Beruflich Dokumente

Kultur Dokumente

Job Safety Anaylisis

Hochgeladen von

hash117Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Job Safety Anaylisis

Hochgeladen von

hash117Copyright:

Verfügbare Formate

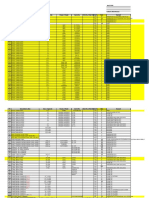

Job Safety Analysis

Doc. No: TML-HSE-GEN-PR-L-108

Revision: 2

Date: June 2010

Page: Appendix 4

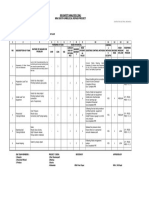

Job Safety Analysis Format

Job:

TO TOP-UP DIESEL

Permit No:

Work Team:

TJ OIL LAND Sdn Bhd

Date:

Performing

Authority (PA):

BASIC JOB STEPS

Issuing Authority

(IA):

RISK RATING

Cat2

POTENTIAL HAZARDS

1-Pumping Diesel

Diesel Spill/Broken hose/Slippery

floor/Fire / burning.

2-Connect hose to the welding

machine and air compressor

Slippery floor/Diesel spill/Hose leak

Cat5

3-Top Up Diesel to the equipment

Diesel spill/Eyes injury/Body / cloth

contaminated diesel fuel

Contamination diesel fuel cloth/Valve

in open position/Fuel leak

Cat4

4-House Keeping

Job Safety Analysis

Cat5

Rev. 0

RECOMMENDED CONTROL MEASURES

Check diesel hoses/Clean work area if diesel

spill/Ensure work area free from electrical source

or fire/Standby fire extinguisher/Ensure the

equipment in good condition.

Ensure work area / floor clean free from oil or

other object/Use proper glove/Ensure diesel hose

in good condition

Diesel spill/Eyes injury/Body / cloth contaminated

diesel fuel

Make sure clean the cloth from diesel

contamination/Make sure the deck floor no oil leak

or oil spill/Wash down the deck or drip pan if have

leak or spill.

Job Safety Analysis

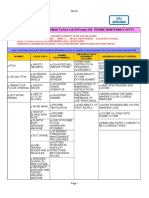

EXPERIENCE

YES

Doc. No: TML-HSE-GEN-PR-L-108

Revision: 2

Date: June 2010

Page: Appendix 4

NO

Have you done this job before?

Are you knowledgeable with the job to be

performed?

Have you referred to technical drawing/vendor

procedure/SSP?

Is supervision/experienced assistance required?

PPE

Hard hat?

Safety Glasses?

Safety shoes?

Ear plugs?

Right type of gloves?

Safety harness?

POTENTIAL HAZARDS

Slippery floor?

Congested area?

Tripping?

Overhead work?

Working at height?

Scaffolding?

Secure ladder?

Heavy load?

Hammer strikes?

Pinch/trap finger, hand?

Back injury hazard?

Swinging object?

Falling object?

Others closeby?

Sharp object?

Eye injury?

Grating/deck opening?

Blocked drains?

Prepared By:

Job Safety Analysis

YES

NO

/

/

/

/

/

YES

/

Work vest?

Apron?

Goggle?

Face shield?

Respiratory protection?

YES

NO

YES

NO

/

/

NO

YES

Trapped pressure?

Pressurized equipment/vessel hazard?

Fire/explosion hazards?

Escape route?

Shock/electricity/static?

Breaker rack out?

Valve isolation?

Guard rotating equipment?

Power tools hazards?

High noise area, double ear protection?

Spark/hot slag?

Burn (heat/chemical)?

Near radioactive materials/sources?

Environmental spill?

Hose connection?

Windy?

Dusty?

Date:

Rev. 0

Sign:

/

/

NO

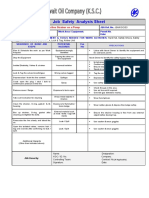

Job Safety Analysis

Reviewed &

Approved By PA:

Reviewed &

Approved By IA:

Doc. No: TML-HSE-GEN-PR-L-108

Revision: 2

Date: June 2010

Page: Appendix 4

Date:

Sign:

Date:

Sign:

Acknowledgement by Work Team

I hereby acknowledge my participation in the toolbox meeting for this job. I understand it is my responsibility to read, understand and adhere to

the control measures written in this Job Safety Analysis.

No

Name

Company / Designation

Risk Matrix for JSA

Job Safety Analysis

Rev. 0

Sign

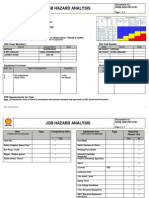

Job Safety Analysis

CATEGORIES IMPLEMENTATION GUIDANCE

Job Safety Analysis

Rev. 0

Doc. No: TML-HSE-GEN-PR-L-108

Revision: 2

Date: June 2010

Page: Appendix 4

Job Safety Analysis

Cat 1 - Very High Risk: Work should not be started or continued until the risk has been reduced.

Cat 2 - High Risk: Work should not be started until the risk has been reduced. Work can only continue with

extreme caution. Risk must be reduced immediately.

Cat 3 - Moderate Risk: Efforts should be made to reduce the risk, but the costs of prevention should be carefully

measured and limited. Risk reduction measures should be implemented within a definite time period.

Cat 4 - Possible Risk: No additional controls are required. Consideration may be given to a more cost-effective

solution or improvement that imposes no additional cost burden. Monitoring is required to ensure that the

controls are maintained.

Cat 5 - Negligible Risk: Further consideration not required. Monitoring is required to ensure that the controls are

maintained.

Job Safety Analysis

Rev. 0

Doc. No: TML-HSE-GEN-PR-L-108

Revision: 2

Date: June 2010

Page: Appendix 4

Das könnte Ihnen auch gefallen

- Area Hard Barrication JsaDokument4 SeitenArea Hard Barrication JsanishantNoch keine Bewertungen

- Cold Cutting PDFDokument9 SeitenCold Cutting PDFAshraf BottaniNoch keine Bewertungen

- Jsa PaintDokument2 SeitenJsa PaintKhalid NaseemNoch keine Bewertungen

- 9 Use of Hand Roller Compactor SafetyDokument2 Seiten9 Use of Hand Roller Compactor SafetyarchieNoch keine Bewertungen

- JSA HCK MOC Hot Tap Drilling Rev1Dokument6 SeitenJSA HCK MOC Hot Tap Drilling Rev1Ijaz Hussain100% (2)

- 3.jsa - Arc Welding-NDokument5 Seiten3.jsa - Arc Welding-NVivek NaikNoch keine Bewertungen

- Jsa Bearing Replacement-OverhaulingDokument2 SeitenJsa Bearing Replacement-Overhaulingashish engineeringNoch keine Bewertungen

- MTA2018-JHA-012 Air Compressor OperationDokument10 SeitenMTA2018-JHA-012 Air Compressor OperationKelvin TanNoch keine Bewertungen

- Ast Jsa - Piping FabricationDokument3 SeitenAst Jsa - Piping Fabricationmd_rehan_2Noch keine Bewertungen

- JSA For Purging NitrogenDokument1 SeiteJSA For Purging Nitrogenlina ekawatiNoch keine Bewertungen

- 4-JSA - Unloading Under Inert - F9030 B NewDokument6 Seiten4-JSA - Unloading Under Inert - F9030 B NewAde RahmadiNoch keine Bewertungen

- GUIDLINES FOR Contr AICDokument5 SeitenGUIDLINES FOR Contr AICmadhulikaNoch keine Bewertungen

- Suspended From Man-Rider (Vertical Rescue Plan)Dokument1 SeiteSuspended From Man-Rider (Vertical Rescue Plan)Paul100% (1)

- Job Safety AnalysisDokument3 SeitenJob Safety AnalysisBhisamS SallehNoch keine Bewertungen

- MSIHC RulesDokument61 SeitenMSIHC RulesAMAN PRATEEK DaradNoch keine Bewertungen

- Rock Breaker Self ChecklistDokument1 SeiteRock Breaker Self ChecklistNair R RakeshNoch keine Bewertungen

- Scaffold TowerDokument20 SeitenScaffold TowerAndhika HerdiawanNoch keine Bewertungen

- JSA Pipe CleaningDokument2 SeitenJSA Pipe CleaningDeni Noiz100% (1)

- Jsa n2 Purging PDF FreeDokument1 SeiteJsa n2 Purging PDF FreeSKH CultureNoch keine Bewertungen

- Lathe Machine Safety OperatingDokument4 SeitenLathe Machine Safety Operatingebad100% (1)

- Fire Prevention PlanDokument25 SeitenFire Prevention PlanEMILYN DEPOLLONoch keine Bewertungen

- PVCMS-BMV-HSE-JSA-001 InsulationDokument6 SeitenPVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNoch keine Bewertungen

- Jsa For Pipe Fabrication ErrectionDokument5 SeitenJsa For Pipe Fabrication Errectionjithin shankarNoch keine Bewertungen

- Jsa Tank CleaningDokument5 SeitenJsa Tank CleaningASLAM MULANINoch keine Bewertungen

- Injury & Illness Prevention Program: Job Safety Analysis FormDokument2 SeitenInjury & Illness Prevention Program: Job Safety Analysis FormArif RachmanNoch keine Bewertungen

- Safety Check (Please Put Tick ( ) Mark in The Appropriate BoxDokument8 SeitenSafety Check (Please Put Tick ( ) Mark in The Appropriate BoxAntony JebarajNoch keine Bewertungen

- R1937-JSA-004 Job Safety Analysis For Pipe PullDokument3 SeitenR1937-JSA-004 Job Safety Analysis For Pipe PullVineet AgrawalNoch keine Bewertungen

- 15.tube Bundle Puller.Dokument3 Seiten15.tube Bundle Puller.Mohammad Fazal Khan100% (1)

- Akk Jha Installation of Diesel TankDokument3 SeitenAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- JSA For Coating and Raping Activity in TankDokument7 SeitenJSA For Coating and Raping Activity in TankEslam lotfy- Eslam elsadatNoch keine Bewertungen

- Jsa Psa & GisDokument3 SeitenJsa Psa & GisMohammed NouzalNoch keine Bewertungen

- JHA-011 (Power Brush & Touch-Up Painting Activities 1)Dokument1 SeiteJHA-011 (Power Brush & Touch-Up Painting Activities 1)shaiful annuar50% (2)

- JSA For Flue Gas Duct Height WorkDokument4 SeitenJSA For Flue Gas Duct Height Worksubhadipmanna8Noch keine Bewertungen

- 15.SMP For Emergency Rescue For Work at HeightDokument6 Seiten15.SMP For Emergency Rescue For Work at Heightananthu.uNoch keine Bewertungen

- Building De-Dusting JSADokument3 SeitenBuilding De-Dusting JSAJayesh J PillaiNoch keine Bewertungen

- Jha Confined SpaceDokument6 SeitenJha Confined SpaceArun ArunbolluNoch keine Bewertungen

- JSA Tubing Leak TestDokument1 SeiteJSA Tubing Leak TestMuhammad Reza Gadran67% (3)

- Appendix A-Job Safety Analysis FormDokument3 SeitenAppendix A-Job Safety Analysis Formjiks_i4uNoch keine Bewertungen

- OSH-18 (PTW) Permit To Work System ProcedureDokument3 SeitenOSH-18 (PTW) Permit To Work System Procedurerizal azizanNoch keine Bewertungen

- 2.0 Windsock Wind SpeedsDokument1 Seite2.0 Windsock Wind SpeedsSoham Mukherjee100% (2)

- PTW JHA Electrical Wiring Installation Work at Air Dryer RoomDokument4 SeitenPTW JHA Electrical Wiring Installation Work at Air Dryer RoomPHH9834Noch keine Bewertungen

- Job Safety Analysis (Rolling For MS Plates)Dokument1 SeiteJob Safety Analysis (Rolling For MS Plates)Muhammad Ali100% (2)

- Jha Piping Insulation Installation and Dismantle Work p28Dokument12 SeitenJha Piping Insulation Installation and Dismantle Work p28AmirHakimRusli100% (1)

- JSA - Main Turbine Lub Oil Pumps - OHDokument2 SeitenJSA - Main Turbine Lub Oil Pumps - OHShubham Gupta0% (1)

- Mig Welding Work JSA HSE ProfessionalsDokument2 SeitenMig Welding Work JSA HSE ProfessionalsNoval Febri100% (1)

- Jsa For The Installation of I EamDokument5 SeitenJsa For The Installation of I EamMohammed MinhajNoch keine Bewertungen

- Petron Bataan Refinery Job Safety Analysis (Jsa)Dokument2 SeitenPetron Bataan Refinery Job Safety Analysis (Jsa)Aldhen Esguerra100% (1)

- Job Safety Analysis Sheet: Cleaning Suction Strainer On A PumpDokument1 SeiteJob Safety Analysis Sheet: Cleaning Suction Strainer On A Pumpjoshua100% (1)

- JOB SAFETY ANALYSIS - Idler Frame StencilingDokument1 SeiteJOB SAFETY ANALYSIS - Idler Frame StencilingSajith C PauloseNoch keine Bewertungen

- Job Hazard Analysis: IP-OPS-066Dokument9 SeitenJob Hazard Analysis: IP-OPS-066ananthu.uNoch keine Bewertungen

- JSA Hydro TestingDokument1 SeiteJSA Hydro TestingZeyad RezkNoch keine Bewertungen

- Work Permit Request For HydrotestingDokument3 SeitenWork Permit Request For HydrotestingZeyad Rezk50% (2)

- 14 - JSA For Replacement of Tube Bundles of (100-EA4-C3, C8) & 284-E52 & 810E7 With New OneDokument1 Seite14 - JSA For Replacement of Tube Bundles of (100-EA4-C3, C8) & 284-E52 & 810E7 With New OneSHAH NAWAZ SAEEDNoch keine Bewertungen

- Argon Welding SafetyDokument2 SeitenArgon Welding SafetyRonald_Bauer4190Noch keine Bewertungen

- Jha To Perform On-Site Verification For Glycol ReboilerDokument2 SeitenJha To Perform On-Site Verification For Glycol ReboilerEdha AliNoch keine Bewertungen

- PTSB (Jsa Form)Dokument5 SeitenPTSB (Jsa Form)hanujaNoch keine Bewertungen

- Air Compressor JHADokument4 SeitenAir Compressor JHAMpire WansNoch keine Bewertungen

- Safety: Safety in The Petro-Chemical IndustryDokument15 SeitenSafety: Safety in The Petro-Chemical IndustrysandystaysNoch keine Bewertungen

- F HSE 008 Job Safety AnalysisDokument27 SeitenF HSE 008 Job Safety AnalysisBoy100% (1)

- Spot Inspection Report: HSESM, 97/02Dokument3 SeitenSpot Inspection Report: HSESM, 97/02Sayed AbbasNoch keine Bewertungen

- Technical Proposal Descaling Removal Pulai - A (2013 ASD)Dokument22 SeitenTechnical Proposal Descaling Removal Pulai - A (2013 ASD)hash117Noch keine Bewertungen

- Equipment Layout LHDP-ADokument10 SeitenEquipment Layout LHDP-Ahash117Noch keine Bewertungen

- Job Hazard Analysis (Jha) WorksheetDokument5 SeitenJob Hazard Analysis (Jha) Worksheethash117Noch keine Bewertungen

- Jtube & Clamp IFR Drawing - RevB (Comment For Shopdrawing Preparation)Dokument20 SeitenJtube & Clamp IFR Drawing - RevB (Comment For Shopdrawing Preparation)hash117Noch keine Bewertungen

- Job Hazard Analysis (Jha) WorksheetDokument5 SeitenJob Hazard Analysis (Jha) Worksheethash117Noch keine Bewertungen

- ANF Profile New 2019Dokument17 SeitenANF Profile New 2019hash117Noch keine Bewertungen

- UPDI & Kenyataan MediaDokument4 SeitenUPDI & Kenyataan Mediahash117Noch keine Bewertungen

- Planning For Idemitsu PaintingDokument4 SeitenPlanning For Idemitsu Paintinghash117Noch keine Bewertungen

- Report For PULAI - A Descaling WorkDokument3 SeitenReport For PULAI - A Descaling Workhash117Noch keine Bewertungen

- Survey Report Sample InsulationDokument21 SeitenSurvey Report Sample Insulationhash117Noch keine Bewertungen

- List of EquipToolConsumable LabuanDokument12 SeitenList of EquipToolConsumable Labuanhash117Noch keine Bewertungen

- Moissanite SGS ReportDokument6 SeitenMoissanite SGS Reporthash117Noch keine Bewertungen

- Scope of Work PULAI - ADokument1 SeiteScope of Work PULAI - Ahash117Noch keine Bewertungen

- Offshore Crew Change & Covid-19 Screening Protocol PDFDokument3 SeitenOffshore Crew Change & Covid-19 Screening Protocol PDFhash117Noch keine Bewertungen

- MPTDokument78 SeitenMPThash117Noch keine Bewertungen

- Lab Manual FGS0074Dokument8 SeitenLab Manual FGS0074hash117Noch keine Bewertungen

- Geran Tanah FikriDokument3 SeitenGeran Tanah Fikrihash117Noch keine Bewertungen

- Task BaruDokument2 SeitenTask Baruhash117Noch keine Bewertungen

- Heavy Transport Multi Axle Trailer & Lifting ServicesDokument12 SeitenHeavy Transport Multi Axle Trailer & Lifting ServicesKaras WillNoch keine Bewertungen

- Untitled Document PDFDokument1 SeiteUntitled Document PDFhash117Noch keine Bewertungen

- Scpa Riser Maintenance: Surface Preparation: Painting System Ricever & Assc PipingDokument8 SeitenScpa Riser Maintenance: Surface Preparation: Painting System Ricever & Assc Pipinghash117Noch keine Bewertungen

- 2019 Sales PresentationDokument13 Seiten2019 Sales Presentationhash117Noch keine Bewertungen

- Air Manifold DrawingDokument3 SeitenAir Manifold Drawinghash117Noch keine Bewertungen

- PROJECT PAPER-Hashim EditedDokument80 SeitenPROJECT PAPER-Hashim Editedhash117Noch keine Bewertungen

- Thahis Cooking Lab: You're Invited To Join Competition For Remake One of The "Thahis Cooking Lab RecipesDokument1 SeiteThahis Cooking Lab: You're Invited To Join Competition For Remake One of The "Thahis Cooking Lab Recipeshash117Noch keine Bewertungen

- QA/QC Requirements On FabricationDokument10 SeitenQA/QC Requirements On Fabricationhash117Noch keine Bewertungen

- OSC Incident - FAC 26 05 15Dokument4 SeitenOSC Incident - FAC 26 05 15hash117Noch keine Bewertungen

- Account Opening Form (NRI)Dokument4 SeitenAccount Opening Form (NRI)hash117Noch keine Bewertungen

- Laws of Malaysia: ACT 651 Malaysian Health Promotion Board Act 2006Dokument13 SeitenLaws of Malaysia: ACT 651 Malaysian Health Promotion Board Act 2006hash117Noch keine Bewertungen

- Sop WarehouseDokument6 SeitenSop WarehouseVamsee Deepak100% (1)

- Uhde Brochures PDF en 16Dokument36 SeitenUhde Brochures PDF en 16KrishnaNoch keine Bewertungen

- Mattco Pulsation Dampener OMM PDFDokument5 SeitenMattco Pulsation Dampener OMM PDFpr_oil100% (4)

- Advanced Snake Drill Technique Method For Improving of Oil Extraction PercentageDokument7 SeitenAdvanced Snake Drill Technique Method For Improving of Oil Extraction PercentageAkhil GodavarthiNoch keine Bewertungen

- Drilling Rig Inspection Checklist: (Day) (Month) (Year)Dokument3 SeitenDrilling Rig Inspection Checklist: (Day) (Month) (Year)Dusty PinkNoch keine Bewertungen

- Motor Perkins 750 KVA PDFDokument2 SeitenMotor Perkins 750 KVA PDFDuda CorrêaNoch keine Bewertungen

- Halliburton Cementing TablesDokument686 SeitenHalliburton Cementing TablesAlex Castañeda100% (4)

- LA 300 PumpsPKL-04-3268 Data SheetDokument2 SeitenLA 300 PumpsPKL-04-3268 Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Profile EaDokument34 SeitenProfile EaMathivanan AnbazhaganNoch keine Bewertungen

- AIRPORETDokument131 SeitenAIRPORETTrang DoNoch keine Bewertungen

- Kubota Manual 9Y011-02153 PDFDokument124 SeitenKubota Manual 9Y011-02153 PDFMiguel Chacon100% (2)

- HG190, HG220 Engine ManualDokument149 SeitenHG190, HG220 Engine Manualمحمد حسنNoch keine Bewertungen

- Internal Combustion Engine: Teknik Mesin Universitas Maarif Hasyim Latf SidoarjoDokument158 SeitenInternal Combustion Engine: Teknik Mesin Universitas Maarif Hasyim Latf SidoarjoAdhi PrayogaNoch keine Bewertungen

- UK MCA 4th Class OralDokument33 SeitenUK MCA 4th Class OralRicky Chua Snr100% (3)

- The Specific Gravity of Some Common Liquids and Fluids Can Be Found in The Table BelowDokument3 SeitenThe Specific Gravity of Some Common Liquids and Fluids Can Be Found in The Table BelowNatalia KristiNoch keine Bewertungen

- Company Profile 2017Dokument20 SeitenCompany Profile 2017roudhotuljannah525Noch keine Bewertungen

- 4000 Series PM SchedulesDokument3 Seiten4000 Series PM SchedulesSoubhik MishraNoch keine Bewertungen

- Considerations For Various Methods For Density and Specific GravityDokument17 SeitenConsiderations For Various Methods For Density and Specific GravityWilman Enrique Alvarez QuirozNoch keine Bewertungen

- Well Testing MilisDokument40 SeitenWell Testing Milisdrg100% (1)

- Maverick HSP Owners Manual V2 0 PDFDokument43 SeitenMaverick HSP Owners Manual V2 0 PDFAbelardo Piña100% (1)

- Danfoss BR42 Datenblatt PDFDokument68 SeitenDanfoss BR42 Datenblatt PDFCalimeroNoch keine Bewertungen

- Hydroxy BoostersDokument265 SeitenHydroxy Boostersmars1976100% (3)

- D 2163 PDFDokument5 SeitenD 2163 PDFseterisparigus100% (1)

- D250D6Dokument4 SeitenD250D6WilmerNoch keine Bewertungen

- 1.0 Introduction To Formation Evaluation Log AnalysisDokument3 Seiten1.0 Introduction To Formation Evaluation Log AnalysisshanecarlNoch keine Bewertungen

- Factsheet Subsea Oil Recovery System 050210a 3 .536819Dokument3 SeitenFactsheet Subsea Oil Recovery System 050210a 3 .536819leetrosenNoch keine Bewertungen

- Technical Service Manual: Heavy Duty Pumps SERIES 4195 and 495 Series GG - Al Section TSM 144 1 Issue BDokument9 SeitenTechnical Service Manual: Heavy Duty Pumps SERIES 4195 and 495 Series GG - Al Section TSM 144 1 Issue BRoshan ShanmughanNoch keine Bewertungen

- PLTMG 50Mn Nii Tanasa: Fuel Analysis ReportDokument3 SeitenPLTMG 50Mn Nii Tanasa: Fuel Analysis ReportpaulNoch keine Bewertungen

- LNG Myanmar Projects 2019Dokument5 SeitenLNG Myanmar Projects 2019Maung OoNoch keine Bewertungen

- All Electric ShipDokument88 SeitenAll Electric ShipOladokun Sulaiman Olanrewaju100% (10)

- Kopex-Ex Hazardous Location Conduit Systems: in This Section..Dokument44 SeitenKopex-Ex Hazardous Location Conduit Systems: in This Section..RaulNoch keine Bewertungen