Beruflich Dokumente

Kultur Dokumente

Control of Nonconformity

Hochgeladen von

Javed IqbalOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Control of Nonconformity

Hochgeladen von

Javed IqbalCopyright:

Verfügbare Formate

Document Code: QC -02/01/01

Formation Date:

01/05/2015

Saudi Can Co Ltd

Quality Systems Procedure

Control of

Nonconformity

Rev # 01

Issue Date: -----------------------

Prepared By:

Sign---------------------------------

Reviewed By:

Sign---------------------------------

Approved By:

Sign---------------------------------

Table of Contents: Sr. #

1.

2.

3.

4.

5.

6.

7.

8.

Contents

Amendment sheet

Document / Record Distribution List

Purpose

Scope

Responsibilities

Terms

Procedure

Page #

2

3

4

4

4

4

7

Records related to Procedure

1.0 Amendment Sheet

Page 1 of 7

Document Code: QC -02/01/01

Formation Date:

01/05/2015

REV.

#

DATE

PAGE #

SECTIO

N

Page 2 of 7

NATURE OF AMENDMENT

Document Code: QC -02/01/01

Formation Date:

01/05/2015

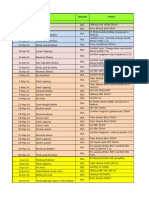

2.0 Document / Record Distribution List

SR.

COPY

LOCATIO

CONDITIO

ISSUE TO

Page 3 of 7

ACKNOWLEGEM

ENT

REMARKS

Document Code: QC -02/01/01

Formation Date:

01/05/2015

3.0 Purpose

To establish a procedure for the control and disposition of nonconforming

products and materials, to prevent their unintentional use or shipment.

3.0 Scope

This procedure is applicable and covers:

All Products used or Manufactured in the Saudi Can.

4.0 Responsibilities

QC is responsible to hold the Nonconforming Product or Materials.

Section Manager is responsible for disposition.

Technical and Production functions are responsible for corrective and

preventive actions.

Supervisor Quality Control ensures that nonconforming products are

suitably identified by logging the Nonconformity.

Section Manager is responsible for reviewing and approving the corrective

and preventive actions.

5.0 Terms

Nonconformity: nonconformity is defined as a product and/or process

which fail to meet the specified or defined standards.

NCR: A report of failure to comply with a requirement of a company's

quality management system.

6.0

Procedure

Page 4 of 7

Document Code: QC -02/01/01

Formation Date:

01/05/2015

6.1

When a nonconforming product or material is discovered by an

employee, he will immediately report it to the QC and QC isolate the

nonconforming product from production by quarantining the product

or material from inventory and/or marking it with a HOLD Tag. No

further work shall be performed on the item until a suitable

disposition developed. Internal NCR will be generated which remains

active until the disposition is decided.

6.2 The Quality Control Manager or QC Supervisor shall maintain a

record of nonconforming products for tin / plastic products and related

materials. This record shall compiled monthly and include Date,

Product, Problem, Cause, Disposition, Material, Weight for each

nonconformance.

6.3 Product or material provided by suppliers or a subcontractor which

is found to be nonconforming after issue to production will be

reported to the Quality Assurance Manager who will review the

nonconformance and recommend a disposition.

6.4 Saudi Can shall deal with nonconforming product in one more of

the following ways

a) Taking action to eliminate the detected nonconformity.

b) Authorizing its use, release or acceptance under concession by

a

relevant authority and, where applicable, by the customer,

Using Concession Form # qc-02/FM/05.

c) Taking action to preclude its original intended use or

application.

d) Scrap the nonconforming product.

e) Returning the nonconforming items from the batch to supplier

for rework, replacement, or refund and allowing the rest of the

6.5

batch to be used for production.

Disposition shall be developed and reported on the Nonconforming

Product List and Nonconformance Report (NCR).

6.6 Product defects discovered during normal production or testing

procedures will be considered defects and not nonconformance if

they can be rectified easily and promptly by the production technician

with tools that are readily available, without assistance from a

supervisor.

6.7 Such defects will not be reported as nonconformance but will be

recorded on a Defect Report, along with the resulting re-works and

Page 5 of 7

Document Code: QC -02/01/01

Formation Date:

01/05/2015

repair labor time. These defects are reviewed monthly by the Section

manager and a report will be generated.

6.8 A multiplicity of the same defect within the same month will be

elevated to a Nonconformance and require the production Supervisor

to complete a nonconformance report, issued by QC.

6.9 The QC will compile a list of nonconformance and update the list as

required.

6.10 The Section

Manager

will

forward

copies

of

completed

nonconformance reports with Dispositions to the QC.

6.11 Materials Hold by QC during Production or due to NCR if

decided to be scrapped are entered in Material Scrapped

Report, by QC and sent to the Operations Manager and General

Manager for approval.

6.12 The QC must attach copies of NCR with disposition approval with

the material scrapped report.

7.0.

Records Related to Procedure

NCR

Material Scrapped Report

Page 6 of 7

Document Code: QC -02/01/01

Formation Date:

01/05/2015

Page 7 of 7

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- BRC FACILITY Hygiene InspectionDokument3 SeitenBRC FACILITY Hygiene InspectionJaved IqbalNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- ISO 9001-2015 Process Audit ChecklistDokument17 SeitenISO 9001-2015 Process Audit ChecklistAhmed Samir Salim100% (12)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- 5 Why FormDokument4 Seiten5 Why FormJaved IqbalNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Iso13chkdemo Doc-607964461Dokument5 SeitenIso13chkdemo Doc-607964461Amb Patrick OghateNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Control of Monitoring and Measuring EquipmentDokument6 SeitenControl of Monitoring and Measuring EquipmentJaved Iqbal0% (1)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Cusotmer Complaints and Followup (New)Dokument41 SeitenCusotmer Complaints and Followup (New)Javed IqbalNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- 5 Why FormDokument4 Seiten5 Why FormJaved IqbalNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- CAPA FORM For Customer ComplaintsDokument1 SeiteCAPA FORM For Customer ComplaintsJaved IqbalNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Math 10 Week 3-4Dokument2 SeitenMath 10 Week 3-4Rustom Torio QuilloyNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Dadm Assesment #2: Akshat BansalDokument24 SeitenDadm Assesment #2: Akshat BansalAkshatNoch keine Bewertungen

- Curriculum Vitae: Educational Background Certification Major Name of Institute PeriodDokument2 SeitenCurriculum Vitae: Educational Background Certification Major Name of Institute PeriodTHEVINESHNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Practice Paper Pre Board Xii Biology 2023-24-1Dokument6 SeitenPractice Paper Pre Board Xii Biology 2023-24-1salamnaseema14Noch keine Bewertungen

- Operation Manual-KINGSTONE SDP-ENG-20120205 PDFDokument49 SeitenOperation Manual-KINGSTONE SDP-ENG-20120205 PDFJiménezNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Mat101 w12 Hw6 SolutionsDokument8 SeitenMat101 w12 Hw6 SolutionsKonark PatelNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Operator Training ManualDokument195 SeitenOperator Training ManualIgnacio MuñozNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Part TOEFLDokument7 SeitenPart TOEFLFrisca Rahma DwinantiNoch keine Bewertungen

- Imaging Anatomy Brain and Spine Osborn 1 Ed 2020 PDFDokument3.130 SeitenImaging Anatomy Brain and Spine Osborn 1 Ed 2020 PDFthe gaangster100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Limited Alembic: Employee Related DataDokument4 SeitenLimited Alembic: Employee Related DataTp EarningsNoch keine Bewertungen

- Amazon VS WalmartDokument5 SeitenAmazon VS WalmartBrandy M. Twilley100% (1)

- Synopsis SsDokument14 SeitenSynopsis SsJYOTI KATIYAR SVUNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- DGKCC Internship ReportDokument17 SeitenDGKCC Internship ReportMuhammad AtharNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- School of Management Studies INDIRA GANDHI NATIONAL OPEN UNIVERSITY Proforma For Approval of Project Proposal (MS-100)Dokument12 SeitenSchool of Management Studies INDIRA GANDHI NATIONAL OPEN UNIVERSITY Proforma For Approval of Project Proposal (MS-100)Pramod ShawNoch keine Bewertungen

- MARKETING STUDY EditedDokument48 SeitenMARKETING STUDY EditedRichard Rhamil Carganillo Garcia Jr.Noch keine Bewertungen

- MODULE 8. Ceiling WorksDokument2 SeitenMODULE 8. Ceiling WorksAj MacalinaoNoch keine Bewertungen

- KPR College of Arts Science and Research: Marketing ManagementDokument127 SeitenKPR College of Arts Science and Research: Marketing ManagementSekar M KPRCAS-CommerceNoch keine Bewertungen

- Assignment OSDokument11 SeitenAssignment OSJunaidArshadNoch keine Bewertungen

- The Two Diode Bipolar Junction Transistor ModelDokument3 SeitenThe Two Diode Bipolar Junction Transistor ModelAlbertoNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Hasan Bin Ekram: Career ObjectiveDokument3 SeitenHasan Bin Ekram: Career ObjectiveHasan SarikNoch keine Bewertungen

- Section ADokument7 SeitenSection AZeeshan HaiderNoch keine Bewertungen

- Review Test 1: Circle The Correct Answers. / 5Dokument4 SeitenReview Test 1: Circle The Correct Answers. / 5XeniaNoch keine Bewertungen

- TOPIC 2 - Fans, Blowers and Air CompressorDokument69 SeitenTOPIC 2 - Fans, Blowers and Air CompressorCllyan ReyesNoch keine Bewertungen

- Mywizard For AIOps - Virtual Agent (ChatBOT)Dokument27 SeitenMywizard For AIOps - Virtual Agent (ChatBOT)Darío Aguirre SánchezNoch keine Bewertungen

- Inglês - Advérbios - Adverbs.Dokument18 SeitenInglês - Advérbios - Adverbs.KhyashiNoch keine Bewertungen

- Mod 2 MC - GSM, GPRSDokument61 SeitenMod 2 MC - GSM, GPRSIrene JosephNoch keine Bewertungen

- Solutions - HW 3, 4Dokument5 SeitenSolutions - HW 3, 4batuhany90Noch keine Bewertungen

- Dokumen - Tips - Dominick Salvatore Microeconomics Wwwpdfsdocuments2comd38dominick SalvatorepdfDokument2 SeitenDokumen - Tips - Dominick Salvatore Microeconomics Wwwpdfsdocuments2comd38dominick SalvatorepdfIshan SharmaNoch keine Bewertungen

- Industrial RevolutionDokument2 SeitenIndustrial RevolutionDiana MariaNoch keine Bewertungen

- The Future Mixed TensesDokument4 SeitenThe Future Mixed TensesChernykh Vitaliy100% (1)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)