Beruflich Dokumente

Kultur Dokumente

Screw Jack Calculations

Hochgeladen von

Daniel SherwinCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Screw Jack Calculations

Hochgeladen von

Daniel SherwinCopyright:

Verfügbare Formate

Selection, Calculation, Checklists

Critical Buckling Force of the Lifting Screws

fk = 0,25

fk = 2

fk = 4

Version S

guided lifting motion with

hinged plate

Version S

non guided lifting motion,

gear firmly mounted

Version S

guided lifting motion,

gear firmly mounted

Version R

for a small L1 there applies: fk = 2

guided lifting motion

Critical buckling force Fk in kN

fk = 1

There is a buckling risk especially

with gearboxes with long, thin

spindles in combination with

compression load. With the

following calculation you can find

the max. allowed axial load acc.

to Euler.

Maximum allowed axial load

Fall = 0.8 x Fk x fk

Fall maximum allowable axial load (kN)

Fk theoretical critical buckling force

(kN) acc. to diagram

fk correction value (considers kind of

bearing support, respectively

guidance of lifting load)

see pictograms above

free length L in mm

If the maximum calculated load is lower than

required, a larger spindle diameter could

be selected. The calculations must then

be reworked.

With the rotating screw version a larger

diameter screw can be selected (from the

next bigger gearbox size).

Any increase in pitch/ lifting speed must

be taken into account.

The safety factors for the type of system

specified must be used, as shown above,

to calculate the max allowable axial load

for the system.

169

Selection, Calculation, Checklists

theoretical spindle whirling speed nkr [min-1]

Critical Whirling Speed of Spindle - R Version

with opposed

bearing plate

fkr = 1

without opposed

bearing plate

fkr = 0.5

Maximum allowable

spindle speed

nall = 0.8 x nkr x fkr

. .

spindle speed =

unsupported screw lengths [m]

For R version gearboxes (with rotating

spindle) with long, thin spindles it is

necessary to calculate the maximum allowable

spindle speed. Please take the theoretical

critical speed nkr from the diagram. Also

consider the additional lengths for spindle

covers, etc. when calculating the unsupported

screw lengths .

Together with the correction factor for

the bearing layout the max. allowable

spindle speed can be calculated.

If the calculated maximum spindle speed is

lower than that required, a larger spindle

should be selected. The calculations must

then be reworked.

If a larger diameter spindle is used in the

R version the potential for higher drive

torque's must be considered.

The safety factors for the type of system

specified must be used, as shown above,

to calculate the maximum allowable axial load

for the system.

170

input speed

igearbox

Selection, Calculation, Checklists

Determining the Drive Torque [MG] of a Lifting Gear

With the formula shown below it is

possible to calculate the necessary

drive torque.

In order to facilitate the calculation of

the drive torque we have determined

multiplication factors out of this formula

and have stated them in the

technical data for the single gearbox

version.

MG

F

Gearbox

Spindle

P

i

ML

PM

Required drive torque [Nm] of a lifting gear

Lifting load (dynamic) [kN]

Efficiency of the lifting gear (without spindle)

Efficiency of the spindle

Spindle pitch [mm]

Transmission of the lifting gear

Idling torque [Nm]

Power of motor

Formula1):

Drive torque: MG =

Example:

F [kN] P [mm]

2

Power of motor: PM[kW] =

Gearbox

i

Spindle

+ ML [Nm]

MG [Nm] n [min-1]

9550

Safety factor (start torque) = calculated

drive torque x 1.3 to 1.5 (for smaller

systems use up to x 2).

MSZ-25-SN

F = 12 kN (lifting load dynamic)

Gearbox = 0.87

Spindle = 0.375

P=6

i=6

MG =

12 kN 6mm

+ 0.36 Nm = 6.21 Nm

0,87 0,375 6

-1

PM =

6.21 Nm 1500 min

= 0.975 kW

9550

Example: 0.975 kW 1.4 = 1.365 kW

motor 1.5 kW

1)

For gearboxes with one-pitch trapezoidal spindles it is also possible to multiply the

factor which is stated on the corresponding gearbox page with the load.

Tr spindle Spindle

Efficiency

single pitch

Tr

12

18

20

30

40

50

60

80

100

120

140

P lubricated

0.427

3

0.399

4

0.375

4

0.375

6

0.344

7

0.314

8

0.368

12

0.368

16

0.314

16

0.273

16

0.288

20

Tr spindle Spindle

Efficiency

double pitch

Tr

12

18

20

30

40

50

60

80

100

120

140

P lubricated

0.592

6

0.565

8

0.540

8

0.540

12

0.509

14

0.474

16

0.532

24

0.532

32

0.474

32

0.426

32

0.444

40

The efficiency of a trapezoid

screw is substantially lower

than that of ball screws due

to friction.

However, the trapezoid screw

is technically more simple

and more favourable. A

safety device (e.g. a brake) is

rarely required for trapezoid

Efficiency of gearboxes

Gearbox

screws due to their selflocking capability.

With a ballscrew system an

efficiency factor of =0.9

can be used.

It is essential to incorporate

a break into a ballscrew

system.

(without spindle) at n = 1.500

5

2

10

25

50 100 150 250 350 500 650

MSZ

N 0.82 0.84 0.86 0.87 0.89 0.85 0.84 0.86 0.87 0.84 0.85

0.77 0.62 0.69 0.69 0.74 0.65 0.67 0.72 0.70 0.62 0.65

L

Idling torques ML of gearboxes [Nm]

5

2

10

25

50 100 150 250 350 500 650

MSZ

N 0.06 0.10 0.26 0.36 0.76 1.68 1.90 2.64 3.24 3.96 5.60

0.04 0.08 0.16 0.26 0.54 1.02 1.20 1.94 2.20 2.84 3.40

L

With ball screws you basically can calculate with an efficiency factor of

171

=0.9

Selection, Calculation, Checklists

Drive Torque for Gearboxes

MR = MG x 2.25

Calculation

The required drive torque of a

lifting gear results from the sum of

the moments of the individual

lifting units. This is increased due to

frictional losses of transmission

components like couplings,

MR = MG x 2.1

MR = MG x 3.1

MR = MG x 3.35

MR = MG x 4.6

MR = MG x 6.8

MR = MG x 4.4

MR = MG x 3.34

MR = MG x 3.27

connecting shafts, bevel gears, etc.

To simplify the calculation, some

factors for determining the drive

torque in the most common

applications are provided below.

MR - Total drive torque for the

whole system

MG - Input torque of a single gearbox

MA - Starting torque max. 1.5 x MR

Example (example from previous page, 12 kN per gearbox)

MR = MG x 4.6 = 6.21 Nm x 4.6 = 28.57 Nm

x safety factor 1.3 = 37.14Nm

172

Attention:

It is recommended to multiply the

calculated value with a safety

factor of 1.3 to 1.5 (for smaller

systems factor up to 2). The

indicated values are applicable in

cases of uniform distribution of the

lifting gear load onto all gears!

Selection, Calculation, Checklists

Maximum Power / Moments

Load definitions

lifting screw

FS

F - Lifting load tension and/or compression

FS - Side forces on the spindle

vH - Lifting speed of the spindle

(or nut of the R version)

FA - Axial load of the input shaft

FR - Radial load of the input shaft

MR - Drive torque

nR - Drive speed

VH

FR

MR

Please examine the information on the following pages before making

your choice of the lifting gear suited for your application. Various

influences and assumptions can only be estimated on the basis of

information gained by experience. In case of doubt please contact T.E.A.

Maximum side force FS [N] (static)

Max. drive torque

The stated values of the table

on the right should not be

exceeded. If gearboxes are

arranged in tandem or in

larger arrangements the

maximum drive torque may

be higher. If there are more

than 5 gearboxes in an

arrangement please contact

T.E.A.

Maximum drive torque MR [Nm]

Radial load on the input

shaft

The radial forces of the table

on the right should not be

exceeded if you use chain

drives or belt drives.

Maximum radial load acting on the input shaft FR [N]

100

360

600

900

3000

5000

5500

9000

15000

29000

34800

46000

200

160

280

470

2000

4000

5000

9000

13000

29000

34800

46000

Type

min-1

MR SN/RN

MR SN/RN

MR SL/RL

MR SL/RL

1500

500

1500

500

300

100

180

300

1300

3000

3900

6500

12000

29000

34800

39000

SHZ02

0.7

1.0

0.5

0.7

extended screw length in mm

500

700

800

900

1000 1200 1500 2000 2500

400

600

55

38

32

28

25

20

18

12

70

45

100

70

60

50

47

40

30

20

15

130

80

180

90

70

60

45

35

130

110

100

240

150

700

330

280

230

160

130

500

420

380

900

600

850

700

600

400

350

950

2300 1800 1500 1300 1100

850

750

500

400

2800 2300 1800 1500 1300 1200 1000

900

760

4900 3800 3000 2500 2200 2000 1900 1450 1250

10000 8800 7000 6000 5500 4800 4300 3500 3000 2000 1600

29000 29000 24000 20000 17000 15000 14000 12000 9000 7000 5600

34800 34800 28800 24000 20400 18000 16800 14400 10800 8400 6720

36000 32000 30000 25000 29000 25000 23500 20000 17000 12000 10000

MSZ5

6.4

10.4

2.6

4.3

MSZ10

12.6

20.5

5.3

8.4

MSZ25

21.7

34.2

7.8

12.5

MSZ50

44.7

70.3

15.5

24.5

MSZ100

72.0

114.9

17.0

27.8

MSZ150

67.3

107.0

17.3

27.7

MSZ250

118.4

185.1

23.5

36.6

MSZ350

187.0

295.7

40.2

63.9

MSZ500

204.3

325.6

42.8

71.2

MSZ650

268.3

427.9

62.8

102.6

MSZ750

415.0

663.0

83.0

132.0

- Consider that the starting torque is factor 1.5 of the operation torque

- Limit values are mechanical - consider thermical factors depending on operating time

FR max.

SHZ02

18

MSZ5

110

MSZ10

215

173

MSZ25

300

FA

input shaft

= worm shaft

Side forces on the spindle

Please refer to the adjoining

table for the maximum

permissible side force. Side

forces should be supported by

a guidance system whenever

possible. The bronze bushings

in the gearbox are a

secondary support only and

should not be relied upon as

adequate guidance. The

maximum side force at a

given screw extension must

not exceed that stated in the

adjoining table. Attention:

only statically allowed!

MSZ

5

10

25

50

100

150

250

350

500

650

750

nR

MSZ50

520

MSZ100

800

MSZ150

810

MSZ250

1420

MSZ350

2100

MSZ500

3780

MSZ650

4536

3000

30

100

250

350

660

1400

4900

5880

8000

Your partner in quality engineering products since 1986

Thank you for viewing product information on TEAs range of engineering components.

Now please contact us at the nearest office to you for any further information, prices and availability:

AUSTRALIA & New Zealand

USA, South America & Canada

T.E.A. Transmissions Pty Ltd

Tahiti Road

Tiaro Qld 4650

Australia

T.E.A. Machine Components Inc.

2281-F Dabney Road

Richmond Virginia 23230

USA

Ph: 61-(0)7 4129 2533

Fax: 61-(0)7 4129 2437

Email: sales@tea.net.au

www.tea.net.au

Ph: 1-804-342-0004

Fax: 1-804-342-0006

Email: sales@teausa.net

www.teausa.net

You are assured of prompt and efficient service at all time.

Das könnte Ihnen auch gefallen

- Roller Chains Design GuidelinesDokument6 SeitenRoller Chains Design GuidelinesDrew TwitchNoch keine Bewertungen

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsVon EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNoch keine Bewertungen

- Belt ConveyorDokument3 SeitenBelt ConveyorJawed AnsariNoch keine Bewertungen

- How To Calculate Size of Filler Wires in A Steel Wire RopesDokument5 SeitenHow To Calculate Size of Filler Wires in A Steel Wire RopesBasil ChikonobayaNoch keine Bewertungen

- Power Hammer Project Report 2015: Guided byDokument51 SeitenPower Hammer Project Report 2015: Guided byTurnitin ReportNoch keine Bewertungen

- Power ScrewDokument21 SeitenPower Screwstruc-engNoch keine Bewertungen

- Guide For DoggersDokument49 SeitenGuide For DoggersEliecer DarbyNoch keine Bewertungen

- Design of The Toggle JackDokument30 SeitenDesign of The Toggle Jackkoanakist91% (11)

- Design procedure of a screw jackDokument6 SeitenDesign procedure of a screw jacksupratim saha100% (1)

- Samyang Gear ReducerDokument6 SeitenSamyang Gear Reducerjuliyanto88Noch keine Bewertungen

- Modular Rack and Pinion System CatalogDokument39 SeitenModular Rack and Pinion System Catalogmeendismurat100% (1)

- Draw SprocketDokument15 SeitenDraw Sprocketfernandop_77Noch keine Bewertungen

- Spiral Springs PDFDokument18 SeitenSpiral Springs PDFEngr Eze Chuklet ChukwumaNoch keine Bewertungen

- Renold Chain CalculationsDokument23 SeitenRenold Chain CalculationsKiran Kumar K T100% (1)

- Rack and Pinion CalculationDokument8 SeitenRack and Pinion CalculationhendrobamaNoch keine Bewertungen

- Z M B (MM) N H (Hours) : Gear Design (Is-4460) (Spur or Helical)Dokument16 SeitenZ M B (MM) N H (Hours) : Gear Design (Is-4460) (Spur or Helical)Babu RajamanickamNoch keine Bewertungen

- Screw Jack Designing Project Report PDFDokument26 SeitenScrew Jack Designing Project Report PDFfasil100% (1)

- Chain Drive CalculationsDokument42 SeitenChain Drive CalculationsAchin67% (3)

- Calculate motor power for 35t LRF transfer carDokument2 SeitenCalculate motor power for 35t LRF transfer carmech_abhiNoch keine Bewertungen

- How To Measure The Pressure Angle of A Physical Spur GearDokument16 SeitenHow To Measure The Pressure Angle of A Physical Spur Gearian_new100% (2)

- Screw Jack OptimizationDokument3 SeitenScrew Jack OptimizationEsmael Adem0% (1)

- Technical Data: Bearing Load CalculationDokument8 SeitenTechnical Data: Bearing Load Calculationmac_devNoch keine Bewertungen

- STAAD Service Stage and Seismic Analysis ResultsDokument14 SeitenSTAAD Service Stage and Seismic Analysis ResultsVikasNoch keine Bewertungen

- Lecture 8 Shaft DesignDokument65 SeitenLecture 8 Shaft DesignYasir A. Al-ShataifNoch keine Bewertungen

- Machine Elements Design Guide for Threaded Joints and Power ScrewsDokument72 SeitenMachine Elements Design Guide for Threaded Joints and Power Screwsf2012265Noch keine Bewertungen

- SKF Industrial PricelistApril2017 Edition2Dokument140 SeitenSKF Industrial PricelistApril2017 Edition2shekar_991985346Noch keine Bewertungen

- Gear4 02Dokument101 SeitenGear4 02pratapslairNoch keine Bewertungen

- What Is The Difference Between Screw Pitch and LeadDokument6 SeitenWhat Is The Difference Between Screw Pitch and LeadnagarajNoch keine Bewertungen

- Calculation of Screw Action ForceDokument3 SeitenCalculation of Screw Action ForceShivam Gukhoul100% (1)

- Tyre Coupling CatalogDokument9 SeitenTyre Coupling CatalogKariem R NoweerNoch keine Bewertungen

- Bearing Centre and Face Width in Conveyor PulleyDokument8 SeitenBearing Centre and Face Width in Conveyor PulleyPrashant MishraNoch keine Bewertungen

- Lecture 16 - Worm Gears Worked Out ProblemsDokument19 SeitenLecture 16 - Worm Gears Worked Out ProblemsApurba haldar50% (2)

- PerhitunganDokument14 SeitenPerhitunganRian Dwi NandaNoch keine Bewertungen

- 11.shafting and Associated Parts - V002Dokument64 Seiten11.shafting and Associated Parts - V002Policarpo AlmeidaNoch keine Bewertungen

- Shaft Design - Overheads PDFDokument20 SeitenShaft Design - Overheads PDFRyan BaleNoch keine Bewertungen

- Objective:: Material Aluminium 7075 GradeDokument12 SeitenObjective:: Material Aluminium 7075 Gradevishal yadav100% (1)

- 3-D modelling and finite element analysis of EOT craneDokument4 Seiten3-D modelling and finite element analysis of EOT craneGogyNoch keine Bewertungen

- 5T X 25.5m DG CraneDokument10 Seiten5T X 25.5m DG CraneRv VaghasiaNoch keine Bewertungen

- Bolt capacity and bending checks as per BS EN-1993-1-8Dokument2 SeitenBolt capacity and bending checks as per BS EN-1993-1-8waweng22Noch keine Bewertungen

- Steel-Smith PDF CatalogueDokument93 SeitenSteel-Smith PDF CatalogueneetadaeroNoch keine Bewertungen

- Feeder Breaker 1200mtph Project01!08!08Dokument3 SeitenFeeder Breaker 1200mtph Project01!08!08Herman AbdullahNoch keine Bewertungen

- Basic Technical Winch InformationDokument7 SeitenBasic Technical Winch InformationMarcos GonzalezNoch keine Bewertungen

- Shaft Calculation Base PDFDokument27 SeitenShaft Calculation Base PDFBarsanu AlexNoch keine Bewertungen

- Motor Torque CalculationDokument5 SeitenMotor Torque CalculationSanjula Darshana WickramasingheNoch keine Bewertungen

- Gear Spindles Ingles PDFDokument24 SeitenGear Spindles Ingles PDFnghiaNoch keine Bewertungen

- Rectangular Hollow Section Cold Formed..BS en 102191997Dokument4 SeitenRectangular Hollow Section Cold Formed..BS en 102191997Jagdish ChhuganiNoch keine Bewertungen

- MSc Mechanical Engineering Final Year Project on Crusher Feeder System DesignDokument97 SeitenMSc Mechanical Engineering Final Year Project on Crusher Feeder System DesignYidenek NgussieNoch keine Bewertungen

- Design of Curved Monorail StructureDokument2 SeitenDesign of Curved Monorail StructuredsanandaNoch keine Bewertungen

- 3.1 Bolted Joint DesignDokument15 Seiten3.1 Bolted Joint Designssn MLNoch keine Bewertungen

- Shell Thickness PDFDokument6 SeitenShell Thickness PDFLucia ZambranoNoch keine Bewertungen

- Stress Analysis of Tractor Trolley Chassis With Effect of Various Thickness and Design Optimization For Weight Reduction Ijariie1894Dokument7 SeitenStress Analysis of Tractor Trolley Chassis With Effect of Various Thickness and Design Optimization For Weight Reduction Ijariie1894anil sajjanarNoch keine Bewertungen

- Rotating TrolleyDokument12 SeitenRotating TrolleyInderdeep TatlaNoch keine Bewertungen

- Crane Wheel Heat Treating MethodsDokument20 SeitenCrane Wheel Heat Treating Methodsgmurdzhev67% (3)

- Spindle DriveDokument8 SeitenSpindle DriveAhmad Reza AtefNoch keine Bewertungen

- Power Press Design, BrakesDokument9 SeitenPower Press Design, Brakeszeynell70100% (2)

- CHAIN CalculationDokument18 SeitenCHAIN CalculationDmitrijs MuhinsNoch keine Bewertungen

- Fenner Wedge Belt Drive Selection 299 - Friction - WedgebeltdrivesDokument22 SeitenFenner Wedge Belt Drive Selection 299 - Friction - WedgebeltdrivesSubramanian ChidambaramNoch keine Bewertungen

- Stepper Motors Synchronous Motors Technical AppendixDokument5 SeitenStepper Motors Synchronous Motors Technical AppendixCARLOSWAR101Noch keine Bewertungen

- Lec # 9 V-Belt DriveDokument46 SeitenLec # 9 V-Belt DriveEl LordNoch keine Bewertungen

- Delhi PPT 11-10-09 PreparedDokument112 SeitenDelhi PPT 11-10-09 PreparedOlivia JacksonNoch keine Bewertungen

- Slide On EBookDokument22 SeitenSlide On EBookDaniel SherwinNoch keine Bewertungen

- Product Disclosure Statement (PDF PDS)Dokument65 SeitenProduct Disclosure Statement (PDF PDS)Daniel SherwinNoch keine Bewertungen

- Car Decision MatrixDokument10 SeitenCar Decision MatrixDaniel SherwinNoch keine Bewertungen

- A Revised Paradigm For Understanding Garment Comfort LimitsDokument26 SeitenA Revised Paradigm For Understanding Garment Comfort LimitsDaniel SherwinNoch keine Bewertungen

- Losberger de Boer Dropstitchtent Product OverviewDokument2 SeitenLosberger de Boer Dropstitchtent Product OverviewDaniel SherwinNoch keine Bewertungen

- BR SZ SH en 2107 WebDokument24 SeitenBR SZ SH en 2107 WebDaniel SherwinNoch keine Bewertungen

- Pds - Velocity Platinum Benefits TncsDokument11 SeitenPds - Velocity Platinum Benefits TncsDaniel SherwinNoch keine Bewertungen

- Ensayo Drop StitchDokument6 SeitenEnsayo Drop StitchDaniel SherwinNoch keine Bewertungen

- AM Tie Downs LegsDokument1 SeiteAM Tie Downs LegsDaniel SherwinNoch keine Bewertungen

- 43 Grand Parade, Epping, Vic 3076Dokument1 Seite43 Grand Parade, Epping, Vic 3076Alex90Noch keine Bewertungen

- Stahl Crane Technology BrochureDokument32 SeitenStahl Crane Technology BrochureDaniel SherwinNoch keine Bewertungen

- The Neural TourniquetDokument5 SeitenThe Neural TourniquetDaniel SherwinNoch keine Bewertungen

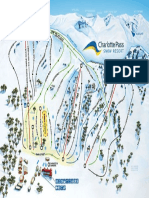

- Charlotte Pass Trail MapDokument1 SeiteCharlotte Pass Trail MapDaniel SherwinNoch keine Bewertungen

- Pandemic Workplace Order 2022 No 10Dokument64 SeitenPandemic Workplace Order 2022 No 10Daniel SherwinNoch keine Bewertungen

- Product Data Sheet: Bisalloy Structural 80 SteelDokument1 SeiteProduct Data Sheet: Bisalloy Structural 80 SteelDaniel SherwinNoch keine Bewertungen

- Guidance For The Pandemic (Public Safety) Order 2022 (No. 3)Dokument22 SeitenGuidance For The Pandemic (Public Safety) Order 2022 (No. 3)Daniel SherwinNoch keine Bewertungen

- 43 Grand Parade, Epping, Vic 3076Dokument1 Seite43 Grand Parade, Epping, Vic 3076Alex90Noch keine Bewertungen

- TIMBER AND As4100 PDFDokument14 SeitenTIMBER AND As4100 PDFAndyNoch keine Bewertungen

- Statement of Information: 1 Village Square, Mount Buller, Vic 3723Dokument2 SeitenStatement of Information: 1 Village Square, Mount Buller, Vic 3723Daniel SherwinNoch keine Bewertungen

- Epic Australia Pass Terms and Conditions 2022Dokument18 SeitenEpic Australia Pass Terms and Conditions 2022Daniel SherwinNoch keine Bewertungen

- Authorised Provider and Worker Permit (Victoria, Australia)Dokument2 SeitenAuthorised Provider and Worker Permit (Victoria, Australia)Daniel SherwinNoch keine Bewertungen

- 2018 Influenza Season in Australia: A Summary From The National Influenza Surveillance CommitteeDokument5 Seiten2018 Influenza Season in Australia: A Summary From The National Influenza Surveillance CommitteeDaniel SherwinNoch keine Bewertungen

- 201Rot.F-1151 Sidney ST: Fractional 2BR With Mountain ViewsDokument4 Seiten201Rot.F-1151 Sidney ST: Fractional 2BR With Mountain ViewsDaniel SherwinNoch keine Bewertungen

- Walk Issue 16 (1965)Dokument73 SeitenWalk Issue 16 (1965)Daniel SherwinNoch keine Bewertungen

- PlateGirder - LRFD (AISC)Dokument10 SeitenPlateGirder - LRFD (AISC)Somi KhanNoch keine Bewertungen

- COVASIM Modelling: Impact of Vaccines On Epidemic Outcomes - 11 June 2021Dokument2 SeitenCOVASIM Modelling: Impact of Vaccines On Epidemic Outcomes - 11 June 2021Daniel SherwinNoch keine Bewertungen

- Stahl Cable Festoon SystemsDokument24 SeitenStahl Cable Festoon SystemsDaniel SherwinNoch keine Bewertungen

- Covid-19 Rat Common-List enDokument27 SeitenCovid-19 Rat Common-List enNavneet ValechaNoch keine Bewertungen

- Weld Design Considerations For Bridge Girders - Weld Type, Quality and CostDokument16 SeitenWeld Design Considerations For Bridge Girders - Weld Type, Quality and CostDaniel SherwinNoch keine Bewertungen

- Iso 12488 1 2005 en FR PDFDokument11 SeitenIso 12488 1 2005 en FR PDFDaniel SherwinNoch keine Bewertungen

- Questions CswipDokument63 SeitenQuestions CswipMohamed ElsayedNoch keine Bewertungen

- Smokevent Calculation..Dokument2 SeitenSmokevent Calculation..Karthy GanesanNoch keine Bewertungen

- How Carburetors Work: Understanding the Six Main SystemsDokument7 SeitenHow Carburetors Work: Understanding the Six Main Systemssaithea25Noch keine Bewertungen

- Alkylation Complex Start Up Plan: ObjectivesDokument10 SeitenAlkylation Complex Start Up Plan: ObjectivesBikas SahaNoch keine Bewertungen

- Miller Spectrum 875 XtremeDokument4 SeitenMiller Spectrum 875 XtremeomaralihasNoch keine Bewertungen

- Goulds 3171 / CV3171: Vertical Sump and Process PumpsDokument16 SeitenGoulds 3171 / CV3171: Vertical Sump and Process PumpsJavier Fernando Agudelo GómezNoch keine Bewertungen

- Steam Turbines Basic Information - Power Generation in PakistanDokument12 SeitenSteam Turbines Basic Information - Power Generation in Pakistannomi607Noch keine Bewertungen

- Electronics 18 E0306Dokument9 SeitenElectronics 18 E0306GiangDoNoch keine Bewertungen

- Apex Status - Issue 2 (2-01-2008)Dokument22 SeitenApex Status - Issue 2 (2-01-2008)BorisLundbergNoch keine Bewertungen

- Salford Journal of Bridge Engineering Jan-18Dokument24 SeitenSalford Journal of Bridge Engineering Jan-18Swaminathan VivekananthamNoch keine Bewertungen

- Automatic Washing Machine 10 Minute Quick Wash FeatureDokument19 SeitenAutomatic Washing Machine 10 Minute Quick Wash FeatureJin HeeNoch keine Bewertungen

- Casing AccessoriesDokument48 SeitenCasing AccessoriesDigger Downhole ToolsNoch keine Bewertungen

- UiiuDokument20 SeitenUiiupravi2010Noch keine Bewertungen

- Pres. 14 (1hr) Blighs TheoryDokument10 SeitenPres. 14 (1hr) Blighs TheoryJahanzeb AliNoch keine Bewertungen

- AS 1056.1-1991 Storage Water Heaters - General RequirementsDokument43 SeitenAS 1056.1-1991 Storage Water Heaters - General RequirementsChetan ChopraNoch keine Bewertungen

- Abs PDFDokument2 SeitenAbs PDFAdonis BasilioNoch keine Bewertungen

- Hiab 320Dokument152 SeitenHiab 320Jasbir Jammu Repairing & Maintence LLCNoch keine Bewertungen

- S Emi Rotary Hand Wing Pumps: A Plication PDokument2 SeitenS Emi Rotary Hand Wing Pumps: A Plication PMarketing CTNNoch keine Bewertungen

- Sheet Metal OperationsDokument27 SeitenSheet Metal OperationsbmvinayNoch keine Bewertungen

- Technical Report: Design of Metal Anchors For Use in Concrete Under Seismic ActionsDokument16 SeitenTechnical Report: Design of Metal Anchors For Use in Concrete Under Seismic ActionsJulioGoesNoch keine Bewertungen

- Crown ToolsDokument20 SeitenCrown ToolsLuis Alberto Rivas GarciaNoch keine Bewertungen

- tn-16 Rate Process Method Projecting Pe PipeDokument8 Seitentn-16 Rate Process Method Projecting Pe Pipeyrdna nawaiteos100% (1)

- TM 5-811-6 Generator and Electrical Facilities DesignDokument26 SeitenTM 5-811-6 Generator and Electrical Facilities DesignrockclaudiuNoch keine Bewertungen

- Directional Soil Improvement Tech for Underground ProjectsDokument38 SeitenDirectional Soil Improvement Tech for Underground ProjectsVanDuongNguyenNoch keine Bewertungen

- CMT Capitolul 4 - Transmisii Curele DintateDokument19 SeitenCMT Capitolul 4 - Transmisii Curele DintateANANoch keine Bewertungen

- AUMA, Assembly InstructionsDokument2 SeitenAUMA, Assembly InstructionsGordinhorsNoch keine Bewertungen

- 32 Landing GearDokument176 Seiten32 Landing GearMaria Fernanda Nuñez RuizNoch keine Bewertungen

- (Datasheet) Eriks - Ketron Peek-1000Dokument2 Seiten(Datasheet) Eriks - Ketron Peek-1000Carlos AlbertoNoch keine Bewertungen

- Centrifugal Compresssor Pre-Commissioning ChecklistDokument3 SeitenCentrifugal Compresssor Pre-Commissioning ChecklistNikhil JadhavNoch keine Bewertungen

- Rds No. Standard Elementary System Size Pressure (Bar (G) )Dokument36 SeitenRds No. Standard Elementary System Size Pressure (Bar (G) )Amit SharmaNoch keine Bewertungen