Beruflich Dokumente

Kultur Dokumente

Tejas Shah: MOM/MES Functional Consultant-Life Sciences

Hochgeladen von

sumitOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Tejas Shah: MOM/MES Functional Consultant-Life Sciences

Hochgeladen von

sumitCopyright:

Verfügbare Formate

Tejas Shah

MOM/MES Functional Consultant- Life Sciences

Pune, Maharashtra, India

Information Technology and Services

Current

Tata Consultancy Services,

Siemens Limited, India

Siemens,

Siemens Limited, India

Previous

Education

Fr. Conciacao Rodrigues Institute Of Technology

307connections

Connect

Send Tejas InMail

More opt ions

https://in.linkedin.com/pub/tejas-shah/16/3a2/912

Background

Summary

Excellent people management skills put together with good motivation skills for team

member to achieve the company goal.

An effective planner with abilities in devising effective strategies & project scheduling for

business excellence;

Excellent interpersonal skills that have been put to good use while interfacing with clients

for ascertaining requirements and delivering need based customize solutions;

An enterprising leader with strong analytical, problem solving, & organizational abilities.

In depth knowledge on process control requirements for Life Sciences customer primary

processes & good understanding on validation of control system as per GAMP5 & 21 CFR

Part 11.

Experience

Associate Consultant

Tata Consultancy Services

July 2015 Present (3 months)

MOM/MES Functional Consultant - Life Sciences

MES - Level 3 Expertise

Siemens Limited, India

February 2014 Present (1 year 8 months)Mumbai

Good understanding on MES solutions for Weighing & Dispensing requirement,

Manufacturing & Packaging.

Good understanding on ISA 95 Part 1 for implementing MES solution for process industry.

Functional Integration of ERP & MES system for Plant Operational data controlling & KPI

review/reporting.

Functional Integration of Automation System with MES system for control & feedback from

real time plant data.

Functional integration of Weighing Scale, Barcode Scanner & Barcode printer to ensure

traceability within process operation.

Good understanding on networking of MES system with ERP, Level 2 Automation System,

Weighing Scale, Barcode Printer, & DAS Server.

Configuration of customer requirements in MES system meeting US FDA Regulatory 21 CFR

Part 11 guidelines.

Handling eBR project for Formulation Plant using Siemens MES (Simatic IT XFP) comprising of

integration with SAP & Level 2 automation domain since Feb14.

Group Head Automation Technology Projects

Siemens Limited, India

January 2012 Present (3 years 9 months)Mumbai

Handling of Control & Automation Technology Projects execution with P&L responsibility of

key accounts in process industry

Providing consultancy to Key accounts in standardizing their plant automation requirements

for achieving, operational excellency, better yield of the product output & to have supporting

documents for trace-ability & regulatory requirements.

Involved in making internal strategies for offering Control &Automation and MES technology

solutions to customers in process industry.

Effective Synergy with multi-resources like Sales, Finance, Design, Application Configuration,

Manufacturing and Logistics teams for better delivery to market requirements.

Expert Support to proposal team for customer confidence building & acquiring strategic

Order.

Supporting Procurement Function in defining requirements for technical products & helping

them in dealing with the vendors.

Reporting & Review of Projects status on periodical basis to Management.

Responsibilities for Performance Evaluation & Career Development for Resources.

(Open) 2 projects

Project Management and Team Lead

Siemens

July 2008 December 2011 (3 years 6 months)Mumbai

Project Management for Control & Automation projects with scope comprising of Design,

Software configuration, Procurement, Manufacturing, Testing and Delivery of system

complying to Qualification as per GAMP5 & 21 CFR Part 11.

Project requirements conceptualization Technical, Commercial, and Contractual detailing.

Managing interest of all stakeholders in the project (customer, supplier and internal).

Monitor and Control the financial status of the project (Billings, budgets, cost projection,

milestone payments, warranty, change order management and potential risk (technical or

other).

Establish professional relationships with customers to ensure customer satisfaction.

Work with sales (as required) to ensure that project proposals are supported with proposal

deliverable e.g. risk/opportunity, project Schedule and optimum cost model.

Good Understanding on ISA S88 & ISA 99 Standards for Implementation of Automation

Projects.

Have worked as Technical Manager for the Batch based projects for end users in process

industry.

Engineering Control & Automation System Design, Commissioning

Siemens Limited, India

July 2005 June 2008 (3 years)Mumbai

Work experience in On Location and Back Office (Design, Engineering and Manufacturing

center) delivery methodology.

Design for Software Templates using DCS / PLC Controller programming tool, to meet the

data collection requirements.

Design documentation for system architecture, Bill of material specifications, power

distribution schemes, signal interconnections diagrams and communication network diagram

for Siemens and third party devices interface.

Software Program development and Logic validation.

Design and prepare I/O assignment and Marshalling Loop drawing development in CAD tools.

Site start-up, loop checks, Cold checks and commissioning support.

Volunteer Experience & Causes

Opportunities Tejas is looking for:

Joining a nonprofit board

Skills-based volunteering (pro bono consulting)

Causes Tejas cares about:

Arts and Culture

Environment

Health

Science and Technology

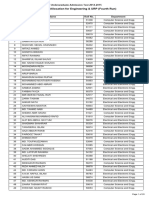

Das könnte Ihnen auch gefallen

- Mukesh Mistry - CRM Functional Consultant PDFDokument4 SeitenMukesh Mistry - CRM Functional Consultant PDFmkshmistryNoch keine Bewertungen

- Resume - Mukesh MistryDokument6 SeitenResume - Mukesh MistrymkshmistryNoch keine Bewertungen

- Avneet Singh: Professional SummaryDokument3 SeitenAvneet Singh: Professional SummaryAvneetNoch keine Bewertungen

- Senior Information Technology Business Analyst in Chicago IL Resume Daniel TownsendDokument2 SeitenSenior Information Technology Business Analyst in Chicago IL Resume Daniel TownsendDanielTownsend100% (1)

- Dbace: 1. Project Title: Sports Authority of Andhra Pradesh (Saap) - ClientDokument5 SeitenDbace: 1. Project Title: Sports Authority of Andhra Pradesh (Saap) - Clientv rajasekharNoch keine Bewertungen

- EASAPBTPDokument5 SeitenEASAPBTPazzuNoch keine Bewertungen

- Bhanu PDF TPMDokument3 SeitenBhanu PDF TPMAshmita BhattacharyaNoch keine Bewertungen

- Resume NEETISHUKLADokument6 SeitenResume NEETISHUKLAAlexa BurridgeNoch keine Bewertungen

- Curriculum VitaeDokument4 SeitenCurriculum Vitaeprashant prajapatiNoch keine Bewertungen

- JHJJKNLKJDokument5 SeitenJHJJKNLKJsandeep kNoch keine Bewertungen

- Sap MM LokeshDokument3 SeitenSap MM LokeshLokesh ModemzNoch keine Bewertungen

- Business - Analyst SampleDokument2 SeitenBusiness - Analyst Samplegautam8882Noch keine Bewertungen

- BA ResumeDokument4 SeitenBA Resumewayoha8160Noch keine Bewertungen

- SAP+PM PP-QM+Ashish+DasDokument8 SeitenSAP+PM PP-QM+Ashish+DasphaniNoch keine Bewertungen

- Ahmed MohdDokument12 SeitenAhmed MohdHARSHANoch keine Bewertungen

- Final Research Project Vibhuti BhushanDokument100 SeitenFinal Research Project Vibhuti BhushanShubham DasNoch keine Bewertungen

- NIEYEx5Uiv - Technology Business AnalystDokument2 SeitenNIEYEx5Uiv - Technology Business AnalystYASH KALA PGP 2021-23 BatchNoch keine Bewertungen

- Business AnalystDokument3 SeitenBusiness AnalystVishnu'sNoch keine Bewertungen

- Resume - Peter Mohan (BSA With 8+ Years Experience)Dokument6 SeitenResume - Peter Mohan (BSA With 8+ Years Experience)Ankit butolaNoch keine Bewertungen

- Pharma Resume by Hamza TariqDokument5 SeitenPharma Resume by Hamza Tariqsaad wainceNoch keine Bewertungen

- Resume Surya C. ADokument6 SeitenResume Surya C. ASurya C. AkasamNoch keine Bewertungen

- Gangadhar Intellectt INC : Role: Integrations Systems Admin - Workday Location: Remote Duration: Long TermDokument1 SeiteGangadhar Intellectt INC : Role: Integrations Systems Admin - Workday Location: Remote Duration: Long TermgangadharNoch keine Bewertungen

- Rajesh SAP+PM+Dokument5 SeitenRajesh SAP+PM+phaniNoch keine Bewertungen

- Ashish PurohitDokument8 SeitenAshish PurohitSAP_SD_HMNoch keine Bewertungen

- Resume Ramses EnglishBAv14Dokument7 SeitenResume Ramses EnglishBAv14Grupo NayarNoch keine Bewertungen

- Aloksrivastava: Profile SummaryDokument3 SeitenAloksrivastava: Profile SummarySuman SharmaNoch keine Bewertungen

- Objective:: M.S.Sivakumar E-MDokument9 SeitenObjective:: M.S.Sivakumar E-MSiva KumarNoch keine Bewertungen

- Sumeet Bhatia - CRM Project ManagerDokument4 SeitenSumeet Bhatia - CRM Project Managersbhatia5454Noch keine Bewertungen

- Srinivas Jaggannagari: Page 1 of 4Dokument4 SeitenSrinivas Jaggannagari: Page 1 of 4Vinay ShrivasNoch keine Bewertungen

- Professional Profile BADokument4 SeitenProfessional Profile BAkartikb60Noch keine Bewertungen

- Mohankumar P-Resume-BADokument3 SeitenMohankumar P-Resume-BAArunaNoch keine Bewertungen

- Lalitha Sr. Business AnalystDokument5 SeitenLalitha Sr. Business AnalystSandeep Kumar100% (1)

- "Patel 908-428-5357 " Sr. Business Analyst Professional SummaryDokument5 Seiten"Patel 908-428-5357 " Sr. Business Analyst Professional SummaryJay ReddyNoch keine Bewertungen

- ERP OverviewDokument33 SeitenERP OverviewKhubaibAhmedNoch keine Bewertungen

- Raghavendra Manohar: 2nd Floor, No. 377, 42nd Cross, Jayanagar 8th Block, Bangalore - 560082Dokument2 SeitenRaghavendra Manohar: 2nd Floor, No. 377, 42nd Cross, Jayanagar 8th Block, Bangalore - 560082Anonymous ALNqtOpNoch keine Bewertungen

- Senthil Kumar: Career ObjectivesDokument6 SeitenSenthil Kumar: Career ObjectivesseenthilNoch keine Bewertungen

- Ankit (Consultant) Resume CompressedDokument5 SeitenAnkit (Consultant) Resume CompressedAnkit SinghNoch keine Bewertungen

- Srinivasa Garlapati - Resume - 7102013 PDFDokument6 SeitenSrinivasa Garlapati - Resume - 7102013 PDFsgarlapati6Noch keine Bewertungen

- Project TitleDokument3 SeitenProject Titlev rajasekharNoch keine Bewertungen

- UntitledDokument6 SeitenUntitledTas ThkNoch keine Bewertungen

- Resume Vikas SAP SDDokument2 SeitenResume Vikas SAP SDVikas AnandNoch keine Bewertungen

- Dice Resume CV AdsdDokument7 SeitenDice Resume CV AdsdsandeepntcNoch keine Bewertungen

- Resume, Business AnalystDokument4 SeitenResume, Business AnalystAmit SharmaNoch keine Bewertungen

- Vagner, Alex.: Executive SummaryDokument4 SeitenVagner, Alex.: Executive SummaryMohitNoch keine Bewertungen

- Bhulinder - BA With PCDokument4 SeitenBhulinder - BA With PCiteam INCNoch keine Bewertungen

- Vibhishan Maharana: Contact No: EmailDokument3 SeitenVibhishan Maharana: Contact No: EmailVIbhishanNoch keine Bewertungen

- Crystal Reports Consultant 0038Dokument6 SeitenCrystal Reports Consultant 0038Cendien ConsultingNoch keine Bewertungen

- Project CharterDokument14 SeitenProject Charterbhatta_ashu3672100% (2)

- Abhash Sharma: Executive SummaryDokument3 SeitenAbhash Sharma: Executive SummaryAbhishek PradhanNoch keine Bewertungen

- Reshma VemulaDokument4 SeitenReshma VemulaAnusha RNoch keine Bewertungen

- IT Infrastructure Project Management in Atlanta GA Resume Deborah ThorntonDokument2 SeitenIT Infrastructure Project Management in Atlanta GA Resume Deborah ThorntonDeborahThorntonNoch keine Bewertungen

- Business Analysis, Implementation and Successful Delivery of Complex SystemsDokument3 SeitenBusiness Analysis, Implementation and Successful Delivery of Complex SystemsJay LingusgurNoch keine Bewertungen

- Chetan Jain CJ4545 2Dokument8 SeitenChetan Jain CJ4545 2kiran2710Noch keine Bewertungen

- CV Project ManagerDokument3 SeitenCV Project ManagerMegha NandiwalNoch keine Bewertungen

- Senior Project Program Manager in NYC New York Resume Simita BrahmaDokument2 SeitenSenior Project Program Manager in NYC New York Resume Simita BrahmaSimitaBrahmaNoch keine Bewertungen

- Natasha Zamir: Herndon, VirginiaDokument4 SeitenNatasha Zamir: Herndon, Virginiavitig2Noch keine Bewertungen

- Enterprise Architect ResumeDokument6 SeitenEnterprise Architect Resumef5dgrnzh100% (2)

- Resume Prashant PrajapatiDokument4 SeitenResume Prashant Prajapatiprashant prajapatiNoch keine Bewertungen

- Software Testing Interview Questions You'll Most Likely Be AskedVon EverandSoftware Testing Interview Questions You'll Most Likely Be AskedNoch keine Bewertungen

- We Want To Help You Upgrade Your License From ME To PME PDFDokument3 SeitenWe Want To Help You Upgrade Your License From ME To PME PDFDidy RobotIncorporatedNoch keine Bewertungen

- INTERNATIONAL ASSOCIATION OF ENGINEERS April 24th ClassDokument4 SeitenINTERNATIONAL ASSOCIATION OF ENGINEERS April 24th ClassSol MoniecNoch keine Bewertungen

- 90 NetDokument4 Seiten90 Nettuan nguyen duyNoch keine Bewertungen

- Nishant CVDokument4 SeitenNishant CVNishant KumarNoch keine Bewertungen

- OOSE Minor ExamDokument9 SeitenOOSE Minor ExamKumar NeelabhNoch keine Bewertungen

- Drainage Report: Maju Integrated Engineers Sdn. BHDDokument13 SeitenDrainage Report: Maju Integrated Engineers Sdn. BHDpawi100% (1)

- DS Pole Sheets Hot-RolledDokument3 SeitenDS Pole Sheets Hot-RolledSalvadorNoch keine Bewertungen

- PLC Exercises: Ladder Diagram ProgrammingDokument27 SeitenPLC Exercises: Ladder Diagram Programmingganeshrudra100% (4)

- NGMA (Greenhouse) Structural Design ManualDokument17 SeitenNGMA (Greenhouse) Structural Design ManualChris HewittNoch keine Bewertungen

- Curriculum Vitae: Pin:673 601 Kerala IndiaDokument3 SeitenCurriculum Vitae: Pin:673 601 Kerala IndiaSarif NazarNoch keine Bewertungen

- Control Systems ResourceS12Dokument5 SeitenControl Systems ResourceS12Anonymous XFh6mcKNoch keine Bewertungen

- Kick of Meeting ReportDokument4 SeitenKick of Meeting ReportJudy TrijogaNoch keine Bewertungen

- Sample Bid DocumentDokument13 SeitenSample Bid Documentapi-245558208Noch keine Bewertungen

- QCP 045 Field Engg Control Procedure (Zuluf Water Supply Facilities B.I. No. 10-12322) SubmittedDokument11 SeitenQCP 045 Field Engg Control Procedure (Zuluf Water Supply Facilities B.I. No. 10-12322) SubmittedRAMAKRISHNANoch keine Bewertungen

- Lecture 4A - Understanding Sanitary Plumbing SystemDokument35 SeitenLecture 4A - Understanding Sanitary Plumbing SystemWong Lipping100% (1)

- Compiled AssistantshipsDokument15 SeitenCompiled AssistantshipsROBI PAULNoch keine Bewertungen

- Dissertation KwaichunghousingDokument116 SeitenDissertation KwaichunghousingGary LoNoch keine Bewertungen

- Publist SciexDokument129 SeitenPublist SciexFroy HuancaNoch keine Bewertungen

- Crossing Boundaries, Building Bridges - Comparing The History of Women Engineers, 1870s-1990sDokument310 SeitenCrossing Boundaries, Building Bridges - Comparing The History of Women Engineers, 1870s-1990sThaísReginaNoch keine Bewertungen

- Cle1011 Engineering-Geology Eth 2.0 40 Cle1011Dokument2 SeitenCle1011 Engineering-Geology Eth 2.0 40 Cle1011Yash ManeNoch keine Bewertungen

- Design and Implementation of An Electrical Lift Controlled Using PLCDokument8 SeitenDesign and Implementation of An Electrical Lift Controlled Using PLCothmanNoch keine Bewertungen

- BUET Students 2014-2015Dokument20 SeitenBUET Students 2014-2015Ismail HossainNoch keine Bewertungen

- Project ReportDokument61 SeitenProject Reportlove goyal100% (2)

- Contoh Project-CharterDokument13 SeitenContoh Project-CharterNailur Rahman ZainiNoch keine Bewertungen

- Step by Step Renishaw Retrofit PDFDokument4 SeitenStep by Step Renishaw Retrofit PDFRizki AdhaNoch keine Bewertungen

- Electrical Note 2Dokument3 SeitenElectrical Note 2sofyan_shahNoch keine Bewertungen

- Analysis of The Structure at The Ultimate Limit StateDokument11 SeitenAnalysis of The Structure at The Ultimate Limit StatetijaNoch keine Bewertungen

- Developing An Android Application For College Management SystemDokument6 SeitenDeveloping An Android Application For College Management SystemHackerNoch keine Bewertungen

- Current SwitchDokument4 SeitenCurrent SwitchSreekanth RaveendranNoch keine Bewertungen

- Vem Brochure - PDF - Digital Signal Processor - Embedded SystemDokument1 SeiteVem Brochure - PDF - Digital Signal Processor - Embedded SystemLeggings LivingNoch keine Bewertungen