Beruflich Dokumente

Kultur Dokumente

Monitoring of Bioprocess

Hochgeladen von

SandiyaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Monitoring of Bioprocess

Hochgeladen von

SandiyaCopyright:

Verfügbare Formate

12B702 -Bioprocess Engineering

UNIT- III

MONITORING OF BIOPROCESSES

1. INTRODUCTION

For most modern industrial production methods, process monitoring plays a

key role; bioprocess systems are no exception to this rule. Effective methods

of monitoring are required in order to develop, optimize, and maintain

biological reactors at maximum efficiently. An optimized process should lead

to streamlined performance, reductions in running and material costs, and

improvements in quality control. A number of bioprocess monitoring

instruments have been regular features of the industry for many years

(Fig.1), in particular, sensors capable of measuring physical parameters. The

challenge is to develop cost-effective devices capable of measuring a much

wider range of parameters, providing process operators with a deeper insight

into the process. Eventually effective monitoring will lead to better control

systems, providing cost and quality benefits.

Figure 1. Major areas of bioprocess monitoring.

Progress in monitoring, modeling and control of bioprocesses

The rapid development in biotechnology during the last few years was

enhanced by progress in genetic engineering. The successful application of

the recombinant micro-organisms and cells for industrial production of

12B702 -Bioprocess Engineering

therapeutically important proteins and in less extent of primary and

secondary metabolites impaired by the lack of suitable production processes.

An adaptation and improvement of the bioprocess engineering to the new

demands was necessary. Quickly turned out that beside improved medium

optimisation more efficient process monitoring is needed, which allows better

process modeling and closer process control. Especially, quick analysis

methods are needed, which allow immediate response to the changes in a

cultivation process. Highly selective in situ and on-line methods are

developed for process monitoring and applied in laboratories. In addition,

new analysis principles are discovered and miniaturization of instruments is

promoted.

However, some key variables, such as cell concentration and viability cannot

be monitored online. Therefore, they are identified by means of measured

data and suitable process model and the estimated state is used for state

estimation and process control.

2. OPERATING FEATURES

For any measuring technique, there are a number of criteria that the device

must satisfy if it is too accepted by commercial bioprocess operators (Fig. 2).

The following list of desirable characteristic is not exhaustive, but does cover

the main areas of concern.

Reliability

Reliability is a key issue for bioprocess monitoring equipment. Confidence in

the ability of an instrument to maintain its credibility in terms of performance

is a fundamental parameter. This encompasses a number of features relating

to the operation of the instrument, for example, ease of use, maintenance,

repair, and replacement. A successful monitoring instrument will have a low

failure rate; again, this is related to reliability.

Accuracy

12B702 -Bioprocess Engineering

Accuracy can be described as the relationship between the measured value

(by the instrument) and the actual value of a bioprocess variable. An

accurate instrument will achieve a low percentage error between these two

values. Generally this can be stated as

% error =(measured value - true value)/true value x 100%

Figure 2. Main criteria for a bioprocess monitoring instrument

Precision

Precision is a measure of instrument reproducibility, that is, the ability to

obtain the same value with repeated measurements of a process variable (at

a constant level). It follows that a precise instrument may not, necessarily,

be accurate. Therefore it is important to distinguish between these two

parameters.

Response time

The measurement of any process variable will entail a time delay between

change in the parameter and display of the measured value. This response

time should not be detrimental to the progress of the bioprocess, particularly

if the measurement is linked to a control action. Response times will be

affected not only by the type of instrument but also by the method of

measurement. Off-line sampling and measuring can involve a number of

time-consuming steps. In contrast, in situ devices can provide a real-time

measurement.

12B702 -Bioprocess Engineering

Calibration

In order to maintain the accuracy of a sensor it is (generally) desirable to

carry out a calibration step. This is carried out using set standards of

comparison. The effects of calibration can impinge on the process; in other

words, it may be difficult to carry out calibration of an in situ sensor, whereas

an on-line device could easily incorporate a calibration step(s) during routine

running.

Linearity

Under ideal conditions, the output signal from a sensor would be directly

proportional to the analyte concentration. However, this is not always the

case, and other models have to be used to reach a true value. Despite this

drawback, linearity is not an overriding prerequisite for a successful

monitoring instrument. Developments in modern software can be adapted to

compensate for nonlinearity.

Threshold and Sensitivity

Sensitivity is the magnitude of the output signal per unit change in the target

analyte concentration. The lowest level of detection is related to the

sensitivity and the signal-to-noise ratio. A number of factors influence the

sensitivity of a monitoring device, including sensor design, the operating

environment, periods of maintenance, and interfering noise levels. The

sensitivity will influence the dynamic range above which the device becomes

saturated; the highest level of detection will be the threshold limit for the

device.

3. METHODS OF MONITORING

In addition to the variety of monitoring devices available, a number of

methods (for carrying out the measurement exist (Fig. 3). Sampling and

sample handling is a vital issue, affecting both the accuracy and frequency of

12B702 -Bioprocess Engineering

measurements. Broadly, the main approaches to sampling can be described

in one of several ways.

Figure 3. Methods of monitoring.

Off-Line or At-Line Monitoring

Off-line monitoring involves taking a sample from the bioreactor and carrying

out the measurement at a different site, usually under laboratory conditions.

Off-line sampling can be detrimental in terms of cost, efficiency, and threat

to asepsis. Manually removing and measuring a sample requires technical

labor. The received signal will not be real time because of the delays. In

order to obtain the sample, the sterility of the bioreactor must be

maintained. Hence, provision must be made to achieve this. In some cases,

decentralized equipment has become available that allows measurements to

be made simply close to the production process (at-line), reducing some of

the delays associated with laboratory analysis.

In Situ or In-Line Monitoring

In situ sensors are placed directly in the bioprocess vessel. The use of in situ

sensors has long been established in the bioprocess industry, where dip-in

devices are used to monitor a number of parameters such as pH and

dissolved gas concentrations. A number of advantages are gained by

operating sensors in this fashion, including real-time monitoring (samplingrelated time delays are eliminated) with the sensors operating continuously

(any rapid change in the analyte concentration can be readily observed), and

5

12B702 -Bioprocess Engineering

labor requirements and problems of contamination are both significantly

reduced. However, in situ sensors can have a number of drawbacks, for

example, the sensor system must be amenable to sterilization; if the lifetime

is short, replacement may be difficult (during a process run); the surface of

the sensor could become fouled by components of the growth medium,

affecting the signal output.

On-Line Monitoring

Methods

of

on-line

monitoring

involve

the

automatic

removal

and

measurement of sample or sample stream from the bioreactor. One example

of this has been the development (since the early 1980s) of flow injection

analysis (FIA). This is a liquid handling technique that has proved flexible in

adapting

to

most

chemical

and

biochemical

reaction

procedures,

representing an effective compromise between the desirability of in situ

monitoring and the technical ease of off-line measurements. The main

advantages of on-line methods include the following: sensor sterilization can

be readily accomplished, sample pretreatment (e.g., gassing, dilution,

removal of interferents), and sensor calibration can be built into the system.

The main disadvantages are a need for an effective and reliable sampling

system and the fact that the signal is discontinuous; frequency measuring

rate is determined by the limitation of the overall FIA arrangement. All of

these methods have their advantages and disadvantages. The choice of

approach adopted depends on a number of factors, not least of which will be

the availability of both sensor and system.

4. MEASUREMENT OF DIFFERENT PARAMETERS

Introduction

The widespread use of advanced control and process automation for

biochemical applications has been lagging as compared with industries such

as refining and petrochemicals whose feedstocks are relatively easy to

characterize

and

whose

chemistry

is

well

understood

and

whose

measurements are relatively straightforward. Biological processes are

6

12B702 -Bioprocess Engineering

extraordinarily complex and subject to considerable variability. The reaction

kinetics cannot be completely determined in advance in a fermentation

process because of variations in the biological properties of the innoculant.

Therefore, information regarding the activity of the process must be

gathered as the fermentation progresses. Directly measuring all the

necessary

variables

which

characterize

and

govern

the

competing

biochemical reactions, even under optimum laboratory conditions, is not yet

achievable. Developing mathematical models, which can be utilized to infer

the biological processes underway from the measurements available,

although useful, is still not sufficiently accurate. Add to this the constraints

and compromises imposed by the manufacturing process and the task of

accurately predicting and controlling the behavior of biological production

processes is formidable indeed. The knowledge base in fermentation and

biotechnology has expanded at an explosive rate in the past twenty-five

years aided in part by the development of sophisticated measurement,

analysis and control technology. Much of this research and technology

development has progressed to the point where commercialization of many

of these products is currently underway.

Measurement Technology

Measurements are the key to understanding and therefore controlling any

process. As it relates to biochemical engineering, measurement technology

can be separated into three broad categories. These are biological, such as

cell growth rate, florescence, and protein synthesis rate; chemical, such as

glucose concentration, dissolved oxygen, pH and offgas concentrations of

CO2, O2, N2, ethanol, ammonia and various other organic substances; and

physical, such as temperature, level, pressure, flow rate and mass. The most

prevalent are the physical sensors while the most promising for the field of

biotechnology are the biological sensors.

Cell Mass Measurement

7

12B702 -Bioprocess Engineering

The on-line direct measurement of cell mass concentration by using

optical density principles promises to dramatically improve the knowledge of

the metabolic processes underway within a bioreactor. This measurement is

most effective on spherical cells such as E. Coli. The measurement

technology is packaged in a sterilizable stainless steel probe which is

inserted directly into the bioreactor itself via a flange or quick-disconnect

mounting.

By comparing the mass over time, cell growth rate can be determined.

This measurement can be used in conjunction with metabolic models which

employ such physiological parameters as oxygen uptake rate (OUR), carbon

dioxide evolution rate (CER) and respiratory quotient (RQ) along with direct

measurements such as dissolved oxygen concentration, pH, temperature,

and off gas analysis to more precisely control nutrient addition, aeration rate

and agitation. Harvest time can be directly determined as can shifts in

metabolic pathways possibly indicating the production of an undesirable byproduct. Cell mass concentrations of up to 100 grams per liter are directly

measured using the optical density probe. In this probe, light of a specific

wavelength, created by laser diode or passing normal light through a

sapphire crystal, enters a sample chamber containing a representative

sample of the bioreactor broth and then passes to optical detection

electronics. The density is determined by measuring the amount of light

absorbed,

compensating

for

backscatter.

Another

technique

used

to

determine cell density is spectrophotometric titration which is a laboratory

procedure which employs the same basic principles as the probes discussed

above. This requires a sample to be withdrawn from the broth during reaction

and therefore exposes the batch to contamination.

Chemical Composition

The most widely used method for determining chemical composition is

chromatography. Several categories have been developed depending upon

the species being separated. These include gas chromatography and several

8

12B702 -Bioprocess Engineering

varieties of liquid chromatography including low pressure (gel permeation)

and high pressure liquid chromatography and thin layer chromatography. The

basic principle behind these is the separation of the constituents traveling

through a porous, sorptive material such as a silica gel. The degree of

retardation of each molecular species is based on its particular affinity for

the sorbent. Proper selection of the sorbent is the most critical factor in

determining separation. Other environmental factors such as temperature

and pressure also play a key role.

The chemical basis for separation may include adsorption, covalent

bonding or pore size of the material. Gas chromatography is used for gases

and for liquids with relatively low boiling points. Since many of the

constituents in a biochemical reaction are of considerable molecular weight,

high pressure liquid chromatography is the most commonly used. Specialized

apparatus is needed for performing this analysis since chromtograph

pressures can range as high as 10,000 psi. Thin layer chromatography

requires no pressure but instead relies on the capillary action of a solvent

through a paper-like sheet of sorbent. Each constituent travels a different

distance and the constituents are thus separated. Analysis is done manually,

typically using various coloring or fluorescing reagents.

Gel permeation chromatography utilizes a sorbent bed and depends on

gravity to provide the driving force but usually requires a considerable time

to effect a separation. All of these analyses are typically performed in a

laboratory; therefore they require the removal of samples. As the reaction is

conducted in a sterile environment, special precautions and sample removal

procedures must be utilized to prevent contaminating the contents of the

reactor.

Oxygen

Generally, oxygen measurement falls into two main categories: dissolved

oxygen and exit gas analysis. For most aerobic fermentations, an accurate

determination of the dissolved oxygen concentration is of particular

9

12B702 -Bioprocess Engineering

importance, for example, in maintaining the concentration above a specified

minimal level. In addition, oxygen transport processes can be determined

only by using an accurate method of measurement. The exit gas analysis for

oxygen, usually in conjunction with CO2 measurement, can be used to

determine the metabolic state of aerobic microorganisms and their oxygen

uptake.

Ex: Dissolved Oxygen Probes

Galvanic Electrodes

O2 Optodes.

Dissolved oxygen is one of the most important indicators in a fermentation or

bioreactor process. It determines the potential for growth. The measurement

of dissolved oxygen is made by a sterilizable probe inserted directly into the

aqueous solution of the reactor. Two principles of operation are used for this

10

12B702 -Bioprocess Engineering

measurement: the first is an electrochemical reaction while the second

employs an amperometric (polarographic) principle. The electrochemical

approach uses a sterilizable stainless steel probe with a cell face constructed

of a material which will enable oxygen to permeate across it and enter the

electrochemical chamber which contains two electrodes of dissimilar

reactants (forming the anode and cathode) immersed in a basic aqueous

solution. The entering oxygen initiates an oxidation-reduction reaction which

in turn produces an EMF which is amplified into a signal representing the

concentration of oxygen in the solution.

In the amperometric (polarographic) approach, oxygen again permeates

a diffusion barrier and encounters an electrochemical cell immersed in basic

aqueous solution. A potential difference of approximately 1.3 V is maintained

between the anode and cathode. As the oxygen encounters the cathode, an

electrochemical reaction occurs:

The hydroxyl ion then travels to the anode where it completes the

electrochemical reaction process:

The concentration of oxygen is directly proportional to the amount of

current passed through the cell.

Viscosity

Information on the rheology, or viscosity, can help in ensuring the

efficiency of a biological process. An example of this would be the

effectiveness of oxygen transfer throughout a medium and determining the

degree of branching of filamentous microorganisms. In addition, viscosity can

effect pumping, mass transfer, and mixing. Viscosity is the apparent shear

resistance between adjacent layers of liquids or gases moving at different

speeds. Typically, in fluids this is the result of molecular cohesion; rising

11

12B702 -Bioprocess Engineering

temperatures lead to a decrease in viscosity. In contrast, viscosity increases

for gases under conditions of rising temperature. This results from an

increased measured molecular activity.

Ex: Cone and plate viscometer.

Coaxial cylinder rotary viscometer.

Impeller viscometer.

Exhaust Gas Analysis

Much can be learned from the exchange of gases in the metabolic process

such as O2, CO2, N2, and ethanol. Infact, most of the predictive analysis is

based upon such calculations as oxygen uptake rate, carbon dioxide

exchange rate or respiratory quotient. This information is best obtained by a

component material balance across the reactor. A key factor in determining

this is the analysis of the bioreactor off gas and the best method for

measuring this is with a mass spectrometer because of its high resolution.

Measurement of pH

12

12B702 -Bioprocess Engineering

Metabolic processes are typically highly susceptible to even slight

changes in pH, and therefore, proper control of this parameter is critical.

Precise manipulation of pH can determine the relative yield of the desired

species over competing by-products. Deviations o as little as 0.2 to 0.3 may

adversely affect a batch in some cases. Like the cell mass probe and

dissolved oxygen probes described earlier, the pH probe is packaged in a

sterilizible inert casing with permeable electrode facings for direct insertion

into the bioreactor.

The measurement principle is the oxidation-reduction potential of the

hydrogen ion and the electrode materials are selected for that purpose.

Measuring pH, along with temperature, is one of the most common practices

in bioprocess monitoring. Correcting action can be taken, either manually or

automatically, to prevent unwanted increases or decreases in pH. The most

common form of pH sensor used for fermentation monitoring is based on the

electrode design introduced by Ingold in 1947.

Temperature

Maintaining optimum conditions for any bioprocess will invariably involve

monitoring and controlling the temperature of the broth. Precise temperature

13

12B702 -Bioprocess Engineering

control and profiling are key factors in promoting biomass growth and

controlling yield.

Generally, bioprocesses are monitored over a temperature range of

between 0 0C and 100 0C (excluding the sterilization cycle). Furthermore, this

may require a control regime operating within a narrow range of

temperatures. A number of devices are available for obtaining an accurate

measurement of temperature conditions during a bioprocess operation,

based on a range of techniques.

Ex: Thermistors

Resistance Thermometers.

Thermocouples

Mercury-in-Glass Thermometers.

Bimetallic Thermometers.

Pressure

Many bioprocesses operate under conditions of overpressure. Monitoring

the magnitude of this pressure is an important factor, both in terms of safety

and optimization of the process. Industrial and laboratory fermenters are

designed to operate up to a safe working pressure. Increasing the applied

pressure above the upper limit can be dangerous. Furthermore, maintaining

a positive reactor head pressure can prevent contamination of the bioreactor.

In order to facilitate effective sterilization, fermenters need an accurate

pressure monitor. Pressure will also affect the solubility of gases (such as O2

and CO2). Several different approaches have been used in the development

of pressure gauges.

14

12B702 -Bioprocess Engineering

Ex: Bourdon Tube Pressure Gauge.

Strain Gauges

Piezoelectric Manometers.

Diaphragm-Type and Pressure Bellows Sensors

Weight

Monitoring fluctuations in the weight of a vessel used for bioprocesses is

an effective way of measuring the contents and flow rate of additions. There

are a number of load cells available for this task. The principle of a load cell

is based on measuring the compressive strain that is placed on the device

(e.g., a solid or tubular steel cylinder) when under an axial load. Electrical

resistance strain gauges can be included in the device structure. A

proportional electrical resistance to the applied load can then be measured;

this varies in relation to changes in load. Obviously, a temperature

compensator must be included in the instrument to account for heat effects

on the resistors. These devices need to be rugged and have long-term

15

12B702 -Bioprocess Engineering

stability. For reasons of safety, it is also desirable for the device to be

accurate. A load cell designed to detect tensile forces can be used for weight

measurements of suspended vessels.

Fig: Schematic of the installation of a load cell.

Liquid Level Measurement

Liquid levels in a vessel can be determined using a number of techniques.

Determining the level can assist in formulating mass balances and

measuring nutrient additions. Hydrostatic pressure can be measured using a

single sensor positioned at the bottom of the vessel. Alternatively, two

sensors spaced at the top and bottom of the vessel (differential design) can

be employed. These sensors are electromechanical devices based on the

deformation of a spring; the resulting signal is displayed as an electrical

signal (capacitance or reactance).

Volumetric Flow Rate

Quite a number of technologies are available for measuring volumetric

flow rates. These include differential pressure transmitters, vortex meters

and magnetic flow meters. Each has its advantages and disadvantages. The

differential pressure transmitter is the most popular and has been in use the

longest. Its measurement principle is quite simple. Create a restriction in the

line with an orifice plate and measure the pressure drop across the

16

12B702 -Bioprocess Engineering

restriction. The measurement takes advantage of the physical relationship

between pressure drop and flow.

The primary disadvantages of the differential pressure producing flow

measurements are the permanent pressure drop caused by the restriction in

the line; sediment buildup behind the orifice plate (which could be a source

of bacterial buildup) and loss of accuracy over time as the edge of the plate

is worn by passing fluid and sediment.

Broth Level

As the broth in a fermenter or bioreactor becomes more viscous and is

subjected to agitation from sparging (the introduction of tiny sterilized air

bubbles at the bottom of the liquid) and from mixing by the impeller, it has a

tendency to foam. This can be a serious problem as the level may rise to the

point where it enters the exhaust gas lines clogging the ultrafilters and

possibly jeopardizing the sterile environment within the reactor. Various

antifoam strategies can be employed to correct this situation, however,

detection of the condition is first required.

Regulatory Control

Automatic regulatory control systems have been in use in the process

industries

for

over

fifty

years.

Utilizing

simple

feedback

principles,

measurements were driven toward their set points by manipulating a

controlled variable such as flow rate through actuators like throttling control

valves. Through successive refinements in first mechanical, then pneumatic,

then electronic and finally digital electronic systems, control theory and

practice has progressed to a highly sophisticated state.

Carbon Dioxide

For many bioprocesses, the measurement of CO2 is an important feature.

Increased levels of dissolved carbon dioxide can inhibit growth and reduce

the production of secondary metabolites.

17

12B702 -Bioprocess Engineering

Redox Potential

Monitoring the redox potential of a bioprocess medium can provide

information about the equilibrium between oxidizing and reducing species

(electron acceptors and donors, respectively) present. Measurement of redox

potential is achieved using a combined metal-reference electrode system.

Mass Spectrometry

The use of on-line mass spectroscopy (MS) has developed since the first

report of Reus et al.

A wide range of gasses, both free and dissolved (e.g., CO2, O2, CH4), can

be measured. In addition, volatile organic compounds such as methanol,

ethanol, acetone, and simple organic acids can be monitored. The technique

is based on the rupture of molecules by a high-energy source into

corresponding ions.

Conductivity Sensors.

Conductivity sensors are particularly suited to monitoring levels of foam

(in a number of fermentations), where in excess it can cause problems. The

sensor consists of a stainless steel probe, insulated except for the tip. The

device can be used with noncorrosive conducting fluids. If the liquid or foam

level rises to contact with the tip, an electric current is passed through the

sensor; the foam acts as an electrolyte and the vessel as a ground. The

sensor can be coupled to a control device that dispenses antifoam to counter

the increased level.

18

12B702 -Bioprocess Engineering

Capacitance Sensors.

Capacitance sensors operate by detecting changes in the relative dielectric

constant of the media, compared with air. Measurements are made by

detecting variations in electrical capacity brought about by changes in the

liquid level.

Acoustic Sensors.

Acoustic sensors operate via transducers that generate and detect ultrasonic

waves. Two formats are available: a single device that both transmits and

receives the signal, and two separate transducers with one function. By

monitoring the time it takes for the sound wave to travel, the liquid level can

be determined. With the single device the sound wave is directed onto the

liquid surface. When the level rises, the time delay is shortened.

Temperature Probes.

Liquid levels can be measured using a series of thermistors sited vertically

through the vessel. During operation, an electrical current is applied to the

sensors, raising their temperature above the ambient. When the liquid (or

foam) level reaches a sensor positioned lower down the vessel, the sensor

cools. This causes a temperature difference and, hence, a change in

electrical resistance. The resistance can be displayed as an output signal

indicating the liquid level.

Flow Measurement

Flow measurement is an important feature for many bioprocesses, for

both gases and liquids. These measurements are carried out on both the

influent and effluent streams.The most common form of gas and liquid

measurement is carried out using a variable area flow meter, or rotameter.

19

12B702 -Bioprocess Engineering

Rotameter

This device consists of vertically mounted (usually conical) tube enclosing

a free-floating body that is able to move up (floating in the gas flow of

interest) and down a tapered bore running through the tube body. Typically,

the tube is constructed of glass or metal and the float is a ball or hollow

thimble shape. Because the position adopted by the flow rate is dependant

on both the gas flow and the viscosity of the medium, the instrument

requires careful calibration.

METHODS OF BIOMASS ESTIMATION

The monitoring of biomass concentration can be carried out using a

number of techniques. Conventionally, biomass concentration is measured

off-line using labor intensive, time-consuming methods such as dry weight

cell, plate or microscopic cell count, and measuring the optical density of

diluted samples. However, a number of more rapid methods have been

developed. Of particular interest is the development of real-time on-line

methods.

Generally, methods for determining biomass concentration can be divided

into two classifications: direct and indirect. The former is based on

determining the physical properties of the cell and its components. In

20

12B702 -Bioprocess Engineering

contrast, indirect methods measure factors related to the cell and its activity

(e.g., respiration, electrochemical behavior, and nutrient fluctuation).

Direct Biomass Measurements

Some measure of the bacterial cell mass or numbers of a culture is almost

always used as the reference basis for measurements of cellular metabolic

activities, the types of morphological characters, or the amount of chemical

constituent; biomass and cell numbers are the two basic independent

parameters of bacterial growth. The methods for measuring biomass seem

obvious and straightforward, but in fact they are complicated if accuracy if

sought. Furthermore, the results may be expressed in different ways and, in

some of these ways, the values may be more relative than absolute.

Wet Weight

A nominal wet weight of bacterial cells originally in liquid suspension is

obtained by weighing a sample in a tared pan after separation and washing

the cells by filtration or centrifugation. In either case, however, diluent is

trapped in the interstitial (intercellular) space and contributes to the total

weight of the mass. The amount of interstitial diluent may be substantial. A

mass of close-packed, rigid spheres contains in its interstices 27% of space.

This is independent of sphere size. A mixture of sizes packs more densely,

and close-packed bacterial cells may contain an intersticial volume of 5 to 30

%, depending on their shape and amount of deformation. This is a problem

that is readily solved if the washing step can be carried out with pure water.

Simple weighing or just measuring the packed volume of cells can be an

excellent and rapid method with filamentous organisms or those that grow as

pellets. Then filter, wash and weigh or centrifuge, and measure the height of

the pellet. Both can be very rapid, and the procedures can be calibrated to

correct for the exogenous water or shapes of centrifuge tubes. Because the

particulate matter in the medium has different physical properties, it can be

possible to separate the cells from the particulates and estimate the cell

21

12B702 -Bioprocess Engineering

volume directly. This correction could be established with radioactive or

fluorescent dextrans or other molecules that are too big to enter the cells.

Dry Weight

A nominal dry weight (solids content) of bacterial cells originally in a liquid

suspension is obtained by drying a measured wet weight or volume in an

oven at 80oC for 10 hrs to constant weight. The cells could be washed with

water (possibly extracting cell components), or (better) a correction could be

made for medium or diluent constituents that are dried along with the cells.

Separating the cells by filtration poses particular problems. More problems

arise if volatile components of the cells can be lost by oven drying, or if some

degradation

and

volatilization

occurs,

evidenced

by

discoloration

(particularly if a higher temperature is used). Some regain of moisture occurs

during the transferring and weighing process in room atmosphere, so this

should be done quickly within a fixed time for all replicate samples,

especially if the relative humidity is high. It is best, of course, to use tared

weighing vessels that can be sealed after drying.

The dry weight of cells may be expressed on a wet weight basis (grams of

solids per gram of wet cells) or on a wet volume basis (grams of solids per

cubic centimeter of wet cells or per cubic centimeter of cell suspension).

Because the drying can be a time-consuming process, and adequate

knowledge about the possibility of volatilization of some cell components is

not known, in the future,

adequate drying quickly at lower temperature

could be done in specially designed vacuum ovens. Such procedures could

also be calibrated for the residual water content. Often, a practical method is

to dry the cells in a microwave oven.

Indirect Biomass Measurements

Bioluminescence and Chemiluminescence: The use of bioluminescent

techniques is based on determining levels of adenosine triphosphate (ATP)

concentration. Generally, levels of ATP remain constant for living cells,

22

12B702 -Bioprocess Engineering

decreasing when the cells die. ATP concentration can, therefore, be related to

biomass. A particular enzyme that has proved useful for this method is

luciferase, which catalyzes the following reaction:

By detecting the light produced by this reaction, ATP concentrations, and

hence, biomass, can be determined. This method can detect cell numbers as

low as 105 cells per ml; it can be automated, and the assay time is fairly

rapid. However, the method does suffer from several drawbacks, for

example, the extraction of ATP may be incomplete, there may be free ATP

present from other sources, and there maybe degradation of ATP by the

extraction reagents. Chemiluminescence is based on the detection of light

produced by the protein-catalyzed oxidation of luminol in the presence of

hydrogen peroxide.

Acoustic Resonance Densitometry. Acoustic resonance density is based

on determining the change in a resonant frequency that results from

changes in cell density. This is a noninvasive method that does not require

contact between the instrument and the culture medium. The method

incorporates an oscillatory circuit, amplifier, and test cell. Theoretically, the

fluid density of the sample can be calculated from the square of its

oscillation. Recent reports have described using this approach to monitor

cultures of hybridomas and human lymphoma cells. Further advantages for

this method include independence from flow rate and viscosity. However,

there are disadvantages including the need for a filtration system (to enable

the resonance density of the medium to be measured in the absence of

cells), with the inherent problems associated with such systems, including

poor sensitivity and problems caused by bubbles and particulate matter.

Capacitance, Conductivity, and Electrochemical Methods.

23

12B702 -Bioprocess Engineering

The electrical properties of cells have been exploited in the development

of a number of techniques. Changes in media capacitance have been related

to biomass concentration (e.g., a decreasing capacitance coupled with an

increasing biomass concentration. In addition, it has been suggested that cell

viability is linked to capacitance measurements. Several in situ commercial

instruments are currently available for determining biomass concentration

based on capacitance measurements. The Biomass Monitor measures the

radio frequency conductance and capacitance of a cell suspension using a

constant

voltage,

four-terminal,

phase-sensitive

detector

system.

Furthermore, the probes can be inserted directly into bioreactors using a

standard 25- mm-diameter port. The probes are fully sterilizable and can be

cleaned in situ during operation.

Fluorescence.

Fluorescence is a characteristic possessed by a number of important

biological compounds including proteins, enzymes, and coenzymes. Simply

de- fined, it is the absorbance of light energy at a particular wavelength,

followed by reemission at a longer wavelength. After the passage of light

energy, the compound returns to its ground-state level. In the field of

bioprocess monitoring, fluorescence has been used, in particular, to monitor

reduced

nicotinamide

adenine

dinucleotide

(NADH)

and

reduced

nicotinamide adenine dinucleotide phosphate (NADPH) concentrations. These

compounds are irradiated at 340 nm and emit at 450 nm. Both compounds

are present in living organisms and are vital components of metabolic

processes. By monitoring the intensity of fluorescence at the characteristic

emission wavelength, it should be possible to calculate the total biomass

concentration. Unfortunately, the use of fluorescence as a marker for cell

concentration does suffer from a number of drawbacks including that the

fluorescence signal can originate from changes in metabolic state and not

from cell concentration levels, sensitivity may be affected by the presence of

24

12B702 -Bioprocess Engineering

compounds that can quench both the excitation and emission wavelengths,

and other compounds may fluoresce at the same wavelength.

Flow Cytometry.

Flow cytometry is a measuring technique based on the irradiation of a

sample solution (containing a cell population) with a suitable light source,

followed by monitoring of the scattered or absorbed light. In addition,

fluorescence can be used as the measuring parameter. This technique can be

used to ascertain a number of cellular features, such as the accumulation of

cellular components (e.g., DNA, RNA, and proteins), and cell dynamics (e.g.,

cell size distribution). Furthermore, flow cytometry can be used to

differentiate and quantify a range of species populations present in a mixed

medium.

Light Scattering and Turbidity.

Optical techniques based on either the scattering of light (nephelometry) or

the degree of transmitted light or optical density (turbidity) have been

developed for determining biomass. By monitoring the degree of light

25

12B702 -Bioprocess Engineering

scattering using nephelometry, both cell numbers and mass can be

determined. This approach is particularly suited for bioprocesses that involve

low cell concentrations, where the background (compared) level is near zero.

Turbidity

measurement

can

be

used

for

both

online

and

off-line

determination of biomass. Light scattering by a turbid medium results from a

number of factors including particle size, shape, and number. Quantification

is based on the Lambert-Beer law

5. MICROBIAL CALORIMETRY

Introduction

Calorimetry is the science of measuring the heat of chemical reactions

or physical changes. Calorimetry involves the use of a calorimeter. Heat is a

universal and unavoidable by product of all biological phenomena, including

those that are exploited in biotechnology at technical scale. Any change in

growth rate, metabolism, biocatalytic activities and in other biological

phenomena occurring in technical reactors will invariably affect the rate at

which heat is released.

Yet heat effects in cellular cultures often go unnoticed when one is

working with conventional laboratory equipment because most of the heat

released by the culture is lost to the environment too quickly to give rise to a

perceivable temperature increase. This, however, is completely different at

large scale. As opposed to laboratory reactors, industrial size fermenters

26

12B702 -Bioprocess Engineering

operate nearly adiabatically due to their much smaller surface to volume

ratio. Thus all the heat released by the culture must be removed by

appropriate cooling facilities.

Systematic monitoring of heat generation rates by the culture in largescale bioreactors would clearly be of considerable benefit for process

optimization and control. The information contained in this signal could be

used together with data on other relevant process parameters to obtain

quantitative on-line estimates of the activity, the metabolism and the state

of the culture.

One method of determining the energy exchange between the reaction

system and its environment is to conduct a calorimetric analysis. A

calorimeter is a thermally insulated container where a reaction system can

be performed and the energy exchange between the system and its

environment can be measured. The calorimeter and its contents are

considered the environment. The reaction system is a chemical or physical

process that occurs within the confines of the calorimeter.

Qsurr = Qcal + Qcontents

The Qcal can be determined if one knows the Heat Capacity of the

calorimeter. This Heat Capacity can be experimentally determined and is

expressed in Kilojoules / C degree. In order to determine the Q cal you multiply

27

12B702 -Bioprocess Engineering

the Heat Capacity of the calorimeter by the difference between the final and

initial temperature. For example if the Heat Capacity of a calorimeter was

determined to be 25.4 KJ/Celsius Degree, determine the Q cal if the initial

temperature during a calorimetric analysis was 30 C and the final

temperature was 50 C.

Qcal = Heat Capacity ( final temp - initial temp) = 25.4 Kj/C ( 50 - 30 C) =

508 Kj

Calorimetric Equipment

In order to make use of heat release measurements in bioprocess control

algorithms, suitable models must be available which relate the heat

evolution rate of the culture to other relevant process variables, such as

substrate consumption, growth rate or oxygen up-take. Numerous workers

have studied these relationships in calorimetric experiments at the

laboratory scale. The need for maintaining technically relevant, strictly

controlled culture conditions made it difficult to obtain meaningful results in

micro calorimeters.

Applications:

Heat as a quantitative indicator of cell metabolism

Control of fermentations by calorimetry

6. FLOW INJECTION ANALYSIS

The concept of flow injection analysis (FIA) was proposed in 1975 by

Ruzicka and Hansen. The fast and intensive development of the FIA

methodology was due to several factors essential for routine analytical

determinations, such as very limited sample consumption, the short analysis

time based on a transient signal measurement in a flow-through detector

and

an

on-line

carrying

out

difficult

operations

of

separation,

preconcentration or physicochemical conversion of analytes into detectable

species.

Principle of the FIA

28

12B702 -Bioprocess Engineering

The three principles or cornerstones of FIA were identified by Ruzicka and

Hansen as sample injection, controlled dispersion of the injected sample

zone, and reproducible timing of the movement of the injected zone from the

injection point to the detector.

(C=carrier;

P=pump;

S=point

of

sample

injection;

RC=reaction

coil;

D=detector; W=waste)

Schematic diagram of the basic FI system

In the simplest form of FIA the sample is injected into a continuous flow of

reagent solution (carrier), dispersed, and transported to detector. Sample

dispersion is controlled through the suitable choice of the injected sample

volume, flow rate of carrier, length of the reaction coil, and diameter of the

tubing used. A schematic diagram of the basic FI system is shown in Figure

29

12B702 -Bioprocess Engineering

Flow Injection Analysis (FIA), the first generation of FIA techniques, is

also probably the most widely utilized. In its simplest form, the sample zone

is injected into a flowing carrier stream of reagent. As the injected zone

moves downstream, the sample solution disperses into the reagent, causing

the product to form. A flow through detector placed downstream records the

desired physical parameter such as colorimetric absorbance or fluorescence.

The modern Flow Injection Analysis system usually consists of a high

quality multichannel peristaltic pump, an injection valve, a coiled reactor, a

detector such as a photometric flow cell, and an autosampler. Additional

components may include a flow through heater to increase the speed of

chemical reactions, columns for sample reduction, debubblers, and filters for

particulate removal.

The typical FIA flow rate is one milliliter per minute, typical sample

volume consumption is 100 microliters per sample, and typical sampling

frequency is two samples per minute. FIA assays usually result in sample

concentration accuracies of a few percent.

Sequential Injection Analysis

Sequential Injection Analysis (SIA) is the second generation approach to

FIA compatible assays. SIA usually consists of a single-channel high precision

bi-directional pump, a holding coil, a multiposition valve, and a flow through

detector. The system is initially filled with a carrier stream into which a zone

of sample and a zone of reagent(s) are sequentially aspirated into a holding

coil, forming a linear stack. These zones become overlapped due the

parabolic profile induced by differences between flow velocities of adjacent

streamlines. Flow reversals and flow acceleration further promote mixing.

The multi position valve is then switched to the detector position, and the

flow direction is reversed, propelling the sample/reagent zones through the

flow cell.

30

12B702 -Bioprocess Engineering

The advantage of SIA over the more traditional flow injection analysis

(FIA) is that SIA typically consumes less than one-tenth the reagent and

produces far less waste an important feature when dealing with expensive

chemicals, hazardous reagents, or online/remote site applications. One

disadvantage of SIA is that it tends to run slower than FIA.

Online process monitoring using SIA is often an ideal solution. The

low reagent/sample consumption, waste production, and nearly hands-off

robustness make SIA the perfect choice. Example online applications include

fermentation monitoring of ammonia, glycerol, and glucose.

Or automated

sample dilutions prior to absorbance monitoring, perhaps many thousands

fold. Also remote site monitoring, where the system may run for days

without user intervention.

Biosensors

One possible answer to the problem of monitoring metabolites, both in

situ and on-line, may be solved in the near future by the use of biosensors.

Since their conception in the 1960s, these devices have generated

considerable interest. This has spread to a diverse range of fields including

clinical diagnostics, environmental protection, bioprocess monitoring, and

defence applications (56). In general the operation of a biosensor is

31

12B702 -Bioprocess Engineering

characterized by three functional steps: recognition, physiochemical signal

generation, and signal processing. The biological component (e.g.,enzyme,

whole cell, antibody, and cell receptor) imparts a high degree of selectivity

on the biosensor. Coupled to the biological component; the transducer is

designed to respond to the changing physicochemical parameters caused by

the specific interaction of the biological component with the substrate. A

range of transducers have been used in the development of biosensors and

include the electrochemical (potentiometric and amperometric), optical,

calorimetric, piezoelectric, and thermometric . Most of these types have

been adopted in the development of biosensors intended for bioprocess

monitoring.

Enzyme-modified field effect transistors (FETs), whereby the biologically

active layer is positioned on top of the ion electrode membrane, have also

been used for bioprocess monitoring. The instrument can be used to

determine a range of metabolites (e.g., glucose, lactate, and ethanol).

Recently the company has introduced an on-line instrument. Indeed, on-line

biosensor systems have been demonstrated using a variety of biologicaltransducer systems . A wide range of metabolites have been monitored using

various bioprocess regimes . Commercially, a significant number of biosensor

devices are available for measuring a range of analytes. However, at

32

12B702 -Bioprocess Engineering

present, the majority of these devices are aimed at the medical diagnostic

market. The goal is to develop cheap, reliable sensors that can operate

under a range of bioprocess conditions for extended periods with a minimum

of maintenance.

Nuclear Magnetic Resonance

Nuclear magnetic resonance is based on the detection of the response

from particular nuclei when exposed to a magnetic field and electromagnetic

radiation. Following absorption, the resonance frequency is shifted in a

characteristic response pattern, according to the environment of the sample

under detection. This approach can be used to determine a range of

intracellular factors such as ATP, ADP, sugar phosphate, and polyphosphate,

as well as pH. In these examples, concentrations of 31P are used to

characterize the compounds. This is an off-line monitoring system that is

currently expensive; hence, its use is primarily in the research field, not in

routine production environments.

Artificial Intelligence

The data obtained using the various measuring instruments already

discussed are invariably used to control and optimize the bioprocess being

carried out. Recent developments in the field of artificial intelligence have

led to investigations into the use of such systems for improving bioprocess

control, based on the received measurement output signals. This has

included the use of both knowledge-based expert systems (64,65) and neural

networks (e.g., 66,67) during bioprocess operation. A recent report (68)

described the successful use of a neural network as a tool for evaluating the

received measurement from an enzyme (penicillin-G amidase) pH-FET sensor

linked to a flow injection system. Undoubtedly, the adaptation of such

intelligent systems will develop over the coming years and will play an

important role in the precise control of bioprocess applications.

33

12B702 -Bioprocess Engineering

Conclusion

Although a diverse range of monitoring equipment is available, only a

relatively narrow range of the more reliable instruments is used routinely in

practice. As culture techniques become more elaborate and high-valueadded products are produced, conventional methods will either prove

insufficient or require supplementation with a range of sensors able to

directly monitor key process parameters. Despite a clear demand for new

sensors (e.g., lactate, glutamine, and glutamate for animal cell culture), cell

cultivation represents only a modest market for analytical instrument

manufacturers. Hence, while progress is to be expected, it may be slower

than might be wished.

During the last 20 years, considerable developments have been obtained

in on-line and in situ process monitoring. Non-measurable variables are now

monitored by observers:state estimators and software sensors. For process

control, mathematical models and hybrid models are applied. The latter

cover mathematical models, literature and live data as well as expert

knowledge. Instead of looking for particular reactions, the network of

biochemical reactions is considered by metabolic flux analysis. The central

metabolism of micro-organisms and cells is well known. Also the biosynthesis

paths of secondary metabolites are well known. By metabolic flux analysis,

the quantitative fluxes can be determined. Most of their genes of the

metabolite network are identified and expressed. In spite of the fact that no

great improvement of the productivity could be obtained, because the

regulation of the metabolic network is still unknown. Metabolic engineering

will be possible, if the dynamic regulation the metabolic network is

determined. This is the aim the next 20 years.

8. COMPUTER BASED DATA ACQUISITION

Traditionally, measurements are done on stand alone instruments of

various types-oscilloscopes, multi meters, counters etc. However, the need

to record the measurements and process the collected data for visualization

34

12B702 -Bioprocess Engineering

has become increasingly important.

Data acquisition involves gathering

signals from measurement sources and digitizing the signal for storage,

analysis, and presentation on a personal computer (PC).

There are five components to be considered when building a basic DAQ

system (Figure 1):

Transducers and sensors

Signals

Signal conditioning

DAQ hardware

Driver and application software

Figure 1. Data Acquisition System

Data acquisition is the sampling of the real world to generate data that

can be manipulated by a computer. Sometimes abbreviated DAQ, data

acquisition typically involves acquisition of signals and waveforms and

processing the signals to obtain desired information. The components of data

acquisition

systems

include

appropriate

sensors

that

convert

any

measurement parameter to an electrical signal, which is acquired by data

acquisition hardware. Acquired data typically is displayed, analyzed, and

stored on a PC. This is achieved by using vendor supplied interactive control

software and hardware such as PowerLab, or custom displays and control can

35

12B702 -Bioprocess Engineering

be accomplished using a programming language such as experix, LabVIEW,

Visual Basic, or C. EPICS is used to build large scale data acquisition systems.

How Data is acquired

Transducers convert measurable physical phenomenon into electric signals.

Examples of tranducers include microphones for sound and photocells for

light.

Signals may be digital or analog depending on the tranducer used.

Signal conditioning may be necessary if the signal from the tranducer is

not suitable for the DAQ hardware to be used. The signal may be amplified or

deamplified, or may require filtering.

DAQ hardware is what usually interfaces between a the signal and a PC. It

could be in the form of modules that can be connected to the computer's

ports (parallel, serial, USB, etc...) or cards connected to slots (PCI, ISA) in the

mother board

Driver Software that usually comes with the DAQ hardware or from other

vendors, allows the operating system to recognize the DAQ hardware and

programs to access the signals being read by the DAQ hardware.

Transducers

Data acquisition begins with the physical phenomenon to be measured. This

physical phenomenon could be the temperature of a room, the intensity of a

light source, the pressure inside a chamber, the force applied to an object, or

many other things.

system

can

An effective DAQ

measure

all

of

these

different

phenomena.

A transducer is a device that converts a physical phenomenon into a

measurable electrical signal, such as voltage or current. The ability of a DAQ

system to measure different phenomena depends on the transducers to

convert the physical phenomena into signals measurable by the DAQ

hardware. Transducers are synonymous with sensors in DAQ systems. There

are specific transducers for many different applications, such as measuring

36

12B702 -Bioprocess Engineering

temperature, pressure, or fluid flow. Figure 2 shows a short list of some

common transducers and the phenomena they can measure.

Figure 2. Phenomena and Existing Transducers

Data Acquisition Systems

Data acquisition systems, as the name implies, are products and/or

processes used to collect information to document or analyze some

phenomenon. In the simplest form, a technician logging the temperature of

an oven on a piece of paper is performing data acquisition. As technology

has progressed, this type of process has been simplified and made more

accurate, versatile, and reliable through electronic equipment. Equipment

ranges from simple recorders to sophisticated computer systems. Data

acquisition products serve as a focal point in a system, tying together a wide

variety of products, such as sensors that indicate temperature, flow, level, or

pressure.

Searching for the Right Data Acquisition Software

Remember when companies had fully staffed departments dedicated to

developing test systems and programs for you? Those days are gone. To stay

competitive in today's job market, you need to put your own test system

together. Choosing the most appropriate data acquisition software for your

application is critical to accomplishing this task.

37

12B702 -Bioprocess Engineering

The first steps toward finding a data acquisition software package that fits

your application are understanding your current and future application

requirements and determining the types of tasks you would like to be able to

perform. These usually include one or more of the following:

Verifying signal connections.

Logging and streaming data to disk.

Monitoring real-time data.

Controlling a test or process.

Analyzing the acquired data.

Generating reports in a variety of graphical formats.

Designing turnkey applications that can be used by lesser-skilled

operators.

10. LABVIEW FOR MEASUREMENT AND DATA ANALYSIS

Thousands of engineers and scientists rely on LabVIEW for a variety of

applications: test and measurement, process control and automation,

monitoring and simulation. LabVIEW is the tool of choice due to its

unparalleled

capabilities,

connectivity

natural

to

instruments,

dataflow-based

powerful

graphical

data

programming

acquisition

interface,

scalability, and overall function completeness. One need that persists

regardless of the area of expertise is the fact that users must manipulate

data and measurements, and make decisions based on it.

Users generally start their work by acquiring data into an application or

program, because their tasks typically require interaction with physical

processes. In order to extract valuable information from that data, make

decisions on the process, and obtain results, the data needs to be

manipulated and analyzed. Unfortunately, combining analysis with data

acquisition and data presentation is not always a straightforward process.

38

12B702 -Bioprocess Engineering

Application software packages typically address one component of the

application, but seldom address all aspects and needs to get to a complete

solution. LabVIEW was designed to address the requirements for a start-tofinish, fully-integrated solution, so that customers can seamlessly integrate

all phases of their application in a single environment.

Figure 1. LabVIEW Virtual Instrument Block Diagram

While there are many tools that independently address each of the

requirements, only LabVIEW combines all of them with the power of

graphical programming and state-of-the-art data acquisition hardware, using

the power of your PC. It is the combination of data acquisition, data analysis,

and presentation of results, that truly maximizes the power of Virtual

Instrumentation. A virtual instrument consists of an industry-standard

computer or workstation equipped with powerful application software, costeffective hardware such as plug-in boards, and driver software, which

together perform the functions of traditional instruments. This is why

applications and programs built with LabVIEW are referred to as VIs (virtual

instruments).

Computer based Data Acquisition Overview:

This overview will help you to understand the basics of data acquisition on a

computer.

Traditionally, measurements are done on stand alone instruments of various

types-oscilloscopes, multi meters, counters etc. However, the need to record

39

12B702 -Bioprocess Engineering

the measurements and process the collected data for visualization has

become increasingly important. There are several ways in which the data can

be exchanged between instruments and a computer. Many instruments have

a serial port which can exchange data to and from a computer or another

instrument. Use of GPIB interface board (General purpose Instrumentation

Bus) allows instruments to transfer data in a parallel format and gives each

instrument an identity among a network of instruments. All HP instruments in

the EE Undergraduate Laboratories and PCs are equipped with GPIB

interfaces. Another way to measure signals and transfer the data into a

computer is by using a Data Acquisition board. A typical commercial DAQ

card contains ADC and DAC that allows input and output of analog and digital

signals in addition to digital input/output channels. In the following overview

we will attempt to explain various aspects of a DAQ card and DAQ system

used in the EE Undergraduate Lab.

Sampling.

The data is acquired by an ADC using a process called sampling. Sampling a

analog signal involves taking a sample of the signal at discrete times. This

rate at which the signal is sampled is known as sampling frequency. The

process of sampling generates values of signal at time interval as shown in

following figure.

40

12B702 -Bioprocess Engineering

The sampling frequency determines the quality of the analog signal that is

converted. Higher sampling frequency achieves better conversion of the

analog signals. The minimum sampling frequency required to represent the

signal should at least be twice the maximum frequency of the analog signal

under test (this is called the Nyquist rate). In the following figure an example

of sampling is shown. If the sampling frequency is equal or less then twice

the frequency of the input signal, a signal of lower frequency is generated

from such a process (this is called aliasing).

41

Das könnte Ihnen auch gefallen

- Introduction To Storage TanksDokument49 SeitenIntroduction To Storage TanksMachineryeng100% (2)

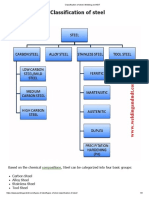

- Classification of Steel - Welding and NDTDokument3 SeitenClassification of Steel - Welding and NDTAshif Iqubal100% (1)

- List of Steel Products Made in The UK PDFDokument120 SeitenList of Steel Products Made in The UK PDFAntonio MarrufoNoch keine Bewertungen

- Astm b571 97 R 13pdfDokument4 SeitenAstm b571 97 R 13pdfkishor150688Noch keine Bewertungen

- Plate and Frame Filter Press ExperimentsDokument13 SeitenPlate and Frame Filter Press Experimentshazwani75% (4)

- Chap9 Downstream ProcessingDokument25 SeitenChap9 Downstream ProcessingsadatrafiaNoch keine Bewertungen

- Joseph S. Alford: What Is A Bioprocess?Dokument8 SeitenJoseph S. Alford: What Is A Bioprocess?rhabarberrhabarberNoch keine Bewertungen

- BF3000Dokument6 SeitenBF3000Jokanoe LertNoch keine Bewertungen

- Relationships Between The Surface Texture of Flexographic Printing Plates and The Printability of Kraft PaperDokument11 SeitenRelationships Between The Surface Texture of Flexographic Printing Plates and The Printability of Kraft PaperQuý Đình Mai MaiNoch keine Bewertungen

- Latest Advances in TFFDokument35 SeitenLatest Advances in TFFSanjay RajputNoch keine Bewertungen

- Instrumentation: Faculty of Science and Natural Resources Department of BiotechnologyDokument43 SeitenInstrumentation: Faculty of Science and Natural Resources Department of BiotechnologyOsama AlrawabNoch keine Bewertungen

- Bioseparation 1Dokument30 SeitenBioseparation 1Kartel KalientitoxNoch keine Bewertungen

- Base Oil Groups Manufacture Properties and PerformanceDokument4 SeitenBase Oil Groups Manufacture Properties and Performanceiosalcido100% (1)

- Properties and Uses: Report by Group 2Dokument56 SeitenProperties and Uses: Report by Group 2Carl Ashlee Perez AsiNoch keine Bewertungen

- Production of Poly (3-Hydroxybutyrate) by Fed-Batch Culture of Filamentation-Suppressed Recombinant Escherichia ColiDokument5 SeitenProduction of Poly (3-Hydroxybutyrate) by Fed-Batch Culture of Filamentation-Suppressed Recombinant Escherichia Coliapi-3743140Noch keine Bewertungen

- Biochemical Engineering - A Laboratory Manual-Jenny Stanford Publishing (2021)Dokument248 SeitenBiochemical Engineering - A Laboratory Manual-Jenny Stanford Publishing (2021)Yamid Andrés Yepes LondoñoNoch keine Bewertungen

- Factors and Methods for Extracting and Isolating ProductsDokument50 SeitenFactors and Methods for Extracting and Isolating ProductsRouf AhmadNoch keine Bewertungen

- Assignment Fermentation (Agitator)Dokument8 SeitenAssignment Fermentation (Agitator)izzat ezmanNoch keine Bewertungen

- Bche Lab Manual 1Dokument121 SeitenBche Lab Manual 1H.J.PrabhuNoch keine Bewertungen

- Experiment 5Dokument8 SeitenExperiment 5talaNoch keine Bewertungen

- Laboratory Manual For BiotechnologyDokument42 SeitenLaboratory Manual For BiotechnologySanjeet SinghNoch keine Bewertungen

- ENZYME KINETICSDokument11 SeitenENZYME KINETICSDianne Villanueva100% (1)

- Final Project 2013Dokument40 SeitenFinal Project 2013Ahmed AliNoch keine Bewertungen

- Exp 2, 3 4 Bakers Yeast Production - StudentDokument3 SeitenExp 2, 3 4 Bakers Yeast Production - StudentIzzu NainNoch keine Bewertungen

- Experiment 6 - Kla DeterminationDokument4 SeitenExperiment 6 - Kla DeterminationHazeq AzaharNoch keine Bewertungen

- Lab 7 - BioeactorDokument43 SeitenLab 7 - Bioeactornur athilahNoch keine Bewertungen

- Bioprocess Lab Manual GuideDokument27 SeitenBioprocess Lab Manual GuideFatih RushdiNoch keine Bewertungen

- Oxygen Transfer LabDokument6 SeitenOxygen Transfer LabSyafiin PeinzNoch keine Bewertungen

- Specific Growth of Bakers Yeast in A Feed Batch SystemDokument52 SeitenSpecific Growth of Bakers Yeast in A Feed Batch SystemDavid OjwangNoch keine Bewertungen

- Experiment 7 KLaDokument6 SeitenExperiment 7 KLaAnonymous e2ws6TNoch keine Bewertungen

- Bonding and Mixtures Answer Key GuideDokument10 SeitenBonding and Mixtures Answer Key GuidemichaelalangcasNoch keine Bewertungen

- FermenterDokument19 SeitenFermenterIshtiaque HossainNoch keine Bewertungen

- KlaDokument7 SeitenKlaThakur VipulNoch keine Bewertungen

- Experiment 7Dokument2 SeitenExperiment 7Zariq NazaruddinNoch keine Bewertungen

- Bioethanol From MSWDokument30 SeitenBioethanol From MSWZafran AliNoch keine Bewertungen

- Bioreactor Instrumentation MeasurementsDokument12 SeitenBioreactor Instrumentation MeasurementsIrish Siaotong100% (1)

- Kinetics Study Batch Fermentation of Baker's YeastDokument5 SeitenKinetics Study Batch Fermentation of Baker's YeastMahathir Mohmed100% (5)

- Bubble Column Fermenter/BioreactorDokument9 SeitenBubble Column Fermenter/BioreactorLouellaNoch keine Bewertungen

- Biochemical Engineering CurriculumDokument4 SeitenBiochemical Engineering Curriculumsunny993Noch keine Bewertungen

- Outline: Fed-Batch OperationDokument21 SeitenOutline: Fed-Batch OperationMuhammadHanifBinBabaNoch keine Bewertungen

- Kla DeterminationDokument23 SeitenKla DeterminationJokanoe LertNoch keine Bewertungen

- Book of AbstractsDokument343 SeitenBook of AbstractsgocyliNoch keine Bewertungen

- A Guide For Bioreactor Landfill OperationDokument46 SeitenA Guide For Bioreactor Landfill OperationPatrick SipatelaNoch keine Bewertungen

- Oxygen Transfer RateDokument11 SeitenOxygen Transfer RatefayeNoch keine Bewertungen

- Economic Case for Immobilizing EnzymesDokument25 SeitenEconomic Case for Immobilizing EnzymesNikki ChauhanNoch keine Bewertungen

- CHAPTER 3 (Material Balances)Dokument76 SeitenCHAPTER 3 (Material Balances)Ali Imran Mohamad0% (1)

- Centrifugation Techniques for Separating Biological ParticlesDokument43 SeitenCentrifugation Techniques for Separating Biological ParticlesSudeeksha RavikotiNoch keine Bewertungen

- Oxygen Transfer To BioreactorsDokument15 SeitenOxygen Transfer To BioreactorsChongMYNoch keine Bewertungen

- Biosepartaion Engineering: Ch.1: Bioseparation & Biological MaterialsDokument89 SeitenBiosepartaion Engineering: Ch.1: Bioseparation & Biological MaterialsAlex MaximusNoch keine Bewertungen

- Assignment 7, 2015 SolutionsDokument6 SeitenAssignment 7, 2015 SolutionsJenna BraszNoch keine Bewertungen

- Introduction To Fermentation Technique & Fermenter: N.M AhmedDokument20 SeitenIntroduction To Fermentation Technique & Fermenter: N.M AhmedNaser_Ahmed11100% (1)

- Baculovirus: A Viral Bioagent For Biological ControlDokument56 SeitenBaculovirus: A Viral Bioagent For Biological ControlA PrashantNoch keine Bewertungen

- Industrial Biotechnology 1Dokument29 SeitenIndustrial Biotechnology 1Abdul Al RajaNoch keine Bewertungen

- Determination of Oxygen-Absorption Rate: Che 514A: Biochemical EngineeringDokument6 SeitenDetermination of Oxygen-Absorption Rate: Che 514A: Biochemical EngineeringEzekielNoch keine Bewertungen

- Bio Reactor EngineeringDokument26 SeitenBio Reactor EngineeringGizachew BalchaNoch keine Bewertungen

- Free Radical and AntioxidantDokument45 SeitenFree Radical and AntioxidantKuu Haku100% (1)

- Ficha Técnica Ctec2Dokument9 SeitenFicha Técnica Ctec2David SebastiánNoch keine Bewertungen

- Biorector 03 Types and Classification of BioreactorsDokument12 SeitenBiorector 03 Types and Classification of BioreactorsWhisnu LinggaNoch keine Bewertungen

- AdenovirusDokument18 SeitenAdenovirusNovika Ayuni RambeNoch keine Bewertungen

- Sterilization of Fermenter-1Dokument11 SeitenSterilization of Fermenter-1Shalini M100% (1)

- Classification of BioreactorsDokument2 SeitenClassification of BioreactorsisabelelmhNoch keine Bewertungen

- Chapter 4 Airlift BioreactorDokument7 SeitenChapter 4 Airlift BioreactorEncikFiiNoch keine Bewertungen

- OTRDokument51 SeitenOTRNithi AnandNoch keine Bewertungen

- 02 Downstream ProcessDokument29 Seiten02 Downstream Processnishit1990Noch keine Bewertungen

- Cryopreservation Technical ManualDokument16 SeitenCryopreservation Technical Manualnevermore78Noch keine Bewertungen

- Salmonella Infections Clinical Immunological and Molecular Aspects Advances in Molecular and Cellular Microbiology PDFDokument402 SeitenSalmonella Infections Clinical Immunological and Molecular Aspects Advances in Molecular and Cellular Microbiology PDFFredNoch keine Bewertungen

- Ftir and Gc-Fid CharacterizationDokument8 SeitenFtir and Gc-Fid CharacterizationIpeghan Otaraku100% (1)

- Membrane Research: Classic Origins and Current ConceptsVon EverandMembrane Research: Classic Origins and Current ConceptsA. L. Muggleton-HarrisNoch keine Bewertungen

- Nano Platforms in Cancer TherapyDokument7 SeitenNano Platforms in Cancer TherapySandiyaNoch keine Bewertungen

- PCR Primers Guide: Selecting Optimal PrimersDokument6 SeitenPCR Primers Guide: Selecting Optimal PrimersDwi Novia PutriNoch keine Bewertungen

- PCRDokument4 SeitenPCRSandiyaNoch keine Bewertungen

- PCR Primers Guide: Selecting Optimal PrimersDokument6 SeitenPCR Primers Guide: Selecting Optimal PrimersDwi Novia PutriNoch keine Bewertungen

- Specific Energy Curve Lab ReportDokument8 SeitenSpecific Energy Curve Lab ReportEngr Muhammad TariqNoch keine Bewertungen

- Rdna Prac 4Dokument2 SeitenRdna Prac 4Mthetheleli NxeleNoch keine Bewertungen

- 2do Taller de Química Inorgánica IIDokument3 Seiten2do Taller de Química Inorgánica IIKaritto EspitiaNoch keine Bewertungen

- Wastewater treatment and sludge digestion process explainedDokument17 SeitenWastewater treatment and sludge digestion process explainedParas KathvadiyaNoch keine Bewertungen

- 10.1016/j.foodres.2014.01.057: Food Research InternationalDokument90 Seiten10.1016/j.foodres.2014.01.057: Food Research Internationaledywiyono2013Noch keine Bewertungen

- Certificado de Calidad Caps SCH-40Dokument1 SeiteCertificado de Calidad Caps SCH-40Jesus CondoriNoch keine Bewertungen

- Everything You Need to Know About Synthetic RubberDokument10 SeitenEverything You Need to Know About Synthetic RubberSneha SahniNoch keine Bewertungen

- Nust ChemistryDokument137 SeitenNust Chemistryahmed ilyasNoch keine Bewertungen

- CNS: GEAS 2 Review Questions and SolutionsDokument5 SeitenCNS: GEAS 2 Review Questions and SolutionsEdward Roy “Ying” AyingNoch keine Bewertungen

- Unit 1 Refrigeration and Air ConditioningDokument20 SeitenUnit 1 Refrigeration and Air ConditioningGaryy EditsNoch keine Bewertungen

- A Seminar Report OnDokument1 SeiteA Seminar Report Onu10ch019Noch keine Bewertungen

- Will Silver Bromide PrecipitateDokument14 SeitenWill Silver Bromide PrecipitateLeonidasNoch keine Bewertungen

- E 632 Â " 82 R96 - RTYZMGDokument6 SeitenE 632 Â " 82 R96 - RTYZMGhans ccNoch keine Bewertungen