Beruflich Dokumente

Kultur Dokumente

Geotechnical Investigation For Performance Prediction of Submarine Trenching Ploughs

Hochgeladen von

Ercan KökdenOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Geotechnical Investigation For Performance Prediction of Submarine Trenching Ploughs

Hochgeladen von

Ercan KökdenCopyright:

Verfügbare Formate

Offshore Szte Znvestzgaaon and Foundatzon Behavzour '98 O SUT 1998

GEOTECHNICAL INVESTIGATION FOR PERFORMANCE PREDICTION OF

SUBMARINE TRENCHING PLOUGHS

P G ALLAN

SEtech Ltd.

Broomhaugh House

Riding Mdl

Northumberland, UK

ABSTRACT

An extensive network of undersea pipehnes and cables exists. For the majonty of these

some form of trench is required for protecuon from fishng acuvihes, stabihty and/or

thermal insulahon. The predichon of the performance of the tool used to form the

trench is based on geotechmcal data obmned as part of the seabed invesugahon.

However, the geotechnical parameters determined may not be of direct relevance to the

fadure modes imposed on the sod by the trenching tool. This paper descnbes the typical

data provided and Qscusses its applicahon to prediction of trenchng tool performance

with parhcular emphasis on submanne ploughs. Modifications and improvements to

existing investigahon techmques are also discussed.

INTRODUCTION

Trenchng and bunal of offshore pipelines and cables is often required for reasons

rangng from protection from fishmg gear and anchors to providmg thermal insulahon

and upheaval buckling resistance. To achieve the reqwed trench, a wide variety of

submarine trenchmg tools are avdable. A number of factors are important in the

assessment and selechon of the correct trenching equipment for the proposed work

including a good understandmg of the geotechnical properties of the sods and rocks

along the route.

The cable industry uthses cable whch can run for considerable distances on the seabed

and has previously adopted an approach based on inveshgating the seabed soils in a

qualitahve manner by use of a scaled down cable plough. T h ~ is

s in contrast to the oil

industry whch uses investigation techniques having then origin in onshore geotechnics.

Typical techniques include cone penetrahon teshng (CPT) and samphng by means of a

Offshore Srte Znvestrgatron and Foundatron Behuvrour '98 O SUT 1998

dnven tube. Such techniques can provide a detaded vertical stratigraphy, but over a

limted area

Thls paper summanses geotechnical invesugauon techmques commonly used for subsea

pipehne and cable routes. Some of the problems encountered in interpretation of data

are bscussed, with suggeshons made for some lrnprovements in investigauon

techmques, based largely on exisung equipment.

TYPES OF TRENCHING TOOL

Emphasis in thls paper is placed on submarine ploughs, whch are one of the most

widely used trenchmg techniques. They have the particular advantage of being

essentially a passive process producing a well defined, stable trench. A minimal number

of moving parts are requrred maxmsing reliabhty. The plough is normally pulled by a

ship or barge mounted winch. For pipehnes, a V shaped trench may be cut before @re

lay) or after (post lay) placing the pipeline. Cable ploughs cut a narrow slot through the

seabed and the cable is placed within the plough share, whch provides temporary

support to the sides. Ploughs work most effectively in sands and clays giving good

performance rates ulth rmnimal maintenance m e . Their capabhty in rocks is highly

dependant on fracture spacing and strength. Whlle there is httle expenence of

ploughing in rock, on most projects on which rock has been encountered, the plough has

generally exceeded the expectations.

Other widely used techmques include jet tools, mounted on a sled, seabed tractor or a

free sw~rnmngROV. Jemng was the earhest technology used for f o m n g submmne

trenches. Excavabon is by a h g h pressure jet of water erobng the soil at the face of the

trench. Advanced jet tools incorporate inductors to remove the soil more effecbvely

from the trench. Operahon is hmted to sands and clays and performance rates tend to

be relabvely slow. For clay, a simple calculation based on undrained shear strength and

jet water pressure can be used to determine whether the tool has sufficient power to

excavate the clay. For sands a smple analysis is not possible, however it is known that

both relauve density and permeabhty are sigmlicant with a dense mpermeable sand

being hardest to jet. In pracbce most performance prdcbons are based on previous

expenence in similar soil types.

Cumng tools, comprising cham and wheel cutters are also available. Both remove sod

or rock from the trench by cumng with a form of tooth or pick, and then transpomg the

debris out of the trench. Cham cutters are generally considered appropriate for sods and

weak, fractured rocks, while wheel cutters are more appropnate to stronger rocks.

Performance is limited by the power available to cut the sod or rock in stronger

materials. In softer matenals the depth of cut can be increased until the volume of

matenal being excavated exceeds the ability of the cutter to transport the spoil out of the

trench.

Offshore Srte Investrgatron and Foundatron Behavrour '98 O SUT 1998

While the above tools are used to form trenches, there may also be a requuement to

backfi a trench, usually for enhanced upheaval buckhng resistance and thermal

insulation. This is normally only required for pipelines, and dedicated backfill ploughs

have been budt to return spod to a trench. They are normally designed to work in

conjunction with a trenchmg plough, but have been used to backfill trenches formed

with a jet tool on occasions

LNVESTIGATION FOR OIL AND GAS PIPELINES

Early offshore installabons were typically large fixed structures imposing large loads

over small areas. Borehole sampling and tesbng, complimented by CPT's, are ideal for

such situations. With the development of subsea pipelines, the techniques used for

fixed structures were adapted to suit pipehnes. Invesbgabon normally compnses

samphng by vibroconng and in situ testing by CPT to shallow depth (normally between

3m and 6m). Such tech~llqueshave many advantages as they idenhfy the strata types

and strengths over the depth range of the proposed trench and provide samples

sufficiently large for most standard laboratory tesbng. However the typical spacing of

lOO0m cannot give an accurate indicabon of all sod types which may be encountered

along the route.

Both the in situ CPT and standard laboratory tests performed on samples were

developed primarily for the purposes of stabc, vertically loaded foundations. While

many of the properties deterrmned, may be used to assist performance predicbons of

trenching tools and backfii, it is important to appreciate the effect that rate of sod

failure and Qsturbance can have on the properties of the soil. Guidance on the selecbon

of suitable tests has been given by the Offshore Site Invesbgation Forum (1996).

Where trenches are to be backfilled, the properbes of the soil, excavated and returned to

the trench, may be completely different to those of the in situ soil. For example Bruton

et a1 (1998) has suggested that a soft clay backfill may be considered as a fncbonal

matenal at low stress levels. Useful guidance on the assessment of soil as backfill has

been provided by Cathie et a1 (1998).

I

INVESTIGATION TECHNIQUES USED FOR CABLE ROUTES

Cables have been l a d on the sea floor for many years (the first transatlanbc cable was

laid in 1854) and where orignally surface laid. Dunng the last twenty to thirty years,

the value of bunal for protection from fishmg gear and small anchors has become

widely appreciated and now cables are routinely buned to water depths between of

500m and 1000m.

Offshore Szte Investzgatzon and Foundatzon Behavzour '98 0 SUT I998

The geotechnical engneenng associated with a cable route is relahvely small compared

to a pipeline and h s is often reflected in the scope of the geotechcal investigation. At

worst a few grab samples or drop cores will be obtained whlle at best CPT's will be

performed at regular intervals with widely spaced samphng and no laboratory teshng.

fistoncally one ophon for inveshgahon of a cable route has been a bunal assessment

survey (BAS). The BAS tool is essentially a scaled down and simplified cable plough.

As such it provides an assessment of the whole route, gving good indicahon of the tow

force and other operahonal parameters such as sinkage and stability which may be of

concern on a very soft seabed. As no convenhonal geotechnical parameters are

obmned, all interpretahon must be based on scahng from the BAS tool with soil types

tentatively interpreted from the tow tension trace. Noad (1993) has discussed in greater

detad the use of BAS tools.

Use of BAS tools has declined in recent years, as they are normally deployed from a

cable ship and relahvely expensive to use. As an alternahve the cable industry is

increasingly using CPT's, penetrabng to a depth of 2m, achievable with a relatively

hght, simple frame. Sampling may also be performed, but is often h t e d to drop cores,

or pushed samphng, incorporated into the CPT frame. Such samphng techmques may

be adequate in very soft soils, where 2m of core may be recovered, however in sands

and s m clays penetrahon may be limited to a few centimetres.

A further replacement of the BAS tool is C-BASS, which has been developed by Cable

and Wlreless recently (Lewis and McGinnis, 1997). C-BASS is a towed sledge like

vehicle incorporabng both geotechnical and geophysical techniques to g v e an

assessment of the geology and ploughabihty along the whole route Geophysical testing

comprises a resistivity array, gving an indication of the porosity of the seabed and a low

frequency acoustic profiler intended give an indication of the grain size and strength of

the sedment. Ground truthing IS provided by a mini cone penetrometer mounted on the

s

has been commercially available for less than 2 years. At the

frame. T h ~ equipment

time of wnhng plough data is becoming avadable and back analyses are expected to be

performed.

USE AND INTERPRETATION OF GEOTECHNICAL PARAMETERS

The complex nature of the soil mechanics associated with rapid shearing of soils make

mathematically ngorous performance predichons for trenclung tools difficult. As a

result the basis of most performance prdchons is previous experience in sumla.soil

types and empirical models (eg Reece and Grinsted, 1986) Attempts have been made

to develop mathemabcal models (eg Palmer, 1998) however the complexity of the

model and uncertainty associated with many of the parameters required, make such

models difficult to use.

Offshore Site Investigation and Foundation Behavlour '98 O SUT 1998

Tow

Force

Plough Speed

Figure 1 : Plough speed/tow force relabonshps in vmous sol1 types.

Typical tow force speed relationships for sands and clays have been hscussed by Reece

and Gnnsted (1986) and Allan (1997) (Figure 1). The tow force required is the sum of

the following forces:1. Fncbonladhesion between the seabed and the plough,

2. Passive resistance of the soil over the cross secbonal area of the trench

3. A rate effect dependant on the speed of ploughing

In a soft clay the tow force may be preQcted relabvely easily. If no layer of sand is

present, the adhesion may be estmated as:Total adhesion = a

. s,

. Ab

Where a = adhesion factor

s, = undrained shear strength

Ab= Bemng area of plough

Passive resistance may be calculated fiom classical soil mechanics. Alteinatively

Palmer (1998) has suggested that the passive resistance will approxlmatelto:-

Total passive resistance = 5

. s, . A,

Where A, = Trench cross secbon area

Offshore Srte Investrgatron and Foundatron Behavrour '98 O SUT 1998

Shear rate effects in very soft clays are not normally simcant when compared to other

forces Shear rate effects in cone penetrahon teshng have been discussed, for example,

by Meigh (1987). Such data may be extrapolated for the case of ploughs. For typical

plouglung speeds, the increase in strength is typically less than 1.25 hmes measured

undraned shear strength at standard teshng rates.

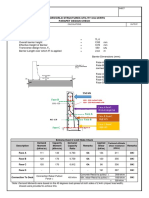

An example of a CPT plot and measured plough tow force is given as Figure 2. The

geology compnsed a veneer of sand, overlying soft clay with an estunated undraned

shear strength of 25kPa Thus tow force may be eshmated as follows and found to

compare favourably with the measured tow force:Passive resistance - Trench area x s, x 5

Fnchon Skids on sand, 450 x tan(35x213) =

Share on clay, 10 x s, x a

Estunated tow force

250kN

195kN

175kN

62OkN

Note: Plough submerged weight = 90Te

Beanng area of shares = 10m2

Medlurn dense SAND

Soft CLAY wth

occasional thm sand

lenses

Plough Performance 1 4m trench depth

600kN tow force

6 O m / m speed

Figure 2 : CPT and plough performance data in soft clay.

Tow forces in soft clay are usually low and therefore not a prime concern. However

very low forces, may present thelr own problems, for example surgng on the plough

due to stored energy in the tow line catenary, partrcularly in deep water. More

significant may be the need to accurately determine the undrained shear strength in very

soft clays. Most ploughs able to operate on seabed clays with strengths greater than

OfJshore Site lnvestigatzon and Foundation Behavlour '98 O SUT 1998

between 3kPa and 10kPa. If the seabed is unable to support the plough, damage to a

pipehne, or overbunal of a cable may occur.

Slmilar relahonshps are also suitable for fm and stiff clays However particular

attenhon should be p a d to the adhesiodfnchon. Eshmates based on undraned shear

strength are hkely to be upperbound and an estimate based on fnchon is hkely to be

more accurate. High quality logging of samples is highly desirable to give an indicahon

of the macrofabnc of the clay as any fissures which may be present can sigmficantly

reduce the required trenching force

The vanous components associated with predichon of trenchng forces in sands may be

estimated from the fnchon between the plough and the seabed, the passive resistance of

the plough and the speed effect. Reece and Gmsted (1986) have suggested the

following re1ahonshp:Tow force = K1 W

+ K2. z3 + K3 . z3 .v . (AVIk)

Where K1 =

W =

K2 =

=

z

K3 =

=

v

AVIk =

Coefficient of friction

Submerged weight of plough

Coefficient relahng to passive resistance

Depth of trench

Coefficient related to geometry of plough

Speed

Volumetric dllation/permeabllityty

Fnchon between sand and steel may be estimated from pile formula. These range from

2/3.tan0to tan(+5). The result is not particularly sensitive to changing 0 with frichon

coefficients in the range 0.4 to 0.5 calculated for typical 0 values. S d a r l y the passive

resistance may be calculated for a range of 0 values and found to be relahvely small.

Whlle the two stahc components of the tow force may be approximated relatively easily,

the most sigmficant is the dynarmc component. l k s is associated with the dilahon

(volume increase) which occurs in any granular matenal dense of it's cntical state

dunng shearing. As the volume increases, the void space also increases. At slow rates

of shearing, the water can flow through the sand mass and occupy the increased void

space. However at hgher speeds water may not be able to flow in sufficiently quickly

and pore 'suchons' (or pore pressure below hydrostahc head) are generated. At high

speeds there is potenhal for cavitation to occur and the head of water above the sand

surface will effechvely act as a surcharge sigmficantly increasing the effective stress in

the sand. The contribution of the vanous components (friction, passive resistance and

effect of cavitation in water depths of 10m and 20rn)are shown as Figure 3 for a typical

pipehne plough trenchmg at 1.4m depth. The friction and passive resistance are

relatively small in comparison to the potenhal effect of cavitation. Clearly in deeper

Offshore Site Investigation and Foundation Behaviour '98 O SUT 1998

water, tow forces of the magnitude imphed cannot be achieved and water must flow into

the sod mass to at least partially relieve pore suctions.

20m

Passive component \ Fnctl-

30

32

34

36

Angle of friction (")

38

40

Figure 3 : Tow force components for a typical pipeline plough trenching

sand at hgh speed in water depths of lorn and 20m.

The mass permeabihty of the sod governs the rate at whch water can flow into the sod

mass whde the volumetnc dilation determnes the total volume required. Unfortunately

neither of these values are determined in a typical geotechnical investigabon. An

approxunation of dllation may be made based on relative density, determined by CPT,

however, permeabhty, which may vary be several orders of magnitude within granular

soils cannot be esbmated other than very approximately from particle size dlstnbubon

curves. For h s reason, empirical correlations associated with the speed component are

normally based on the paxhcle size &stribubon of the sod

The sigmficance of the soil permeabihty may be demonstrated by experience on a recent

project. Two CPT's were performed adjacent to the pipeline route, approximately lkrn

apart and are reproduced as Figure 4. CPT A encountered a very dense sand, whde CPT

B encountered a loose silty sand. Confirmation of the sllty nature of the sand at CPT B

was confirmed by a particle size dlstnbution analysis from an adjacent vibrocore.

Offshore Slte Investlgatlon and Founahtlon Behavrour '98 0 SUT 1998

Analysis ignonng dilahon and permeabhty would indicate sand at CPT A being

sigruficantly harder to plough. In practice slmilar tow tensions were required to acheve

slrmlar speeds. The low permeability of the loose sdty sand at CPT B offset the reduced

volumetric dilation on sheanng and lower passive resistance Reliable predichon of tow

forces in intermedate sods can only be acheved when samples are obtamed and

subjected to appropnate laboratory tests.

Loose sllty SAND,

becomng very dense

with depth

(PSD 100% fine sand)

Plough Performance 1 4m trench depth

1800kN tow force

1O

m

/

mspeed

CPT B

Soft sandy CLAY

Loose sllty SAND

(PSD 10%clay

17% sllt

73% sand)

Plough Performance 1.3m 'trench depth

1800kN tow force

1 2 m l m speed

Figure 4 : Comparison of CPT and Plough Data in Sand

Offshore Site Investigation and Foundation Behaviour '98 O SUT 1998

In sands, loose of cnbcal state, no speed effect is observed as no dilahon occurs and

hence no pore sucbons are developed However in practice such sands are rare and it is

normal for some &labon to occur dunng ploughing.

RECOMMENDATIONS FOR GEOTECHNICAL INVESTIGATION

The above &scussion has idenhfied the man parameters which are desirable for the

predicbon of plough performance. The suitability of standard techniques to detemne

relevant sod parameters more accurately is descnbed in Table 1. Some of the

hmtahons in problemahc soils are discussed below with suggesbons for mprovement.

Sampling and

standard

laboratory

tesbng

Suitabhty of tests

A : Good,

B : Intermdate

C : Poor

Undrained shear

strength

SoiVsteel fncbon

Soil as backfill

A'

B2

B

B3

Parhcle size

distribution

Volumetrrc ddation

Permeability

Sod as backfill

A

A

B

B3

Notes

1) F m and stiff clays

2) Dependant on specification

3) Dependant on tests performed

Table 1 : Suitability of vanous tests methods for detemnahon of soil properties for

estlrnabon of plough performance.

Soft Clays

The accurate measurement of the strength of very soft clays (<lOkPa) is essenbal with a

change in undrained shear strength of 1 or 2kPa potenhally making a sigmficant

difference to the suitab~htyof particular ploughs. Thls is of particular relevance to cable

laying where such very (or super) soft clays are often present in the deep waters towards

the edge of the conbnental shelf. However strengths of thls magnitude may not be

reliably measured. Tests performed on soil samples, are hkely to be basic field tests

with low accuracy equipment operahng at the lower end of ~ t suitability

s

with samples

subject to disturbance.

>

- .

Offshore Szte Investzgation and Foun$atzon Behavzour '98 0 SUT 1998

<$,?

For in situ measurement of undrained shear strength, either a standard CPT or a T bar

test may be performed. However it may be noted that for a lotonne cone penetrabng

3kPa clay, the electncal output is 0.06% of full scale deflection. The T bar test,

developed at the Umversity of Western Austraha (Stewart and Randolph, 1994) has

many advantages. Commercial versions are designed for use with standard size (10cm2)

cones and comprises a honzontal 50mm hameter bar of 200mm length, replacing the

comcal point of the cone. The bar therefore presents a face area of 100cm2increasing

the sensitivity of the cone by a factor of 10 Further, the falure modes associated with

pushmg a honzontal bar into the ground can be modelled with a more ngorous

used for

mathemabcal approach. Thrs pemuts smaller vanabon in the factor (Nk)

correlahon between penetrahon resistance and undraned shear strength.

While a knowledge of the strength of very soft clays is essenbal, the basic requirement

is to determine whether the strength of the clay is capable of supporhng the plough.

Estimates of tow force are not usually cnbcal as more than adequate force is normally

avalable. Machn (1998) has proposed a 'drop ball test' which as its name mplies,

consists of a ball placed on the seabed and the depth of penetrabon modelled. The ball

may be deployed from either a ROV, or alternabvely a seabed frame could be developed

to deploy the ball and measure the penetrabon.

Fine Sands and Silts

Prediction of trenclng speeds in fine sands and silts presents the greatest challenge in

interpretation of geotechnical data and its apphcation to plough performance.

Volumetnc ddabon of a sand experiencing shear from a dense or very dense state would

typically be less than 20% (eg Bolton, 1986), however the permeability may change

c a clean fine sand to 10-'dsec for a silt (eg Lee ET al, 1983). If only

from 1 0 ~ d s e for

CFT results are avadable, then there is a real dficulty in estimabng with confidence the

speed component on the tow force. It may also be noted that grading is important for

operabon of jet tools, particularly with n g d pipehnes which will touchdown on the

trench bottom some distance behlnd the jet tool. If a coarse material is present,

settlement bmes will be that much faster and sipficant reduction in trench depth may

occur with mulhpassing required.

The interpretahon of CPT in intermediate soils has been d~scussedby Lunne et al

(1996). Bugno and McNedan (1984) have suggested that true undrained response with

a standard 10cm2cone, operabng at a penetration rate of 2cdsec, wdl be observed in

sods with a permeability of less than 10-'to 10-'dsec. Soil with a permeabihty in the

range lo-' to 10-'dsec, includmg most sdts, was anbcipated to behave in a part~ally

drained manner. However it is important to note that for example a cable plough mght

be pulled at 1000m/hr, or 28cdsec, which is 14 times faster than the standard cone

penetration rate. The volume of soil failed is also much smaller, with a cross sectional

area of 0.001m2 for a cone and 0.5m2 for a typical small cable plough. The net result is

that plough performance prediction from standard CFT is very dficult Cases are

Offshore Szte Znvestrgatron and Foundatzon Behavrour '98 O SUT 1998

known to the author of ploughmg rates of 5Omlhr being acheved in soil whch would

appear to be looselvery soft The plough may be noted to pitch aft in a manner

consistent with low beanng capacity of the underlying sod, confirming its looselsoft

nature. The consequences of h s in terms of s h p programme and cost can be

significant. Sampling and laboratory testing, including parhcle size analysis is helpful

but cannot provide the complete answer.

It is probable that with m n i cones (being increasingly used for subsea invesbgations)

the dranage path is shortened and finer grained soils are hkely to behave in a h n e d

manner. This may negate some expenence obtaned with standard size cones.

An obvious method for assessing the speed effect is by varylng the speed of the cone to

assist deterrmnabon of the dilatancylspeed effect. Thls was done by Grinsted (1985) as

part of research into sheanng of submerged sands. Results are shown in Figure 5 for a

known to be relahvely hard to

very silty fine sand (permeabhty = 4 x 10-~m/sec),

plough when submerged. A measurable change in cone resistance was recorded in the

silty fine sand, however a large change in speed was used and the results are wthin the

normal vanabon whch might be expected w i h n a single geological unit. S d a r tests

were also performed in a medlum sand (permeability (4 x 10-~m/sec).The recorded

vanation in cone resistance was within the scatter of the data. It is concluded that thls is

consistent wth full h n a g e occumng dunng the test. Unfortunately a piezocone was

not used for these tests, further work with a piezocone could be beneficial.

Cone Resistance, qc (MPa)

0

Figure 5 : Effect of varylng cone penetrabon speed in a sdty fine sand

(permeability = 4 x 10-~m/sec)

'

>

Osshore Slte Investzgatzon and Foundaaon Behavzour '98 O SUT 1998

r-

In prachce, varyng speed would require a mnimum of two profiles at each test location

and confidence that both tests were being performed in slrmlar soil. While further

inveshgahon is required, it is probable that the inherent varia~onin test results would

not sigmficantly Improve plough performance prehctions.

CONCLUSIONS

A large number of geotechnical investgations are performed for subsea cable and

pipehne routes. These are often done to a standarhsed 'formula' which may not give

the informahon desired. There is scope for adaptmg standard techniques to improve the

data obtaned, and in particular for very soft clays and fine sllty sands.

ACKNOWLEDGEMENTS

The author wishes to thank DSND Oceantech Ltd and PGS Offshore Technology Ltd

for permssion to publish plough and soil investigation data Thanks are also extended

to Chns h m a x for proof reading the manuscript and Tim Gnnsted for permission to

pubhsh data from hls PhD thesis.

REFERENCES

Allan, P.G. (1997) Ploughmg forward, Ground Engineering, 29, August 1997, 26-27.

Bolton, M.D. (1986) The strength and dllatancy of sands. Gbotechnique, 36, No. 1,6578.

Bruton, D.A.S., Bolton, M.D. and Nicolson, C.T. (1998) Posiedon Project - Pipehne

design for weak clay. 21StAnnual Offshore Pipeline Technology Conference, Oslo

1998.

Bugno, W.T. and McNeilan, T.W (1984) Cone penetration test results in offshore

Cahfornia silts. Strength testing of manne sediments: Laboratory and in situ

measurements. ASTM special t e c h c a l pubhcation no. 883,55-71.

Catlue, D., Banas, S. and M a c h , J. (1998) Backffing pipelines : State of the art. 21"

Annual Offshore Pipehne Technology Conference, Oslo 1998.

Lee, I.K., m t e , W. and Ingles, O.G. (1983) Geotechnical Engineering, Pitman (pg

154).

Offshore Srte Znvestrgatron and Foundatron Behavrour '98 O SUT 1998

Lewis, S. and McGinnis, T (1997) C-BASS: A cable bunal assessment survey system

Sub-Optic '97, Los Angeles.

Lunne, T., Powell, J. and Robertson, P. (1996) Use of piezocone tests in non-textbook

matenals. Int. Conf. on advances in site inveshgat~onpractice, Institution of Civil

Engineers, 438 - 45 1.

Machin, J.B. (1998) Pipeline Foundahon Considerations Society for Underwater

Technology, Offshore Site Investigahon And Foundahon Behaviour "New Frontiers".

Meigh, A.C. (1987) Cone Penetration Teshng Methods and Interpretetahon.

Construction Industry Reseach Association and Butterworths

Noad, J. (1993) Successful Cable Burial - Its dependence on the correct use of plough

assessment and geophysical surveys. SUT Conf. Offshore Site Investigahon and

Foundahon Behaviour, 39 - 56.

Offshore Site Inveshgation Forum, Pipehnes Worlung Group (1996) Gmdance notes on

geotechnical invesbgahon for mmne pipehnes

Palmer, A. (1998) Speed effects in cumng and plouglung. Submtted to Gkotechnrque.

Reece, A.R. and Gnnsted, T.W. (1986) Sol1 Mechmcs of Submarine Ploughs. lgth

Annual Offshore Technology Conference, Houston, Texas, 453 - 46 1.

Stewart, D.P. and Randolph, M.F. (1994) T-Bar penetration teshng in soft clay. ASCE

Journal of Geotechnrcal Engineering, 120, No. 12,2230 - 2235.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Jobsite Inspection Checklist 1Dokument5 SeitenJobsite Inspection Checklist 1Sahnavaz SaiyyedNoch keine Bewertungen

- Cable Profile For Box Girder DesignDokument2 SeitenCable Profile For Box Girder DesignPunithan PunithanNoch keine Bewertungen

- Design For Manufacturability For CNC MachiningDokument4 SeitenDesign For Manufacturability For CNC Machiningviorelu99Noch keine Bewertungen

- Civil2020 v3.2 Release NoteDokument10 SeitenCivil2020 v3.2 Release NoteVarun VermaNoch keine Bewertungen

- AUTOCLAVE - AdapterCouplingDokument52 SeitenAUTOCLAVE - AdapterCouplingAjimKe'enNoch keine Bewertungen

- 02 Sleeper Pads For Ballasted Tracks PDFDokument16 Seiten02 Sleeper Pads For Ballasted Tracks PDFSzabolcs Attila KöllőNoch keine Bewertungen

- Booklet Tier I I PhaseDokument48 SeitenBooklet Tier I I PhaseAkhlaq HussainNoch keine Bewertungen

- Imp PSC DesignDokument107 SeitenImp PSC DesignTouseef Ahemed Attar50% (2)

- Rate Analysis and Estimate: Brick Work With 1:6 Cement Sand MortarDokument11 SeitenRate Analysis and Estimate: Brick Work With 1:6 Cement Sand MortarVinay HadimaniNoch keine Bewertungen

- Beam-Design-including torsion-IS 456Dokument7 SeitenBeam-Design-including torsion-IS 456Swapnil KNoch keine Bewertungen

- Cost Estimation Manual For Low Rise Buildings: Bureau of ConstructionDokument3 SeitenCost Estimation Manual For Low Rise Buildings: Bureau of Constructionjhomel garcia100% (1)

- Purlin DESIGN Car ParkDokument8 SeitenPurlin DESIGN Car ParkNasrul Torres0% (1)

- Hydromechanical Work Tools CPH v1.1 03.13.14Dokument53 SeitenHydromechanical Work Tools CPH v1.1 03.13.14Joshwa SimamoraNoch keine Bewertungen

- TAOM Fact Sheet 9 Geothermal PipelinesDokument1 SeiteTAOM Fact Sheet 9 Geothermal PipelinesTalang AkarNoch keine Bewertungen

- Pavement Design Concepts-Flexible PavementsDokument3 SeitenPavement Design Concepts-Flexible PavementsSuryasis DasguptaNoch keine Bewertungen

- Assignment IDokument2 SeitenAssignment IShivpreet SharmaNoch keine Bewertungen

- Motorworld Structures Utility Culverts Parapet Design Check: MM MM 1070 TL-5 1330Dokument1 SeiteMotorworld Structures Utility Culverts Parapet Design Check: MM MM 1070 TL-5 1330Jemicah YumenaNoch keine Bewertungen

- Modelling of Structures and Numerical SimulationDokument17 SeitenModelling of Structures and Numerical SimulationObinna ObiefuleNoch keine Bewertungen

- Baroda Mumbai Express HighwayDokument319 SeitenBaroda Mumbai Express HighwayBRIJNoch keine Bewertungen

- Manual For Design Using Etabs PDFDokument46 SeitenManual For Design Using Etabs PDFPankaj Sardana100% (1)

- Corrugated Galvanised Iron (Cgi) Specifications For RoofingDokument2 SeitenCorrugated Galvanised Iron (Cgi) Specifications For RoofingYeshaswee VaidayNoch keine Bewertungen

- Choice of A Drainage System: Topographic FactorsDokument4 SeitenChoice of A Drainage System: Topographic Factorsفردوس سليمانNoch keine Bewertungen

- American Marsh Srem PDFDokument28 SeitenAmerican Marsh Srem PDFdiuska13Noch keine Bewertungen

- Drain Piping Layout Plan of Air Compressor RoomDokument1 SeiteDrain Piping Layout Plan of Air Compressor RoomTôn Huỳnh ĐoànNoch keine Bewertungen

- AMC FormatDokument4 SeitenAMC FormatGroup RMRNoch keine Bewertungen

- Ship Structural StrengthDokument13 SeitenShip Structural StrengthZhihao LiNoch keine Bewertungen

- Detail Engineering Assessment For Existing BuildingsDokument4 SeitenDetail Engineering Assessment For Existing BuildingsSayem Ahammed100% (2)

- Daikin VRV III Heat Pump Sound Pressure Page 181Dokument13 SeitenDaikin VRV III Heat Pump Sound Pressure Page 181Octavian BumbescuNoch keine Bewertungen

- Slip Formwork: Guided by Prof. VRK Murthy Submitted by Vikas B. More (73036) Aniruddha S. Namojwar (73038)Dokument27 SeitenSlip Formwork: Guided by Prof. VRK Murthy Submitted by Vikas B. More (73036) Aniruddha S. Namojwar (73038)simple_ani100% (1)

- Chart of Plastic MaterialsDokument4 SeitenChart of Plastic MaterialsvyakshiNoch keine Bewertungen