Beruflich Dokumente

Kultur Dokumente

Riprap Specs

Hochgeladen von

Karen-John Richard NelsonCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Riprap Specs

Hochgeladen von

Karen-John Richard NelsonCopyright:

Verfügbare Formate

SPECIFICATIONS FOR THE

CONSTRUCTION OF GROUTED RIP-RAP

GENERAL SCOPE OF WORKS AND SPECIFICATIONS

All person involved in the construction project shall use proper protective gears and

equipments. Any person that does not wear proper protective gears and

equipments shall not be allowed to enter the job site and commence their

respective works.

The Contractor shall always consult or request the approval of the Supervising

Engineer on or before proceeding into the subsequent scope of work listed in this

article. This should be constantly observed by the two parties to prevent technical

misconstruction during the duration of the project.

GENERAL EXCAVATION WORKS

Bedrock shall be reached or stable ground where the foundation structure shall set.

If the bedrock or solid ground is established before the minimum depth of

excavation reflected on the detailed plans, the Contractor shall seek approval to the

Engineer before discontinuing the excavation works.

The Supervising Engineer and the Contractor shall inspect the layout, stakes, batter

boards, and any other markings for the excavation works. It will be their

responsibility to inspect all excavation dimensions including the provision for

necessary clearances for work areas as the activity progresses.

If in case that the depth of excavation is high enough that the cut slope turned out

to be unstable, the Contractor shall provide sand bag buttresses as a temporary

slope protection or may use any other slope protection method applicable.

INSTALLATION OF DOWEL REBAR

Reinforcing steel bar sizes to be installed shall conform with the plans; must be free

from rust and shall be firmly tied with gauge 16 GI tie wire.

All boreholes shall be 16mm in diameter and a minimum drilled depth of 200mm.

Boreholes shall be filled with cement grout before inserting the dowel rebar.

The Supervising Engineer shall always inspect the spacing, longitudinal, transverse,

horizontal and vertical alignments of the rebar that are being installed.

All reinforcing bars to be installed shall be of grade 230.

CONCRETING WORKS FOR FOUNDATION

Prior to placement of boulders, the surface of the foundation should be clean and

free from any debris. Lean concrete shall be poured on the foundation with

specified thickness as stated on the plans and drawings.

Concrete mix for the foundation shall be 1:2:4 (One 40kg bag of cement: Two (2)

parts of sand: Four (4) parts of gravel). Gravel diameter size should range from

inch to 1 1/2 inch. Both fine and coarse aggregates that will be used in concreting

activities shall be washed with clean water to remove soil and other debris.

Water to be used for concreting shall be visibly clean and free from any

contaminants.

GROUTED RIP-RAP WORKS

Diameter of boulder to be used shall be 200mm minimum and maximum of 400mm.

Boulders shall be rectangular in shape. Each boulder shall be of good shape and be

free of depressions and projections that might weaken or prevent it from being

properly bedded.

Boulders shall be cleaned thoroughly and wetted immediately before being set and

the bed which is to receive them shall be cleaned and moistened before the mortar

is spread.

Boulders intended to be used should be rectangular in section as possible, tough,

dense, durable and free of foreign objects. It must also be resistance from weather

conditions (air and water) and is suitable for the purpose intended.

Boulders should be arranged or fitted in a manner that void spaces in between

boulders shall be minimized.

Cement grout / mortar mix shall be 1:3 (One (1) 40kg bag of cement: Three (3) cubic

feet of sand). The horizontal and vertical contact surfaces between stones shall be

embedded by cement mortar having a minimum thickness of 20mm. Sufficient

mortar shall be used to completely fill all voids leaving the face of the stones

exposed.

Intersections of boulders are to be filled with smaller ones or broken fragments and

cleaned from foreign objects before applying cement mortar.

Placement of boulders on both faces (front and back), shall be laid carefully by hand

in such a way that its longer axis lays horizontally on its preceding layer or in its bed

/ foundation for the first layer. The longer axis must also be perpendicular with the

rip raps face.

Das könnte Ihnen auch gefallen

- Subgrade and Pavement MaterialsDokument30 SeitenSubgrade and Pavement MaterialshimathkumarNoch keine Bewertungen

- Method Statement For Earthwork Cutting and FillingDokument8 SeitenMethod Statement For Earthwork Cutting and FillingABDO ALLIANoch keine Bewertungen

- Repairing of Plaster WallsDokument4 SeitenRepairing of Plaster WallsSayan GharNoch keine Bewertungen

- Clearing, Grubbing and ExcavationDokument11 SeitenClearing, Grubbing and ExcavationArah Louise ApostolNoch keine Bewertungen

- Method Statement For ScaffoldingDokument3 SeitenMethod Statement For ScaffoldingDouglas JambaNoch keine Bewertungen

- Concreting MethodologyDokument2 SeitenConcreting Methodologyervnglen08Noch keine Bewertungen

- Method Statement For Installation of Road Culverts in Water CoursesDokument5 SeitenMethod Statement For Installation of Road Culverts in Water Coursesabsalom mkhatshwaNoch keine Bewertungen

- Part R10 Construction of EarthworksDokument10 SeitenPart R10 Construction of EarthworksCK TangNoch keine Bewertungen

- Concrete Slope ProtectionDokument10 SeitenConcrete Slope ProtectionTAHER AMMARNoch keine Bewertungen

- Field Density FDT FormDokument3 SeitenField Density FDT FormPedjaNoch keine Bewertungen

- Form WorkDokument25 SeitenForm Workhina khanNoch keine Bewertungen

- Construction Method Statement PDFDokument22 SeitenConstruction Method Statement PDFFaruk AtalarNoch keine Bewertungen

- Method Statement For Screed Concreting Aerator TWTDokument4 SeitenMethod Statement For Screed Concreting Aerator TWTChamara Nilantha KarunarathnaNoch keine Bewertungen

- Sewerage and WWTP measures in the city of Korca“ project testing proceduresDokument9 SeitenSewerage and WWTP measures in the city of Korca“ project testing proceduresJohnny RamboNoch keine Bewertungen

- Road Construction MethodsDokument150 SeitenRoad Construction Methodsblaze14911100% (1)

- Method Statement For Construction of EmbankmentDokument6 SeitenMethod Statement For Construction of EmbankmentRabnawaz Imam100% (1)

- Method Statement For Embankment FillingDokument9 SeitenMethod Statement For Embankment Fillingdamith50% (2)

- Methodology For Convreting WorksDokument7 SeitenMethodology For Convreting WorksLokesh SaranNoch keine Bewertungen

- Quality Procedure For ConcreteDokument12 SeitenQuality Procedure For ConcreteEdrian DiazNoch keine Bewertungen

- Erosion control planDokument7 SeitenErosion control planSui Su Yong100% (1)

- CIDCO Earthwork SpecificationsDokument19 SeitenCIDCO Earthwork SpecificationsAjoy McNoch keine Bewertungen

- General Earthwork SpecificationDokument17 SeitenGeneral Earthwork SpecificationDennis KuehNoch keine Bewertungen

- Do 147 S2017Dokument5 SeitenDo 147 S2017ZA TarraNoch keine Bewertungen

- Excavation: Drawings Required For Excavation 1. Centreline Drawing or Gridline DrawingDokument7 SeitenExcavation: Drawings Required For Excavation 1. Centreline Drawing or Gridline DrawingAnonymous ze9ag1Noch keine Bewertungen

- rev01-METHOD STATEMENT FOR INSTALLATION OF LINER TANK FOUNDATIONDokument7 Seitenrev01-METHOD STATEMENT FOR INSTALLATION OF LINER TANK FOUNDATIONMahaboob PashaNoch keine Bewertungen

- CC Road Construction: Materials, Machinery and StepsDokument18 SeitenCC Road Construction: Materials, Machinery and StepsJayesh GojiyaNoch keine Bewertungen

- Concrete Floor Slab Construction ProcessDokument5 SeitenConcrete Floor Slab Construction ProcessAh RashedNoch keine Bewertungen

- Methodology of Earth WorksDokument8 SeitenMethodology of Earth WorksMartinNoch keine Bewertungen

- Procedure For Slab To SlabDokument5 SeitenProcedure For Slab To SlabKarthik Chalageri 7100% (1)

- Construction Method Statement For Under Ground Water TankDokument2 SeitenConstruction Method Statement For Under Ground Water Tanksandycrackjack0% (1)

- Grouted RiprapDokument2 SeitenGrouted Riprapflmm09100% (1)

- Road Pav LayerwDokument10 SeitenRoad Pav LayerwAurelius GoraNoch keine Bewertungen

- Removal of Structures and Obstruction: Prepared By: Raymar B. CuerpoDokument9 SeitenRemoval of Structures and Obstruction: Prepared By: Raymar B. Cuerporay cuerpoNoch keine Bewertungen

- Method Statement For Excavation Works-Eastern Regional Hospital Project-Phase - 1Dokument9 SeitenMethod Statement For Excavation Works-Eastern Regional Hospital Project-Phase - 1NORTSEN ALBERTNoch keine Bewertungen

- Rapid Repair Embankment Slope Failure - Fhwa report-2019-Texas-ArlingtonDokument227 SeitenRapid Repair Embankment Slope Failure - Fhwa report-2019-Texas-ArlingtonRakesh KapoorNoch keine Bewertungen

- Work Methodology For Clearing and Grubbing of Trees and ShrubsDokument2 SeitenWork Methodology For Clearing and Grubbing of Trees and ShrubsNasser Issa Abu HalimehNoch keine Bewertungen

- Method Statement For Sheet PilingDokument8 SeitenMethod Statement For Sheet PilingAbdul Muneer PalapraNoch keine Bewertungen

- Concrete and Concrete Structures: Modular Concepts India PVT LTDDokument24 SeitenConcrete and Concrete Structures: Modular Concepts India PVT LTDArunKumar ChandrasekarNoch keine Bewertungen

- Method Statement of Bored Piles 21Dokument40 SeitenMethod Statement of Bored Piles 21Dharma Pratap LamgadeNoch keine Bewertungen

- Screeding WorksDokument1 SeiteScreeding WorksCindy AmyzaNoch keine Bewertungen

- Football Field Construction GuideDokument29 SeitenFootball Field Construction GuideNicklaus TanNoch keine Bewertungen

- FDT FormDokument3 SeitenFDT FormEdison WalitNoch keine Bewertungen

- Pipe Jacking & Microtunnelling GuideDokument48 SeitenPipe Jacking & Microtunnelling GuideHizbar ArsjadNoch keine Bewertungen

- Gabion Wall Installation GuideDokument5 SeitenGabion Wall Installation GuideJoel KomaNoch keine Bewertungen

- Method Statement For Pad FoundationDokument13 SeitenMethod Statement For Pad FoundationAbdul Rahman Hilmi0% (1)

- Bored PilingDokument3 SeitenBored PilingAdonis AlabiNoch keine Bewertungen

- Loffelstein Installation ManualDokument16 SeitenLoffelstein Installation Manuallarushkan100% (2)

- Pavment Design GuideDokument54 SeitenPavment Design GuideNahomNoch keine Bewertungen

- Cracking Concrete SurfacesDokument2 SeitenCracking Concrete SurfacesCivilEngClubNoch keine Bewertungen

- Earthworks Method Statement - 1Dokument5 SeitenEarthworks Method Statement - 1Liz LizzyNoch keine Bewertungen

- Chapter04 - Boring Log PreparationDokument18 SeitenChapter04 - Boring Log PreparationTomas Santiago Hanccoccallo PauccaraNoch keine Bewertungen

- Foundation Rehabilitation TechniquesDokument14 SeitenFoundation Rehabilitation TechniquesShraddha KaushikNoch keine Bewertungen

- Detailed Specification For Earth Work ExcavationDokument24 SeitenDetailed Specification For Earth Work ExcavationMadumitha RameshNoch keine Bewertungen

- L-Shape Wall Mar13Dokument2 SeitenL-Shape Wall Mar13Wan MahiramNoch keine Bewertungen

- GEOTECHNIC 2 - Site InvestigationDokument14 SeitenGEOTECHNIC 2 - Site InvestigationMohd Farhan Syazwan100% (1)

- Pre-pour checklistDokument1 SeitePre-pour checklistPradeep SinghNoch keine Bewertungen

- Shallow Foundations Dec. 18Dokument39 SeitenShallow Foundations Dec. 18kesharinareshNoch keine Bewertungen

- Residential Bungalow Renovation SpecsDokument13 SeitenResidential Bungalow Renovation SpecsThomasNoch keine Bewertungen

- SpecificationDokument13 SeitenSpecificationPaula Marie AgripaNoch keine Bewertungen

- Specifications-Reice MillDokument5 SeitenSpecifications-Reice MillAYSON N. DELA CRUZNoch keine Bewertungen

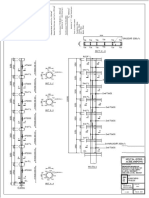

- RC GraphDokument1 SeiteRC GraphKaren-John Richard NelsonNoch keine Bewertungen

- Sample Asset DescriptionDokument3 SeitenSample Asset DescriptionKaren-John Richard NelsonNoch keine Bewertungen

- Detailed Estimate For Budget 2015 PDFDokument16 SeitenDetailed Estimate For Budget 2015 PDFKaren-John Richard NelsonNoch keine Bewertungen

- Https Akkhrakh - Files.wordpress - Com 2011-09-6 Design of Pad Foundations1Dokument78 SeitenHttps Akkhrakh - Files.wordpress - Com 2011-09-6 Design of Pad Foundations1boyzesNoch keine Bewertungen

- Wps Format (Qw-482)Dokument2 SeitenWps Format (Qw-482)Sebastian RajeshNoch keine Bewertungen

- Excel - Matrix OperationsDokument25 SeitenExcel - Matrix OperationsKaren-John Richard NelsonNoch keine Bewertungen

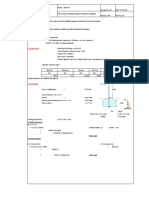

- Sample ComputationsDokument2 SeitenSample ComputationsKaren-John Richard Nelson100% (1)

- WPS PQRDokument51 SeitenWPS PQRLuis Muñoz100% (1)

- Sample EstimateDokument2 SeitenSample EstimateKaren-John Richard NelsonNoch keine Bewertungen

- Measuring Tools For Mechanical PartsDokument23 SeitenMeasuring Tools For Mechanical PartsKaren-John Richard NelsonNoch keine Bewertungen

- Standard WireropesDokument6 SeitenStandard Wireropesmohkal1260Noch keine Bewertungen

- TIG WeldingDokument1 SeiteTIG WeldingKaren-John Richard NelsonNoch keine Bewertungen

- Using STAAD Pro 2005 CoursewareDokument83 SeitenUsing STAAD Pro 2005 Coursewaredktiong100% (2)

- OHC Operations ManualDokument27 SeitenOHC Operations ManualKaren-John Richard NelsonNoch keine Bewertungen

- 2.2 Guidelines For Hydraulic Design of Small Hydro PlantsDokument117 Seiten2.2 Guidelines For Hydraulic Design of Small Hydro PlantsPrabath Perera100% (4)

- 3phase Blast WallDokument39 Seiten3phase Blast WallKaren-John Richard NelsonNoch keine Bewertungen

- Staad (1) .Pro 2006 Technical Reference (Halid)Dokument702 SeitenStaad (1) .Pro 2006 Technical Reference (Halid)Victoria WU MengqianNoch keine Bewertungen

- 2.2 Guidelines For Hydraulic Design of Small Hydro PlantsDokument117 Seiten2.2 Guidelines For Hydraulic Design of Small Hydro PlantsPrabath Perera100% (4)

- Staad (1) .Pro 2006 Technical Reference (Halid)Dokument702 SeitenStaad (1) .Pro 2006 Technical Reference (Halid)Victoria WU MengqianNoch keine Bewertungen

- Tucson Development Standards GuideDokument575 SeitenTucson Development Standards GuideKaren-John Richard NelsonNoch keine Bewertungen

- Staad - Foundation Manual V8iDokument420 SeitenStaad - Foundation Manual V8iKaren-John Richard Nelson86% (7)

- BMP Field Master FullSize Final-Jan03Dokument107 SeitenBMP Field Master FullSize Final-Jan03kupaloidNoch keine Bewertungen

- Design of Partially or Fully Composite Beams, With Ribbed Metal Deck, Using LRFD SpecificationsDokument19 SeitenDesign of Partially or Fully Composite Beams, With Ribbed Metal Deck, Using LRFD SpecificationsMala RattanNoch keine Bewertungen

- Civil 3dDokument210 SeitenCivil 3dCapacitacion Topografica100% (1)

- Design of Partially or Fully Composite Beams, With Ribbed Metal Deck, Using LRFD SpecificationsDokument19 SeitenDesign of Partially or Fully Composite Beams, With Ribbed Metal Deck, Using LRFD SpecificationsMala RattanNoch keine Bewertungen

- Transformer Foundation DesignDokument13 SeitenTransformer Foundation Designengage4u202067% (3)

- Entregable 1 InglesDokument8 SeitenEntregable 1 InglesMoisés NouNoch keine Bewertungen

- 1 Floor 2 Wall: Description Main BuildingDokument26 Seiten1 Floor 2 Wall: Description Main BuildingtolaNoch keine Bewertungen

- Sedimentation in Water TreatmentDokument27 SeitenSedimentation in Water TreatmentTruc Nguyen Lai ThanhNoch keine Bewertungen

- Loose Measurement Sheet-2: LamjungDokument12 SeitenLoose Measurement Sheet-2: LamjungBhim DahalNoch keine Bewertungen

- Interlocking Concrete Pavement: Materials, Manufacturing & UsesDokument18 SeitenInterlocking Concrete Pavement: Materials, Manufacturing & UsesJello UcagNoch keine Bewertungen

- Pile Foundation Design - A Student GuideDokument82 SeitenPile Foundation Design - A Student GuideMaurice BalkissoonNoch keine Bewertungen

- STATIC FORCE PROCEDUREDokument10 SeitenSTATIC FORCE PROCEDURECharlyn CostalesNoch keine Bewertungen

- New/Revised IRC Publications NoticeDokument1 SeiteNew/Revised IRC Publications Noticemanish upadhyayNoch keine Bewertungen

- BollardDokument2 SeitenBollardJoe Nadakkalan100% (1)

- IS-10262 CONCRETE MIXDokument9 SeitenIS-10262 CONCRETE MIXKamal SinghNoch keine Bewertungen

- BridgeDokument30 SeitenBridgeClaudinee BalawisNoch keine Bewertungen

- Figure 1 Problem Geometry in PLAXIS 2D: ExternalDokument6 SeitenFigure 1 Problem Geometry in PLAXIS 2D: ExternalmiksanitariaNoch keine Bewertungen

- UPVC AustralianDokument64 SeitenUPVC AustralianAnonymous 4IpmN7OnNoch keine Bewertungen

- Design Manual To CoP2004 (Housing)Dokument265 SeitenDesign Manual To CoP2004 (Housing)jjj201187Noch keine Bewertungen

- Steel Design Key Terms and NotationDokument50 SeitenSteel Design Key Terms and Notationisrar khanNoch keine Bewertungen

- Electrical and HVAC Installation WorksDokument18 SeitenElectrical and HVAC Installation WorksTri MprasetyoNoch keine Bewertungen

- 132 kV Transmission Line Foundation Design for Nigeria DeltaDokument57 Seiten132 kV Transmission Line Foundation Design for Nigeria DeltavoilNoch keine Bewertungen

- EMK FormsDokument42 SeitenEMK FormsJred MondejarNoch keine Bewertungen

- What Is New With DSA Potential Upcoming Additions To Specification Information For PM Field TripDokument56 SeitenWhat Is New With DSA Potential Upcoming Additions To Specification Information For PM Field TripNrjNoch keine Bewertungen

- A 11Dokument1 SeiteA 11Yaw KrahNoch keine Bewertungen

- Rail JointsDokument22 SeitenRail JointsSauradeep DebnathNoch keine Bewertungen

- Soil Nail Wall - Soil Nailing - Deep ExcavationDokument7 SeitenSoil Nail Wall - Soil Nailing - Deep ExcavationAlok Mehta0% (1)

- Automatic Self-Climbing Formwork PeriDokument2 SeitenAutomatic Self-Climbing Formwork PeriSivaram KottaliNoch keine Bewertungen

- In-Place Methods To Estimate Concrete Strength: Reported by ACI Committee 228Dokument41 SeitenIn-Place Methods To Estimate Concrete Strength: Reported by ACI Committee 228yusak santosoNoch keine Bewertungen

- Steel beam connection design checksDokument11 SeitenSteel beam connection design checksafiqNoch keine Bewertungen

- Compression Member LSMDokument1 SeiteCompression Member LSMSuman NakarmiNoch keine Bewertungen

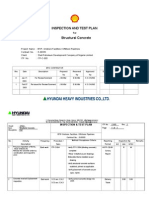

- ITP C 005 (Structural Concrete)Dokument4 SeitenITP C 005 (Structural Concrete)segun ajibolaNoch keine Bewertungen

- BSCE EXCAVATION FILLING GRADINGDokument16 SeitenBSCE EXCAVATION FILLING GRADINGMark AvanzadoNoch keine Bewertungen

- 2014-09-09 Construction Meeting Minutes PDFDokument3 Seiten2014-09-09 Construction Meeting Minutes PDFIthacaVoiceNoch keine Bewertungen

- Castigliano's TheoremDokument13 SeitenCastigliano's TheoremSkektNoch keine Bewertungen