Beruflich Dokumente

Kultur Dokumente

Halac Sy 1958

Hochgeladen von

Anonymous sAmJfcVCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Halac Sy 1958

Hochgeladen von

Anonymous sAmJfcVCopyright:

Verfügbare Formate

Alger has touched upon a problem of

major importance. With the growing emphasis in college curriculums on electronic

circuits, field theory, information theory,

and many other recent developments, the

time available for study of machinery is being severely limited, and in some colleges

there is even thought of eliminating the

systematic study of machinery altogether.

With the important part that machines

play in the applications of electrical engineering today, this would appear to be a

grievous mistake. However, it is evident

that the methods of presenting machinery,

basically unchanged in most curriculums

for decades, must be radically overhauled.

In such an overhaul it seems highly desirable to make better use of equivalent circuits as a unifying concept, to show the

basic similarities of various types of machines. Field theory may be called upon

to establish the validity of the circuit concepts, but there is strong evidence that

circuit methods are simpler and easier to

Temperature Rise of Dry-Type

Transformers

A. A. HALACSY

MEMBER AIEE

THE CALCULATION of the temperature rise of dry-type transformers

differs from that of liquid-filled transformers because radiation from the core

and coil plays a considerable part in the

heat transmission and because the temperature of the cooling air is not as uniform as that of liquids. Very little, if

anything has been published about calculation of temperature rise of dry-type

transformers for design purposes. This

paper presents a method for such a

calculation.

Limitations

This paper deals only with the temperature rise of the coils of dry-type transformers.

Only the steady state of the coils is

considered. This is the temperature at

which they stay at unchanged load, voltage, and ambient temperature. Transient phenomena, like temperature rise

due to short circuits, are not discussed;

neither is forced air cooling. Air is mentioned as coolant throughout the text.

The results are applicable to other gases

by changing the constants accordingly.

High- and low-voltage (and tertiary,

if any) parts of a coil are considered as

separate units, because different amounts

of heat are generated in those parts perPaper 58-155, recommended by the AIEE'Transformers Committee and approved by the AI EE

Technical Operations Department for presentation

at the AIEE Winter General Meeting, New York,

N. Y., February 2-7, 1958. Manuscript submitted

October 11, 1957; made available for printing

November 26, 1957.

A. A. HALACSY is with the H. K. Porter Company,

Philadelphia, Pa.

456)

unit volume of copper and per-unit heattransfer area. Experience has shown that

the high- and low-voltage parts of a coil

frequently have quite different temperatures.

Proposed Procedure

In sumnmary, this paper proposes calculating the temperature rise by the following method:

1. Calculating the total watts WI which

can be dissipated at a series of coil temperatures T, where T= Tamb+ Trie, and

drawing a curve

WI=f(T)

(1)

in Cartesian co-ordinates.

2. Calculating the total watts W2 generated

in the coil at the same series of temperatures

T, and drawing another curve

W2 =f2( T)

(2)

apply than field methods in obtaining

numerical results, and therefore should be

fully utilized.

The author would again like to thank

Alger for his encouragement which has beeti

one of the important motivations in the

preparation of the present paper.

REFERENCE

DEFINITIONS OF ELECTRICAL TBRMS:

1.

ING MACHINERY.

ROTAT-

ASA C42.10-1957, American

Standards Association, New York, N. Y., 1957.

These mathematical expressions are for

the steady state, where w is the heat

energy leaving the area A of the surface

per-unit time; T is the temperature of

the surface; TA is the bulk temperature of

the surrounding fluid; TB is the temperature of an opposite surface; F is the

view factor, a function of the geometry

of the two opposite surfaces; e is the

emissivity; x is the length of the path

with the cross section A through which

the heat streams; and S, h, and k are

constants.

All the heat from the surface of a solid

is transferred to a fluid by radiation and

convection. In the case of a dry-type

transformer, the fluid is air. Conduction

is mentioned only because an additional

temperature drop across a solid insulating

layer covering the copper is caused by

convection.

Radiation

Only a negligible error is introduced if

the temperature of the enclosure is considered to be equal to that of the coolant

in equation 1, in cases where the enclosure

forms the opposite surface to radiation in

a conventional dry transformer.

TB = TA

(6)

in the same Cartesian co-ordinates.

3. Reading the coil temperature rise Tcoil,

where Tc0 = (T- Tamb), at the intersection

of the two curves, WI and W2.

Calculation is simplified if equation 3

is made similar to equation 4. Such a

form is quite arbitrarily written in the

center of equation 7

Heat Dissipation

w,= qAF=SAFe(T4 -TA4)

(7)

This equation, being arbitrary, holds

only if qr is defined as follows

Heat is transferred by radiation, convection, and conduction. Radiation follows the Stefan-Boltzmann law in a somewhat modified form

(3)

Wr-S.4 F e(T4 -TB4)

Convection follows Newton's law

wc=hA (T-TA)

(4)

qr Se(T4-TAI)

=

The numerical value of the StefanBoltzmann constant is properly converted

to watts,/sq in (square inch) X (degrees

Kelvin)4

S=36.8X 10-12

Conduction follows Fourier's law

A

w5= k -(T -TB)

x

(5)

(8)

is

(9)

The relative emissivity of the surface

e =0.9

(10)

Ilal,acsy-Temperature Rise of Dry-Type Transformers

AUGUST 1 958

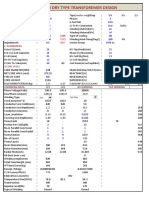

Table 1. Constants for Temperature Calculations

qc, Watts/Sq In

q, Watts/

TA* T-TA* SqIn Lt=0.5

T*

q=qr +qo, Watts/Sq In

L=1.5

L=1

L=2

L=2.5

L=3

L=0.5

L=1

L1.S

L=2

L=2.5

L=3

(234. S +T)

254.5

75... .30.... 45...0.203... .0.170... .0.143... .0.130....0. 121 ... .0.114 ....0.109....0.373....0.346....0.333....0.324... .0.317.. .0.312.... 1.21

85....30.... 55...0.264....0.219.... 0.184.... 0.166 ....0.154.... 0 146 ....0.140.... 0.481.... 0.448.... 0.431.... 0.419.... 0.411.... 0.404....1.25

110.... 30.... 80.. .0.433.... 0.351... .0.295....0.267.... 0.248.... 0.235 .... 0.224.... 0.781.... 0.729.... 0.701.... 0.679....0.666.... 0.657.... 1.35

140 .... 30 .... 110 ... 0.690.... 0. 523....0.439....0.396 ... 0. 369 ... 0. 349 .... 0.333 ... 1. 209 .... 1.125 .... 1.085....1.057 .... 1.040....1.020 .... 1.47

180.... 30.... 150... 1.14 .... 0.776 ... 0. 652 .... 0.590 .... 0.548....0.518 .... 0.495 .... 1.906 .... 1.782 .... 1.722 .... 1.680.... 1. 653....1.630....1.63

210 .... 30.... 180...1.525 .... 0.962 .... 0.810 .... 0.731 .... 0.678 .... 0.6458....0.616 .... 2.487....2.335 .....2.259 .....2.203 .... 2.171 .... 2.141 ... 1.75

*

All

temperatures measured in C. t All L measured in feet.

for materials used on the surface of

dry transformer coils. Pooling all this

information results in",2

q,=33.2 X 10-1( T4T-TA4) watts/sq in (11)

if T's are in degrees Kelvin; and thus the

heat in watts wr, transferred by radiation

through an A-sq-in surface at (T- TA)

degrees centigrade (C) temperature difference between surface and ambient, may

computed by equation 7.

(12)

wr =qrAF

Typical values of qr are listed in Table

I.

Convection

While the Stefan-Boltzmann constant

S is a purely dimensional constant, the

heat-convection coefficient h in equation

4 is a function of the geometry of the particular device and of the properties and

condition of the cooling air. A film of

air is heated by conduction from the vertical surface of the dry transformer coil

and begins to rise as it becomes lighter

than its surroundings. Thus a flow of

the air is started.

Indeed the best correlation3 of test

W

w

qr.--

=It

_T i

iIIII

I I .t I:-tt

__4 __

SO.N57=4_+

_

5_

4

3 _ 06

IIIi-

I;

HI,

,.

r

-1~

li r

l_T tX

2>l_T-

20

5>>

ls7+

VILXJ

--;

I I

02

0.1IL

T;w3C *.C

T: a

1 It

I!5

I0*

75 85 110 140 180 210

Fig. 1. Heat transfer constants; q = convection and radiation, qc = convection only

AUGUST 1 958

NP.

NN=f(NGXNP)

(13)

The value of the (NGX NP) product

determines the nature of the air flow,

turbulent or laminar. In the usual temperature range and at atmospheric pressure the air flow is laminar, along naturally cooled dry transformer coils. A

simplified equation is derived from equation 11 and given for h in this range in

textbooks,3 which may be written4 with a

dimension, watts/sq in, as follows

h=1.23X10-3(T-TA)O.26

(14)

Multiplying by (T- TA) gives, in watts/

sq in,

1.23X10-3(T-TA)2

(15)

Typical values of q, are listed in Table I

for L = 0.5- to 3-foot-high coils.

A combination of equations 4, 14, and

15 gives, in watts, the heat wc transferred by convection through A-sq-in

surface at (T- TA) C temperature difference.

wc-=qA

(16)

Total Heat Transferred

The sum of equations 12 and 16 gives

the total watts W, dissipated from the coil,

at a (T- TA) C temperature difference:

W1 =wr +w =(qrF+qc)A

(17)

FT

.

0.3

results regarding convection from a

vertical surface to air was presented in

terms of moduli used in aerodynamics as

the Grashof number NG, the Nusselt

number NN, and the Prandtl number

This is rewritten for the purpose of a

simplified calculation as

W1=(qr+qc)FA +q(1 -F)A

(18)

q =qr+qc

(19)

Within the usual limits of temperatures, T, to T2, which prevail in practical

dry-type transformers, both q's are well

approximated by exponential functions,

one

coil.

function for each L height of the

q(T, -TA\"

q2 \T-TAI/

(20)

The logarithm of this function is obviously a linear function

log,o q, - logio q2

=n[log,s (TL-T'A)-log,o(T2-TA)J (21)

where

n = 1.25 for q,

n= 1.28 to 1.77 for qr

n = 1.36 approximately for q

and the temperatures are measured in C;

see Appendix I.

Straight lines represent such functions

on a double-log-scaled graph paper, Fig.

1, for L=0.5- to 3-foot-high coils.

Grouping of Surface Sections

It is more practical to split the total

surface A into n sections, A,,, and to group

together the sections with similar heattransfer characteristics than to consider

an over-all view factor for the whole surface area. Equation 18 is rewritten accordingly

WI =q

n

FnAIn+qGE(1-Fn)A

I

(22)

The most practical grouping is into internal and external surfaces.

Internal Surfaces

Internal surfaces are those on which

F,=O, because radiation is cancelled by

an opposing surface. Such are the inside

surface of a coil facing the core, and surfaces of cooling ducts. For these

n

WI =

qCEA int

(23)

Of course, the statement Fn = 0 is

strictly true for these surfaces only if the

opposite surface intercepting the radiation

is at the same temperature and has the

same emissivity. The differences ob-

Halacsy-Temperature Rise of Dry-Type Transformers

457

Kw

0.5

_i

8

4

8

2

8

4

8

WIuM OF COOUNG DUCT. INCHES

Fig. 2. The corretion factor Kw versus

radial width of a cooling duct

The length L is of course always the

cooling length, which does not include

the end fillers or spacers made of insulating material, but only the length from the

bottom to the top face of the copper,

minus the axial width of any gap in the

surface; e.g., the cooling length of a

pancake coil is L= (number of pancakes)

X (axial width of one copper pancake).

The cooling length of an uninterrupted

barrel coil is L = (length of copper coil) (end pitch).

The narrower the cooling duct, the more

it chokes the airstream and reduces cooling. Published test results proved that

air masses farther than 3/8 to 1/2 inch

from the vertical surface do not participate appreciably in the cooling, so that

the influence of the width of the cooling

duct levels off around 1-inch width. Fig.

2 shows the values of a correction factor

K. for the width of the duct. Combining equations 23 and 25, and K,, gives

n

Fig. 3. Graphic detemination of the view

angle B between coils

Wi =

qcl {IL [2DnAv,duotX T2(number of spacer, n) (width of

spacer, n]Kb,,

Kj,,,}

(26)

External Surfaces, View Factor

Fig. 4. Graphic determination of the view

angle p between disks

served in the discussed group of transformers usually can be neglected, but can

be taken into account by further subgrouping, adding correction factors to

equation 22, in cases where these differences warrant it.

Proper judgment has to be used to determine how many square inches of each

area are heat-transfer units. For example, the part of a surface covered by

spacer sticks in a cooling duct is not one.

The surface of those ducts which are

blocked by some obstacle at their entrance

or exit and have no air circulation are not

ones. Such obstacles can be heavy leads,

most likely in a low-voltage coil of great

kva capacity, protruding insulation of

taps, bracings or clampings of the coil,

protruding core clamps, etc. The blocked

ducts can be considered by a factor

(number of ducts) TIP

_

b=

Fp= 1-2)

(27)

The view angle a is the solid angle

within which the point views an obstruction to radiation, and 2,r solid angle is the

surface area of a half-sphere of unit radius

seen unobstructed. Parts of the same or

of anotlher coil and phase barriers between

coils obstruct radiation. Averaging for a

certain area A. gives the view factor of

that area

metrv. Thus, the view factor can be calculated for their axial section, see Fig. 4.

Solid Insulation Layers

Any solid insulation 1/32 inch or more

thick over the copper must be taken into

account because a temperature drop

occurs across solid insulations according

to equation 5. This drop is negligible for

less than 1/32 inch of insulation, and

approximated well enough by reducing the

q's for 20 C by 0.01 watt/sq in for each

1/32-inch thickness.

Summation of the Heat Transferred

The watts transferred through each

part of the coil surface are totaled according to equation 22, and this calculation is

carried through for a series of tempera-

-I

Soc

roo___ I_PW

I ---.-

TOC

600

Fn=l--

Zfap

I

2rP

-_ _1_-

500

I-

400

I0 I/ _

---

(28)

The outer surface of a coil has cylindrical symmetry. Fringe effects can

be neglected, therefore the surface can be

reduced to a circular circumference of a

section across the axis, and the solid

angles to plane angles 0,,; see Fig. 3.

Equation 28 reduces to equation 29

(number of blocked ducts)

(number of ducts)

(24) I F=l-

An = LKb [2DnAV, duet X w2(number of spacers) (width of one spacer)]

(25)

458

External surfaces are the ones from

which radiation is not fully cancelled.

The view factor for a point P of such a

surface is, by definition,

can be averaged from few values. The

calculation is carried out for the center

phase, the hottest in a 3-phase transformer, where, by reasons of symmetry,

it is enough to consider only one quarter

of the circumferential circle. The shaded

view angles 3,B see obstruction as shown in

Fig. 3, at points p= 2 and p= 6.

The same treatment can be applied to

surfaces between disks, where the surfaces are rings and have a circular sym-

TO

40

CAM ENT

110- C TOTAL

CO* C RISE

s0

50

Fig. 5. Graphic determination of temperature of coil shown rn Fig. 6

7rp

(29)

The view angle ,B changes continuously

around the circumference; therefore it

Fig.

6.High-voltage pr of2

14 STICKS

NQ3

5 75

Fig. 6. Hi'Sh-voltage part of coil

Halacsy-Temperature Rise of Dry-Type Transformers

A.UGUST 1.958

tures in the range where the final temperature is expected. It is sufficient to

select certain significant temperatures,

such as 55, 80, 110, 150, and 180 C rise

above 30 C ambient and suppose a linear

continuity of W1 between them.

Of course, such a calculation is done

easily in a preprinted tabular form and by

a single setting of the slide rule, as the only

terms changing with the temperature are

q and q, in equation 22. The resulting

tabulated function represents equation 1.

Table II. Calculations and Test Results Compared

VT

I is the rms value of the coil current in

amperes; pw=0.67X1104 ohm/in/sq in

for copper, and a corresponding value for

other conductor materials. Values of

the factor (234.5+T)/254.5 are given in

Table I.

The stray losses'-" are Y % of the d-c

losses and can be accounted for by a

Equation 32 is the amplified form of

equation 2.

Temperature Rise

........

112'/2

.......

Difference

Test

test values were generally considered

satisfactory. There were two cases

amnong the 30 reported where the difference was 11 C, one positive, the other

negative. These cases will probably

prove to be extreme or erroneous if more

results will enable a statistical evaluation.

Test Results

From equation 15,

T2 -TA

log q,-log q47s-1.25

!log(Ti-TA)-log(Tg-TA)] (34)

From equation 11,

qc2

qri T14-TA

qT2 T24 -TA4

log qr,-log qr2 10(T4- TA4)-

(35)

(5

log(T24-TA4) (36)

It is more convenient to have an exponential function, though arbitrary, on

the right-hand side, thus

log q'-lIog q,2

Calculated

Test Difference

Appendix IL. Temperature Rise

of Coil Shown in Fig. 6

Heat Transferred

The initial calculations for the cylindrical

inner surface (one side of a duct) of the coil,

shown as no. 1, are as follows:

diameter= 12. 7

circumference- 11. 75X 36. 85

less (14 spacersX0. 375 inch each) -5.25

cooling circumference-36.85-5.25=31.60

k, for 3/8-inch-wide duct -1

circumference cooled by convection= 1 X

31. 60 = 31. 60 inches

The calculations for the cylindrical inner

surface (both sides of a duct) of the coil,

shown as no. 2, are as follows:

mean diameter= 13. 675 inches

2X (mean circumference) -2(13.675X T)

-85.60

less (14 spacersX0.375 inch eachX2)

=-10.50

circumference -85.60-- 10.50

cooling

-75.10

k. for 3/8-inch-wide duct = 1

circumference cooled by convection =1 X

75.10=75. 10 inches

The calculations for the cylindrical outer

surface of the coil, shown as no. 3, are as

follows:

([log(T,-TA)-log(T2-TA)] (37)

where n by combination of equations 36 and

37 is as follows

log( Ti4- TA4)-log( T24- TA4)

log( T, -TA ) -log( T2 -TA)

(38)

The values of n calculated from equation

38 for a series of temperatures are as follows:

Ti

Table II shows a series of test results

compared with calculations made according to the method of this paper. Differences of

8 C between calculated and

Voltage

Appendix 1. Calculation oF

Heat-Transfer Function

The curves representing equations 1 and

2 or rather, 22 and 32, intersect where just

as much heat is transferred as is generated,

so that balance is reached. The temperature read at that point is the steady

state of temperature of the coil; Fig. 5.

Appendix II is a sample calculation for

the sample coil, Fig. 6.

The temperature calculated in this

way is the average temperature of

the respective high-voltage, low-voltage,

tertiary, etc., part of the coil shown in

Fig. 6.

AUGUST 1958

112!/2

Calculated

600 ... 81

.

73 . 79 ..... -6

......1.. 120 .

80 .

71

73 .......-2

120 . 70 . 76 ..... -6

0

70

7. 120 . 69 . 69 .....

480

77

...

-3

150 ........

480 .. 48 . . 55 ......-7

66 ......

120

70

53

78 ... -8

150 ........

480

-6

....59..

-4

61 ...-4... 120

150

70 .....74

4,160 .57

65

150

69 .....

i68 ...-3... 120 . 68

-1

4,160

.6 .....

225

480

55

61

-6

6

120..

72

225

... .400. ...... 87

2

76

11

480 . 67 ...

225 ... .....

480 ...... 72

74.. ..

-2 .

3

80...... 74.. .. 71

225

-3

480.........

4

.......160 68...... 71

71 ....

-7

300 ...... ..

79

480. 63

62...

62

i68

I...... 120

- 115

.12

300 ........ 2,400 ..

0

60 ...

70 75

72 ..... 78.

500 ........ 6,763 ...72

-6 .

67

4

5

-2

500 ........ 6,763 .. 76.

5.60

71

Rf fi O

480

500 ........12.000 ...74 . 84...

-10 . 120. 92 ..... 90

2

.

750 ........ 4,160 ... 58 . 62 .

-4

72 ..... 66

6

480

.

.

750 ...

56 ...... 60

-4 . 480 . 75

70 . 5

4,160

0. 480 . 78

72.

6

1,000 ... 12.000 . 76 ...... 76.

~~~~~~~(31)

Since fy, is small in practical dry transformers, it is permissible to write

(32)

W2=fy vW(234.5+ T)/254.5

Voltage

112/ ........71 2,400

.

niultiplise

y

fy=l+100

Temperature, C

Three-Phase

Transformers,

Kva

Heat Generation

Equation 2 shows the total watts generated versus temperature. D-c losses

account for the largest portion of the total

watts generated. These d-c losses are,

at T C,

+T)

(30)

"P01A (234.5

VrI'P25

254.5

Low-Voltage Coil

Temperature, C

High-Voltage Coil

(Ti-TA)

358 ...... 55

80

383 ..

413

110

453 ..

150 .

T2

diameter= 14. 65

circumference= 14. 65 X =46. 00

view factor derived geometrically, 1- F

=0.486

0. 486X46.00=22.40

total of circumferences cooled only by convection = 129.10 inches

cooling length=15.75-0.22=15.53

(T2-TA)

log (Ti-TA)10 (T2-TA)

log (T,4-TA4)10 (T2'-TA')

3

0.

0 .....

413

453

483 .

-0 162 .....

110 .......... -0.139 ..

... -0 135

150

180.

Halacsy-Temperature Rise of Dry-Type Transformers

..

-0.078 .

..

..

-0.208.... 1 .28

.

-0 197

1. 42

.

-0 215

1.59

-0 138 ....

1.77

459

area cooled by convection=15. 53X129.10

-2,005 sq in

circumference cooled by radiation and convection = (1 -0 . 486) X 46. 00 = 23.60

area cooled by radiation and convection

-15.5.3X23.60=366.5 sq in

The total heat transferred is as follows:

C rise

above 30 C= 45. 5.80... .110

C total =

75. 85.... 110. ..140

260.6. .322.8..535... .740

2,005 X q=

366.5Xq=

122.0..158... .257...397.6

WI, watts= 382.6. .480.8. .792.. 1,137.6

Heat Generated

The calculations for the heat generated

are as follows:

Discussion

N. A. Hills (Moloney Electric Company of

Canada, Ltd., Toronto, Ont., Canada): In

dry-type transformer temperature-rise

calculations, designers are interested in

obtaining rises that are close to the temperature class limits. With this in mind

I would think the process as outlined in

this paper could be simplified by establishing the watts loss at the temperature

limit for the class and obtain the temperature rise by reference to Fig. 1,

rather than by a graphical plot as in Fig. 5.

If the rise is close to the desired limit, as it

should be, the error introduced would be

quite small.

This approach in effect establishes relationships between surface watts/sq in and

temperature rises for different duct lengths

and with duct-size corrections that could be

listed in a relatively short table. This form

for the information would be easy to incorporate into a computer design program.

I would appreciate the author's comments

on the following:

1. How great an error is introduced by

assuming that the correction for duct

length and the correction for duct size can

be considered independently.

2. Fig. 2 would indicate that two 1/4-inch

ducts would be preferable to. one 1/2-inch

duct. Our experience would indicate that

this is not so.

3. No mention is made of the relative

effectiveness of ducts which have hot surfaces on one side only as compared with

ducts with hot surfaces on both sides.

J. J. Kunes (Westinghouse Electric Corporation, Sharon, Pa.): This paper describes an interesting method of calculating the temperature rise of dry-type transformers, derived from the familiar equations

for the three modes of heat transfer. Because it will be placed in the literature, however, I would like to argue the following

point for the record.

Equation 18 seems an unnecessary comnplication of equation 17. It would be more

straightforward to calculate directly the

total heat dissipated by convection, and

then calculate the heat dissipated by radi-

460

copper wire, 0.112 X0.220=0.024620 sq in

deduction for round corners= 0.000838

cross-sectional area A =0.024620-0.00838

=0.023782 sq in

length of wire=42.80X240 turns= 10,260

inches

-=41. 7 amperes, 12= 1,740

Substitution of these values in equation 31

gives

V2o 1,740 X 0.67X 10-6 X 10,260/0.023782

=

503 watts

For different temperatures (in C) the

total watts generated (from equation 30)

are as follows:

C=

220... 75...85... 110.. .140

W2, watts=503.. .606.. .626.. .676. ..737

ReFerences

1. ELECTRICAL COILS AND CONDUCTORS (book).

H. B. Dwight. McGraw-Hill Book Company, Inc.,

New York, N. Y., 1945, p. 51.

2. THREE PHASE INDUCTION REGULATOR (Der

Drehstrom Induktionsregler) (book), H. F. Schait.

Julius Springer, Berlin, Germany, 1927.

HEAT TRANSMISSION (book), W. H. McAdams.

McGraw-Hill Book Company, Inc., 1954, pp. 167,

3.

173.

4. CoNvERsioN FACTORS (book), 0. T. Zimmerman, I. Lavine. Industrial Research Service Inc..

Dover, N. H., 1955, pp. 29, 77.

5. Dwight, op cit., pp. 26-32.

6. STRAY CURRENT LossEs IN STRANDED WINDINGS OF TRANSFORMERS, H. J. Kaul. AIEE Transactions, vol. 76, pt. III, June 1957, pp. 137-49.

7. PHYSICAL AND CHEMICAL CONSTANTS (book),

G. W. C. Kaye, T. H. Laby. Longmans, Green and

Company, London, England, 1948, p. 81.

ation, using the areas involved in each case.

This would eliminate the approximation involved in the value of the exponent n for q.

Also the view factor F would be used with

radiation, where it has physical significance,

instead of in a convection term.

If the author has conducted any such

compromise temperature-rise tests, any

information or comments he may have to

offer on this subject should also be very

helpful to this working group in preparing

proposals for compromise temperature rise

tests on dry-type transformers.

M. F. Beavers (General Electric Company,

Pittsfield, Mass.): The author has presented an analysis of a rather complex

problem of heat flow as applied to dry-type

transformers. As indicated in this study,

convection and radiation play a large part

in the heat-flow problem in such arrangements as concentric coil surfaces and adjacent core surfaces in dry-type transformers.

However, in an oil-immersed transformer,

radiation plays such a minor role, that the

proximity effect of the winding and of the

core on each other is negligible. Therefore,

for the purpose of determining temperature

rises, it has been found entirely satisfactory

to make compromise tests (such as the shortcircuit temperature-rise test) on oil-immersed transformers in which the core is

excited at a very low value-essentially

REFERENCE

impedaince voltage.

In the case of dry-type transformers, however, a compromise temperature-rise test,

in which the core and windings are not at

their respective temperatures simultaneously, is subject to error and requires either

further tests or a fundamental understanding of the interrelations of heat flow which

pennit certain corrections to be applied to

the compromise test result.

It is not clear from the paper as to the

test method used by the author, but it is

assumed that the test data presented in this

paper were obtained under the conditions

of a load-back heat run such as recommended in the revised Test Code for drytype transformers proposed by the AIEE

Project Group on "Methods for Making

Ternperature Rise Tests on Transformers."'

This working group is hopeful of ascertaining a compromise test on dry-type

transformers which will permit making a

temnperature test on a single unit. The

writer has recently conducted some compromise tests on single units which, with

certain corrections, show some promise of

being substantially equivalent to data

obtained on the same units under load-back

test conditions. These data are being

prepared for presentation in the near future.

1. ASA TRANSFORMER STANDARDS C57.22-TEBPERATURE RISES TESTS ON TRANSPORMERS, AIR3:E

Project Group. Electrical Engineering, vol. 72,

Jan. 1953, pp. 70-74.

L. C. Whitman (General Electric Company,

Pittsfield, Mass.): The calculation of the

temperature rise of the dry-type transformers is considerably more involved than

for liquid-immersed transformers due to the

poor thermnal conductivity of the air medium

and the existence of considerable radiation

effects. In a liquid-immersed transformer,

a thin oil film suppresses radiation effects so

that internal radiation effects are practically

nonexistent.

The author has outlined one approach to

the heat-transfer problem in dry-type

transformers and he is to be commended for

his basic approach. I would like to offer a

few suggestions which consider some of the

effects encountered in the application of this

approach to actual cases.

The thermal gradients between component parts of dry-type transformers are of

considerable magnitude, and interaction

between core and windings, between the

windings themselves, and between the

windings and casing, must be considered.

The assumption is made that, "...temperature of the enclosure is considered to be

equal to that of the coolant...." If Dr.

Halascy is referring to the core and coils of a

dry-type transformer operating without an

enclosing casing this is essentially correct as

the walls of a room are presumably of the

same temperature as the ambient air.

However, the conventional ventilated drytype transformer has an enclosing sheetmetal casing with ventilating louvers for

safety, appearance, and partial shielding

from dirt, as well as from possible water

dripping from condensate of overhead pipes.

This casing temperature is somewhat

higher than the room ambient temperature.

From heat-run data, the average temperature rise of this casing is in the range of 15%

Halacsy--Temperature Rise of Dry-Type Transformers

AUGUST 1958

Das könnte Ihnen auch gefallen

- SolidWorks Simulation Black BookDokument40 SeitenSolidWorks Simulation Black BookAnonymous sAmJfcV50% (6)

- Transformer Dry Type Handbook1Dokument73 SeitenTransformer Dry Type Handbook1Anonymous sAmJfcVNoch keine Bewertungen

- Heat Transfer Collection of Formulas and Tables - 2009Dokument78 SeitenHeat Transfer Collection of Formulas and Tables - 2009Suta Vijaya100% (1)

- Steam TurbinesDokument38 SeitenSteam Turbinesmanoj100% (1)

- EHV Cables Laying MethodDokument22 SeitenEHV Cables Laying MethodSudharsanan Sitrarasu100% (2)

- METALS Structured Questions and Worked SolutionsDokument9 SeitenMETALS Structured Questions and Worked SolutionsYoviNoch keine Bewertungen

- Fan Lub CFM56-7 - HandbookDokument44 SeitenFan Lub CFM56-7 - HandbookANDRANoch keine Bewertungen

- MAK 302L Experiment 3 Extended Surface Heat Transfer 1. PurposeDokument5 SeitenMAK 302L Experiment 3 Extended Surface Heat Transfer 1. PurposeYEe FaNgNoch keine Bewertungen

- SolidWorks API Series 1 - Programming & Automation PDFDokument268 SeitenSolidWorks API Series 1 - Programming & Automation PDFAnonymous sAmJfcV86% (7)

- Heating and Current Capacity of Bare ConductorsDokument16 SeitenHeating and Current Capacity of Bare ConductorsdrboudriauNoch keine Bewertungen

- Free and Forced ConvectionDokument7 SeitenFree and Forced ConvectionRenewable Energy Engi50% (2)

- Simulation Heat Transfer Convection Fired HeatersDokument8 SeitenSimulation Heat Transfer Convection Fired HeatersPedro DiazNoch keine Bewertungen

- Treatise on Irreversible and Statistical Thermodynamics: An Introduction to Nonclassical ThermodynamicsVon EverandTreatise on Irreversible and Statistical Thermodynamics: An Introduction to Nonclassical ThermodynamicsBewertung: 1 von 5 Sternen1/5 (1)

- Calculating Core TemperatureDokument6 SeitenCalculating Core TemperatureAnonymous sAmJfcVNoch keine Bewertungen

- Catalogue DM AhuDokument54 SeitenCatalogue DM AhurianaNoch keine Bewertungen

- Natural and Forced Convection ExperimentsDokument12 SeitenNatural and Forced Convection ExperimentsOmar Yamil Sanchez Torres25% (4)

- 110 WS Gas Stoichiometry KeyDokument2 Seiten110 WS Gas Stoichiometry Keyエルミタ ジョイ ファティマ100% (1)

- Radial Conduction Lab ReportDokument11 SeitenRadial Conduction Lab Reportapi-310519283100% (2)

- Lamarche, L. (2019) - Horizontal Ground Heat Exchangers Modelling. Applied Thermal EngineeringDokument37 SeitenLamarche, L. (2019) - Horizontal Ground Heat Exchangers Modelling. Applied Thermal EngineeringIrvinSerranoJNoch keine Bewertungen

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringVon EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringNoch keine Bewertungen

- Cooling Load Versus COP Characteristics For An Irreversible Air Refrigeration CycleDokument9 SeitenCooling Load Versus COP Characteristics For An Irreversible Air Refrigeration CycleYalçın DurmuşoğluNoch keine Bewertungen

- ME 315 - Heat Transfer Laboratory Experiment No. 8 Forced Convection From A Circular Cylinder Subjected To Cross FlowDokument11 SeitenME 315 - Heat Transfer Laboratory Experiment No. 8 Forced Convection From A Circular Cylinder Subjected To Cross FlowSharath SharuNoch keine Bewertungen

- TE Lab 2Dokument50 SeitenTE Lab 2Gopi RaguNoch keine Bewertungen

- The Effect of Collector Aspect Ratio On The Collector Efficiency of Flat-Plate Solar Air HeatersDokument7 SeitenThe Effect of Collector Aspect Ratio On The Collector Efficiency of Flat-Plate Solar Air Heatersaxel_oscNoch keine Bewertungen

- 13 - Chapter One - SixDokument34 Seiten13 - Chapter One - SixazlanNoch keine Bewertungen

- Steady State Temperature Profiles in Rods PaperDokument20 SeitenSteady State Temperature Profiles in Rods PapergizatowerNoch keine Bewertungen

- Overall - Finned TubeDokument14 SeitenOverall - Finned TubeSakthi VelNoch keine Bewertungen

- Paper Ed7 16Dokument12 SeitenPaper Ed7 16RashaM.AtwiNoch keine Bewertungen

- Applied Heat Transfer Design For The HpiDokument149 SeitenApplied Heat Transfer Design For The Hpidomenico133Noch keine Bewertungen

- Kabelac Solar EnergyDokument6 SeitenKabelac Solar EnergyJulio CarvalhoNoch keine Bewertungen

- ChE 154Dokument16 SeitenChE 154DennisShinNoch keine Bewertungen

- Heat 4Dokument4 SeitenHeat 4Kasar nagib 2002Noch keine Bewertungen

- PRGRN603: Module 5: Stationary CollectorsDokument18 SeitenPRGRN603: Module 5: Stationary CollectorsRony Bou cheblNoch keine Bewertungen

- HTC SingleFin in Water 031506Dokument5 SeitenHTC SingleFin in Water 031506Anya CooperNoch keine Bewertungen

- Combined Convection and RadiationDokument8 SeitenCombined Convection and RadiationZAVEN TORTIANNoch keine Bewertungen

- 6 Heat TransferDokument19 Seiten6 Heat TransferPrecious Mae Cuerquis BarbosaNoch keine Bewertungen

- Modelling and Simulation Techniques For Forced Convection Heat Transfer in Heat Sinks With Rectangular FinsDokument26 SeitenModelling and Simulation Techniques For Forced Convection Heat Transfer in Heat Sinks With Rectangular FinsFunda DurmazNoch keine Bewertungen

- Lab Report Content: ME-341, Heat and Mass Transfer: ExperimentsDokument12 SeitenLab Report Content: ME-341, Heat and Mass Transfer: ExperimentsAnonymous R7wV0zbMNoch keine Bewertungen

- Design of Heat ExchangersDokument20 SeitenDesign of Heat ExchangersSudhir JadhavNoch keine Bewertungen

- Andersen 1962Dokument10 SeitenAndersen 1962ali ahmadiNoch keine Bewertungen

- Collis 1959Dokument28 SeitenCollis 1959Manu K VasudevanNoch keine Bewertungen

- 05.02heat TransferDokument21 Seiten05.02heat TransferjationonaNoch keine Bewertungen

- Cross Flow HEDokument6 SeitenCross Flow HEleong_guoNoch keine Bewertungen

- Experiment No. 03 Aim: To Determine The Heat Transfer Coefficient in Natural ConvectionDokument6 SeitenExperiment No. 03 Aim: To Determine The Heat Transfer Coefficient in Natural Convectionpriya3939Noch keine Bewertungen

- Unsteady State Heat TransferDokument4 SeitenUnsteady State Heat Transfernaser hasan fauziNoch keine Bewertungen

- 1 s2.0 0960148194904111 MainDokument10 Seiten1 s2.0 0960148194904111 MainSadegh AhmadiNoch keine Bewertungen

- Lab 2Dokument17 SeitenLab 2Callum BiggsNoch keine Bewertungen

- Mak 302 Rapor 4Dokument23 SeitenMak 302 Rapor 4Akay BayatNoch keine Bewertungen

- Chapter 5Dokument56 SeitenChapter 5kwangjin1980Noch keine Bewertungen

- ME 2306 Thermal Engineering Lab - I Lab ManualDokument43 SeitenME 2306 Thermal Engineering Lab - I Lab ManualShane HarrisNoch keine Bewertungen

- Heat and Mass Transfer.: SolnDokument14 SeitenHeat and Mass Transfer.: SolnGaettan KatambaNoch keine Bewertungen

- Steady State Temperature Distribution of Cast Resin Dry Type Transformer Based On New Thermal Model Using Finite Element MethodDokument5 SeitenSteady State Temperature Distribution of Cast Resin Dry Type Transformer Based On New Thermal Model Using Finite Element MethodAnonymous sAmJfcVNoch keine Bewertungen

- New Heat Transfer Factors For Flat Plate Solar CollectorsDokument5 SeitenNew Heat Transfer Factors For Flat Plate Solar Collectorshassan zohairNoch keine Bewertungen

- Unit3 HT Phase ChangeDokument21 SeitenUnit3 HT Phase ChangeShivamKumarNoch keine Bewertungen

- Temperature On CRTDokument9 SeitenTemperature On CRTsaravanaplusNoch keine Bewertungen

- Heat Transfer PDFDokument64 SeitenHeat Transfer PDFAdeoti OladapoNoch keine Bewertungen

- Heat Transfer in Natural ConvectionDokument6 SeitenHeat Transfer in Natural ConvectionAbhishek AnandNoch keine Bewertungen

- 01 - Heat Loss in Bare, Finned, & Lagged PipesDokument17 Seiten01 - Heat Loss in Bare, Finned, & Lagged PipesAllen Jerry AriesNoch keine Bewertungen

- Thermal Analysis of Heat Pipe Shell-Fin Structures With Selective Coatings Under RadiationDokument7 SeitenThermal Analysis of Heat Pipe Shell-Fin Structures With Selective Coatings Under RadiationLuis ReyesNoch keine Bewertungen

- Lab de Termodinamica No 3Dokument9 SeitenLab de Termodinamica No 3edja5Noch keine Bewertungen

- Heat Transfer Through Natural ConvectionDokument19 SeitenHeat Transfer Through Natural ConvectionRahul Mondal100% (2)

- Air Temperature EffectDokument7 SeitenAir Temperature Effectvillaniea annisaNoch keine Bewertungen

- Research On Calculation Method of Thermal Design Load in Radiant Heating and Cooling SystemsDokument8 SeitenResearch On Calculation Method of Thermal Design Load in Radiant Heating and Cooling SystemsKyaw San OoNoch keine Bewertungen

- FoE - Heat TransferDokument18 SeitenFoE - Heat TransferPamela KennedyNoch keine Bewertungen

- Cooling Under TunnelDokument7 SeitenCooling Under TunnelSYED MUDASSIR NAZARNoch keine Bewertungen

- A Modern Course in Statistical PhysicsVon EverandA Modern Course in Statistical PhysicsBewertung: 3.5 von 5 Sternen3.5/5 (2)

- Commandbutton1 Commandbutton2: Shaft 2 Dia 0.5 Bevel 2 Dia 2Dokument1 SeiteCommandbutton1 Commandbutton2: Shaft 2 Dia 0.5 Bevel 2 Dia 2Anonymous sAmJfcVNoch keine Bewertungen

- 02 2 Maxwell Eddy CurrentDokument12 Seiten02 2 Maxwell Eddy CurrentAnonymous sAmJfcVNoch keine Bewertungen

- Icepak-Intro 14.5 L01 Agenda and ANSYS Intro PDFDokument11 SeitenIcepak-Intro 14.5 L01 Agenda and ANSYS Intro PDFAnonymous sAmJfcVNoch keine Bewertungen

- Guaranteed Technical Particulars: 1. SpecificationsDokument2 SeitenGuaranteed Technical Particulars: 1. SpecificationsAnonymous sAmJfcVNoch keine Bewertungen

- Distribution TransformerDokument17 SeitenDistribution TransformerveerendraprasadNoch keine Bewertungen

- Solidworks Api Demystified: Who Am I?Dokument8 SeitenSolidworks Api Demystified: Who Am I?Anonymous sAmJfcVNoch keine Bewertungen

- Distribution TransformerDokument17 SeitenDistribution TransformerveerendraprasadNoch keine Bewertungen

- Haritha ThesisDokument105 SeitenHaritha ThesisAnonymous sAmJfcVNoch keine Bewertungen

- 5cast Resin Dry-Type TransformerDokument2 Seiten5cast Resin Dry-Type TransformerAnonymous sAmJfcVNoch keine Bewertungen

- Models - Mph.heat Transient AxiDokument6 SeitenModels - Mph.heat Transient AxiAnonymous sAmJfcVNoch keine Bewertungen

- Furnace & Rectifier TransformersDokument3 SeitenFurnace & Rectifier Transformersjoydeep_d3232Noch keine Bewertungen

- 800kva Cast Dry TransformerDokument1 Seite800kva Cast Dry TransformerAnonymous sAmJfcV100% (1)

- Models - Heat.electronic Enclosure CoolingDokument20 SeitenModels - Heat.electronic Enclosure CoolingAnonymous sAmJfcVNoch keine Bewertungen

- Models - Acdc.ecore TransformerDokument34 SeitenModels - Acdc.ecore TransformerAnonymous sAmJfcVNoch keine Bewertungen

- 800kva Cast Dry TransformerDokument1 Seite800kva Cast Dry TransformerAnonymous sAmJfcV100% (1)

- Siemens MS2014Dokument4 SeitenSiemens MS2014Carlos TuestaNoch keine Bewertungen

- Thermal Analysis of Electrical Machines Limits and Heat Transfer PrinciplesDokument2 SeitenThermal Analysis of Electrical Machines Limits and Heat Transfer PrinciplesAnonymous sAmJfcVNoch keine Bewertungen

- Steady State Temperature Distribution of Cast Resin Dry Type Transformer Based On New Thermal Model Using Finite Element MethodDokument5 SeitenSteady State Temperature Distribution of Cast Resin Dry Type Transformer Based On New Thermal Model Using Finite Element MethodAnonymous sAmJfcVNoch keine Bewertungen

- Pierce 1991Dokument7 SeitenPierce 1991Anonymous sAmJfcVNoch keine Bewertungen

- Transformer Design and Optimization - A Literature SurveyDokument26 SeitenTransformer Design and Optimization - A Literature Surveykrmurali2000Noch keine Bewertungen

- Convection Heat Transfer CoefficientDokument9 SeitenConvection Heat Transfer CoefficientAnonymous sAmJfcVNoch keine Bewertungen

- Technical Specifcation of Electrical MaterialsDokument53 SeitenTechnical Specifcation of Electrical MaterialsAnonymous sAmJfcVNoch keine Bewertungen

- Iso AnnealingDokument2 SeitenIso AnnealingPurushottam Sutar100% (1)

- Geas FinalDokument489 SeitenGeas FinalroselleNoch keine Bewertungen

- CCWDokument2 SeitenCCWspearboraNoch keine Bewertungen

- Sample Chapter ch17 PDFDokument37 SeitenSample Chapter ch17 PDFMaitraNoch keine Bewertungen

- Using An Automatic PipetteDokument6 SeitenUsing An Automatic PipetteMaria Jayiera Alkiela Pe�alesNoch keine Bewertungen

- I. Reading Development A. Before You ReadDokument11 SeitenI. Reading Development A. Before You Readhilda wirandaNoch keine Bewertungen

- Special Safety Practices For CSL2Dokument1 SeiteSpecial Safety Practices For CSL2ipliprensNoch keine Bewertungen

- Environmental Permitting Guidance The Solvent Emissions DirectiveDokument44 SeitenEnvironmental Permitting Guidance The Solvent Emissions Directiveultimet1Noch keine Bewertungen

- Pinch TechnologyDokument7 SeitenPinch TechnologyAakanksha MahajanNoch keine Bewertungen

- Soal Latihan Promanu 2020Dokument3 SeitenSoal Latihan Promanu 2020Jabir 08Noch keine Bewertungen

- Safety Data Sheet: Mastertile RSG 705 Grey Part C Also Mastertile 550 Grey AggregateDokument7 SeitenSafety Data Sheet: Mastertile RSG 705 Grey Part C Also Mastertile 550 Grey AggregateSamseyla Hun100% (2)

- Heat Transfer QuestionsDokument1 SeiteHeat Transfer QuestionsThebe Tshepiso Maitshoko0% (1)

- Brosur Closet TotoDokument177 SeitenBrosur Closet TotoWahyu KurniawanNoch keine Bewertungen

- Installation Manual For Bifacial PV M OduleDokument20 SeitenInstallation Manual For Bifacial PV M OdulejosepablohgNoch keine Bewertungen

- Common Forms OF MedicationDokument19 SeitenCommon Forms OF MedicationJonica AngNoch keine Bewertungen

- 12th Chemistry - Revision Test 1 Model Question Paper - English Medium PDF DownloadDokument4 Seiten12th Chemistry - Revision Test 1 Model Question Paper - English Medium PDF DownloadAathss AadhiNoch keine Bewertungen

- Pixl Knowit!: Gcse BiologyDokument66 SeitenPixl Knowit!: Gcse BiologyEsther SparksNoch keine Bewertungen

- Principles of Food Processing and Halal Requirement (WEEK 11)Dokument48 SeitenPrinciples of Food Processing and Halal Requirement (WEEK 11)aishah1997Noch keine Bewertungen

- NMR Lecture SOSDokument43 SeitenNMR Lecture SOSpoornanandhanNoch keine Bewertungen

- Biodegradation of Keratin Waste Theory and Practical AspectsDokument13 SeitenBiodegradation of Keratin Waste Theory and Practical AspectsRodrigo Lara100% (1)

- Catalogue 2018Dokument44 SeitenCatalogue 2018Hoa PhamNoch keine Bewertungen

- Nutrient Recovery From Wastewater Stream PDFDokument10 SeitenNutrient Recovery From Wastewater Stream PDFPedro RipaceNoch keine Bewertungen

- Chapter-1 Ishida2011Dokument79 SeitenChapter-1 Ishida2011sasidharkanthetiNoch keine Bewertungen

- Fischer Esterification of Benzyl AcetateDokument3 SeitenFischer Esterification of Benzyl AcetateMarjory CastilloNoch keine Bewertungen