Beruflich Dokumente

Kultur Dokumente

Active and Passive Fire Protection

Hochgeladen von

ApaLakamo AmanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Active and Passive Fire Protection

Hochgeladen von

ApaLakamo AmanCopyright:

Verfügbare Formate

22.10.

2009

International Conference on

Operational Safety of

Underground Facilities

06.-07. October 2009, Istanbul, Turkey

Active and passive fire

protection

which way should we go ?

General

starting

situation:

Busy traffic

tunnels with

passenger and

goods transport

Alfred Haack

STUVA, Cologne, Germany

ITA, Lausanne, Switzerland

Fire Catastrophes - Road

Mt. Blanc Tunnel (F/I)

24.03.1999

39 Fatalities

Tauerntunnel (A)

29.05.1999

12 Fatalities

Gotthardtunnel (CH)

24.10.2001

11 Fatalities

Fire Catastrophes - Metro

Hamburg S-Bahn (D)

08.04.1980

3 injured

London Metro (GB)

(Station Kings Cross)

18.11.1987

31 fatalities

Daegu Metro (South Korea)

Fire Catastrophes - Rail

Station Koblenz (D)

07.11.1983

No injured

Eurotunnel (F / GB)

18.11.1996

31 injured

Station Offenbach (D)

23.11.2001

No injured

Active and passive fire

protection

which way should we go?

This question given with the title

concerns technical,

operational, and commercial

matters as well!

18.02.2003

196 fatalities

22.10.2009

Basic reflection

Using effective measures against fire is

not at all a new idea!

Since many decades it is systematically

followed in the field of:

Industrial plants

Storage facilities

Warehouse departments

Public assembly places

Basic reflection

In contrast the combustible masses

in traffic tunnels are moving which

makes it more difficult to handle a

starting fire.

with combustible masses more or less

lying steadily in the same place

Basic reflection

Designing any industrial or commercial facility

raises immediately the question:

What is the best?

An active or a passive fire protection

or a combination of both?

Active Fire Protection

Fixed Fire Fighting Systems as:

Low or high pressure water mist

Sprinklers

Deluge systems

Advantages:

Avoidance of fire spreading

Improved accessibility of the fire place

Better protection of infrastructure

In industrial or commercial facilities

Disadvantages:

usually active fire protection measures are

Destratification of smoke layer

More complex equipment

Reduction of visibility

supplemented by passive ones.

Fixed Fire Fighting Systems

do not extinguish large fires

are often overestimated with regard to

their capability

BUT

slow down the fire development

reduce or avoid fire jump from

car to car

improve by that conditions for escape

better protection of infrastructure

22.10.2009

Fixed Fire Fighting Systems

Require:

precise and early detection

efficient localisation of fire

activation at right time

Fire Detection

To trace vehicle fire

fastly

reliably

Aiming at immediate

information of tunnel users

modification of tunnel operation

Basic Requirements to

Fixed Fire Fighting Systems

at any time functionable

reliable even under the rough

conditions of tunnel atmosphere

(moist and salty air, dust, soot)

acceptable investment costs

low maintenance costs

Easy to install and to use

Automatic Fire Suppression

Advantages of

water based systems:

Fire and smoke restricted to shorter

tunnel section

Cut down of fire jump from one

car to another

Cooling effect

22.10.2009

Automatic Fire Suppression

Problems of water based systems:

immediately reduced visibility

destratification of smoke

no or low efficiency for fires inside

vehicles

in special cases dangerous chemical

reactions

Automatic Fire Suppression

Automatic Fire Suppression

Australian experience:

Dutch experience:

in urban road tunnels with

- manned control center or

- video/automatic incident

detection facilitating precise

event location

no extinction of fire inside vehicle

to minimize fire growth

to reduce probability of flashover

reduced risk of fire propagation

immediate reduction of visibility

large amount of steam if fire

> 15 MW

22.10.2009

Automatic Fire Suppression

Japanese experience:

no fire extinction at all

cut down of fire jump from one car to

another

cooling effect for tunnel structure

no immediate activation to keep better

escape conditions

no promotion of sprinklers in tunnels

intended

Fixed fire suppression systems

world wide so far not often installed

intensive global discussion

regarding:

optimal time of activation

cost benefit effects

L-surF Project

Questions left with

Fixed Fire Fighting Systems

Is there any economic compensation

given with the investment for a FFFS

e.g. savings for ventilation?

What is the mutual impact of various

components of safety systems?

L-surF

Design Study for a Large Scale

Underground Research Facility on

Safety and Security

2005 2008

VSH (CH) + 5 partners

feasibility study to establish a panEuropean test facility

scientific and technological research

business plan for test programme

www.l-surf.org

Recent German research project

22.10.2009

Passive Fire Protection

Structural components of a tunnel as:

mineral boards or plasters

fire resistant concrete tunnel lining

enlarged concrete cover and additional

reinforcement layer

special perforated steel sheet

Advantages:

no operational maintenance

no failings

Mineral Boards and Plaster (1)

Fire protection

of tunnel lining

mineral cladding / mineral plaster

large covering and additional

reinforcement

perforated steel plates with foaming

coating

fire resistant concrete

Heating up of bars <

300C

Minimization of spalling

Mineral Boards and Plaster (2)

Advantages:

Disadvantages:

installation in already existing tunnels

larger excavation cross section

mostly no maintenance

longer construction time

no risk of failing in case of fire

risk for absorption of seapage water

causing loss of thermal insulation

capacity

risk of local falling down due to

increase of dead weight

22.10.2009

Mineral Boards and Plaster (3)

Disadvantages:

risk for corrosion of board fasteners

no visual access of lining for inspection

renewal after 25 to 30 years: 3 to

4 times during life cycle of a tunnel

risk of partial falling down due to

sucking and pressure load of fast trucks

Fire resistant Concrete

Special mix required:

maximum core group of aggregates

consisting of basaltic gravel

quarzite, no chalky aggregates

addition of 3 kg/m Polypropylene

fibres

quality class C 25/30

Fire resistant Concrete

several years research work by:

Hochtief AG (contractor)

TU Braunschweig, Germany

STUVA, Cologne, Germany

fire test 1200 C over 90 minutes

no severe spalling, locally restricted only

spalling depth less than 10 mm

22.10.2009

Fire resistant Concrete:

advantages during construction

omission of fire proof cladding

smaller excavated cross section

shorter construction time

sufficient fire protection already

during construction

simplier assembling of

tunnel installations

BUT

not applicable in existing tunnels

Fire resistant Concrete:

advantages during operation

free access for tunnel inspection

life cycle like for the tunnel

no problems caused by sucking

and pressure loads of fast trucks

problem-free tunnel cleaning

no problems with water seepage

low damage in case of vehicle

collision

nearly no spalling in case of fire

Enlarged concrete cover for

structural reinforcement

Requires additional layer of steel mat

set up towards the fire affected side

of the lining to reduce spalling

Disadvantages:

increase of costs

thicker lining

additional working step

Perforated

steel sheet with

foaming coating

22.10.2009

Passive Fire Protection

Passive Fire Protection

avoids structural disintegration

reduces spalling

meets only some of the important

objectives

BUT

BUT

does not prevent fire spreading

does not cause any cooling effect

gives no protection for persons and

vehicles

we need a holistic fire safety concept with:

Conclusion

Active and passive

fire protection

which way should we go?

best chances for a successful escape

optimum safety for tunnel users

use of all available technical options

We need an

efficient and balanced combination

of both!

Active fire protection measures can only

be complimentary to passive ones as

useful component in a holistic fire safety

concept!

This has proven to be very effective,

useful, and pragmatic in the field of

industrial and commercial facilities.

Many thanks for your

attention!

Das könnte Ihnen auch gefallen

- Appendix 7G Rational Fire Design ReportDokument21 SeitenAppendix 7G Rational Fire Design ReportRendani VeleNoch keine Bewertungen

- Sonic Pipe Inspection IntroductionDokument9 SeitenSonic Pipe Inspection IntroductionTim FrederickNoch keine Bewertungen

- NBC 2016-Vol-2 PDFDokument1.026 SeitenNBC 2016-Vol-2 PDFSaurabh GuptaNoch keine Bewertungen

- Exp 2017 - Effect of Aggregate Size On The Spalling of High-Strength Wall Panels Exposed To Hydrocarbon FiresDokument11 SeitenExp 2017 - Effect of Aggregate Size On The Spalling of High-Strength Wall Panels Exposed To Hydrocarbon FiresMaha Ass'ad100% (1)

- Concrete Tunnel Lining Fire Resistance and ProtectionDokument8 SeitenConcrete Tunnel Lining Fire Resistance and ProtectionMehdi BakhshiNoch keine Bewertungen

- Guidelines For The Provision of Refuge Chambers in Tunnels Under ConstructionDokument16 SeitenGuidelines For The Provision of Refuge Chambers in Tunnels Under Constructionovion_itaNoch keine Bewertungen

- Best Practices and Perspectives For Cross Connections in Twin-Tube Rail Tunnels PDFDokument10 SeitenBest Practices and Perspectives For Cross Connections in Twin-Tube Rail Tunnels PDFMacarena Arriagada AguilarNoch keine Bewertungen

- Case Study of Design For Noise Mitigation Measures For Public Housing Developments in Hong KongDokument31 SeitenCase Study of Design For Noise Mitigation Measures For Public Housing Developments in Hong KonghkfengxueNoch keine Bewertungen

- Engineering Solutions For Fire Truck AccesDokument21 SeitenEngineering Solutions For Fire Truck AccesRizalNoch keine Bewertungen

- Fire Resistance Study of Concrete in The Application of TunnelDokument9 SeitenFire Resistance Study of Concrete in The Application of Tunnelsagar jainNoch keine Bewertungen

- 3M Fire Stop Fire Protection Full Line BRO RevDDokument32 Seiten3M Fire Stop Fire Protection Full Line BRO RevDap00Noch keine Bewertungen

- Channel Tunnel. Advantages N SafetyDokument9 SeitenChannel Tunnel. Advantages N SafetyAkhilesh GojeNoch keine Bewertungen

- Fire Ratings of Masonry Walls - tcm68-1374563Dokument3 SeitenFire Ratings of Masonry Walls - tcm68-1374563ervikas34Noch keine Bewertungen

- Building & Construction - Fire Safety StandardsDokument2 SeitenBuilding & Construction - Fire Safety StandardsCarrie BradleyNoch keine Bewertungen

- Fire Detailing Guide For Non Combustable Masonry Structures 2015Dokument13 SeitenFire Detailing Guide For Non Combustable Masonry Structures 2015dalton wongNoch keine Bewertungen

- Safety in Railway TunnelsDokument12 SeitenSafety in Railway TunnelsIsmet Hizyolu100% (1)

- Fire Protection: Ac - 804 Advance Construction Techniques and ManagementDokument69 SeitenFire Protection: Ac - 804 Advance Construction Techniques and ManagementMegha ShahNoch keine Bewertungen

- Giorgio Micolitti - Regulations Guidelines For Fire Safe Design in Rail TunnelsDokument135 SeitenGiorgio Micolitti - Regulations Guidelines For Fire Safe Design in Rail TunnelsGiorgio Micolitti100% (5)

- Fire and Fire ExtinguisherDokument3 SeitenFire and Fire ExtinguisherRohan DhandNoch keine Bewertungen

- Safety in TunnelsDokument90 SeitenSafety in TunnelsNaveen Jaiswal100% (1)

- Eurocode 1998 PDFDokument2 SeitenEurocode 1998 PDFDanNoch keine Bewertungen

- Structural Fire Design According To EurocodesDokument56 SeitenStructural Fire Design According To EurocodesHenryNoch keine Bewertungen

- Calculating Masonry's Fire ResistanceDokument4 SeitenCalculating Masonry's Fire Resistancedarshanakp123Noch keine Bewertungen

- Dix Report - Burnley Tunnel Incident 2007Dokument182 SeitenDix Report - Burnley Tunnel Incident 2007ALARP (Arnold Dix)100% (1)

- 13 Fans For Metro Tunnel DesignDokument34 Seiten13 Fans For Metro Tunnel DesignYuttapong Supattaravong100% (1)

- Stability of An Immersed Tunnel in Offshore Conditions Under Deep Water Wave ImpactDokument8 SeitenStability of An Immersed Tunnel in Offshore Conditions Under Deep Water Wave ImpactRonald HeijmansNoch keine Bewertungen

- 2019 - 10-11 - Ventilation StudyDokument78 Seiten2019 - 10-11 - Ventilation StudyrodolfoNoch keine Bewertungen

- Boston Big Dig Highway Tunnel Leak Assessment ReportDokument36 SeitenBoston Big Dig Highway Tunnel Leak Assessment ReportWilliam R. Murrell, III100% (1)

- Fixed Fire Fighting Systems in Road TunnelsDokument70 SeitenFixed Fire Fighting Systems in Road TunnelsJose Gregorio Prada Rodriguez100% (1)

- CH 8 Water-Based Fire-Suppression Systems ForDokument25 SeitenCH 8 Water-Based Fire-Suppression Systems ForkesharinareshNoch keine Bewertungen

- Smoke Movement: FV 3002 Fire Protection EngineeringDokument48 SeitenSmoke Movement: FV 3002 Fire Protection EngineeringRaccoon Mr.Noch keine Bewertungen

- NBC107 Fire SafetyDokument10 SeitenNBC107 Fire SafetyManoj Paudel0% (1)

- Passive Fire Protection SystemDokument33 SeitenPassive Fire Protection Systemfayis u m100% (1)

- Undergound Fuel TanksDokument4 SeitenUndergound Fuel TanksMubashar SharifNoch keine Bewertungen

- Waterproofing TunnelsDokument12 SeitenWaterproofing TunnelsSharifah Normala100% (1)

- Kingspan Trapezoidal Roof KS1000 RW Installation Guide 012016 NZ enDokument2 SeitenKingspan Trapezoidal Roof KS1000 RW Installation Guide 012016 NZ envincent_devine777dNoch keine Bewertungen

- Lorient BrochureDokument28 SeitenLorient BrochureJerry Lee LiongsonNoch keine Bewertungen

- Safety On Railway TunnelsDokument80 SeitenSafety On Railway Tunnelsandcrisdanmat100% (1)

- Fire Doors-All Tech SheetsDokument16 SeitenFire Doors-All Tech SheetsSusheel JNoch keine Bewertungen

- Hilt I Fire Stop AmirDokument56 SeitenHilt I Fire Stop Amirromeojr sibullasNoch keine Bewertungen

- Geocell 6098Dokument31 SeitenGeocell 6098Akshay DesaiNoch keine Bewertungen

- Methods of Fire Protection of Steel StructuresDokument10 SeitenMethods of Fire Protection of Steel StructuresArbaz AhmedNoch keine Bewertungen

- Norwegian Road Tunnel 1Dokument31 SeitenNorwegian Road Tunnel 1hungNoch keine Bewertungen

- Fire Smoke DampersDokument2 SeitenFire Smoke DampersTrần Khắc ĐộNoch keine Bewertungen

- Introduction To Fr-Acp (Fire Retardant Aluminum Composite Panels)Dokument12 SeitenIntroduction To Fr-Acp (Fire Retardant Aluminum Composite Panels)Syed RaziuddinNoch keine Bewertungen

- Fire Norms: Codes of Practice and Bye LawsDokument36 SeitenFire Norms: Codes of Practice and Bye LawsRohan MittalNoch keine Bewertungen

- FIT Annex2 Technical Report Part 1 Design Fire ScenariosDokument161 SeitenFIT Annex2 Technical Report Part 1 Design Fire Scenariosbhuvaneshwaran85Noch keine Bewertungen

- F5 05 GD FFO Building Hydrant Systems DRAFT PDFDokument18 SeitenF5 05 GD FFO Building Hydrant Systems DRAFT PDFAlif Rahmat FebriantoNoch keine Bewertungen

- Rohit Ranjan 38, ProjectDokument124 SeitenRohit Ranjan 38, ProjectAman Jha100% (1)

- Evaluation and Repair of A Liquid Sulphur Holding TankDokument4 SeitenEvaluation and Repair of A Liquid Sulphur Holding TankChanFKNoch keine Bewertungen

- 101 170905 1031313131 Fire Briefing 30082017Dokument186 Seiten101 170905 1031313131 Fire Briefing 30082017Lee TaiNoch keine Bewertungen

- PRE - Fire Design and Eurocodes - M.johnson - 2010 - 0365Dokument61 SeitenPRE - Fire Design and Eurocodes - M.johnson - 2010 - 0365nebojsadj6411Noch keine Bewertungen

- Tender 1.2Dokument519 SeitenTender 1.2Luana ChanNoch keine Bewertungen

- Fire Truck Singapore RequirementDokument38 SeitenFire Truck Singapore RequirementyngranNoch keine Bewertungen

- Jack in Pile PDFDokument4 SeitenJack in Pile PDFlattmdyNoch keine Bewertungen

- Fire Protection For Structural SteelDokument8 SeitenFire Protection For Structural SteelcheckshinlNoch keine Bewertungen

- Fire Door CatalogDokument29 SeitenFire Door CatalogcharibackupNoch keine Bewertungen

- Soil CompactionDokument19 SeitenSoil CompactionArthNoch keine Bewertungen

- Presentation - Fire Safety - DSMDokument10 SeitenPresentation - Fire Safety - DSMDr AmirNoch keine Bewertungen

- Ducker - GAT - SpecifiersmaDokument109 SeitenDucker - GAT - SpecifiersmaKutty Kutty MalayaliNoch keine Bewertungen

- Telecommunication Switching Systems and Networks by Thiagarajan Viswanathan Manav Bhatnagar B00tqoystkDokument5 SeitenTelecommunication Switching Systems and Networks by Thiagarajan Viswanathan Manav Bhatnagar B00tqoystkKittu KumarNoch keine Bewertungen

- Diff BW CBO and RBODokument2 SeitenDiff BW CBO and RBORamreddy BollaNoch keine Bewertungen

- QAch 02Dokument13 SeitenQAch 02Rami Alnajjar100% (1)

- 3G Video Alarm System User Manual - V4.1Dokument25 Seiten3G Video Alarm System User Manual - V4.1Andres VilloutaNoch keine Bewertungen

- FSP 851Dokument3 SeitenFSP 851RICHINoch keine Bewertungen

- StetindDokument6 SeitenStetindGiovanniNoch keine Bewertungen

- Software Project Engineer in Richland Kennewick Pasco WA Resume Robert VeklotzDokument2 SeitenSoftware Project Engineer in Richland Kennewick Pasco WA Resume Robert VeklotzRobertVeklotzNoch keine Bewertungen

- APL APOLLO - Chaukhat - Catalogue A4 English - 04 03 2022 - Low ResDokument48 SeitenAPL APOLLO - Chaukhat - Catalogue A4 English - 04 03 2022 - Low ResarrsshaNoch keine Bewertungen

- Rectangular Tank SizingDokument8 SeitenRectangular Tank Sizingvofaith100% (16)

- CHAPTER 2 Eff Comm ModelsDokument9 SeitenCHAPTER 2 Eff Comm ModelsSubhash SoniNoch keine Bewertungen

- Tata MotorsDokument9 SeitenTata MotorsNaim Ahmed SisirNoch keine Bewertungen

- Chapter Two History and Vision of Digital LibrariesDokument16 SeitenChapter Two History and Vision of Digital LibrariesakliluNoch keine Bewertungen

- 4wd SystemDokument31 Seiten4wd SystemManuales Transmisiones AutomaticasNoch keine Bewertungen

- Civil Engineering Interview QuestionsDokument12 SeitenCivil Engineering Interview Questionsjadgug100% (1)

- Netbackup UsefulDokument56 SeitenNetbackup Usefuldnyan123Noch keine Bewertungen

- Operation Manual: Smart-UPS Uninterruptible Power SupplyDokument18 SeitenOperation Manual: Smart-UPS Uninterruptible Power SupplyHafeez AhmadNoch keine Bewertungen

- Flowable-Fill Final 03-2006Dokument22 SeitenFlowable-Fill Final 03-2006Hector Alberto Garcia LopezNoch keine Bewertungen

- Negative Skin Friction Aaron Budge Minnesota State UniversityDokument46 SeitenNegative Skin Friction Aaron Budge Minnesota State UniversityNguyễn Thành NhânNoch keine Bewertungen

- SAP ABAP ResumeDokument3 SeitenSAP ABAP Resumeshakti1392821Noch keine Bewertungen

- PowerMaxExpress V17 Eng User Guide D-303974 PDFDokument38 SeitenPowerMaxExpress V17 Eng User Guide D-303974 PDFSretenNoch keine Bewertungen

- Press Working OperationsDokument23 SeitenPress Working OperationsKanagaraj Ganesan100% (1)

- Full Marks: 50 Duration: 3 HoursDokument2 SeitenFull Marks: 50 Duration: 3 HoursK JaiswalNoch keine Bewertungen

- Installation & Stock Detail of Ignition Modules & Magnetos of Gas Compressor Units (All Fields)Dokument4 SeitenInstallation & Stock Detail of Ignition Modules & Magnetos of Gas Compressor Units (All Fields)Atiq_2909Noch keine Bewertungen

- X MGR Direct Fastening Technology Manual DFTM 2018 Product Page Technical Information ASSET DOC 2597885Dokument4 SeitenX MGR Direct Fastening Technology Manual DFTM 2018 Product Page Technical Information ASSET DOC 2597885arnoldNoch keine Bewertungen

- Ebara Pump Brochure DML-DMLFDokument15 SeitenEbara Pump Brochure DML-DMLFkutecoolNoch keine Bewertungen

- Indicsoft ProfileDokument13 SeitenIndicsoft ProfileMahmood AkhtarNoch keine Bewertungen

- Gpfsworkshop2010 Tutorial v17 2Dokument381 SeitenGpfsworkshop2010 Tutorial v17 2atretauNoch keine Bewertungen

- 1-Introduction To Process ControlDokument30 Seiten1-Introduction To Process ControlRazif Metta100% (4)

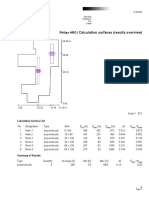

- Calculation Surfaces (Results Overview) : Philips HRODokument4 SeitenCalculation Surfaces (Results Overview) : Philips HROsanaNoch keine Bewertungen

- University of Wah Wah Engineering College Assignment # 05Dokument6 SeitenUniversity of Wah Wah Engineering College Assignment # 05Ha M ZaNoch keine Bewertungen