Beruflich Dokumente

Kultur Dokumente

Understanding Corrosion Inhibition of Mild Steel in Acid Medium by Some Furan Derivatives: A Comprehensive

Hochgeladen von

MarcTimOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Understanding Corrosion Inhibition of Mild Steel in Acid Medium by Some Furan Derivatives: A Comprehensive

Hochgeladen von

MarcTimCopyright:

Verfügbare Formate

Journal of The Electrochemical Society, 157 3 C116-C124 2010

C116

0013-4651/2010/1573/C116/9/$28.00 The Electrochemical Society

Understanding Corrosion Inhibition of Mild Steel in Acid

Medium by Some Furan Derivatives: A Comprehensive

Overview

K. F. Khaledz

Electrochemistry Research Laboratory, Chemistry Department, Faculty of Education, Ain Shams

University, Roxy, Cairo 11566, Egypt and Materials and Corrosion Laboratory, Chemistry Department,

Faculty of Science, Taif University, Taif, Al-Haweiah, 888, Kingdom of Saudi Arabia

The inhibition performance of some furan derivatives, namely, methyl 2-furoate, ethyl 2-furoate, and amyl 2-furoate on mild steel

in normal hydrochloric acid medium 1 M HCl at 25C, was studied by weight loss, potentiodynamic polarization, electrochemical impedance spectroscopy EIS, and electrochemical frequency modulation measurements EFM. Furan derivatives inhibit the

acidic corrosion even at very low concentrations, reaching a value of inhibition efficiency up to 93% at a concentration of 20 mM.

The results obtained from the different corrosion evaluation techniques are in good agreement. Polarization curves indicate that the

studied furan derivatives are mixed-type inhibitors. Data obtained from EIS measurements were analyzed to model the corrosion

inhibition process through an appropriate equivalent circuit model. A constant phase element has been used. The adsorption of

furan derivatives on the steel surface in 1 M HCl solution was found to obey Langmuirs adsorption isotherm with a negative

. Molecular dynamics simulations were carried out to establish the inhibition

value of the free energy of adsorption Gads

mechanism.

2010 The Electrochemical Society. DOI: 10.1149/1.3274915 All rights reserved.

Manuscript submitted July 24, 2009; revised manuscript received October 26, 2009. Published January 12, 2010.

Corrosion inhibition of mild steel is a matter of theoretical as

well as practical importance.1 Acids are widely used in industries

such as pickling, cleaning, descaling, etc. Because of their aggressiveness, inhibitors are used to reduce the rate of dissolution of

metals. Compounds containing nitrogen, sulfur, and oxygen have

been reported as inhibitors.2-4 The most efficient organic inhibitors

are organic compounds having -bonds in their structures. The efficiency of an organic compound to act as an inhibitor is mainly

dependent on its ability to get adsorbed on the metal surface which

requires replacement of water molecule at a corroding interface as

Orgsol + nH2Oads Orgads + nH2Osol

An experimental inquiry into the kinetics of mild steel dissolution

and corrosion inhibition has been carried out with a view to clarify

certain debatable aspects about the mechanism of corrosion inhibition. Previous work in our laboratory has led us to a chemisorption

step as a possible mechanism of inhibition which accounts for the

persistence, specificity, and structural effects of the inhibitors.5,6 It

has been shown that systematic and orderly changes in the molecular structure of the organic compounds can be correlated to inhibition efficiency IE.7-9 This correlation is based on certain physicochemical properties of the inhibitor molecule such as functional

groups, steric factors, aromaticity, electron density at the donor atoms, and orbital character of the donating electrons.10-12

Because adsorption is the key to the explanation of inhibition

mechanism by organic molecules, the primary phenomenon of adsorption is as important as the subsequent phenomenon of inhibition.

The relationship between adsorption and inhibition has been inadequately explained in the literature.13-15 One reason for this is the

meagerness of available experimental techniques for in situ measurement of adsorption at electrodes. Evaluation of adsorption from

corrosion current measurements is indirect and with so many assumptions as to make the conclusions questionable. Donahue et al.

proposed adsorption involving surface complex formation between

the inhibitor and one of the intermediates in the anodic dissolution

of mild steel.16

Although heterocyclic compounds have been evaluated and used

extensively as corrosion inhibitors of mild steel, furan and its derivatives have not been given sufficient attention for such applications. Vaidyanathan and Hackerman14 tested such furan derivatives

as furfurylamine, furoic acid tetrahydrofurfurylamine, and tetrahy-

E-mail: khaledrice2003@yahoo.com

drofurfuryl alcohol for their inhibitive action on anodic dissolution,

cathodic partial processes, and corrosion currents. They found that

inhibitive efficiency of these compounds could be explained on the

basis of structure-dependent electron donor properties. Mitra17

tested furan, furfuryl amine, and furfuryl alcohol and correlated their

IEs with some quantum chemical values, namely, the energy of the

highest occupied molecular orbital and the lowest free molecular

orbital.

This study aims to use some furan derivatives as possible corrosion inhibitors for mild steel in 1 M HCl solutions. Measurements

were conducted using several corrosion monitoring techniques, such

as weight loss, potentiodynamic polarization, and electrochemical

impedance spectroscopy EIS. Electrochemical frequency modulation EFM, which is a recent nondestructive corrosion measurement

technique that can directly give values of corrosion current without

prior knowledge of Tafel constants, is also presented here with the

aim to make an accurate determination of the corrosion rate. It is

also the purpose of this paper to elucidate the adsorption behavior of

some furan derivatives at the mild steel surface using molecular

dynamics simulations.

The present work also involves an extensive investigation of

many furan derivatives, which have been chosen to evaluate the

effects of systematic changes in the molecular structure and the

polar function of the compound. This is achieved by changing the

substituent with respect to the oxygen polar function. Also, an attempt is made to discuss the inhibitive action of the tested compounds according to the interface and interphase modes of inhibition.

Experimental

The structures of the furan compounds studied are presented below

All the investigated compounds were obtained from Aldrich Chemical Co.; they were put in 1.0 M HCl Fisher Scientific without

pretreatment at concentrations of 5, 10, 15, and 20 mM.

All electrochemical measurements were performed in a typical

three-compartment glass cell that consisted of the mild steel rod

C = 0.14 wt %, S = 0.05 wt %, Si = 0.01 wt %, Mn = 0.9 wt %,

Downloaded 18 Mar 2010 to 202.170.57.251. Redistribution subject to ECS license or copyright; see http://www.ecsdl.org/terms_use.jsp

Journal of The Electrochemical Society, 157 3 C116-C124 2010

30 min

60 min

120 min

240 min

60

-Z"/ cm2

and Fe = balance, its surface area was 0.28 cm2 as a working electrode WE prepared using emery papers of different grit sizes up to

4/0 grit, polished with Al2O3 0.5 m particle size, the platinum

mesh as a counter electrode, and a saturated calomel electrode

SCE as the reference electrode. Solutions were prepared from bidistilled water. The electrode potential was allowed to stabilize for

60 min before starting the measurements. All experiments were conducted at 25C. The electrolyte solution was made from analytical

reagent grade HCl.

The electrodes were arranged in such a way that a onedimensional potential field existed over the WE surface in solution.

To get an impression about the process that occurred at the iron/acid

interface, Tafel curves were obtained by changing the electrode potential automatically from 250 to + 250 mVSCE vs open-circuit

potential with a scan rate of 1 mV/s. Also, EIS measurements were

carried out in a frequency range of 10040 mHz with an amplitude

of 10 mV peak to peak using ac signals at open-circuit potential.

EFM was carried out using frequencies of 2 and 5 Hz. The base

frequency was 1 Hz, so the waveform repeats after 1 s. The higher

frequency must be at least two times the lower one. The higher

frequency must also be sufficiently slow that the charging of the

double layer does not contribute to the current response. Often,

10 Hz is a reasonable limit. In this study, we use a perturbation

signal with an amplitude of 10 mV for both perturbation frequencies

of 2 and 5 Hz. The choice for the frequencies of 2 and 5 Hz was

based on three arguments.18 First, the harmonics and intermodulation frequencies should not influence each other. Second, the frequency should be as low as possible to avoid influence of the capacitive behavior of the electrochemical double layer. Third, the

frequency should be as large as possible to reduce time needed to

perform a measurement. While these arguments do not allow the

selection of perfect frequencies, the chosen frequencies were considered as reasonable compromise.

Measurements were performed with a Gamry potentiostat/

galvanostat/ZRA. This includes a Gamry framework system based

on the ESA400, Gamry applications that include DC105 for dc corrosion measurements, EIS300 for EIS measurements, and EFM140

to calculate the corrosion current and the Tafel constants along with

a computer for collecting the data. Echem Analyst 4.0 software was

used for plotting, graphing, and fitting data.

Gravimetric experiments were carried out in a double glass cell

equipped with a thermostated cooling condenser. The solution volume was 100 mL. The iron specimens used have a rectangular form

length = 2 cm, width = 1 cm, and thickness = 0.06 cm with an

exposed surface area of 4.36 cm2. The duration of tests was 6 h at

25 1C. Duplicate experiments were performed in each case, and

the two values obtained are very similar so the mean value of the

weight loss is reported. The weight loss allowed the calculation of

the mean corrosion rate in g cm2 h1.

C117

40

20

10

20

30

40

50

60

Z'/ cm

Figure 1. Impedance spectra recorded at different times of immersion of the

mild steel WE in 1 M HCl.

60 min exposure. Rp is determined from the real part of the complex

plane impedance diagram Nyquist plot because it is defined by

2

Rp = lim Zre

0

where Zre is the real part of the Nyquist plots, is the frequency in

radians, and Zre is the real part of faradaic impedance.22 Therefore,

at tending to 0, the imaginary part of the impedance Zimg 0,

while the real one Zre Rp + Rs, where Rs is the ohmic resistance

of the solution and the electrical leads. The fitted results derived

using the corresponding equivalent circuit, which is described later,

are presented in Table I.

Inspection of Fig. 1 and 2 shows that the initial dissolution of the

WE depends to a great extent on the electrodes preliminary treatment. At the beginning of the experiment, the dissolution process is

the greatest on the sharp edges of the WE, then the corrosion rate

decreases with time due to the formation of the corrosion products

and the depletion of the sharp edges that were found in the beginning. When all of these processes have taken place, the dissolution

rate is predominantly determined by the metals nature and the experimental conditions.23 Then the preliminary treatments effect

should not essentially affect the process any longer. The polarization

resistance decreases as the time of immersion increases after 1 h

Fig. 2. The corrosion products, which result from the dissolution of

70

Computational Details

60

Rp / cm2

The Discover molecular dynamics module in Materials Studio

4.3 software from Accelrys Inc.19 allows selecting a thermodynamic

ensemble and the associated parameters, defining simulation time

and temperature and pressuring and initiating a dynamics calculation. The molecular dynamics simulation procedures have been described in detail elsewhere.20,21

30 min.

60 min.

120 min.

240 min.

50

40

Results and Discussion

EIS measurements. Effect of exposure time in 1 M HCl solution. The effect of the exposure time of a mild steel WE in 1 M

HCl on the EIS spectra was studied. The results obtained provided

the determination of the WE exposure time. EIS was recorded after

exposures of 30, 60, 120, and 240 min. The results are presented in

Fig. 1. It is seen that the diameter of the impedance semicircle

depends on the duration of the WE exposure in the acid solution.

Figure 2 illustrates the variation in the polarization resistance Rp

with the exposure time t. It passes through a maximum at about

30

20

50

100

150

200

250

300

Time / min.

Figure 2. Dependence of polarization resistance Rp on the immersion time in

1 M HCl.

Downloaded 18 Mar 2010 to 202.170.57.251. Redistribution subject to ECS license or copyright; see http://www.ecsdl.org/terms_use.jsp

Journal of The Electrochemical Society, 157 3 C116-C124 2010

C118

300

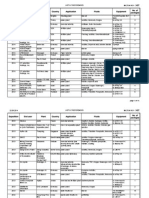

Table I. Fitted parameters for iron in 1 M HCl after different

immersion times at 25C derived using equivalent circuit in Fig.

5a.

Immersion

time

min

250

Blank

5 mM ETF

10 mM ETF

15 mM ETF

20 mM ETF

30

60

120

240

Rs

cm2

CPE/Y 0

F cm2

25

60

30

22

0.40

0.35

0.39

0.52

600

580

630

700

0.82

0.84

0.85

0.81

-Z"/ cm2

200

Rp

cm2

150

100

50

0

mild steel in HCl, start to form on the electrode surface as soon as

the electrode immersed in the corrosive media. Their amount is insignificant, and besides, they have no protective properties. However, they could affect to a certain extent the impedance investigations at longer exposure time of the WE. Thus it was found

experimentally that 1 h exposure under the conditions stated above

was the compromise duration in view of minimization of the effect

of the electrodes preliminary treatment and of the corrosion products.

Effect of concentrations of furan derivatives. The effect of the

concentration of the studied furan derivatives was studied from

5 to 20 mM in 1 M HCl solutions at 25C 1. Organic compounds are known to yield unreliable and irreproducible results for

concentrations higher than 20 mM.24,25 For the same reasons, the

present work tests the compounds only up to a concentration of

20 mM, employing concentration intervals of 5 mM. Several factors

determine the appropriate inhibitor concentration in corrosion inhibition studies. Solubility of the inhibitor in the corrosive medium is

one of the key factors in determining the optimum concentrations.

No significant increase in the IE is obtained for the studied inhibitors above 20 mM. In the presence of methyl 2-furoate MEF and

ethyl 2-furoate ETF in the whole concentration range, the electro300

Blank

5 mM MEF

10 mM MEF

15 mM MEF

20 mM MEF

250

-Z"/ cm2

200

150

50

100

150

50

0

0

50

100

150

200

250

300

Z'/ cm2

Figure 3. Measured and simulated complex plane impedance plots of mild

steel corrosion in 1 M HCl solutions at Ecorr in the absence and presence of

MEF at 25C.

250

300

350

Figure 4. Measured and simulated complex plane impedance plots of mild

steel corrosion in 1 M HCl solutions at Ecorr in the absence and presence of

ETF at 25C.

chemical impedance spectra in Nyquist plots are characterized by

one semicircle, which its center lies under the real axis Fig. 3 and

4. The quantitative analysis of the electrochemical impedance spectra was studied based on a physical model of the corrosion process

with hydrogen depolarization and with charge-transfer controlling

step. The simplest model includes the polarization resistance Rp in

parallel to the constant phase element CPE connected with the

solution resistance Rs. The solid electrode is inhomogeneous both on

a microscopic and a macroscopic scale, and corrosion is a uniform

process with fluctuating active and inactive domains where anodic

and cathodic reactions take place at the corroding surface. The size

and distribution of these domains depend on the degree of surface

inhomogeneities.

Inhomogeneities may also arise from adsorption phenomena and

formation of porous and nonporous layers by passivation on

coating.26-28 For this reason the frequency distributed CPE was used

instead of the capacitance of the double layer Cdl at the mild steel/

solution interface. More generally, the CPE behavior could be

treated as a space fractality, i.e., as manifestation of a selfsimilarity in the frequency domain.29 The CPE impedance is given

by26,27,30,31

ZCPE =

100

200

Z'/ cm2

1

inA

where A is a proportionality coefficient and n has the meaning of the

phase shift, which value can be considered as a measure of the

surface inhomogeneity.26,30,32,33 The transfer function is thus represented by an equivalent circuit, having only one time constant Fig.

5a. Parallel to the double layer capacitance modeled by a CPE is

the polarization resistance Rp, Rs being the electrolyte resistance.

The fitted parameter values are presented in Tables II and III, while

the calculated curves, using this parameter set, are presented in Fig.

3 and 4 as solid lines.

Figure 5. Color online Equivalent circuits used to model impedance data in

1 M HCl solutions.

Downloaded 18 Mar 2010 to 202.170.57.251. Redistribution subject to ECS license or copyright; see http://www.ecsdl.org/terms_use.jsp

Journal of The Electrochemical Society, 157 3 C116-C124 2010

C119

Table II. Fitted parameters for iron in 1 M HCl in the absence and presence of various concentrations of MEF at 25C derived using equivalent

circuit in Fig. 5a.

MEF

Conc

Rp

cm2

Rs

cm2

CPE/Y 0

F cm2

IEi

%

Blank

60

0.35

580

0.84

5 mM

10 mM

15 mM

20 mM

93

114

157

261

0.6

0.65

0.63

0.7

30

28

27

22

0.76

0.78

0.81

0.83

35.48

47.36

61.78

77.01

In amyl 2-furoate AMF, an additional time constant becomes

visible, very well expressed in the Nyquist presentation Fig. 6. In

this case, it is possible to separate the processes of the double layer

charging and of the adsorption pseudocapacitance. It is clear that for

AMF, the structural model of Fig. 5a is inadequate and a two-timeconstant model Fig. 5b is used to describe the electrochemical

impedance spectra. The fitted parameters are presented in Table IV

and the calculated curves are presented in Fig. 6 as solid lines. This

model is valid for all concentrations of AMF. It can be seen that the

values of Rp are highly increased when the description is changed

from the one-constant model to the two-constant one. The values of

polarization resistance in AMF are composed of two components:

the charge-transfer resistance and the inhibitor film resistance Rf.

ing that the addition of furan derivatives reduces the anodic dissolution and also retards the cathodic hydrogen evolution reaction.

From Tafel curves in Fig. 7-9, it is clear that both anodic metal

dissolution and cathodic reduction reactions were inhibited when the

furan derivatives were added to the acid solution and this inhibition

was more pronounced with increasing inhibitor concentration. The

cathodic polarization curves give rise to parallel Tafel lines with the

nearly constant cathodic Tafel slopes c, indicating that the addition of inhibitor to the aggressive solution does not modify the proton reduction mechanism and this reaction is activation controlled.36

The inhibitor is first adsorbed onto iron surface and then impedes by

merely blocking the active sites of iron surface. In this way, the

surface area available for H+ ions is decreased, while the actual

reaction mechanism remains unaffected.36

Tafel polarization measurements. Polarization measurements

have been carried out to gain knowledge concerning the kinetics of

the anodic and cathodic reactions. Polarization curves of the mild

steel in 1 M HCl solutions without and with addition of different

concentrations of furan derivatives are shown in Figs. 7-9. The anodic and cathodic current-potential curves are extrapolated up to

their intersection at a point where corrosion current density jcorr

and corrosion potential Ecorr are obtained.34 The values of associated electrochemical parameters, i.e., corrosion potential Ecorr, corrosion current density jcorr, cathodic Tafel slopes c, anodic

Tafel solpes a, and percentage IE IEp % values, were calculated from polarization curves and listed in Table V. The IE IEp

% was calculated from corrosion current density measurements

according to the relation given below

IEp % =

0

jcorr

jcorr

0

jcorr

100

EFM. Figure 10 shows a plot of current density

jfrequency f that was obtained by fast Fourier transform from

the experimental current jtime t data determined with EFM on

iron after 1 h immersion in 1 M HCl solutions. The data in Fig. 10

were analyzed assuming that the cathodic reaction was under activation control. The EFM data were calculated for the studied system

and presented in Table VI. The electrochemical parameters presented in Table VI include corrosion current density jcorr, Tafel

slopes a,c, and causality factors CF-2 and CF-3, which act as

an internal check for the validity of EFM data. Inspections of these

data conclude that the values of causality factors obtained under

different experimental conditions are approximately equal to the theoretical values of 2 and 3, indicating that the measured data are of

high quality.37-40

As can be seen from Table VI, the corrosion current densities

decrease by increasing the concentrations of furan derivatives.

The IEs EEFM % calculated from Eq. 5 increase by increasing

furan derivative concentrations

0

and jcorr are uninhibited and inhibited corrosion current

where jcorr

densities, respectively. They are determined by extrapolation of

Tafel lines to the respective corrosion potentials. It is shown from

Figs. 7-9 that increasing the furan derivative concentrations reduces

both the cathodic and the anodic currents, and there is no definite

trend in the shift of Ecorr values. These results indicate that all furan

derivatives act as mixed-type inhibitors.35

Based on the marked decrease in the cathodic and anodic current

densities upon introducing the inhibitor in the aggressive solution,

furan derivatives can be considered as a mixed-type inhibitor, mean-

IEEFM % =

0

jcorr

jcorr

0

jcorr

100

0

where jcorr

and jcorr are the corrosion current densities in the absence

and presence of furan derivatives, respectively. As can be seen from

Table VI, as the inhibitor concentration increases, the inhibition increases up to 86% with the addition of 20 mM from AFM inhibitor.

Table III. Fitted parameters for iron in 1.0 M HCl in the absence and presence of various concentrations of ETF at 25C derived using

equivalent circuit in Fig. 5a.

ETF

Conc

Rp

cm2

Rs

cm2

CPE/Y 0

F cm2

IEi

%

Blank

60

0.35

580

0.84

5 mM

10 mM

15 mM

20 mM

106

134

194

286

1.2

1.5

2.3

1.9

10

8

6

2

0.83

0.81

0.79

0.80

43.39

55.22

69.07

79.02

Downloaded 18 Mar 2010 to 202.170.57.251. Redistribution subject to ECS license or copyright; see http://www.ecsdl.org/terms_use.jsp

Journal of The Electrochemical Society, 157 3 C116-C124 2010

C120

-0.3

600

Blank

5 mM AMF

10 mM AMF

15 mM AMF

20 mM AMF

-Z"/ cm2

400

300

Blank

5 mM MEF

10 mM MEF

15 mM MEF

20 mM MEF

-0.4

E / VSCE

500

200

-0.5

-0.6

100

0

-0.7

100

200

300

400

Z'/ cm

500

600

700

1e-7

1e-5

1e-4

1e-3

1e-2

1e-1

j / A cm-2

Figure 6. Measured and simulated complex plane impedance plots of mild

steel corrosion in 1 M HCl solutions at Ecorr in the absence and presence of

AMF at 25C.

Weight loss measurements. Table VII shows the values of IE

and corrosion rate Wcorr obtained from weight loss measurements

at different concentrations of furan derivatives at 25C. From the

weight loss values, the IEw % of each concentration were calculated using the following equations41

1e-6

w0 w

IEw % =

100

w0

where w0 and w are the corrosion rates in the absence and presence

of inhibitors, respectively. It has been found that IE of all of these

compounds increases by increasing their concentrations. The maximum IE for each compound was achieved at 20 mM and a further

increase in concentration did not cause any appreciable change in

the performance of the inhibitors data not included.

In Fig. 11 comparison figures, the corrosion rates obtained with

four different techniques including potentiodynamic polarization

curve, EIS, EFM, and weight loss are compared. In general, the

corrosion rates determined with the EFM technique are much higher

than the values determined with other techniques, exhibiting low

corrosion rates.42 The results from EFM, EIS, and polarization curve

are integral averages of the data in the experimental period of 1 h.

As electrochemical techniques, the EFM technique gives a higher

corrosion rate than analysis of the potentiodynamic polarization

curve, EIS, and weight loss measurements because the entire frequency range of the EFM measurement cannot be low enough to be

in the dc limit region of the impedance spectrum. The corrosion

rates obtained with the electrochemical techniques are both lower

than that with weight loss method. The results obtained with the four

techniques are at the same order of magnitude and show the same

trend, which is acceptable. The corrosion rates determined with the

EFM technique for the mild steel/HCl system are reasonable and

Figure 7. Anodic and cathodic Tafel polarization curves for mild steel in the

absence and presence of various concentrations of MEF in 1 M HCl at 25C.

significant. Meanwhile, the EFM technique proves that it can be

implemented to measure corrosion rates in a simple, inexpensive

way.

Adsorption isotherm. The corrosion inhibition process is based

on the adsorption of the furan derivative molecules on the metal

surface. It is essential to know the mode of adsorption and the adsorption isotherm that fits the experimental results.

The most frequently used adsorption isotherms are Langmuir,

Temkin, and Frumkin with the general formula

7

f,xexp 2a = KC

where is the surface coverage, x is the number of water molecules

replaced by one inhibitor molecule, a is the lateral interaction between adsorbed molecules, K is the adsorption equilibrium constant,

and C is the inhibitor concentration.

Plots of the data for each isotherm showed that all of the investigated compounds agreed with the Langmuir isotherm Fig. 12 that

is given by43

C 1

=

+C

K

To calculate the surface coverage , it was assumed that the IE is

due mainly to the blocking effect of the adsorbed species and hence

IE % = 100.44

In this work, the surface coverage was calculated from the

relation IEEFM % = 100 using the IE calculated from the EFM

technique.

The value of K is related to the standard free energy of adsorption Gads by the following equation45

Table IV. Fitted parameters for iron in 1 M HCl in the absence and presence of various concentrations of AMF at 25C derived using equivalent

circuit in Fig. 5b.

Rp

cm2

AMF

5 mM

10 mM

15 mM

20 mM

Rct

cm2

Rf

cm2

Cf

F cm2

Rs

cm2

CPE/Y 0

F cm2

IEi

%

138

175

371

520

17

33

45

93

900 106

1.2 103

1.5 103

1.7 103

2.1

2.3

2.5

3.5

30

20

15

10

0.81

0.83

0.79

0.82

61.29

71.15

85.57

90.21

Downloaded 18 Mar 2010 to 202.170.57.251. Redistribution subject to ECS license or copyright; see http://www.ecsdl.org/terms_use.jsp

Journal of The Electrochemical Society, 157 3 C116-C124 2010

-0.3

Blank

5 mM ETF

10 mM ETF

15 mM ETF

20 mM ETF

E / VSCE

-0.4

-0.5

-0.6

-0.7

1e-7

1e-6

1e-5

1e-4

1e-3

1e-2

1e-1

j / A cm-2

Figure 8. Anodic and cathodic Tafel polarization curves for mild steel in the

absence and presence of various concentrations of ETF in 1 M HCl at 25C.

Gads

= RT ln55.5Kads

where R is the gas constant and T is the absolute temperature. The

value of 55.5 is the molar concentration of water in solution expressed in mol l1.

-0.3

Blank

5 mM AMF

10 mM AMF

15 mM AMF

20 mM AMF

E / VSCE

-0.4

-0.6

-0.7

1e-8

1e-7

1e-6

The values of adsorption constant, slope, and linear correlation

coefficient R2 can be obtained from the regressions between C/

and C, and the results are listed in Table VIII. The result shows that

all the linear correlation coefficients and all the slopes are close to 1

and confirm that the adsorption of furan derivatives in 1 M HCl

follows the Langmuir adsorption isotherm. The thermodynamic parameters for adsorption process obtained from Langmuir adsorption

isotherms for the studied furan derivatives are given in Table VIII.

The negative values of Gads 21.1, 21.6, and 23.2 for MEF,

ETF, and AMF, respectively and the higher values of K reveal the

spontaneity of the adsorption process and they are characteristic of

strong interaction and stability of the adsorbed layer with the steel

surface. The absolute value of the standard free energy of adsorption

Gads of the investigated furan derivatives follows the order

AMF ETF MEF.

Generally, the energy values of 20 kJ mol1 or less negative are

associated with an electrostatic interaction between charged molecules and charged metal surface physisorption; those of

40 kJ mol1 or more negative involve charge sharing or transfer

from the inhibitor molecules to the metal surface to form a coordinate covalent bond chemisorption.46 The calculated Gads value,

being closer to 20 kJ mol1, between the threshold values for

physical adsorption and chemical adsorption indicates that adsorption of furan derivatives on the steel surface involves the two types

of interaction.47

There are many limitations on the application of Langmuir adsorption isotherm for the analysis of inhibition phenomena and related data. Some of these limitations are discussed below.

Simple adsorption is applicable only under the following conditions.

1. The surface of the metal is homogeneous.

2. The adsorbate is specifically adsorbed, and each adsorbed

species occupies only a single site of the surface.

3. There is no surface diffusion of the adsorbed compound.

4. The standard free energy of adsorption is independent of the

degree of coverage.

-0.5

1e-9

C121

1e-5

1e-4

1e-3

1e-2

1e-1

j / A cm-2

Figure 9. Anodic and cathodic Tafel polarization curves for mild steel in the

absence and presence of various concentrations of AMF in 1 M HCl at 25C.

The Langmuir adsorption isotherm is somewhat idealized notwithstanding the fact that the adsorption may be highly selective

with electrode reaction and may be potential-dependent, and the

adsorbates may be competitive with water molecules. Adsorption

isotherms are nonetheless useful if the uninhibited corrosion current

is, in fact, proportional to the total number of sites that can possibly

Table V. Electrochemical parameters calculated from polarization measurements on the mild steel electrode in 1 M HCl solutions without and

with various concentrations of the three furan derivatives at 25C.

Inhib.

M

a

mV dec1

c

mV dec1

Blank

83.1

158.5

MEF

5 mM

10 mM

15 mM

20 mM

101.6

101.5

99.9

109.8

ETF

5 mM

10 mM

15 mM

20 mM

AMF

5 mM

10 mM

15 mM

20 mM

Inhibitor

jcorr

A cm2

Ecorr

mVSCE

IEp

%

768

498

147.3

217

180.1

165.5

539

437

315

207.0

533

506

535

549

29.82

43.09

58.98

73.04

105.3

108.4

99.5

103.4

150.7

154.3

139.5

150.2

499

393

301.0

194

531

541

545

544

35.03

48.83

60.81

74.74

92.4

100.6

97.2

79.5

134.5

159.9

133.1

122.1

370.0

270.0

185.0

108

541

544

552

538

51.82

64.84

75.91

85.94

Downloaded 18 Mar 2010 to 202.170.57.251. Redistribution subject to ECS license or copyright; see http://www.ecsdl.org/terms_use.jsp

C122

Journal of The Electrochemical Society, 157 3 C116-C124 2010

Figure 10. Color online Intermodulation spectrum for mild steel in 1 M HCl in the absence and presence of various concentrations of furan derivatives at

25C.

adsorb inhibition. This, however, is not necessarily so, as it is known

that a substantial corrosion rate is often observed at the saturation

coverage of the inhibitor.

In this paper, such discussions cannot be supported with detailed

experimental data, which would be beyond the scope of this work.

Such analysis would involve a detailed study employing transient

experiments, in addition to the present dc and ac study. Moreover, it

could require some spectroscopic measurements, X-ray analysis, or

a combination of these techniques. Thus, it should be stressed at this

stage that the following discussion is mainly qualitative and, to a

significant degree, speculative.

The tested furan derivatives showed a good capacity to inhibit

the corrosion of mild steel for the tested range of the concentration.

They inhibited the corrosion reactions of the substrate active sites by

covering them with one or more of the interface adsorbing modes

mentioned previously to form a protective layer of these molecules.

The coverage of inhibitor particles may come out by adsorption

chemisorption, with electron donating or sharing of the polar function of the inhibitors, rather than van der Waals forces physisorption, which are known to be reversible and do not yield an effective

interface inhibition.

It is believed that even if a complexation takes place between

these compounds and the corrosion products or intermediates, it will

be with weak formation forces and hardly affecting bonding forces,

holding the surface atoms in the metal lattice and thus, the possibility of catalyzed reactions is very limited.

Understanding the adsorption phenomena is of key importance in

corrosion problems. Monte Carlo simulations help in finding the

most stable adsorption sites on metal surfaces through finding the

low energy adsorption sites on both periodic and nonperiodic substrates or to investigate the preferential adsorption of mixtures of

adsorbate components.

Adsorption energy as well as several outputs and descriptors calculated by the Monte Carlo simulation are presented in Table IX.

The parameters presented in Table IX include total energy, in

kJ mol1, of the substrateadsorbate configuration. The total energy

is defined as the sum of the energies of the adsorbate components,

the rigid adsorption energy, and the deformation energy. In this

study, the substrate energy iron surface is taken as zero. In addition, the adsorption energy, in kJ mol1, reports the energy released

or required when the relaxed adsorbate components furan derivatives are adsorbed on the substrate. The adsorption energy is defined as the sum of the rigid adsorption energy and the deformation

energy for the adsorbate components. The rigid adsorption energy

reports the energy, in kJ mol1, released or required when the un-

Downloaded 18 Mar 2010 to 202.170.57.251. Redistribution subject to ECS license or copyright; see http://www.ecsdl.org/terms_use.jsp

Journal of The Electrochemical Society, 157 3 C116-C124 2010

C123

Table VI. Electrochemical parameters calculated from EFM measurements on mild steel electrode in 1 M HCl solutions without and with

various concentrations of the three furan derivatives at 25C.

Concentration

M

jcorr

A cm2

a

mV dec1

c

mV dec1

CF-2

mV dec1

CF-3

mV dec1

IEEFM

%

Blank

734.89

83

126

1.99

2.89

MEF

5 mM

10 mM

15 mM

20 mM

488.11

394.89

303.87

231.94

91

93

109

101

131

127

136

141

1.89

1.99

2.01

1.97

2.96

2.89

2.96

3.01

33.58

46.26

58.65

68.44

ETF

5 mM

10 mM

15 mM

20 mM

447.00

350.11

266.44

190.76

110

115

111

112

151

139

153

148

1.96

2.02

1.98

1.89

2.99

2.96

2.89

2.88

39.17

52.36

63.74

74.04

AMF

5 mM

10 mM

15 mM

20 mM

331.76

235.61

170.28

99.82

90

93

98

101

133

142

146

152

1.76

1.85

1.98

1.89

2.95

2.94

2.29

3.00

54.85

67.94

76.83

86.42

Concentration

M

Corrosion rate

mg cm2 h1

IEw

%

Blank

4.95

MEF

5 mM

10 mM

15 mM

20 mM

2.98

2.517

1.81

0.93

39.79

49.15

63.43

81.21

ETF

5 mM

10 mM

15 mM

20 mM

2.70

2.00

1.22

0.76

45.45

59.59

75.35

84.64

5 mM

10 mM

15 mM

20 mM

1.33

1.03

0.58

0.33

73.13

79.19

88.28

93.33

Inhibitor

AMF

80

Inhibition Efficiency / %

Table VII. Corrosion rate (in g cm2 h1) and IE values obtained

from weight loss measurements for mild steel in 1 M HCl solutions without and with various concentrations of furan derivatives at 25C.

100

EFM

EIS

Polarization

Weight loss

60

40

20

MEF

ETF

AMF

Furan Derivatives

Figure 11. Comparison of IE obtained in the presence of 20 mM of the furan

derivatives by using EFM, EIS, Tafel polarization, and weight loss measurements at 25C.

0.035

0.030

MEF

ETF

AMF

0.025

C/ (M)

relaxed adsorbate components i.e., before the geometry optimization step are adsorbed on the substrate. The deformation energy

reports the energy, in kJ mol1, released when the adsorbed adsorbate components are relaxed on the substrate surface. Table I also

shows dEads /dNi, which reports the energy, in kJ mol1, of

substrateadsorbate configurations where one of the adsorbate components has been removed.

As can be seen from Table IX, AMF gives the maximum adsorption energy in a negative value found during the simulation process.

0.020

0.015

Table VIII. Thermodynamic parameters for the adsorption of

furan derivatives in 1 M HCl on the mild steel at 25C.

Inhibitor

Slope

K

M1

R2

Gads

kJ mol1

MEF

ETF

AMF

0.939

0.943

0.937

90.19

113.53

203.92

0.979

0.989

0.999

21.1

21.6

23.2

0.010

0.005

0.004

0.006

0.008

0.010

0.012

0.014

0.016

0.018

0.020

0.022

C (M)

Figure 12. Langmuir adsorption plots for mild steel in 1 M HCl in various

concentrations of furan derivatives at 25C.

Downloaded 18 Mar 2010 to 202.170.57.251. Redistribution subject to ECS license or copyright; see http://www.ecsdl.org/terms_use.jsp

C124

Journal of The Electrochemical Society, 157 3 C116-C124 2010

Table IX. Outputs and descriptors calculated by the Monte Carlo simulation for adsorption of furan derivatives on iron (100).

Inhibitor

MEF

ETF

AMF

Total energy

kJ mol1

Adsorption energy

kJ mol1

Rigid

adsorption

energy

kJ mol1

176.3

192.51

210.32

26.32

28.63

32.15

25.12

27.83

31.52

High values of adsorption energy obtained in AMF molecules explain its highest IE. From the molecular structure of iron, it is evident that the unoccupied d-orbital exhibits a tendency to obtain the

electron. The furan derivative, which is discussed in the present

work, has many lone-pair electrons containing atoms on oxygen

atoms, making it possible to provide electrons to the unoccupied

orbitals of iron, to form a stable coordination type of bond. Therefore, the studied molecules are likely to adsorb on the iron surface to

form stable adlayers and protect iron from corrosion.

Conclusions

The IEs of the three inhibitors obtained from weight loss, potentiodynamic polarization, and impedance methods well agree with

those obtained from the EFM technique.

Potentiodynamic polarization studies have shown that furan derivatives act as mixed-type inhibitors, and their inhibition mechanism is adsorption. Data obtained from EIS measurements were analyzed to model the corrosion inhibition process through appropriate

equivalent circuit model; a CPE has been used.

The adsorption of furan derivatives on the steel surface in 1 M

HCl solution was found to obey Langmuirs adsorption isotherm

with a negative value of the free energy of adsorption Gads

.

Monte Carlo simulation technique incorporating molecular mechanics and molecular dynamics can be used to simulate the adsorption of furan derivatives on the iron 110 surface in 1 M HCl.

References

1. S. A. Ali, M. T. Saeed, and S. V. Rahman, Corros. Sci., 45, 253 2003.

2. K. C. Emregul and O. Atakol, Corros. Sci., 82, 188 2003.

3. M. Lagrenee, B. Mernari, M. Bouanis, M. Traisnel, and F. Bentiss, Corros. Sci.,

44, 573 2002.

4. M. Elayyachi, A. El Idrissi, and B. Hammouti, Corros. Sci., 48, 2479 2006.

5. K. Babic-Samardzija, K. F. Khaled, and N. Hackerman, Anti-Corros. Methods

Mater., 52, 11 2005.

6. K. F. Khaled, K. Babic-Samardzija, and N. Hackerman, Electrochim. Acta, 50,

2515 2005.

7. K. F. Khaled and N. Hackerman, Electrochim. Acta, 49, 485 2004.

8. K. F. Khaled and N. Hackerman, Electrochim. Acta, 48, 2715 2003.

9. K. F. Khaled, Electrochim. Acta, 48, 2493 2003.

10. K. Aramaki and N. Hackerman, J. Electrochem. Soc., 105, 1007 1968.

11. K. Aramaki and N. Hackerman, J. Electrochem. Soc., 106, 568 1969.

12. N. Hackerman and K. M. Hurd, in Corrosion Inhibition and Molecular Structure,

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

Deformation

energy

kJ mol1

dEads /dNi

kJ mol1

1.2

0.8

0.83

26.32

28.63

32.15

First International Congress on Metallic Corrosion, Butterworth, London, p. 166

1962.

A. C. Makrides and N. Hackerman, Ind. Eng. Chem., 46, 523 1954.

H. Vaidyanathan and N. Hackerman, Corros. Sci., 1, 737 1971.

K. F. Khaled, Electrochim. Acta, 53, 3484 2008.

F. M. Donahue, A. Akiyama, and K. Nose, J. Electrochem. Soc., 114, 1006 1967.

A. Mitra, Indian J. Chem., 15A, 451 1977.

R. W. Bosch, J. Hubrecht, W. F. Bogaerts, and B. C. Syrett, Corrosion (Houston),

57, 60 2001.

J. Barriga, B. Coto, and B. Fernandez, Tribol. Int., 40, 960 2007.

K. F. Khaled and M. A. Amin, Corros. Sci., 51, 1964 2009.

K. F. Khaled and M. A. Amin, Corros. Sci., 51, 2098 2009.

W. J. Lorenz and F. Mansfeld, Corros. Sci., 21, 647 1981.

A. Popova, S. Raicheva, E. Sokolova, and M. Christov, Langmuir, 12, 2083

1996.

B. Donnelly, T. C. Downie, R. Grzeskowiak, H. R. Hamburg, and D. Short, Corros.

Sci., 18, 109 1978.

G. Trabanelli, in NACE International Corrosion Conference, on Corrosion Inhibition, Dallas, Texas, p. 144 1983.

Z. B. Stoynov, B. M. Grafov, B. Savova-Stoynova, and V. V. Elkin, Electrochemical Impedance, Nauka, Moscow 1991.

K. Juttner, Electrochim. Acta, 10, 1501 1990.

J. Pang, A. Briceno, and S. Chander, J. Electrochem. Soc., 137, 3447 1990.

Z. Stoynov, Electrochim. Acta, 35, 1493 1990.

F. B. Growcock and R. J. Jasinski, J. Electrochem. Soc., 136, 2310 1989.

J. R. Macdonald, J. Electroanal. Chem. Interfacial Electrochem., 223, 25 1987.

D. A. Lopez, S. N. Simison, and S. R. Sanchez, Electrochim. Acta, 48, 845 2003.

U. Rammelt and G. Reinhard, Corros. Sci., 27, 373 1987.

F. Bentiss, M. Traisnel, H. Vezin, and M. Lagrene, Ind. Eng. Chem. Res., 39,

3732 2000.

H. Amar, A. Tounsi, A. Makayssi, A. Derja, J. Benzakour, and A. Outzourhit,

Corros. Sci., 49, 2936 2007.

R. Solmaz, G. Karda, B. Yazc, and M. Erbil, Colloids Surf., A, 312, 7 2008.

S. S. Abdel-Rehim, K. F. Khaled, and N. S. Abd-Elshafi, Electrochim. Acta, 51,

3269 2006.

K. F. Khaled, Mater. Chem. Phys., 112, 104 2008.

K. F. Khaled, J. Appl. Electrochem., 39, 429 2009.

K. F. Khaled, Mater. Chem. Phys., 112, 290 2009.

P. Li, J. Y. Lin, K. L. Tan, and J. Y. Lee, Electrochim. Acta, 42, 605 1997.

E. Kus and F. Mansfeld, Corros. Sci., 48, 965 2006.

M. Christov and A. Popova, Corros. Sci., 46, 1613 2004.

E. Machnikova, K. H. Whitmire, and N. Hackerman, Electrochim. Acta, 53, 6024

2008.

M. Z. A. Rafiquee, N. Saxena, S. Khan, and M. A. Quraishi, Mater. Chem. Phys.,

107, 528 2008.

E. Kamis, F. Bellucci, R. M. Latanision, and E. S. H. El-Ashry, Corrosion (Houston), 47, 677 1991.

M. Behpour, S. M. Ghoreishi, N. Soltani, M. Salavati-Niasari, M. Hamadanian, and

A. Gandomi, Corros. Sci., 50, 2172 2008.

Downloaded 18 Mar 2010 to 202.170.57.251. Redistribution subject to ECS license or copyright; see http://www.ecsdl.org/terms_use.jsp

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- A Mine LevelsDokument5 SeitenA Mine LevelsMarcTimNoch keine Bewertungen

- So Kero L Tech ReportDokument8 SeitenSo Kero L Tech ReportMarcTimNoch keine Bewertungen

- 2444 102611Dokument147 Seiten2444 102611anirbanbhowmick88Noch keine Bewertungen

- Watermath Corrosivity Estimator Limited2Dokument5 SeitenWatermath Corrosivity Estimator Limited2MarcTimNoch keine Bewertungen

- WTAnalyser - Filtration v3.2Dokument291 SeitenWTAnalyser - Filtration v3.2MarcTimNoch keine Bewertungen

- Boiler Film Forming Amines Hydrocarbon Engineering Sept2015Dokument5 SeitenBoiler Film Forming Amines Hydrocarbon Engineering Sept2015MarcTimNoch keine Bewertungen

- Describe: Characterize: Group: Organize: Systematize: System: Classify: Class: Category: Kind: Type: Methodology: Scheme: TaxonomyDokument7 SeitenDescribe: Characterize: Group: Organize: Systematize: System: Classify: Class: Category: Kind: Type: Methodology: Scheme: TaxonomyMarcTimNoch keine Bewertungen

- Mats Hanson 09 HG Index A CompleteDokument643 SeitenMats Hanson 09 HG Index A CompleteMarcTimNoch keine Bewertungen

- CEAlertBrochure3 Latest Eg Main 017276Dokument6 SeitenCEAlertBrochure3 Latest Eg Main 017276MarcTimNoch keine Bewertungen

- Chemical Technopark of Sverdlovsk region: on the base of Open Joint Stock Company «Uralсhimplast»Dokument21 SeitenChemical Technopark of Sverdlovsk region: on the base of Open Joint Stock Company «Uralсhimplast»MarcTimNoch keine Bewertungen

- Israel Corporation LTD.: (Unaudited)Dokument189 SeitenIsrael Corporation LTD.: (Unaudited)MarcTimNoch keine Bewertungen

- Reference List MPTDokument14 SeitenReference List MPTAnonymous ItzBhUGoiNoch keine Bewertungen

- NPCDokument29 SeitenNPCMarcTimNoch keine Bewertungen

- Chemical Cleaning of Refinery and Petrochemical Distillation EquipmentDokument6 SeitenChemical Cleaning of Refinery and Petrochemical Distillation EquipmentMarcTimNoch keine Bewertungen

- Rapports Salle Des F TesDokument180 SeitenRapports Salle Des F TesMarcTimNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Ad1 MCQDokument11 SeitenAd1 MCQYashwanth Srinivasa100% (1)

- The Cognitive Enterprise For HCM in Retail Powered by Ibm and Oracle - 46027146USENDokument29 SeitenThe Cognitive Enterprise For HCM in Retail Powered by Ibm and Oracle - 46027146USENByte MeNoch keine Bewertungen

- Evidentiary Value of NarcoDokument2 SeitenEvidentiary Value of NarcoAdv. Govind S. TehareNoch keine Bewertungen

- Ar 2003Dokument187 SeitenAr 2003Alberto ArrietaNoch keine Bewertungen

- Contracts 2 Special ContractsDokument11 SeitenContracts 2 Special ContractsAbhikaamNoch keine Bewertungen

- Music 20 Century: What You Need To Know?Dokument8 SeitenMusic 20 Century: What You Need To Know?Reinrick MejicoNoch keine Bewertungen

- ASME-Y14.5.1M 1994 Mathematical Definition of Dimensioning and Tolerancing Principles PDFDokument89 SeitenASME-Y14.5.1M 1994 Mathematical Definition of Dimensioning and Tolerancing Principles PDFwulfgang66Noch keine Bewertungen

- Em - 1110 1 1005Dokument498 SeitenEm - 1110 1 1005Sajid arNoch keine Bewertungen

- Rita Ora - Shine Ya LightDokument4 SeitenRita Ora - Shine Ya LightkatparaNoch keine Bewertungen

- 25 ConstitutionDokument150 Seiten25 ConstitutionSaddy MehmoodbuttNoch keine Bewertungen

- Bagon-Taas Adventist Youth ConstitutionDokument11 SeitenBagon-Taas Adventist Youth ConstitutionJoseph Joshua A. PaLaparNoch keine Bewertungen

- MSDS PetrolDokument13 SeitenMSDS PetrolazlanNoch keine Bewertungen

- DELA CRUZ - LAC 1 - 002 - Individual Learning Monitoring Plan - Bugtongnapulo INHSDokument2 SeitenDELA CRUZ - LAC 1 - 002 - Individual Learning Monitoring Plan - Bugtongnapulo INHSGilbert Dela CruzNoch keine Bewertungen

- Multiple Linear RegressionDokument26 SeitenMultiple Linear RegressionMarlene G Padigos100% (2)

- India: SupplyDokument6 SeitenIndia: SupplyHarish NathanNoch keine Bewertungen

- Understanding Ui-Ux-By Harry Muksit - SDokument109 SeitenUnderstanding Ui-Ux-By Harry Muksit - Sgodzalli44100% (1)

- Final Box Design Prog.Dokument61 SeitenFinal Box Design Prog.afifa kausarNoch keine Bewertungen

- Stockholm KammarbrassDokument20 SeitenStockholm KammarbrassManuel CoitoNoch keine Bewertungen

- Crime Scene Manual FullDokument19 SeitenCrime Scene Manual FullMuhammed MUZZAMMILNoch keine Bewertungen

- LittorinidaeDokument358 SeitenLittorinidaeSyarif Prasetyo AdyutaNoch keine Bewertungen

- Syllabus For B.A. (Philosophy) Semester-Wise Titles of The Papers in BA (Philosophy)Dokument26 SeitenSyllabus For B.A. (Philosophy) Semester-Wise Titles of The Papers in BA (Philosophy)Ayan AhmadNoch keine Bewertungen

- The John Molson School of Business MBA 607 Final Exam June 2013 (100 MARKS)Dokument10 SeitenThe John Molson School of Business MBA 607 Final Exam June 2013 (100 MARKS)aicellNoch keine Bewertungen

- Tan vs. Macapagal, 43 SCRADokument6 SeitenTan vs. Macapagal, 43 SCRANikkaDoriaNoch keine Bewertungen

- Faringitis StreptococcusDokument16 SeitenFaringitis StreptococcusnurNoch keine Bewertungen

- AdvacDokument13 SeitenAdvacAmie Jane MirandaNoch keine Bewertungen

- Jordana Wagner Leadership Inventory Outcome 2Dokument22 SeitenJordana Wagner Leadership Inventory Outcome 2api-664984112Noch keine Bewertungen

- 4 Major Advantages of Japanese Education SystemDokument3 Seiten4 Major Advantages of Japanese Education SystemIsa HafizaNoch keine Bewertungen

- Ottley Sandra 2009Dokument285 SeitenOttley Sandra 2009Lucas Fariña AlheirosNoch keine Bewertungen

- Sop 2Dokument43 SeitenSop 2naveengargnsNoch keine Bewertungen

- "We Like": Rohit Kiran KeluskarDokument43 Seiten"We Like": Rohit Kiran Keluskarrohit keluskarNoch keine Bewertungen