Beruflich Dokumente

Kultur Dokumente

Investigation of Surface Integrity in Dry M

Hochgeladen von

Adarsh KumarOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Investigation of Surface Integrity in Dry M

Hochgeladen von

Adarsh KumarCopyright:

Verfügbare Formate

Int J Adv Manuf Technol

DOI 10.1007/s00170-013-5198-0

ORIGINAL ARTICLE

Investigation of surface integrity in dry machining

of Inconel 718

Domenico Umbrello

Received: 20 April 2013 / Accepted: 12 July 2013

# Springer-Verlag London 2013

Abstract Machining of advanced aerospace materials have

grown in the recent years although the diffucult-to-machine

characteristics of alloys like titanium or nickel-based alloys

cause higher cutting forces, rapid tool wear, and more heat

generation. Therefore, machining with the use of cooling

lubricants is usually carried out. To reduce the production

costs and to make the processes environmentally safe, the

goal is to move toward dry cutting by eliminating cutting

fluids. This objective can be achieved by using coated tool,

by increasing cutting speed, and by improving the product

performance in term of surface integrity and product quality.

The paper addresses the effects of cutting speed and feed on

the surface integrity during dry machining of Inconel 718

alloy using coated tools. In particular, the influence of the

cutting conditions on surface roughness, affected layer,

microhardness, grain size, and microstructural alteration

was investigated. Results show that cutting conditions have

a significant effect on the parameters related to the surface

integrity of the product affecting its overall performance.

Keywords Machining . Inconel 718 . Surface integrity

1 Introduction

Nickel-based superalloys were created in the 1940s primarily

for gas turbine application due to their long-time strength and

toughness at high temperature and more creep resistance

property than available stainless austenitic steels. Nickel

base superalloys are also used for other applications such

as marine equipment, nuclear reactors, etc. They are used in

D. Umbrello (*)

Department of Mechanical, Energy and Management Engineering,

University of Calabria, Via P. Bucci, Cubo 45/C,

87036 Rende, CS, Italy

e-mail: d.umbrello@unical.it

URL: www.unical.it

these aggressive environments because of their ability to

maintain high resistance to corrosion, mechanical and thermal fatigue, mechanical and thermal shock, creep, and erosion at elevated temperatures [1]. Within the commercially

available nickel-based superalloys, Inconel 718 is the most

frequently used for many applications: aircraft gas turbines,

reciprocating engines, metal processing (e.g., hot work tools

and dies), space vehicles (e.g., aerodynamically heated skins,

rocket engine parts), heat treating equipments, nuclear power

plants, chemical and petrochemical industries, and heat

exchangers.

Although it is the most common nickel superalloy used in

the aerospace industry, some drawbacks are noticed and

within these, the poor machinability is probably the worst.

In fact, machining of nickel-based alloys generate high temperatures at the cutting tool edge, impairing their performance as they are subjected to high compressive stresses

acting on the tool tip. This leads to the plastic deformation of

the tool edge, severe notching and flank wear [1, 2].

Severe wear are also due to the high hot hardness and

strength causes deformation of the cutting tool during machining and the austenitic matrix of nickel alloys which

causes rapid work hardening during machining. The poor

thermal conductivity of nickel-based alloys, raises temperature at the toolworkpiece interface during machining, thus,

it accelerates the undesired tool wear and results in the

shortening of cutting tool life [2, 3].

Therefore, all the cutting parameters, such as tool and

coating materials choice, tool geometry, machining strategy,

cutting speed, feed rate, depth of cut, lubrication, etc., must

be controlled and selected in order to achieve an acceptable

tool life and a correct surface integrity for the machined parts

[4, 5]. Itakura et al. [6] conducted dry turning experiments to

clearly identify the tool wear mechanisms when a commonly

used coated cemented carbide tool cuts Inconel 718. Jindal

et al. [7] studied the relative merits of physical vapor deposition (PVD) TiN, TiCN, and TiAlN coatings on cemented

Int J Adv Manuf Technol

carbide substrate (WC-6 wt% Co alloy) in the turning of

Inconel 718. Prengel et al. [8] performed Inconel 718 turning

tests with a coolant and different PVD-coated carbide cutting

tools.

Furthermore, in order to keep increasing the machining

performance, different assistance methods have been recently developed to replace the conventional process [9]. One

of them presents high-pressure jet assistance (HPJA), which

aims at upgrading conventional machining, using the thermal and mechanical properties of a high-pressure jet of water

or emulsion directed into the cutting zone [1012]. By applying a high-pressure fluid jet to the cutting zone, it is

possible to achieve advantages such as significantly decreased temperature in the cutting zone, prolonged tool life,

and lower forces. These results have also shown improved

surface integrity and better dimensional accuracy of the

produced aeroengine components [13].

As recently described in a literature review proposed by

Ulutan and Ozel [14], a large number of researches have

been carried out in order to investigate and to optimize the

machining process of Inconel 718 alloy in terms of improving quality and surface integrity of the components, increasing productivity and lowering cost. However, the main

works concerning machining Inconel 718 were performed

using cutting fluids even when advanced cooling techniques

like HPJA [1012] or hybrid techniques [15] were involved.

Thus, the effect of dry conditions, especially on the surface

integrity of machined products, was little investigated. Recently, Devillez et al. [16] analyzed the role played by the

suppression of cutting fluid on surface finish and residual

stresses during turning of Inconel 718. They also executed

microhardness measurements at various locations on the

cross section of the machined samples to determine the

machining affected layer by plastic deformation. Their results highlight that the workpiece machined in dry condition

was hardened more than the one machined under wet conditions and the hardened layers were about 250 m beneath the

machined surface. Comparable microhardness values and

gradients were measured by Pawade et al. [17] and by

Ezugwu and Tang [18].

Within the perspective to move toward dry cutting by

eliminating cutting, this paper aims to investigate the effects

of cutting speed and feed on the surface integrity during dry

machining of Inconel 718 alloy using coated tools. The

effects of the cutting conditions on surface roughness, affected layer, grain size variations, and phase changes/modification were investigated.

2 Experimental procedure

Dry orthogonal cutting tests were conducted on Inconel 718

(4299 HV0.05) using a high-speed Mazak computer numerical

control (CNC) turning center and setting a configuration as

schematically indicated in Fig. 1a. In particular, a bar of

347 mm as initial diameter was gently machined in order to

create several disks characterized by thin wall geometry

(10 mm depth and 2 mm thick) spaced 4 mm from each other.

Coated DNMG Sandvik tool (ISO S-DNMG150616) was selected and mounted on a Sandvik DDJNR/L tool holder (providing rake and clearance angles of 6 and 4, respectively) as

shown in Fig. 1b.

In order to avoid effects on the machined surface related

to transient condition (in either feed or speed) due to the

orthogonal configuration, the experiments were executed in

the following sequence:

1. The tool was aligned and brought close to the rotating

workpiece by single-stepping through the CNC program

(i.e., only one block/line of program code is executed

with each press of the button by the operator).

2. All the instruments are set to record mode and the

CNC program is taken out of single-step mode.

3. With the next press of the button the rest of the program

is executed uninterrupted, i.e., the tool enters the workpiece and continues cutting at the prescribed feed rate up

till the prescribed end-of-cut diameter, and then instantaneously retracts at maximum feed. This insures that the

rubbing of the tool against the final machined workpiece

surface is minimal (though it may not be zero) and,

equally importantly, invariant/constant for all the experimental conditions. Further, since the feed rate employed

is in the low range (0.0500.100 mm/rev) according to

the tool makers, and due to the large workpiece diameter

(347 mm at start and 338 at the end) the rpm corresponding to the cutting speeds employed are also low (47

66 rpm), it is possible for the CNC machine's hardware

to change from radially inward feed to outward extraction almost instantaneously for all practical purposes.

Hence, the transient effects were minimal, and this was

confirmed from the force signals recorded during the

cutting.

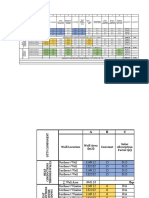

Disks were machined at varying of three cutting speeds

and three feed rates as illustrated in Table 1; three replications were performed for each test. It is important to underline that the use of these ranges for the cutting parameters

were determined taking into account the tool maker recommendations for typical and industrial machining operations

on nickel-based alloys. The cutting time of each test was 80

90 s in order to reach the mechanical and thermal steadystate conditions.

After machining, samples of 55 mm were sectioned by

wire-EDM, then polished and etched for 35 s using Kalling's

reagent (number 2) to observe microstructural changes (affected

layer and grain size) using a light optical microscope (1,000).

The surface roughness, Ra, of the machined workpiece was

Int J Adv Manuf Technol

Fig. 1 a Scheme of the

orthogonal machining; b

obtained disks from Inconel

718 bar and coated DNMG

Sandvik tool positioned for the

orthogonal machining operation

measured using a Zygo optical white light interferometrybased surface profilometer. The surface and subsurface hardness

values were also measured on a micro hardness indenter Future

Tech F-7. Additionally, the X-ray diffraction (XRD) Bruker

AXS D8 Discover with a quarter Ellurian cradle sample holder

was used for investigating the microstructural phase composition of the machined surface. The X-ray diffractometer used CuK radiation ( =1.54184 , K 1/K 2 =0.5) from a source

operated at 40 kV and 40 mA. Samples were accordingly

positioned at the center of plate into the X-ray goniometric in

order to ensure a correct beam irradiation. The 2 scans were

carried out between 30 and 100 2. The scan increment was

0.05; the corresponding acquisition time was accordingly

varied.

Figure 2 also shows a mapped region called turning

replaces grinding where only cutting speed of 70 m/min

produces comparable Ra values with grinding.

3.2 Microhardness

Figure 3 shows the variation in microhardness values for the

different experimental conditions employed. In particular,

the results highlight that, in all of the investigated cases,

the surface hardness is higher than that of the bulk material.

Also, the value of the ratio HV0.05max/HV0.05initial increases

with the increasing of both cutting speed and feed rate.

Furthermore, higher cutting speed and feed rate allow the

material to reach a deeper hardness variation. The depth

containing hardness values greater than the one in the bulk

material ranges from 6065 m for test ID 1 up to 120

130 m for test ID 9.

3 Experimental results and discussion

3.3 Grain size and affected layer

3.1 Surface roughness

The surface roughness values, Ra, of the machined sample

were measured five times for each test to evaluate the characteristic of the machined surface. As shown in Fig. 2, the

surface roughness measurements for all the test conditions

are always below 0.3 m, which is a very good finish surface

quality. It has been shown that, a smooth surface with better

surface roughness would prevent the initiation of cracks

under cyclic loads [19].

Table 1 Experimental machining test conditions

The structure of each machined surface and subsurface has

been measured by optical microscope (1,000). It was found

that all the examined samples presented a refinement of size

near to the machined surface and beneath it (the initial grain

size in the bulk averages at 18 m). Figure 4 shows the

optical images for tests ID 1 and ID 9, while Fig. 5 shows

Turning replaces grinding

Cutting speed

Feed rate [mm/rev]

0.050

0.075

0.100

50 m/min

60 m/min

70 m/min

ID 1

ID 2

ID 3

ID 4

ID 5

ID 6

ID 7

ID 8

ID 9

Fig. 2 Surface roughness, Ra, on machined samples at varying of

cutting speeds and feed rates

Int J Adv Manuf Technol

Grain size on the bulk material

b

Grain size on the bulk material

c

Grain size on the bulk material

Fig. 5 Grain size evolution near the machined surface and below it: a

50 m/min, b 60 m/min, and c 70 m/min

Fig. 3 Surface and subsurface hardness profiles at varying of cutting

speed: a 50 m/min, b 60 m/min, and c 70 m/min

Fig. 4 Optical images of the

machined surface and subsurface:

a test ID 1 and b test ID 9

affected featureless layer

affected featureless

layer

Int J Adv Manuf Technol

Fig. 6 Thickness of the affected layer measured on machined samples

at varying of cutting speeds and feed rates

Estimation of this layer for all the samples was executed

by Image Pro Plus software; results are reported in Fig. 6. As

observed, the affected featureless layer ranges between 3.5

and 6 m and it increases with both the cutting speed and

feed rate. However, the influence of cutting speed is more

significant when feed higher than 0.075 mm/rev is utilized.

Finally, it is important to underline that depth containing

grains slightly smaller than the one in the bulk material

ranges from 75 m for test ID 1 up to 120130 m for tests

characterized by the higher feed rate (IDs 3, 6, and 9). These

depths are in accordance with those found by analyzing the

microhardness (Fig. 3).

3.4 XRD phase analysis

grain size variation from machined surface to the bulk material for all the investigated tests. Results clearly show that

the cutting conditions influence the final microstructure of

the machined product. In fact, the grain size becomes smaller

when higher cutting speeds and feed rates are utilized.

Moreover, in several tests, the grain size on the machined surface cannot be revealed by optical microscope

even when the largest magnification was used (1,000)

since affected featureless structures appear. The appearance of the featureless layers formed under machining

(Fig. 4b) were similar to the white layers in the machined

surfaces of nickel-based superalloy IN-100 [20], where

significant grain refinement to nanocrystalline level was

found due to dynamic recrystallization.

Figure 7 shows diffraction patterns of Inconel 718 for several

machined samples and for the as received material. In particular, Fig. 7a reports the influence of the feed rate for the cutting

speed of 50 m/min (tests IDs 1, 2 and 3), while Fig. 7b shows

the effect of the feed rate at the higher cutting speed (tests IDs

7, 8, and 9). The X-ray phase analysis on the as received

material shows five peaks at 43.7, 50.9,75.3, 91.3, and

96.4 which, according to Bragg's law, correspond to Ni alloy

in a face-centered cubic (FCC) structure at (111), (200), (220),

(311), and (222) Miller's indices, respectively [21].

According to the Hanalwalt method [22] phase and crystal

structure are defined by the peaks intensity of powder pattern.

In particular, the sequence of the three strongest lines is

(111)

(200)

(111)

(200)

(220)

(311) (222)

Fig. 7 X-ray phase analysis of machined Inconel 718 samples at varying

(220)

(311) (222)

Int J Adv Manuf Technol

Fig. 8 Comparison of XRD

patterns between the as received

sample and the machined sample

at 70 m/min and 0.1 mm/rev

(ID 9)

(111)

(200)

(004)

(200)

(004)

responsible of the different phase and crystal structure. Tests

from ID 1 to ID 6 do not highlight any phase modification,

since their XRD patterns show that the three strongest intensities are ordered as the virgin sample [(111), (200), (311) ].

Then, by applying the Hanalwalt search technique the virgin

material and the machined samples from ID 1 to ID 6 are

characterized by a gamma prime, , structure (PDF 18872).

Gamma prime, the first of the two phases to precipitate during

heat treatment, is a coherent, ordered Ni 3(A1,Ti) face-centered

cubic structure with nickel present on the cube faces and

niobium on the corners of the unit cell.

In contrast, tests carried out at the higher cutting speed (ID

7, 8, and 9) show a different sequence of the three strongest

intensities [(111), (311), (200)], indicating that the structure

on the machined samples is affected by the cutting process.

This evidence is clearer when the highest cutting speed and

(220)

(311)

(222)

feed rate are considered (test ID 9): the presence of precipitating phase (004) at 48.5 2 can be observed (Fig. 8).

Precipitating phase , together with , are responsible

for the heat resistance properties of the matrix gamma ()

phase [23]. Gamma double prime, which nucleates and

coarsens on the particles, is a coherent but misfitting and

ordered metastable body-centered tetragonal Ni3Nb structure

with the nickel atoms sitting on the faces and niobium,

titanium, and aluminum on the corners in the body center

sites. Both and enhance the mechanical properties of

the Inconel 718 alloy by anti-phase boundary strengthening

and coherency strains [2426] although the metastability of

the primary strengthening (, gamma double prime) phase

is typically unacceptable for applications above about

650 C. As a result, other more costly and difficult to process

alloys, like Waspalloy, are used in such applications [27].

Fig. 9 XRD peak and width of Ni alloy in a FCC structure at (111) of both machined and as received samples under a different cutting speeds for the

feed rate of 0.1 mm/rev and for b different feed rates for the cutting speed of 70 m/min

Int J Adv Manuf Technol

Finally, another cardinal aspect to be highlighted from the

XRD analysis is related to the influence of the cutting parameters on the peak relative intensity and its width.

According to Herbert et al. [28], different intensity and width

represent different grain size. As it is clearly seen in Fig. 9,

grain refinements are observed when higher cutting speeds

and feed rates are utilized. Moreover, for the cutting parameters employed in this research, the influence of the feed rate

seems to be more predominant on grain refinements than the

cutting speed. In fact, observing Fig. 9b, the peaks fitting of

the machined samples are almost similar while some differences can be seen when the cutting speed is varied (Fig. 9a),

highlighting that moderate cutting speed does not allow to

reach a high grain refinement.

4 Conclusions

In this paper, an experimental study is proposed for investigating the dry machining of Inconel 718 alloy in terms of surface

integrity indicators (surface roughness, microhardness, affected layer, grain size and phase changes); consequently, the

following conclusion can be drawn:

&

&

&

&

&

Surface roughness in machining Inconel 718 alloy are

comparable with those obtained by finishing processes

(e.g., grinding process), when coated tool are used, and

cutting speeds higher than 70 m/min and low feed rates

are chosen.

Higher cutting speed and feed rate allow the material to

reach a higher surface hardness and a deeper hardness

variation.

All the examined samples presented a refinement of

size and, for certain conditions, the grain size on the

machines surface cannot be revealed by optical microscope since affected featureless structures appear. The

appearance of this layer formed under machining underline that significant grain refinement occurred due

to dynamic recrystallization.

XRD observations highlight that there is a phase change

on the machined surface for tests carried out at 70 m/min.

Also, XRD results show that the peak relative intensity

and its width are influenced by the cutting process parameters. In particular, high grain refinements are observed when higher cutting speeds and feed rates are

utilized. Moreover, the influence of the feed rate seems

to be more predominant on grain refinements than the

cutting speed.

XRD pattern for test ID 9 (70 m/min and 0.1 mm/rev)

shows the presence of precipitating phase which,

together with , are responsible for the heat resistance

properties of the matrix gamma () enhancing the mechanical properties of the Inconel 718 alloy.

Acknowledgments The author gratefully thanks Mr. J. Backus from

Kentucky Geological Survey for his help with the XRD measurements.

The author also acknowledges the undergraduate student Diego Maida

for his contribution with the analysis of the microscope images.

References

1. Ezugwu EO (2005) Key improvements in the machining of difficultto-cut aerospace superalloys. Int J Machine Tools & Manuf 45(12

13):13531367

2. Ezugwu EO, Bonney J, Yamane Y (2003) An overview of the

machinability of aeroengine alloys. J Mater Proc Technol 134(2):

233253

3. Puavec F, Kramar D, Krajnik P, Kopa J (2010) Transition to

sustainable productionpart II: evaluation of sustainable machining technologies. J Cleaner Prod 18(12):12111221

4. Arunachalam RM, Mannan MA, Spowage AC (2004) Surface

integrity when machining age hardened Inconel 718 with coated cutting tools. Int J Machine Tools & Manuf 44(14):1481

1491

5. Thakur DG, Ramamoorthy B, Vijayaraghavan L (2009) Machinability investigation of Inconel 718 in high-speed turning. Int J Adv

Manuf Technol 45:421429

6. Itakura K, Kuroda M, Omokawa H, Itani H, Yamamoto K, Ariura Y

(1999) Wear mechanism of coated cemented carbide tool in coated

tool in cutting of Inconel 718 super-heat resisting alloy. Int Japan

Soc Prec Eng 33(4):326333

7. Jindal PC, Santhanam AT, Schleinkofer U, Shuster AF (1999)

Performance of PVD TiN, TiCN and TiAlN coated cemented

carbide tools in turning. Int J Refract Metals Hard Mater 17(1

3):163170

8. Prengel HG, Jindal PC, Wendt KH, Santhanam AT, Hedge PL,

Penich RM (2001) A new class of high performance PVD coating

for carbide cutting tools. Surf Coat Technol 139(1):2534

9. Shokrani A, Dhokia V, Newmann ST (2012) Environmentally

conscious machining of difficult-to-machine materials with

regard to cutting fluids. Int J Machine Tools & Manuf 57:

83101

10. Lpez de Lacalle LN, Prez-Bilbatua J, Snchez JA, Llorente JI,

Gutirrez A, Albniga J (2000) Using high pressure coolant in the

drilling and turning of low machinability alloys. Int J Adv Manuf

Technol 16:8591

11. Courbon C, Kramar D, Krajnik P, Puavec F, Rech J, Kopa J

(2009) Investigation of machining performance in high-pressure

jet assisted turning of Inconel 718: an experimental study. Int J

Machine Tools & Manuf 49(11):11141125

12. Nandy AK, Gowrishankar MC, Paul S (2009) Some studies on

high-pressure cooling in turning of Ti6Al4V. Int J Machine Tools

& Manuf 49(2):182198

13. Ezugwu EO, Bonney J, Da Silva RB, akir O (2007) Surface

integrity of finished turned Ti6Al4V alloy with PCD tools using

conventional and high pressure coolant supplies. Int J Machine

Tools & Manuf 47(6):884891

14. Ulutan D, Ozel T (2011) Machining induced surface integrity in

titanium and nickel alloys: a review. Int J Machine Tools & Manuf

51(3):250280

15. Feyzi T, Safavi MS (2013) Improving machinability of Inconel 718

with a new hybrid machining technique. Int J Adv Manuf Technol

66:10251030

16. Devillez A, Le Coz G, Dominiak S, Dudzinski D (2011) Dry

machining of Inconel 718, workpiece surface integrity. J Mater

Proc Technol 211:15901598

Int J Adv Manuf Technol

17. Pawade RS, Joshi SS, Brahmankar PK (2008) Effect of machining

parameters and cutting edge geometry on surface of high speed

turned Inconel 718. Int J Machine Tools & Manuf 48:1528

18. Ezugwu EO, Tang SH (1995) Surface abuse when machining cast

iron (G-17) and nickel base superalloy (Inconel 718) with ceramic

tools. J Mater Proc Technol 55:6369

19. McClung RC (2007) A literature survey on the stability and significance of residual stresses during fatigue. Fatigue Frac Eng Mater &

Struct 30:173205

20. Wusatowska-Sarnek AM, Dubiel B, Czyrska-Filemonowicz A,

Bhowal P, Ben Salah N, Klemberg-Sapieha J (2011) Microstructural characterization of the white etching layer in nickel-based

superalloy. Metall Mater Trans A 42:38133825

21. Joint Committee on Powder Diffraction Standards (2010) Powder

Diffraction File, Inorganic Phases, sets: 160. International Centre

for Diffraction Data Inc

22. Joint Committee on Powder Diffraction Standards (2012) Powder

Diffraction File, Hanawalt Search Manual for Experimental Phases,

Inorganic Phases: sets 162. International Centre for Diffraction

Data Inc

23. Collier JP, How Wong S, Tien JK, Phillips JC (1988) The effect of

varying Al, Ti, and Nb content on the phase stability of INCONEL

718. Metall Trans A 19(7):16571666

24. Paulonis DF, Oblak JM, Duvall DS (1969) Precipitation in nickelbase alloy 718. Trans ASM 62:611622

25. Kriege OH, Baris JM (1969) The chemical partitioning of

elements in gamma prime separated from precipitationhardened, high-temperature nickel-base alloys. Trans ASM

62:195200

26. Oblak JM, Paulonis DF, Duvall DS (1974) Coherency strengthening in Ni base alloys hardened by Do22 gamma double prime

precipitates. Metall Trans 5:143153

27. Kushan MC, Uzgur SC, Uzunonat Y, Diltemiz F (2012) ALLVAC

718 Plus superalloy for aircraft engine applications. In: Agarwal

RK (ed) Recent advances in aircraft technology. InTech, Rijeka

(Croatia), pp 7596

28. Herbert C, Axinte D, Hardy M, Brown PD (2012) Investigation into the characteristics on the white layers produced in a

nickel-based superalloy from drilling operations. Mach Sci

Technol 16(1):4052

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Block Brake With Long ShoeDokument9 SeitenBlock Brake With Long ShoeAdarsh KumarNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Model Question Paper B Tech. / M.Tech. / MCA Year End ExaminationsDokument1 SeiteModel Question Paper B Tech. / M.Tech. / MCA Year End ExaminationsAdarsh KumarNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Optimization of Mig Welding Parameters On Tensile Strength of Aluminum Alloy by Taguchi ApproachDokument7 SeitenOptimization of Mig Welding Parameters On Tensile Strength of Aluminum Alloy by Taguchi ApproachAdarsh KumarNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Chap3 0130473928Dokument137 SeitenChap3 0130473928Adarsh KumarNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- WCE2007 pp1068-1071Dokument4 SeitenWCE2007 pp1068-1071Adarsh KumarNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- B S N MurthyDokument1 SeiteB S N MurthyAdarsh KumarNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- E8/8#) .8/8F-5&G$ (-G56: Gh&i@'7jklm'ij@Dokument6 SeitenE8/8#) .8/8F-5&G$ (-G56: Gh&i@'7jklm'ij@Adarsh KumarNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Improvement of Prandtl Mixing Length Theory and Application in Modeling ofDokument5 SeitenImprovement of Prandtl Mixing Length Theory and Application in Modeling ofAdarsh KumarNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- 133 Eng103Dokument12 Seiten133 Eng103Adarsh KumarNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Group 1 NotifDokument1 SeiteGroup 1 NotifAdarsh KumarNoch keine Bewertungen

- A GENERAL PHYSICS II Q4M2 Teacher Copy Final Layout PDFDokument31 SeitenA GENERAL PHYSICS II Q4M2 Teacher Copy Final Layout PDFRETCHIE JOY PISANANoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- F FiberglassDokument66 SeitenF Fiberglassosvald97Noch keine Bewertungen

- Capacity Based DesignDokument12 SeitenCapacity Based DesignnagarajuNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Cemented SandsDokument9 SeitenCemented SandsAnonymous kxOcSmhcNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- PeakForce SECM AppNote-AN147Dokument11 SeitenPeakForce SECM AppNote-AN147Fabien CazesNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Effects of Longitudinal Heat Conduction in Compact Plate-Fin and Tube-Fin Heat Exchangers Using A Finite Element MethodDokument17 SeitenThe Effects of Longitudinal Heat Conduction in Compact Plate-Fin and Tube-Fin Heat Exchangers Using A Finite Element MethodchrissbansNoch keine Bewertungen

- Chemistry of Newer MaterialsDokument30 SeitenChemistry of Newer MaterialsDr. Dhondiba Vishwanath100% (1)

- ESHF RSHF GSHF For Different SystemsDokument2 SeitenESHF RSHF GSHF For Different Systemsgowtham gNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Cogbill Construction - Wear Pads BrochureDokument1 SeiteCogbill Construction - Wear Pads BrochureCogbillConstructionNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- VSR - Popustanje Napetosti VibriranjermDokument8 SeitenVSR - Popustanje Napetosti Vibriranjermdag9Noch keine Bewertungen

- Best Practices in Compressor MountingDokument9 SeitenBest Practices in Compressor MountingDaniel Puello RodeloNoch keine Bewertungen

- Two-Dimensional Conduction: Shape Factors and Dimensionless Conduction Heat RatesDokument12 SeitenTwo-Dimensional Conduction: Shape Factors and Dimensionless Conduction Heat RatesCarlos AlmacheNoch keine Bewertungen

- Heat TransferDokument4 SeitenHeat TransferSelwah Hj AkipNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- StressHead - Design Concept - 170223Dokument15 SeitenStressHead - Design Concept - 170223Juan ManuelNoch keine Bewertungen

- An Innovative No Hot Work Approach To Hull Repair On in Service FPSOs Using Sandwich Plate System OverlayDokument7 SeitenAn Innovative No Hot Work Approach To Hull Repair On in Service FPSOs Using Sandwich Plate System Overlaythlim19078656Noch keine Bewertungen

- PDS Stopaq Wrapping BandDokument2 SeitenPDS Stopaq Wrapping BandSinan A AzizNoch keine Bewertungen

- Ship StressesDokument32 SeitenShip StressesLuisPazPerdomoNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Nodia and Company: Gate Solved Paper Civil Engineering 2007Dokument17 SeitenNodia and Company: Gate Solved Paper Civil Engineering 2007Raj BakhtaniNoch keine Bewertungen

- Critical Review Paper of Steam Turbine Blades Corrosion and Its SolutionsDokument9 SeitenCritical Review Paper of Steam Turbine Blades Corrosion and Its Solutionsijsret100% (1)

- Electrode PolarizationDokument27 SeitenElectrode PolarizationMahesh BabuNoch keine Bewertungen

- 9619 LG Flatron L1917S Chassis CL-82 Monitor LCD Manual de ServicioDokument26 Seiten9619 LG Flatron L1917S Chassis CL-82 Monitor LCD Manual de ServicioPa PlastireNoch keine Bewertungen

- Free Downloads FileDokument5 SeitenFree Downloads FileJoJa JoJaNoch keine Bewertungen

- PM 4Dokument3 SeitenPM 4ashish kumarNoch keine Bewertungen

- Course Outline MAT 404 2018Dokument3 SeitenCourse Outline MAT 404 2018Sherif HishamNoch keine Bewertungen

- 2.2 RRLDokument7 Seiten2.2 RRLJogily Quijano GaleosNoch keine Bewertungen

- Solutions For Heat Transfer Quiz-IV: D. VelocityDokument2 SeitenSolutions For Heat Transfer Quiz-IV: D. VelocitymkvemulaNoch keine Bewertungen

- OTTV Calculation - Faiz Kamal (2020963327)Dokument16 SeitenOTTV Calculation - Faiz Kamal (2020963327)Nuratiqah SharifahNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Anodising InformationDokument2 SeitenAnodising InformationanbuskpNoch keine Bewertungen

- Review PPT 2023Dokument7 SeitenReview PPT 2023Cjs GamingNoch keine Bewertungen

- Decarburization and Desulphurization of SteelDokument10 SeitenDecarburization and Desulphurization of SteelHitesh KumarNoch keine Bewertungen