Beruflich Dokumente

Kultur Dokumente

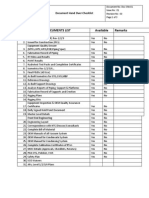

Att. 6.1 General Inspection and Testing

Hochgeladen von

bayuCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Att. 6.1 General Inspection and Testing

Hochgeladen von

bayuCopyright:

Verfügbare Formate

PART 4 Technical Requirements

SECTION 3 Technical Specifications

M-014 Inspection and Testing

TABLE OF CONTENTS

M-014 INSPECTION AND TESTING

1.

SCOPE OF WORK

Page No.

M.014 - 1

2.

CODES AND STANDARDS

M.014 - 1

3.

DEFINITION OF INSPECTION LEVEL

3.1. SPOT WTTNESS (SW)

3.2. WITNESS (W)

3.3. HOLD(H)

3.4. APPROVAL (A)

3.5. REVIEW (R)

M.014 - 1

M.014 - 1

M.014 - 1

M.014 - 1

M.014 - 2

M.014 - 2

4.

DESIGN AND OPERATING CONDITIONS.

M.014 - 2

5.

DETAILED REQUIREMENT

5.1. GENERAL

5.2. INSPECTION AND TESTS AT MANUFACTURER'S WORKS

M.014 - 2

M.014 - 2

M.014 - 3

M.014 - i GRATI CCPP (PEAKER) EXTENSION PROJECT

501 MW (GROSS OUTPUT)

PART 4 Technical Requirements

SECTION 3 Technical Specifications

M-014 Inspection and Testing

M-014 INSPECTION AND TESTING

1.

SCOPE OF WORK

The Contractor shall inspect, examine and test all test the equipment

and material during fabrication in shop and at site and also after

erection at site.

Test procedure shall be submitted to the Owner prior conduct the test.

AIl of inspection examine and test reports, shall be submitted to the

Owner for review and approval.

2.

CODES AND STANDARDS

The Contractor shall comply with the requirements of Part 4, Section 2.5

"Codes and Standards".

3.

DEFINITION OF INSPECTION LEVEL

3.1.

SPOT WITNESS (SW)

Spot Witness inspection point is an activity during implementation of

works where interim measurements, and/or witness of activity

conformation Normally take place, prior to the final measurement or

inspection being lone.

3.2.

WITNESS (W)

Witness inspection point is an activity during implementation of works

where inspection, measurements and/or testing take place and shall be

documented.

Prior to performing the inspections, measurements or tests, the

Contractor is required to give written notice to the Owner. However in

some cases this will not be possible, in such cases the Owner will

depend on the amount of notice given and availability of the Owner, he

will endeavour to attend the inspection or test. If it is not possible aid

depending on the criticality of the inspection, the Owner may waive his

attendance or ask for the inspection to be deferred until the Owner is

available. If the inspection is waived, the Contractor may proceed with

his own inspection witnessing. The result shall be fully documented and

submitted to the Owner for approval.

3.3.

HOLD(H)

3.3.1.

Hold point is an activity during implementation of works where

inspection, measurement, testing must take place, having mandatory

M.014 - 1 GRATI CCPP (PEAKER) EXTENSION PROJECT

501 MW (GROSS OUTPUT)

PART 4 Technical Requirements

SECTION 3 Technical Specifications

M-014 Inspection and Testing

attendance of the Owner. The Cotractor cannot proceed with the next

work step activity until the inspection, measurement, or test has been

witnessed and approved by all the attending parties. Again, the

Contractor shall give written notification in advance to the Owner for

measurement and work quality inspections.

3.3.2.

Inspections conducted under hold point category will not be waited for

the Owner attendance.

3.4.

APPROVAL (A)

A document or drawing which is required approval to the Owner prior to

proceeding with the activity.

3.5.

REVIEW (R)

3.5.1.

Documents or drawings which are submitted for review to the Owner.

3.5.2.

The Contractor shall prepare a detailed inspection and test plan

indicating inspection level based on definition herein. The inspection

and test plan shall include attendance requirements by the Owner.

4.

DESIGN AND OPERATING CONDITIONS.

(Not used)

5.

DETAILED REQUIREMENT

5.1.

GENERAL

5.1.1.

All plant and materials shall be subject to inspection and test as

required for this plant. Approval of part or the whole of the plant by the

Owner, or the passing of any such inspection or test, will not, however

prejudice the Owner's right to reject the equipment. The cost of all tests

and inspections shall be borne by the Contractor. Furthermore,

inspecting and expediting by the Owner in no way relieves the

Contractor of his responsibility for quality assurance and delivery

commitments.

5.1.2.

Before any equipment is packed or dispatched from the main or SubContractor's Weeks, all relevant tests called for in tits section shall have

been successfully carried out in accordance with appropriate standards

and to the satisfaction of the Owner or his representatives, who shall

have seen and approved the test results.

5.1.3.

The Owner shall be given the option of witnessing all tests, and at least

21 days notice shall be given before tbe equipment or plant is ready for

inspection or test to enable the Owner to make necessary arrangements

for witnessing the test.

M.014 - 2 GRATI CCPP (PEAKER) EXTENSION PROJECT

501 MW (GROSS OUTPUT)

PART 4 Technical Requirements

SECTION 3 Technical Specifications

M-014 Inspection and Testing

5.1.4.

Every facility shall be provided by the Contractor and his Sub-Contractor

for inspection or test to enable the Owner to carry out the necessary

inspection and witnessing of tests.

5.1.5.

All tests on materials and equipment shall be conducted in accordance

with the codes and standards indicated in this Specification. Any tests

on materials or equipment not covered by codes or standards in this

Specification are to be agreed in advance by the Owner.

5.1.6.

The Contractor shall provide test pieces as required by the Owner and

shall perform mechanical tests required by the relevant codes and

standards.

5.1.7.

If any test piece fails to comply with the requirements of the appropriate

Specification, the Owner reserves the right to reject the material in

question and have it replaced.

5.1.8.

The Contractor shall provide the Owner with 4 (four) copies of all suborders and inter-works orders at the time of issue. These shall be in the

English Language, suitably endorsed, "Subject to inspection, and

expediting by the Owner and/or their nominated representative".

5.1.9.

1 (one) original and 5 (five) copies of Mill and test certificates, which

shall be in English, shall be supplied to the Owner. The Contractor shall

supply at the ex-works stage 6 (six) bound copies of all certification,

suitably indexed to cover all tests of material and equipment.

5.1.10.

Where type test are specified, in addition to routine tests the Contractor

may submit to the Owner type test certificates in lieu of actual type

tests, provided these have, been independently witnessed and cover

identical items of plant.

5.1.11.

For all non-destructive examination (NDE), the Contractor shall propose

the best of Acceptance Criteria Levels to be used for testing subject to

the Owner's approval, unless otherwise specified.

5.2.

INSPECTION AND TESTS AT MANUFACTURER'S WORKS

5.2.1.

General

Works inspection shall include mechanical and hydraulic tests, as well,

as running and functional tests (under simulated conditions) on the

assembled equipment, prior to shipment to the Site, in accordance with

the relevant standards or as otherwise agreed with the Owner.

5.2.2.

Non-destructive Testing

Materials requiring non-destructive tests, except where stated otherwise

in this Specification, shall be performed in accordance with the

following:

M.014 - 3 GRATI CCPP (PEAKER) EXTENSION PROJECT

501 MW (GROSS OUTPUT)

PART 4 Technical Requirements

SECTION 3 Technical Specifications

M-014 Inspection and Testing

ASTM El 14 ................ Standard Practice for Ultrasonic Pulse-Echo

Straight-Beam

Examination by the Contact Method

ASTM E94 .................. Standard Guide for Radiographic testing

ASTM E142 ................ Controlling Quality of Radiographic Testing

ASTM E709 ............... Standard Guide for Magnetic particle inspection

ASTM El65 ................. Standard Test Method for Liquid penetrant

Inspection

5.2.3.

Welding

5.2.3.1.

Prior to commencement of any welding of the work, the Contractor shall

have all welding procedures, welding equipment and operators qualified

in accordance with ASME Boiler and Pressure Vessel Code Section IX

welding qualifications or other standards as approved by the Owner. All

welding procedure and welder certificates shall be submitted to the

Owner for his approval. A list of the qualified operators to be used in the

work must be available for the Owner's inspection prior to start of any

welding.

5.2.3.2.

Strict measures of quality control shall be exercised throughout the

work.

5.2.3.3.

The Owner may call for a radiograph of the work of any operator who in

his opinion is not maintaining the standard of workmanship required.

Where the interpretation of radiograph proves the welding to be of poor

quality, the Owner reserves the right to re-examine all radiographs on all

production welds done by the operator. Should the welding prove

unacceptable, the operator is to be removed from any further production

welding until re-qualified, and all defective or sub-par weld shall be reworked by other qualified operator. Indonesian welders who are

involved in the Project shall have certificates issued by Man Power

Department of Government of Indonesia.

5.2.3.4.

Ultrasonic inspection when called for in the code or in this Specification

shall be in accordance with:

ASTM E164 Standard Practice for Ultrasonic Contact Examination of

Weldments

5.2.3.5.

Imperfection found by ultrasonic examination shall be judged against

the acceptance - rejection standards outlined in ASME Code Section

VIII Div. 1, Appendix 12, and in the case of radiographic examination as

outlined in paragraph UW 51 or UW 52 as applicable.

5.2.4.

Castings

5.2.4.1.

Each pressure retaining casting and each major load-bearing casting

shall have an integral test bar, wherever possible, from which

mechanical test specimens can be taken. Test specimens shall be in

accordance with ASTM A370 "Methods and Definitions for Mechanical

M.014 - 4 GRATI CCPP (PEAKER) EXTENSION PROJECT

501 MW (GROSS OUTPUT)

PART 4 Technical Requirements

SECTION 3 Technical Specifications

M-014 Inspection and Testing

Testing of Steel Products" and ASTM E8 "Tension Testing of Metallic

Materials". Nondestructive testing when required shall be carried out in

accordance with the standards outlined in Clause 4.2.2. The standard

as mentioned shall be the latest edition.

5.2.4.2.

Defects in castings which have been found by radiography, magnetic

particle or liquid penetrant inspection are to be assessed against the

following standards which shall be used as a basis for acceptance or

rejection of the casting.

a)

b)

c)

d)

ASTM E186: Standard Reference Radiographs for Heavy-Walled

(51 to 144 mm) Steel Castings

ASTM E280: Standard Reference Radiographs for Heavy-Walled

(114 to 305 mm) Steel Castings

ASTM E446: Standard Reference Radiographs for Steel Casting

Up to 51 mm in Thickness

ASTM E125: Standard Reference Photographs for Magnetic

Particle Indications on Ferrous Casting

5.2.4.3.

For N.D.T acceptance/rejection standards refer to ASME Sect. VIII Div.

5.2.4.4.

Except where stated otherwise the limit of acceptability for all major

castings such as boiler and turbine stop valves, turbine casings, strainer

chests and boiler feed pump casings which have been radiographed,

shall be severity level 1. All parts of castings over 300 mm thick shall be

ultrasonically examined.

5.2.4.5.

Castings rejected through the application of the above techniques may

be repaired by welding, subject to meeting the requirements states in

ASME Section VIII, Division 1 and ASTM A-488 "Recommended

Practice Qualification of Procedures and Personnel for the Welding of

Steel Castings". Repairs will not be allowed to grey iron castings having

injurious defects.

5.2.4.6.

Where a casting forms part of welded assembly, the welds shall be

examined in accordance with ASME Section VIII, Division 1, and

paragraph UW 51.

5.2.4.7.

Boiler feed pump casings, impellers and diffusers shall be subjected to

a complete magnetic particle or dye penetrant test. In addition

radiographs shall be taken on all impellers, covering the shroud areas,

from the neck to the outside diameter.

5.2.5.

Forgings

5.2.5.1.

Test pieces shall be provided for all steel forgings and subjected to

physical tests in accordance with ASTM A370 and ASTM E38, except

where specified otherwise in this specification. All steel forgings after

rough machining shall be subject to an ultrasonic examination in

accordance with ASTM A388 "Ultrasonic Examination of Heavy Steel

M.014 - 5 GRATI CCPP (PEAKER) EXTENSION PROJECT

501 MW (GROSS OUTPUT)

PART 4 Technical Requirements

SECTION 3 Technical Specifications

M-014 Inspection and Testing

Forgings". Magnetic particle inspection shall also be carried out at areas

of fillets and change of section in accordance with ASTM A275

"Magnetic Particle Examination of Steel Forgings".

5.2.5.2.

Imperfection found by ultrasonic examination shall be judged against

the acceptance/rejection standards outlined in ASME Section VIII.

5.2.6.

Rotor Forgings

5.2.6.1.

Rotor for gas turbines, steam turbines, generators, boiler feed pumps

and other equipments, shall be tested and inspected by Ultrasonic in

accordance with ASTM A418 "Ultrasonic Inspection of Turbine and

Generator Steel Forgings". The choice of rotating or stationary tests

shall be based on the specific design of the rotor to be tested and shall

be subject to the approval of the Owner. The Contractor shall perform

thermal stability tests on turbine rotors in accordance with ASTM A472.

5.2.6.2.

All generator rotor forgings shall be subject to fracture appearance

transition temperature tests, and magnetic permeability and resistivity

tests. An ultrasonic examination shall be carried out in accordance with

ASTM A418 after rough machining.

5.2.6.3.

Ultrasonic and magnetic permeability tests shall be carried out for rotor

end winding retaining ring forgings. The retaining ring shall be ultrasonic

and dye penetrant checked in the rough machined state and

hydraulically tested followed by dye penetrant inspection after final

machining. Ultrasonic inspection shall be in accordance with ASTM

A351 "Ultrasonic Inspection of Turbine Generator Steel Retaining

Rings".

5.2.7.

Fabricated Components

5.2.7.1.

All components machined or fabricated from plate, sheet or bar stock

shall meet, the material requirements of ASTM or material specification

approved by the Owner.

5.2.7.2.

All components shall be subjected to two or more of the following tests,

as agreed by the Owner:

a).

b).

c).

d).

e).

5.2.7.3.

Visual and dimensional

Dye penetrant

Magnetic particle

Ultrasonic

Radiographic

These tests shall be in accordance with the recommended practices of

the ASTM. The terms of reference for acceptance shall be the

applicable ASTM specifications or equivalent standard as applicable.

M.014 - 6 GRATI CCPP (PEAKER) EXTENSION PROJECT

501 MW (GROSS OUTPUT)

PART 4 Technical Requirements

SECTION 3 Technical Specifications

M-014 Inspection and Testing

5.2.8.

Alloy Valves

Alloy steel valves, steam chests and fittings shall be supplied complete

with forged stub ends of material suitable for site welding of the

adjoining pipe. Weld preparations shall be subjected to a crack

detection test and be fully radiographed for a distance of 75 mm from

each end in accordance with ASTM E94 "Recommended practice for

Radiograph Testing" and shall be judged by reference Radiographs for

Steel Castings ASTM E186 and E446 as applicable. Acceptance

standards for crack detection tests shall be in accordance with ASTM

Section VIII Division 1.

5.2.9.

Heat Treatment

All parts subject to heat treatment shall have adequate records kept,

giving details of rate of rise and fall of temperature, holding time,

temperature and method of cooling.

5.2.10.

HRSG Pressure Parts

All HRSG pressure parts shall be tested in accordance with the

requirements of the ASME Boiler and Pressure Vessel Code unless

otherwise specified.

5.2.11.

Pipework

5.2.11.1.

All fabricated pipework shall be in accordance with standards as

specified by ANSI B31.1 "Power Piping", latest edition.

5.2.11.2.

Temperature records of hot forming and heat treatment operations shall

be made, and submitted to the Owner.

5.2.11.3.

The wall thickness of hot fomied bends shall be checked by ultrasonic

method. Records of these tests shall be kept and made available to the

Owner.

5.2.11.4.

Where random radiography is specified, it shall refer to the final weld

only, and shall be at Owner's selection and discretion.

5.2.11.5.

For the purposes of radiographic inspection a root pass is defined as

the first complete weld run.

5.2.11.6.

All piping not covered by 100 % radiography shall be hydraulic ally

tested to 1.5 times the design pressure.

5.2.11.7.

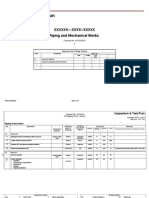

The following table 1 gives the butt weld radiographic requirements for

the major steam, water, oil lines.

5.2.11.8.

Quantitative Non-destructive Examination Requirement for Piping

System.

M.014 - 7 GRATI CCPP (PEAKER) EXTENSION PROJECT

501 MW (GROSS OUTPUT)

PART 4 Technical Requirements

SECTION 3 Technical Specifications

M-014 Inspection and Testing

In additional to the NDT requirements stated in ANSI B31.1 paragraph

136, percentages given are percentages of the total number of welds to

be examined by radiographic testing for nominal pipe sizes over 50 mm

and by magnetic particle or liquid penetrant testing for sizes 50 mm and

less.

(Table 1) Quantitative Non-destructive Examination Requirements for

Piping Systems

Piping

Roor Pass

Final Pass

(After PWHT

where applicable)

Main steam (HP, IP and LP). HP

auxiliary ami glind steam

HP turbine by-pass, loop pipes

LP auxiliary steam, make-up and

recirculation drain system

100%

100%

100%

None

100%

10%

All drain system, and vents

HP feedwater

LP bypass, LP fsedwater, condensate, oil

system, air system

None

100%

None

10%

100%

20%

Fuel oil, natural gas, bleed steam, all

process water (including circulating

and closed cooling) system, CO2 system

None

10%

The above requiements are applicable to both site and shop welds.

5.2.12.

Magnetic Particle or Dye Penetrant Inspection

5.2.12.1.

All nozzles, branch connections, butt welds and attachment welds in

alloy steel pipe shall be subjected to magnetic particle or dye penetrant

inspection.

5.2.12.2.

Magnetic particle inspection shall be carried out in accordance with

ASTM E709.

5.2.12.3.

When dye penetrant method is used, it shall be contacted in accordance

with ASTM E165 and applied as directed by the penetrant

manufacturer.

5.2.13.

Turbine, Generator and Auxiliaries

5.2.13.1.

The Contractor shall perform all tests and inspection necessary to

ensure that the material and workmanship conform to the Contract and

design drawings and those tests are adequate to demonstrate that the

equipment will comply with the requirements of these Specifications and

meet the guarantees specified.

M.014 - 8 GRATI CCPP (PEAKER) EXTENSION PROJECT

501 MW (GROSS OUTPUT)

PART 4 Technical Requirements

SECTION 3 Technical Specifications

M-014 Inspection and Testing

5.2.13.2.

The generator and the turbine rotors shall be overspeed tested at 20%

above rated speed and balanced in accordance with IEC Publication 45.

The generator rotor test shall be carried out to demonstrate the absence

of shorted turns in the rotor winding. These tests shall be performed

throughout the speed range of the generator. High voltage dielectric

tests and insulation resistance measurements shall be carried out on

the rotor winding before and after the overspeed test.

All items such as assemblies, sub-assemblies and systems shall be

subject to inspection by the Owner. Such items shall include but not

limited to: casing, bedplate, coupling, coolers, bearings, stator core,

rotor, brushgear, terminations, auxiliaries, piping. Systems such as

lubrication, seal oil, demineralized water and shall have both their

individual components and the whole system functionally tested.

Where possible functional tests of the systems shall be carried out

connected to the generator, and before shipping to Site.

Where the generator or main parts are not fully assembled in the shop,

the items shall be trial fitted together before shipping.

The build-up tolerances shall be checked and recorded.

5.2.13.3.

The generator stator casing and end shield shall be hydrostatically

pressure tested, for 15 minutes to specified design pressure.

A ring flux test shall be carried out on the completed stator core to

demonstrate absence of local hot spots,

All parts subject to steam or water pressure shall be tested with

hydraulic pressure of 50% in excess of the highest working gauge

pressure to which the component will be subjected. All equipment shall

be tested under simulated working conditions and conducted in

accordance with the appropriate ASME Power Test Code.

5.2.14.

Condenser and Auxiliaries

5.2.13.4.

The condenser tube bundles including tube sheets, tube support plates,

baffles, and all stay bars shall be assembled in the Contractor's or SubContractor's works to ensure correct alignment of mating pieces and the

supports.

5.2.13.5.

All condenser tubes shall be pneumatically tested to 10 kg/cm2g

internal pressure and carefully inspected prior to shipment.

5.2.13.6.

Should the Owner deem it necessary, the Contractor shall perform an

ultrasonic test on the condenser tubes in addition to hydraulic testing.

5.2.15.

Deaerator and Heat Exchangers

M.014 - 9 GRATI CCPP (PEAKER) EXTENSION PROJECT

501 MW (GROSS OUTPUT)

PART 4 Technical Requirements

SECTION 3 Technical Specifications

M-014 Inspection and Testing

All materials, welding and non-destructive testing shall meet the

requirements outlined in ASME Section VIII "Pressure Vessel Code" and

ASME Section IX "Welding Qualification".

All parts subject to steam or water pressure shall be tested at a hydraulic

pressure 1.5 time of the design pressure.

All closed cooling water heat exchanger tubes shall be pneumatically

tested to 10 kg/cm2g internal pressure and carefully inspected prior to

installation.

5.2.16.

Circulating Water Pump & Screen

5.2.13.7.

The Circulating Water pumps shall be tested at the specified minimum

submergence and static lift to confirm pump total head and power

requirements between shut-off, maximum rated flow and run-out

conditions. On completion of the tests the submergence shall be

decreased to verify the NPSH requirements at maximum rated flow.

5.2.13.8.

The Close Circuit Water pumps shall be tested to determine

head/capacity, and head/power characteristic curves and to verify

freedom from vibration between shut-off, maximum rated flow and runout conditions.

5.2.13.9.

The Contractor shall submit detail inspection and test procedure

complete with references, codes and standards, and acceptance criteria

to the Owner for review and approval prior to perform the test.

5.2.13.10.

Each travelling band screen or drum screen shall be completely

assembled in the Contractor's or Sub-Contractor works to ensure

correct alignment of mating parts and supports.

5.2.13.11.

All parts subject to pressure shall be hydraulically tested to 1.5 time of

the design pressure prior to shipment.

5.2.17.

Pumps-General

5.2.13.12.

All casting and forgings shall meet the requirement stated in Clause

5.2.4 and 5.2.5. herein.

All parts subject to pressure shall be tested at a hydraulic pressure 1.5

time of the specified design pressure.

The pumps shall be shop tested in accordance with the Hydraulic

Institute Standard for the centrifugal pumps.

5.2.13.13.

Certified pump performance curves and list certificates shall be

submitted to the Owner for approval, and for records.

Pumps shall not be shipped until the Owner has seen and approved the

test results.

M.014 - 10 GRATI CCPP (PEAKER) EXTENSION PROJECT

501 MW (GROSS OUTPUT)

PART 4 Technical Requirements

SECTION 3 Technical Specifications

M-014 Inspection and Testing

Where applicable, pumps shall be assembled with their spare inner

assemblies and shall be shown to be interchangeable.

5.2.18.

Valves

a)

All Valves

Valves shall be hydrostatically tested in accordance with ANSI

B16.34 or API 598.

Circulating Water Butterfly Valve

The Contractor shall test the butterfly valves at his works prior to

shipping, in accordance with AWWA Standard 504.

b)

Power Operated Valves

Completed valves and actuators shall be tested under load to

determine the following:

Valve operating time to open and close

ii Clutch coil current at rated voltage

iii Motor currents at rated voltage for the following condition:

Starting

Full load

Maximum during opening operation

Maximum during closing operation

5.2.19.

Pressure Vessels

5.2.19.1.

All pressure vessels shall be inspected and tested in accordance with

ASME Section VIII, Division 1 latest edition. Specially for hydrostatic

test, 1.5 times of design pressure shall be applied as a test pressure.

5.2.19.2.

When the vessel is subjected to local regulations, it may have to

undergo a second official test following the first one.

5.2.19.3.

The Contractor shall submit complete manufacturing data records that

consisting of list of qualified welders, welding procedures, welding map,

welder certificates, NDE records, hydrostatic test. etc. for each pressure

vessel fabricated at shop or site to the Owner for review and approval.

5.2.20.

Inspection and Tests at the Site

The Contractor shall submit to the Owner for approval a comprehensive

quality control plan, covering die pressure pans of the HRSG, erection

of the turbine generator, welding of the associated pipework, and

erection of all ancillary plant and the electrical equipment.

This document shall identify the number of supervisory personnel and

degree of inspection and tests expected to be carried cut during

erection up to completion. It should be equal to that level of ccitrol

which has been applied at the works and in compliance with the codes

and standards identified in this Specification. In addition, records of all

M.014 - 11 GRATI CCPP (PEAKER) EXTENSION PROJECT

501 MW (GROSS OUTPUT)

PART 4 Technical Requirements

SECTION 3 Technical Specifications

M-014 Inspection and Testing

welders' qualification are to be submitted to the Owner for approval

prior to welding. Records of all heat treatment aid non-destructive tests

carried out are also to be submitted to the Owner.

5.2.21.

Hydrostatic Testing

The Contracor shall, upon completion of erection, subject all the

pressure parts to a hydraulic pressure test which meets ASME Boiler

and Pressure Vessel Code requirements. All pressure parts shall be

subjected to the test prior to any boiler casing installation, the

Contractor shall supply and install all equipment, piping and materials,

inducing lhe safety valve gauges and pumps, required and necessary

for the tests.

5.2.22.

Site Pipe work ind Hydrostatic Test

5.2.22.1.

The table for butt weld radiography given in this Section shall be used

as the basis for the extent of radiography requirements at the Site.

5.2.22.2.

Where radiographs of Site butt welds joint root or initial passes are

called for, they shall be radiographed hot by the Contractor, subject to

the minimum weld deposit thickness as given in ANSI Power Piping

Code, B.31.1, Section 131.

5.2.22.3.

The Contractor shall perform hydrostatic test on all pipework not

covered by 100% radiogaphy to a pressure not less than 1.5 times

design pressure. These tests shall be carried out in the presence of the

Owner or his representatives. For the purposes of the hydrostatic test,

the Contractor shall provide temporary blanking off pieces.

5.2.23.

Tanks

5.2.23.1.

Vertical Tanks

a) All tanks constructed at site, except where specified otherwise in

this Specification, shall be subject to inspection and testing, in

accordance with the requirements stated in API 650.

b) The Contractor before carrying out any welding shall meet the

conditions stated in Clause 5.2.3 of this Specification.

c) Checking of the welded seams shall be by spot radiography. The

number and location of radiographs shall be as specified in API

650, Section 6. The Owner reserves the right to call for additional

nondestructive tests as he may consider necessary.

d) On completion, all tanks shall be subjected to the tests prescribed

in API 650, Section 5.

5.2.23.2.

Horizontal Tanks

a) All tanks constructed at site, except where specified otherwise in

this Specification shall be subject to inspection and testing, in

M.014 - 12 GRATI CCPP (PEAKER) EXTENSION PROJECT

501 MW (GROSS OUTPUT)

PART 4 Technical Requirements

SECTION 3 Technical Specifications

M-014 Inspection and Testing

accordance with the requirements stated in ANSI/AWWA D100

Standard for Welded Steel Tanks for Water Storage.

b) The Contractor before carrying out any welding shall meet the

conditions stated in Clause 5.2.3 of this Specification.

c) Checking of the welded seams shall be by spot radiography except

those welds excluded by ANSI/AWWA D100. The number and

location of radiographs shall be as specified in ANSI/AWWA D100

Section 11.

d) On completion, all tanks shall be subjected to the tests prescribed

in ANSI/AWWA D100 Section 11 "Testing".

5.2.24.

Rotating Equipment, Vibration

5.2.24.1

Rotating Equipment such as pumps shall be subject to a test for

checking correct rotation, and to verify vibration and noise guarantees.

5.2.24.2

Unless otherwise stated or agreed by the Owner each rotating machine

has to comply with the requirements for vibration magnitude (criterion I)

designation as "zone A" stipulated by ISO Specification 10816 for the

respective group of machinery. If the vibration magnitude is greater than

stipulated as "zone B", the Owner has the right to reject the concerned

equipment.

5.2.24.3

Noise emissions shall meet the requirements of Part 4 Section 2.9 and

2.16.

5.2.25.

Rubber Lining (Piping & Tanks)

5.2.25.1.

Pin-hole test and visual check of complete lining including any patched

portion shall be carried out. The voltage used shall be 75 % of the

breakdown voltage of the coating. This break-down voltage shall be first

determined using test plates coated with the specified rubber lining and

thickness, separately. The coating on the test plate shall also be microsectioned, by the applicator to show that it is free from vacuoles and

other defects.

5.2.25.2.

If the defects revealed by the above test procedure do not exceed one

part per 5 m2 of coating surface, the coating need not be retested after

the defects have been repaired. If the defects exceed one part, per 5 m2

of coating surface, the repairs shall be retested, and this procedure shall

be repeated until the defects are less than one part, per 5 M2 of coating

surface.

5.2.26.

Additional Tests

5.2.26.1.

In addition to the tests listed above, the Contractor shall demonstrate

the function and capability of all equipment and systems supplied under

M.014 - 13 GRATI CCPP (PEAKER) EXTENSION PROJECT

501 MW (GROSS OUTPUT)

PART 4 Technical Requirements

SECTION 3 Technical Specifications

M-014 Inspection and Testing

the Contract, to perform in accordance with the Specification

requirement, and shall be conducted in accordance with the testing

procedure.

(Last page of M-014)

M.014 - 14 GRATI CCPP (PEAKER) EXTENSION PROJECT

501 MW (GROSS OUTPUT)

Das könnte Ihnen auch gefallen

- EP-MS-P7-F5 Check List of Documents Required For Pre-Qualification of 11KV ID Switchgear PanelsDokument2 SeitenEP-MS-P7-F5 Check List of Documents Required For Pre-Qualification of 11KV ID Switchgear PanelsME4ARDNoch keine Bewertungen

- Inspection Request: Report #: RE/INRQ/ Date: 24-Sep-17 Page: 1 of 1Dokument1 SeiteInspection Request: Report #: RE/INRQ/ Date: 24-Sep-17 Page: 1 of 1mansih457Noch keine Bewertungen

- 14 Inspection and TestingDokument3 Seiten14 Inspection and TestingelmiraNoch keine Bewertungen

- Engineering Document ListDokument98 SeitenEngineering Document ListRamahNoch keine Bewertungen

- 00-GE-EQA-001 (Rev.a) Site Inspection and Test Plan For Electrical and I&C WorkDokument12 Seiten00-GE-EQA-001 (Rev.a) Site Inspection and Test Plan For Electrical and I&C WorkAbdul Mohid SheikhNoch keine Bewertungen

- 012 QualityNewsLetter - January2012Dokument8 Seiten012 QualityNewsLetter - January2012ரமேஷ் பாலக்காடுNoch keine Bewertungen

- Handover To QAQC-Anand KumarDokument6 SeitenHandover To QAQC-Anand KumarAnonymous fBkcEze1Noch keine Bewertungen

- Document Hndover ChecklistDokument3 SeitenDocument Hndover ChecklistM Uzair ShaikhNoch keine Bewertungen

- Inspection Test Plan For ElectricalDokument38 SeitenInspection Test Plan For ElectricalkhoerulNoch keine Bewertungen

- Handover CertificateDokument1 SeiteHandover CertificateAnonymous lYh4o1ybNoch keine Bewertungen

- ITP-000 Piping Fabrication (Exemple)Dokument5 SeitenITP-000 Piping Fabrication (Exemple)alinor_tn100% (1)

- Electrical Method Statement GN 8Dokument5 SeitenElectrical Method Statement GN 8Chandree BoonzaaierNoch keine Bewertungen

- Rotating Equipment PreservationDokument7 SeitenRotating Equipment PreservationaamirapiNoch keine Bewertungen

- Contractor QAP for HT Breaker PanelDokument1 SeiteContractor QAP for HT Breaker Panelmadhu_bedi12Noch keine Bewertungen

- Sa P 030Dokument4 SeitenSa P 030Haleem Ur Rashid BangashNoch keine Bewertungen

- Endorsement Sheet For QP: Reference / Standard / Field Quality Plan (RQP / SQP/RFQP/SFQP) To Be Filled in by NTPCDokument33 SeitenEndorsement Sheet For QP: Reference / Standard / Field Quality Plan (RQP / SQP/RFQP/SFQP) To Be Filled in by NTPCEzhil Vendhan Palanisamy100% (1)

- Field Mechanical Work Inspection & Test Plan: Job No.: Owner: Client: ProjectDokument12 SeitenField Mechanical Work Inspection & Test Plan: Job No.: Owner: Client: ProjectbasukiNoch keine Bewertungen

- Checklist of C&i For Full Load OperationDokument9 SeitenChecklist of C&i For Full Load Operationrohit_me083Noch keine Bewertungen

- MNT-INTG-2007OP - Maintenance Welding InspectionDokument43 SeitenMNT-INTG-2007OP - Maintenance Welding InspectionNatarajan MurugesanNoch keine Bewertungen

- MQP of PanelDokument1 SeiteMQP of Panelrahulchitrakoot123Noch keine Bewertungen

- QC EngineerDokument4 SeitenQC EngineerSajjad AfzalNoch keine Bewertungen

- Itp PWHTDokument1 SeiteItp PWHTTridib DeyNoch keine Bewertungen

- PO No 2037-PL-PL-0058 Inspection Notification No-015 r1 PDFDokument1 SeitePO No 2037-PL-PL-0058 Inspection Notification No-015 r1 PDFDadaso Baburao JamdarNoch keine Bewertungen

- 3x200KVA UPS System Technical SpecificationsDokument46 Seiten3x200KVA UPS System Technical Specificationspradeep.selvarajanNoch keine Bewertungen

- Upgrade Waste Water Systems Electrical Tie-InsDokument75 SeitenUpgrade Waste Water Systems Electrical Tie-InsHaleem Ur Rashid Bangash100% (1)

- Presentation On NTPC Inspection ServicesDokument34 SeitenPresentation On NTPC Inspection ServicesAshwani Dogra100% (3)

- Inspection and Test Plan For Induction MotorDokument5 SeitenInspection and Test Plan For Induction Motormuhammad wafi100% (1)

- UNIT 1 Routine Maintenance Check On Gas TurbineIIIDokument3 SeitenUNIT 1 Routine Maintenance Check On Gas TurbineIIImuaz_aminu1422Noch keine Bewertungen

- Saudi Aramco Typical Inspection Plan: Pneumatic Pressure Testing SATIP-A-004-01 MechanicalDokument10 SeitenSaudi Aramco Typical Inspection Plan: Pneumatic Pressure Testing SATIP-A-004-01 MechanicalTariqMalikNoch keine Bewertungen

- Piping Inspection and Test PlanDokument22 SeitenPiping Inspection and Test PlanHaythem Ben Zid100% (1)

- Design of A Chemical Plant PDFDokument2 SeitenDesign of A Chemical Plant PDFAdarsh SvNoch keine Bewertungen

- Factory and site testing of electrical switchgearDokument2 SeitenFactory and site testing of electrical switchgearAlla Naveen KumarNoch keine Bewertungen

- Inspection Report For Pipeline Route Survey Sign Copy and Blank FormatDokument1 SeiteInspection Report For Pipeline Route Survey Sign Copy and Blank FormatVishvjeet Prakash TiwariNoch keine Bewertungen

- 502mva Transformer Installation ScheduleDokument4 Seiten502mva Transformer Installation ScheduleNaukhez A. KashifNoch keine Bewertungen

- Electrical Works Grounding ITPDokument3 SeitenElectrical Works Grounding ITPUtku Can KılıçNoch keine Bewertungen

- ITR-B (Piping) Witness Joint1Dokument1 SeiteITR-B (Piping) Witness Joint1Momo ItachiNoch keine Bewertungen

- AUH QA&QC MS 01 Receiving InspectionDokument5 SeitenAUH QA&QC MS 01 Receiving Inspectionsaifullah629Noch keine Bewertungen

- Template (Electrical Works)Dokument10 SeitenTemplate (Electrical Works)Anonymous Qu7LeENoch keine Bewertungen

- ITP (Electrical)Dokument6 SeitenITP (Electrical)petroniko8880% (5)

- Inspection and Test Plan For Induction MotorDokument5 SeitenInspection and Test Plan For Induction MotorDino PedutoNoch keine Bewertungen

- Cable Tray InstallationDokument1 SeiteCable Tray InstallationNaeemNoch keine Bewertungen

- Medium voltage switchgear for marine and offshore applicationsDokument20 SeitenMedium voltage switchgear for marine and offshore applicationsnicholasleeNoch keine Bewertungen

- Incoming Equipment For Factory Inspection/Testing (FAT) : StepsDokument1 SeiteIncoming Equipment For Factory Inspection/Testing (FAT) : StepsGoyal SanjaiNoch keine Bewertungen

- Inspection General for Plant's EquipmentDokument80 SeitenInspection General for Plant's EquipmentRjeb mohamedNoch keine Bewertungen

- Fieid Quality Plan: DC Industrial Plant Services Pvt. Ltd. KOLKATA - 700 016Dokument4 SeitenFieid Quality Plan: DC Industrial Plant Services Pvt. Ltd. KOLKATA - 700 016Sam100% (1)

- Bolt Torque Sequence 01Dokument17 SeitenBolt Torque Sequence 01gechaves1Noch keine Bewertungen

- QA/QC EngineeringDokument2 SeitenQA/QC EngineeringStrahinja RadakovicNoch keine Bewertungen

- Maint - Check List - Oil Filled TransforsDokument2 SeitenMaint - Check List - Oil Filled TransforsramNoch keine Bewertungen

- CV PM Om 04 06 2019Dokument6 SeitenCV PM Om 04 06 2019soumya19800000000Noch keine Bewertungen

- Inspection and Test PlanDokument10 SeitenInspection and Test PlanixoteeNoch keine Bewertungen

- Inspection and Testing Plan (Itp) Item: Instruments Air PipingDokument9 SeitenInspection and Testing Plan (Itp) Item: Instruments Air PipingNguyen DienNoch keine Bewertungen

- F01 Rev.1 Inspection Checklist 1Dokument1 SeiteF01 Rev.1 Inspection Checklist 1kamilNoch keine Bewertungen

- Fin fan cooler cleaning scopeDokument2 SeitenFin fan cooler cleaning scopeShams TabrezNoch keine Bewertungen

- BGR-PPD-208-EL-FQP-0553, REV0 - 28.01.2015 - Action 5Dokument4 SeitenBGR-PPD-208-EL-FQP-0553, REV0 - 28.01.2015 - Action 5Santoshkumar GuptaNoch keine Bewertungen

- Engine Generator Set Inspection Checklist: Section A - Customer DataDokument2 SeitenEngine Generator Set Inspection Checklist: Section A - Customer Datasri_lntNoch keine Bewertungen

- Control Panel Inspection Test PlanDokument4 SeitenControl Panel Inspection Test PlanPradipta SetioNoch keine Bewertungen

- Appendix 11, Electrical Inspection and Test PlanDokument1 SeiteAppendix 11, Electrical Inspection and Test PlanBraulio MartinezNoch keine Bewertungen

- Testing and CommissioningDokument10 SeitenTesting and Commissioningsallammohamed100% (1)

- Total Technical Specs PDFDokument259 SeitenTotal Technical Specs PDFBhavesh KeraliaNoch keine Bewertungen

- General Technical Specification: © 2007 MECON Limited All Rights ReservedDokument5 SeitenGeneral Technical Specification: © 2007 MECON Limited All Rights ReservedAK TRIPATHINoch keine Bewertungen

- Daily Manpower Report CJP 2x1000 MW ProjectDokument32 SeitenDaily Manpower Report CJP 2x1000 MW ProjectbayuNoch keine Bewertungen

- Colour Shape and PaternsDokument1 SeiteColour Shape and PaternsbayuNoch keine Bewertungen

- Daftar Harga MaterialDokument8 SeitenDaftar Harga MaterialbayuNoch keine Bewertungen

- Scaffolding Calculation - Sep-Nov 2019Dokument2 SeitenScaffolding Calculation - Sep-Nov 2019bayuNoch keine Bewertungen

- Construction Performance Control in Steel Structures Projects 2169 0316 1000201Dokument11 SeitenConstruction Performance Control in Steel Structures Projects 2169 0316 1000201JamalNoch keine Bewertungen

- Semi Gantry backup machine parts listDokument1 SeiteSemi Gantry backup machine parts listbayuNoch keine Bewertungen

- BI Stock PortfolioDokument100 SeitenBI Stock PortfoliobayuNoch keine Bewertungen

- Standart Design Tower SST 53 MDokument23 SeitenStandart Design Tower SST 53 Mbayu100% (1)

- Pt. Indo Cipta Konstruksi: Project Schedule NoDokument1 SeitePt. Indo Cipta Konstruksi: Project Schedule NobayuNoch keine Bewertungen

- 4 - GA-03 - Rev A ModelDokument1 Seite4 - GA-03 - Rev A ModelbayuNoch keine Bewertungen

- Direct & Indirect Manpower Time Sheet: Description Working Time 100% 150% 200% TotalDokument1 SeiteDirect & Indirect Manpower Time Sheet: Description Working Time 100% 150% 200% TotalbayuNoch keine Bewertungen

- Semi Gantry x2Dokument1 SeiteSemi Gantry x2bayuNoch keine Bewertungen

- 5 Seaside.: T: Rise 1Dokument1 Seite5 Seaside.: T: Rise 1bayuNoch keine Bewertungen

- 5 - GA-04 - Rev A ModelDokument1 Seite5 - GA-04 - Rev A ModelbayuNoch keine Bewertungen

- 3 - GA-03 - Rev A ModelDokument1 Seite3 - GA-03 - Rev A ModelbayuNoch keine Bewertungen

- X StructureDokument1 SeiteX StructurebayuNoch keine Bewertungen

- Semi Gantry2Dokument1 SeiteSemi Gantry2bayuNoch keine Bewertungen

- Gkl2011 - Girder - Rev A ModelDokument1 SeiteGkl2011 - Girder - Rev A ModelbayuNoch keine Bewertungen

- 2 - GA-02 - Rev A ModelDokument1 Seite2 - GA-02 - Rev A ModelbayuNoch keine Bewertungen

- 1 - GA-01 - Rev A ModelDokument1 Seite1 - GA-01 - Rev A ModelbayuNoch keine Bewertungen

- WPS Form for FCAW-S WeldingDokument1 SeiteWPS Form for FCAW-S WeldingbayuNoch keine Bewertungen

- 1 Regular Type HoistDokument1 Seite1 Regular Type HoistbayuNoch keine Bewertungen

- 6Dokument1 Seite6bayuNoch keine Bewertungen

- 7Dokument1 Seite7bayuNoch keine Bewertungen

- 10Dokument1 Seite10bayuNoch keine Bewertungen

- SiteplanDokument1 SeiteSiteplanbayuNoch keine Bewertungen

- Fasade Front & BackDokument1 SeiteFasade Front & BackbayuNoch keine Bewertungen

- 2Dokument1 Seite2bayuNoch keine Bewertungen

- Secton A & BDokument1 SeiteSecton A & BbayuNoch keine Bewertungen

- Man L27-38 Serv ExpDokument15 SeitenMan L27-38 Serv ExpmaronnamNoch keine Bewertungen

- Need of This ProjectDokument38 SeitenNeed of This ProjectThomas BakerNoch keine Bewertungen

- Catalisis ReviewsDokument625 SeitenCatalisis ReviewsGabriel PestanaNoch keine Bewertungen

- AMTED398078EN Part2 (Web)Dokument54 SeitenAMTED398078EN Part2 (Web)jobpei2Noch keine Bewertungen

- Boiler BurnerDokument12 SeitenBoiler BurnerSumeet SawantNoch keine Bewertungen

- Piezoelectric It Yan Energy Source For Future Railway StationsDokument8 SeitenPiezoelectric It Yan Energy Source For Future Railway StationsYekian IanNoch keine Bewertungen

- Design A Hybrid Solar BicycleDokument32 SeitenDesign A Hybrid Solar Bicycleakash100% (1)

- Ceil Pb1094vrla 101104 LowresDokument6 SeitenCeil Pb1094vrla 101104 Lowrespjl112008Noch keine Bewertungen

- YX-280D Autoclave Use's ManualDokument6 SeitenYX-280D Autoclave Use's ManualKarakeñitaSivanaMkPt100% (1)

- The Design, Performance and CFD Analyses of Regenerative BlowerDokument5 SeitenThe Design, Performance and CFD Analyses of Regenerative BlowerBucur Stefan GabrielNoch keine Bewertungen

- 2017 listCN 10february2017Dokument15 Seiten2017 listCN 10february2017Sheri Abhishek ReddyNoch keine Bewertungen

- Alternative GREEN Furnace With No Fire - Non-Fossil-FueledDokument45 SeitenAlternative GREEN Furnace With No Fire - Non-Fossil-FueledChris BoydNoch keine Bewertungen

- 2009 H2 Physics Prelim Exams (9745) Suggested SolutionsDokument4 Seiten2009 H2 Physics Prelim Exams (9745) Suggested SolutionsnasyrahNoch keine Bewertungen

- Solid q50 Denind 1808 V11webDokument2 SeitenSolid q50 Denind 1808 V11webNinditya NugrohoNoch keine Bewertungen

- IkeaDokument8 SeitenIkeaChristine DoxeyNoch keine Bewertungen

- Manufacturing Solar Grass CutterDokument4 SeitenManufacturing Solar Grass CutteramarparimiNoch keine Bewertungen

- Power Plants Programme 2014Dokument138 SeitenPower Plants Programme 2014sbiliristhodNoch keine Bewertungen

- Pscad Modelling PDFDokument8 SeitenPscad Modelling PDFalcfieeNoch keine Bewertungen

- IELTS 2 - MidTerm Test NewDokument4 SeitenIELTS 2 - MidTerm Test NewLan Anh Lương100% (1)

- Physics Checkpoint Syllabus UnderstandingDokument3 SeitenPhysics Checkpoint Syllabus UnderstandingKalidasan VasodavanNoch keine Bewertungen

- Unit 1.2 Chemistry As Book EditedDokument20 SeitenUnit 1.2 Chemistry As Book EditedJamsheed KakarNoch keine Bewertungen

- Grid Connect PV Design Guidelines CEC Issue 5 - 1Dokument22 SeitenGrid Connect PV Design Guidelines CEC Issue 5 - 1Lakshmi NarayananNoch keine Bewertungen

- DPS Presentation-0317Dokument9 SeitenDPS Presentation-0317Lucas de MedeirosNoch keine Bewertungen

- Hydropower enhances lives in IndonesiaDokument2 SeitenHydropower enhances lives in IndonesiaTaraFKhairaNoch keine Bewertungen

- Business Studies: Bharat Heavy Electricals LimitedDokument43 SeitenBusiness Studies: Bharat Heavy Electricals LimitedVenkatramana K0% (2)

- Solar Pond - Case StudyDokument20 SeitenSolar Pond - Case StudyManish GhimireNoch keine Bewertungen

- Avery 112Dokument5 SeitenAvery 112Leed ENNoch keine Bewertungen

- Analysis of Three Large Scale Biomass Combustion Plants in the UKDokument9 SeitenAnalysis of Three Large Scale Biomass Combustion Plants in the UKJimmy Nuñez VarasNoch keine Bewertungen

- Heat Rate Calculation - JITPLDokument8 SeitenHeat Rate Calculation - JITPLbnswain1Noch keine Bewertungen

- Shaangu Group Brochure 2017Dokument22 SeitenShaangu Group Brochure 2017zzgiadinhzz0% (1)