006frodo frodoNoch keine Bewertungen

- Xperia™Z: Environmental Declaration ForDokument4 SeitenXperia™Z: Environmental Declaration ForandreskalikasansaraNoch keine Bewertungen

- Outline For PhotosynthesisDokument6 SeitenOutline For Photosynthesiswitzy11Noch keine Bewertungen

- Design of O-Rings For SealingDokument87 SeitenDesign of O-Rings For Sealingsiva rajaNoch keine Bewertungen

- Calculation Cover Sheet: ClientDokument8 SeitenCalculation Cover Sheet: Clientanamaria ursuNoch keine Bewertungen

- 50 Years After The Nobel Prize Ziegler Natta Catalysis - Claverie2013Dokument6 Seiten50 Years After The Nobel Prize Ziegler Natta Catalysis - Claverie2013Erika AndradeNoch keine Bewertungen

- ApplicationNote PH Measurement JamJellies EN 30538204Dokument4 SeitenApplicationNote PH Measurement JamJellies EN 30538204MarcinNoch keine Bewertungen

- Qorpak 2018 CatalogDokument104 SeitenQorpak 2018 Catalog東栄大出Noch keine Bewertungen

- Hydrocarbon Migration and Trapping MechanismsDokument51 SeitenHydrocarbon Migration and Trapping MechanismsReddy Setyawan100% (3)

- Introduction to Multicomponent Distillation DesignDokument60 SeitenIntroduction to Multicomponent Distillation DesignAnonymous a6dqwz4Y7B100% (2)

- Inorganic 3Dokument7 SeitenInorganic 3Ephraim PeasahNoch keine Bewertungen

- 11 Chapter Reaction Kinetics Text Book Exercise PDFDokument14 Seiten11 Chapter Reaction Kinetics Text Book Exercise PDFBilal KhanNoch keine Bewertungen

- Carbon Compounds Chemistry GuideDokument20 SeitenCarbon Compounds Chemistry Guideirisyyy27Noch keine Bewertungen

- LM Product BrochureDokument20 SeitenLM Product BrochurekashishNoch keine Bewertungen

- Roof Drainage DesignDokument9 SeitenRoof Drainage DesignarbiNoch keine Bewertungen

- Cetco Hydraul EzDokument4 SeitenCetco Hydraul Ezjaredf@jfelectric.comNoch keine Bewertungen

- Material Science QuestionsDokument40 SeitenMaterial Science QuestionsLucky KapoorNoch keine Bewertungen

- As 2219.1.5-2002 Methods of Test For Vitreous Enamel Coatings Chemical Tests - Determination of Resistance ofDokument4 SeitenAs 2219.1.5-2002 Methods of Test For Vitreous Enamel Coatings Chemical Tests - Determination of Resistance ofSAI Global - APACNoch keine Bewertungen