Beruflich Dokumente

Kultur Dokumente

Gold Jewellery Manufacturing Process: Step-1 Step-2 Step-3

Hochgeladen von

Siva KumarOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Gold Jewellery Manufacturing Process: Step-1 Step-2 Step-3

Hochgeladen von

Siva KumarCopyright:

Verfügbare Formate

Gold Jewellery Manufacturing Process

Step-1

Receiving the 24 Karat Bullion at our authorised premises

Step-2

24 Karat Bullion is mixed with alloys like silver and copper to get the desired purity level

Step-3

The 24 Karat purity gold is put into carbon crucibles and then melted at approx. 1150 degrees

celcius in furnace.

Step-4

Once the gold melts into liquid, it is poured from the carbon crucibles into special containers,

to cool and harden into strips of desired purity.

Step-5

Quality control QC is done to check purity level.

Step-6

The strip is then passed on to skilled karigars for making of different components like wires,

plates, pipes etc.

Step-7

Thinner wires are drawn as per requirement.

Step-8

Production manager distributes the components weight wise to different karigars as per

design.

Step-9

Designers sit with the manufacturing dept. to discuss finalized designs. The designs are as per

orders and as per research feedback on latest trends forecasting.

Step-10

From the plates, thinner plates are cut as per design, from the wires hollow and solid balls,

collets, chains, screws, dies and mountings are made and from the pipes colets are made.

These components as per design. The designing department gives the designs to the

manufacturing dept., as per orders.

Step-11

All the different components are set on moulding wax and given a definite shape as per

design.

Step-12

Quality Control QC is done by the QC team alongwith designers to check for accuracy of

design and manufacturing.

Step-13

From the moulding wax, the components are transferred on plaster of paris and allowed to

harden.

Step-14

The different components now set in plaster of paris cast are shouldered and joined on the

reverse with gold wires.

Step-15

The pieces are taken off from the plaster of paris mould and given for acid washing. In this

process the surface gets cleaned of any impurities. The pieces are washed and put in

Magnetic Polisher.

Step-16

The pieces are further put in Vibrating Polisher for a better shine. This stage polishes the

rearside and other non-reachable corners of the piece and give the pieces a better look.

Finally the pieces are buffed and polished to give the pieces the glitter and shine.

Step-17

The pieces are weighed by the production manager to ascertain polishing & manufacturing

loss.

Step-18

Quality Control QC is done for design, finish, polishing and purity.

Step-19

The final approved pieces are hallmarked and stamped for purity and branding.

Step-20

Quality Control -Finally the pieces are checked and re-checked for any manufacturing defects

by the quality control department. The designing dept. also plays a role during final approval

of the finished piece.

Step-21

The final pieces are ready for onward dispatch.

Das könnte Ihnen auch gefallen

- Descriptive Pamphlet of the Richmond Mill Furnishing WorksVon EverandDescriptive Pamphlet of the Richmond Mill Furnishing WorksNoch keine Bewertungen

- Jewelry Manufacturing ProcessDokument8 SeitenJewelry Manufacturing Processagga1111Noch keine Bewertungen

- Project ReportDokument44 SeitenProject ReportluvlinamoryaNoch keine Bewertungen

- The Design of Products To Be Hot-Dip Galvanized After FabricationDokument25 SeitenThe Design of Products To Be Hot-Dip Galvanized After FabricationHANEENNoch keine Bewertungen

- YytrfDokument54 SeitenYytrfpratikchothani866Noch keine Bewertungen

- How We Craft Jewellery ?: Vogue Crafts & DesignsDokument10 SeitenHow We Craft Jewellery ?: Vogue Crafts & DesignsRaja Sekhar Reddy PaluruNoch keine Bewertungen

- Induction Presentation 2Dokument24 SeitenInduction Presentation 2manishjnagdaNoch keine Bewertungen

- Jewellery HandmadeDokument15 SeitenJewellery Handmadelahsivlahsiv684Noch keine Bewertungen

- Plant LayoutDokument47 SeitenPlant LayoutAnupam RanaNoch keine Bewertungen

- A. Manufacturing ProcessDokument7 SeitenA. Manufacturing ProcessPHILIPANTHONY MASILANGNoch keine Bewertungen

- Presentation On Fabcon Design & Enginnering Raiwind Lahore PakistanDokument37 SeitenPresentation On Fabcon Design & Enginnering Raiwind Lahore PakistanpishoosloanNoch keine Bewertungen

- Method Statement Painting WorkDokument5 SeitenMethod Statement Painting WorkTaqiuddinHarith78% (9)

- Drum ManufacturingDokument20 SeitenDrum ManufacturingTricia Marie Tumanda0% (1)

- Industrial Visit ReportDokument6 SeitenIndustrial Visit ReportEngr Muhammad EhsanNoch keine Bewertungen

- SRIC InstallTechniqueDokument84 SeitenSRIC InstallTechniqueJackson Vu100% (1)

- Sample Galvanizing Procedure +ITPDokument14 SeitenSample Galvanizing Procedure +ITPsubash sivalingam67% (3)

- Unit-1 (1) MPDokument189 SeitenUnit-1 (1) MPVishvas SinghhNoch keine Bewertungen

- Quartz ToleranceDokument36 SeitenQuartz Tolerancenick10686Noch keine Bewertungen

- Sagar Forge & Fitting: An Iso 9001:2008 Certified CompanyDokument4 SeitenSagar Forge & Fitting: An Iso 9001:2008 Certified Companyraj varmaNoch keine Bewertungen

- Investment Casting ProcessDokument10 SeitenInvestment Casting ProcessPRINCE KUMARNoch keine Bewertungen

- Mos Galvanizing ProceduresDokument23 SeitenMos Galvanizing ProceduresRajeswaran Rajachockalingam100% (1)

- 2 LG Manual Engl PDFDokument100 Seiten2 LG Manual Engl PDFwayne1925Noch keine Bewertungen

- GlasscementchargefabriDokument30 SeitenGlasscementchargefabriMani KandanNoch keine Bewertungen

- Plaster Mold CastingDokument2 SeitenPlaster Mold CastingIzzat GhafarNoch keine Bewertungen

- 08 Inspection & QCDokument92 Seiten08 Inspection & QCAntony Bruno GenewinNoch keine Bewertungen

- Gratare MetaliceDokument100 SeitenGratare MetaliceTrandafir ViorelNoch keine Bewertungen

- Key - Ductile Iron Pipes & Fittings CatalogueDokument14 SeitenKey - Ductile Iron Pipes & Fittings CatalogueDFNoch keine Bewertungen

- Introduction To Piping FabricationDokument5 SeitenIntroduction To Piping FabricationSyed IbrahimNoch keine Bewertungen

- Beverage Manufacturing ProcessesDokument11 SeitenBeverage Manufacturing ProcessesPoulami DeNoch keine Bewertungen

- Coating Inspector ResumeDokument4 SeitenCoating Inspector Resumetulasirao.nammiNoch keine Bewertungen

- Work Method Statement PranavDokument8 SeitenWork Method Statement PranavpranavdoorsNoch keine Bewertungen

- Coating Application & Inspection Procedure-Rev 0Dokument27 SeitenCoating Application & Inspection Procedure-Rev 0tinphat100% (1)

- Calendering ProcessDokument37 SeitenCalendering ProcessShubham ChaudharyNoch keine Bewertungen

- Implications of NORSOK M-650 Standard in The OffshoreDokument27 SeitenImplications of NORSOK M-650 Standard in The OffshoreJoherNoch keine Bewertungen

- Fabrication Shop ObservationsDokument1 SeiteFabrication Shop ObservationsPerminder SinghNoch keine Bewertungen

- Foundry ProcessDokument81 SeitenFoundry ProcessGopalakrishnan Kuppuswamy100% (1)

- Sandvik Seamless Heat Exhanger Tubings 154 Eng.03.2008Dokument20 SeitenSandvik Seamless Heat Exhanger Tubings 154 Eng.03.2008Anghelo AlcaldeNoch keine Bewertungen

- Sequence of Operaion of SpinningDokument68 SeitenSequence of Operaion of SpinningShivam AgnihotriNoch keine Bewertungen

- Piping Inspect & Testing ProcedureDokument11 SeitenPiping Inspect & Testing ProcedureErlanggaBonaparteNoch keine Bewertungen

- Manufacturing Process of Tungsten Carbide Blanks-2013Dokument2 SeitenManufacturing Process of Tungsten Carbide Blanks-2013Cristina Garcia RamosNoch keine Bewertungen

- Detail TyreDokument1 SeiteDetail TyreMohammed AliNoch keine Bewertungen

- Fiber FabricationDokument30 SeitenFiber FabricationPraveen AndrewNoch keine Bewertungen

- Building SpecificationsDokument222 SeitenBuilding SpecificationsdinaquaNoch keine Bewertungen

- Material HandlingDokument8 SeitenMaterial HandlingSuman MukherjeeNoch keine Bewertungen

- Investment CastingDokument28 SeitenInvestment CastingKristin Louise Agbulos100% (1)

- 06 QC Inspection - Grade1Dokument68 Seiten06 QC Inspection - Grade1Harry Doble100% (1)

- PAM Product Guide - EnglishDokument95 SeitenPAM Product Guide - EnglishZivadin LukicNoch keine Bewertungen

- Jungbluth Main Catalogue-LanacDokument60 SeitenJungbluth Main Catalogue-LanacMilenkoBogdanovicNoch keine Bewertungen

- Mmc-Gamuda Conquas Road ShowDokument86 SeitenMmc-Gamuda Conquas Road ShowAlsonChinNoch keine Bewertungen

- Industrial Visit ReportDokument11 SeitenIndustrial Visit ReportRahulNoch keine Bewertungen

- Stainless Steel Pipe and Tube Manufacturing Process: Pearlite Steel Stainless Steel Blog Uncategorized No CommentDokument2 SeitenStainless Steel Pipe and Tube Manufacturing Process: Pearlite Steel Stainless Steel Blog Uncategorized No CommentpritiNoch keine Bewertungen

- Asphalt Production, Laying & Compaction 1Dokument3 SeitenAsphalt Production, Laying & Compaction 1Jawad GhauriNoch keine Bewertungen

- ISI Reballing September 2012Dokument15 SeitenISI Reballing September 2012Gonçalo RomãoNoch keine Bewertungen

- Mitas BoltDokument8 SeitenMitas BoltusonNoch keine Bewertungen

- Report of Corporate Internship 1Dokument28 SeitenReport of Corporate Internship 1Ijaz SultanNoch keine Bewertungen

- Publication - Painting, Coating & Corrosion Protection - Pickling and Passivating 2015Dokument7 SeitenPublication - Painting, Coating & Corrosion Protection - Pickling and Passivating 2015zinha_alNoch keine Bewertungen

- Total Quality Process Control for Injection MoldingVon EverandTotal Quality Process Control for Injection MoldingBewertung: 5 von 5 Sternen5/5 (1)

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryVon EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNoch keine Bewertungen

- Screwcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsVon EverandScrewcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsNoch keine Bewertungen

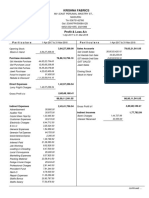

- PandL KF PDFDokument2 SeitenPandL KF PDFSiva KumarNoch keine Bewertungen

- Tax Audit: Tax Audit Conditions As Per Section 44AB-Every PersonDokument1 SeiteTax Audit: Tax Audit Conditions As Per Section 44AB-Every PersonSiva KumarNoch keine Bewertungen

- Revised PAN ApplicationDokument8 SeitenRevised PAN ApplicationKapil Dev SaggiNoch keine Bewertungen

- Tally Shot Cut KeyDokument5 SeitenTally Shot Cut KeykannnamreddyeswarNoch keine Bewertungen

- Test Project Sheet MetalDokument10 SeitenTest Project Sheet MetalSyed Idrus Syed OmarNoch keine Bewertungen

- HG Fuse Set 11kvDokument3 SeitenHG Fuse Set 11kvsbpathiNoch keine Bewertungen

- Materials Selection: Lecturer: Muhammad SulaimanDokument15 SeitenMaterials Selection: Lecturer: Muhammad SulaimanHussain AliNoch keine Bewertungen

- OA Cutting and WeldingDokument24 SeitenOA Cutting and WeldingJames Hale0% (1)

- Diacid Corrosion Water Based FluidsDokument18 SeitenDiacid Corrosion Water Based FluidsNgũ Viên Gia CácNoch keine Bewertungen

- Alucobond How To ManualDokument53 SeitenAlucobond How To Manualhkd2Noch keine Bewertungen

- 15 Difference Between Pipe and TubeDokument6 Seiten15 Difference Between Pipe and TubegetashishvaidNoch keine Bewertungen

- Stainless Steel Putty (ST) : Technical Data SheetDokument2 SeitenStainless Steel Putty (ST) : Technical Data SheetSreenivasNoch keine Bewertungen

- MM102 NotesDokument7 SeitenMM102 NotesHassan AliNoch keine Bewertungen

- 09162014114959monograph Chromite PDFDokument162 Seiten09162014114959monograph Chromite PDFTamirat WorkuNoch keine Bewertungen

- EVMSU3Dokument5 SeitenEVMSU3Marcos Ulises Luis MonzonNoch keine Bewertungen

- Portfolio Entry No. 3: Minerals and Their UsesDokument4 SeitenPortfolio Entry No. 3: Minerals and Their UsesReizel Joy Borja RasonaNoch keine Bewertungen

- SMST-Tubes Product Range en 2010 WebDokument16 SeitenSMST-Tubes Product Range en 2010 Webalbejo_r9Noch keine Bewertungen

- Steel Process and Element DetailDokument12 SeitenSteel Process and Element Detaildh24992499Noch keine Bewertungen

- Hydrofluoric Alkylation:: Corrosion and PreventionDokument26 SeitenHydrofluoric Alkylation:: Corrosion and PreventionJarukit Jr JunjiewchaiNoch keine Bewertungen

- CHG 308LDokument1 SeiteCHG 308LImmalatulhusnaNoch keine Bewertungen

- Spool & Sleeve ValveDokument31 SeitenSpool & Sleeve ValveSayak Ghosh100% (1)

- MSRIT Muralidhara.M.K MechDokument7 SeitenMSRIT Muralidhara.M.K Mechசெல்வ குமார்Noch keine Bewertungen

- Electrode: Flux Lime Silica Calcium FluorideDokument2 SeitenElectrode: Flux Lime Silica Calcium FluoridemihirthakkarNoch keine Bewertungen

- FrictionDokument20 SeitenFrictionvarun_009Noch keine Bewertungen

- Kathrein 80010303 PDFDokument3 SeitenKathrein 80010303 PDFEmmersonLisboaNoch keine Bewertungen

- Triple Beam Balance-Accuracy Matters-2Dokument3 SeitenTriple Beam Balance-Accuracy Matters-2api-386082175Noch keine Bewertungen

- ArcelorMittal SPEC GUIDE 20070801Dokument78 SeitenArcelorMittal SPEC GUIDE 20070801SH1961Noch keine Bewertungen

- CA-1001 Cherrymax Tool CatalogueDokument40 SeitenCA-1001 Cherrymax Tool CataloguekamaleshaiahNoch keine Bewertungen

- Refractorymaterials 150313053315 Conversion Gate01Dokument19 SeitenRefractorymaterials 150313053315 Conversion Gate01tesfayregs gebretsadikNoch keine Bewertungen

- Study of The Effect of Metal Coupling OnDokument11 SeitenStudy of The Effect of Metal Coupling OnmeenumathurNoch keine Bewertungen

- Astm A 193-2020Dokument14 SeitenAstm A 193-2020Mohammed Ali100% (1)

- Chemistry - Chapter 9 Study GuideDokument4 SeitenChemistry - Chapter 9 Study GuideJohnHanaNoch keine Bewertungen

- AFS Casting Defect HandbookDokument119 SeitenAFS Casting Defect Handbooktyagimanoj90100% (7)

- Mechanical TestingDokument45 SeitenMechanical TestingshrikantajitNoch keine Bewertungen