Beruflich Dokumente

Kultur Dokumente

Conbextra Ep300

Hochgeladen von

Venkata RaoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Conbextra Ep300

Hochgeladen von

Venkata RaoCopyright:

Verfügbare Formate

Conbextra EP300*

Low exotherm, epoxy resin free flow grout

Uses

Suitable for use where heavy, dynamic or mobile loads are

encountered. Particularly well suited to applications where

long working time and/or low exotherm properties are required

n Grouting under reciprocating or rotating equipment

n Heavy crane/transporter rails

n High speed turbines and centrifuges

n Grouting over long distances or in thick sections

n All applications under conditions of high ambient

temperature

Advantages

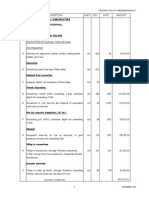

Properties

23C

Compressive strength

BS6319 Part2:1983 :

3 days

7 days

Tensile strength

BS6319 Part 7: 1983 :

7 days

Flexural strength

BS 6319 Part 3: 1983:

7 days

Density

:

Pot life

:

n Low creep characteristics under sustained loading.

n Resistant to repetitive dynamic loads.

Chemical resistance:

n Non-shrink and hence ensures complete surface contact

and bond.

n High compressive, tensile and flexural strengths.

n Withstands a wide range of chemicals.

Description

Conbextra EP300 is a low exotherm material which is

particularly suitable where long working time is needed; for

large gaps (up to 300 mm) or for grouting at high ambient

temperatures (up to 55C).

Conbextra EP300 is a three component system consisting

of base resin, liquid hardener and specially graded inert fillers.

Technical support

Fosroc offers a comprehensive range of high performance,

high quality construction products all backed by BS 5750

certification. Fosroc offers a technical support package to

specifiers and contractors as well as technical advice from

staff with unrivalled experience in the industry.

40C

50C

75N/mm2 82N/mm2 100N/mm2 110N/mm2

11N/mm2

12.5N/mm2

30N/mm2 30N/mm2

1950 kg/m

50 mins at 40C

90 mins at 30C

240 mins at 20C

Oil, grease, fats, most chemicals,

mild acids and alkalis, fresh and

sea water.

Note: Consult the local Fosroc Office when exposure to

solvents or concentrated chemicals is anticipated.

Specification

Supplier specification

All epoxy resin grouting where shown on the contract

documents, shall be carried out using Conbextra EP300

manufactured by Fosroc and used in accordance with the

manufacturer's current data sheet.

Performance specification

All epoxy resin grouting where shown on the contract

documents must be carried out with a factory packed

product. The hardened grout must have strengths exceeding:

Compressive strength :

Tensile strength

:

Flexural strength

:

80 N/mm2 at 7 days

10 N/mm2 at 7 days

27 N/mm2 at 7 days

Conbextra EP300

The storage, handling and placement of the grout must be in

strict accordance with the manufacturer's instructions.

Instructions for use

Foundation surface

Preparation

This must be free from oil, grease, or any loosely adherent

material. If the concrete surface is defective or has laitence, it

must be cut back to a sound base. Bolt holes or fixing pockets

must be blown clean of any dirt or debris.

Underplate grouting

The unrestrained surface area of the grout must be kept to a

minimum. Generally, the gap between the perimeter formwork

and the plate edge should not exceed 75 mm on the pouring

side and 25 mm on the opposite side. Formwork on the flank

sides should be kept tight to the plate edge. Air pressure relief

holes should be provided to allow venting of any isolated high

spots.

Formwork

The formwork should be constructed to be leak proof as

Conbextra EP300 is a free flow grout. This can be achieved by

using foam rubber strip or mastic sealant beneath the

constructed formwork and between joints. Loss of grout once

the material is placed, but not hardened, will result in

incomplete filling of the gap.

For free flow grout conditions, it is essential to provide a

hydrostatic head of grout. To achieve this a feeding hopper

should be used - please consult your local Fosroc office for

more details.

Base plate

If delay is likely before placing steel base plates, it is

recommended that the underside and edges are coated with

Nitoprime 25* to prevent rust formation and ensure bonding

with the Conbextra EP10 grout. All metal surfaces should be

cleaned to a bright finish in accordance with Swedish Standard

SA 2 or equal. Nitoprime 25 can be applied directly onto

newly cleaned steel surfaces even if they are damp.

Mixing

Pour all the contents of the hardener pack into the base

container. Mix using a slow speed power mixer until

homogeneous.

Pour all the resultant liquid into a container with a capacity of

20 - 25 litres. Add all the filler provided and mix using a slow

speed power mixer for two minutes or until a uniform colour

is achieved in the grout.

Placing

The mixed grout should be poured steadily from one side only

to eliminate the entrapment of air.

Typical on-plate shutter system

Removable hopper: for larger pours the grout may be hand

placed or pumped into a removable hopper (trough)

Continuous grout flow is essential.

Sufficient grout must be available prior to starting.

The time taken to pour a batch should be regulated to the time

taken to prepare the next batch.

Flow characteristics

The maximum distance of flow is governed by the gap

thickness, the head of grout applied and the ambient

temperature.

Cleaning

All tools and equipment should be cleaned immediately after

use with Fosroc Solvent 102*. Spillages should be absorbed

with sand or sawdust and disposed in accordance with local

regulations.

Conbextra EP300 - Page 2 of 4

Low temperature working

Precautions

Whilst the performance of Conbextra EP300 at low

temperatures is assured, application under such conditions

can sometimes be difficult. It is therefore suggested that, for

temperatures below 25C, the following guidelines are

adopted:

Health and safety

(i)

Store unmixed materials in a warm(preferably temperature

controlled) environment.

(ii)

Keep mixing and placing equipment warm, arranging

protection if necessary. It is especially important to keep

warm those surfaces of the equipment which will come

into direct contact with the material itself.

(iii) Try to eliminate application in the coldest time of the day,

and certainly avoid application at night.

Conbextra EP300 contains resins which may cause

sensitisation by skin contact. Avoid contact with skin and

eyes and inhalation of vapour. Wear suitable protective

clothing, gloves and eye/face protection. Barrier creams

provide additional skin protection. Should accidental skin

contact occur, remove immediately with a resin removing

cream, followed by soap and water. Do not use solvent. In case

of contact with eyes, rinse immediately with plenty of clean

water and seek medical advice. If swallowed seek medical

attention immediately - do not induce vomiting.

Fire

(iv) Minimum temperature of the mixed material to be 25C,

and loading shall only be allowed 72 hours after pouring.

Fosroc Solvent 102 is flammable. Keep away from sources of

Ignition. No smoking. In the event of fire extinguish with CO2

or foam. Do not use a water jet.

Limitations

Flash points

Fosroc Solvent 102

Grouts should not be placed in any unrestrained situation,

i.e. base plate plinths, etc. Failure to comply may lead to

crack development in the grout.

At temperatures below 25C the cure rate may be slow, but

will go to completion provided the temperature remains

above 5C.

The cured grout, which is resistant to frost and sub-zero

temperatures, is most suited for ambient temperatures in

the range of 25 to 55C.

Supply

:

33C

For additional information see relevant Material Safety Data

Sheet.

Estimating

Conbextra EP300

14 litre packs

Storage

All Conbextra EP300 has a shelf life of 12 months if kept in

dry conditions at 20C. If stored at high temperatures the

shelf life will be reduced.

Conbextra EP300 - Page 3 of 4

Additional Information

Fosroc manufactures a wide range of complementary

products which include :

n waterproofing membranes & waterstops

n joint sealants & filler boards

n cementitious & epoxy grouts

n specialised flooring materials

Fosroc additionally offers a comprehensive package of

products specifically designed for the repair and

refurbishment of damaged concrete. Fosrocs Systematic

Approach to concrete repair features the following :

n hand-placed repair mortars

n spray grade repair mortars

n fluid micro-concretes

n chemically resistant epoxy mortars

n anti-carbonation/anti-chloride protective coatings

n chemical and abrasion resistant coatings

For further information on any of the above, please consult

your local Fosroc office - as below.

* Denotes the trademark of Fosroc International Limited

REGIONAL SALES OFFICES IN :

Al Gurg Fosroc LLC

P. O. Box 657

Dubai

United Arab Emirates

TEL : (04) 285 8606

FAX : (04) 285 9649

DUBAI

ABU DHABI

BAHRAIN

KUWAIT

OMAN

QATAR

Al Gurg Fosroc

Al Gurg Fosroc

YBA Kanoo

Boodai

GETCO

Tadmur

TEL : 285 8787

TEL : 673 1779

TEL : 738200

TEL : 481 7618

TEL : 771 5080

TEL : 441 3628

FAX : 285 2023

FAX : 673 1449

FAX : 732828

FAX : 483 2124

FAX : 771 7554

FAX : 444 0812

Important note

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard terms and conditions of sale, copies of which

may be obtained on request. Whilst Fosroc endeavours to ensure that the technical information on this data sheet is correct at the time of printing, it is the

customers responsibility to satisfy himself, by checking with the company that this information is still current at the time of use, that the product is suitable for

the intended application, and that the actual conditions of use are in accordance with those recommended. Because Fosroc has no control over the conditions of

use of its products, all recommendations or suggestions regarding the use of these products are made without guarantee.

www.fosrocgulf.com

UAE/0426/0!/C

Das könnte Ihnen auch gefallen

- (PDS) Conbextra EP300Dokument4 Seiten(PDS) Conbextra EP300Faizal HaziziNoch keine Bewertungen

- How to Build a Simple Three Bedroom Shipping Container HouseVon EverandHow to Build a Simple Three Bedroom Shipping Container HouseBewertung: 4 von 5 Sternen4/5 (2)

- Conbextra EP300Dokument4 SeitenConbextra EP300Venkata Raju KalidindiNoch keine Bewertungen

- Water-Based Paint Formulations, Vol. 3Von EverandWater-Based Paint Formulations, Vol. 3Bewertung: 4.5 von 5 Sternen4.5/5 (6)

- Conbextra EP10Dokument2 SeitenConbextra EP10MuhammedHafis100% (1)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesVon EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Conbextra EP10Dokument4 SeitenConbextra EP10Venkata Raju KalidindiNoch keine Bewertungen

- Nitobond Ep..Dokument4 SeitenNitobond Ep..budhikurniawanNoch keine Bewertungen

- Conbextra EP10TGDokument2 SeitenConbextra EP10TGBambang SasikiranaNoch keine Bewertungen

- Conbextra EP75Dokument4 SeitenConbextra EP75Venkata Raju KalidindiNoch keine Bewertungen

- Conbextra EP10Dokument4 SeitenConbextra EP10Binoy Sankar SarkerNoch keine Bewertungen

- Conbextra EP10 : High Strength, Epoxy Resin GroutDokument2 SeitenConbextra EP10 : High Strength, Epoxy Resin GroutBudhi KurniawanNoch keine Bewertungen

- Nitocote Ep403Dokument4 SeitenNitocote Ep403pravi3434Noch keine Bewertungen

- Nitobond EP : Constructive SolutionsDokument4 SeitenNitobond EP : Constructive SolutionsmilanbrasinaNoch keine Bewertungen

- Renderoc HSDokument2 SeitenRenderoc HSAdnan JadoonNoch keine Bewertungen

- Nitotile 489Dokument2 SeitenNitotile 489Venkata RaoNoch keine Bewertungen

- Nitocote Et550Dokument4 SeitenNitocote Et550Venkata RaoNoch keine Bewertungen

- Nitocote cm210Dokument4 SeitenNitocote cm210Venkata RaoNoch keine Bewertungen

- Conbextra Ep75Dokument4 SeitenConbextra Ep75Sathiya SeelanNoch keine Bewertungen

- Conbextra EP300Dokument3 SeitenConbextra EP300Tori SmallNoch keine Bewertungen

- Renderoc FCXtra SubmittalDokument35 SeitenRenderoc FCXtra SubmittalAjit Singh Rathore100% (1)

- Nitoprime ZincrichDokument4 SeitenNitoprime ZincrichVenkata RaoNoch keine Bewertungen

- Nitomortar FCDokument3 SeitenNitomortar FCBalasubramanian AnanthNoch keine Bewertungen

- Cicol EtslurryDokument4 SeitenCicol EtslurryVenkata RaoNoch keine Bewertungen

- Nitoseal 290Dokument4 SeitenNitoseal 290shanon33Noch keine Bewertungen

- Nitomortar TC2000Dokument3 SeitenNitomortar TC2000MuhammedHafis100% (1)

- Nitocote NT550Dokument4 SeitenNitocote NT550Venkata Raju KalidindiNoch keine Bewertungen

- Nitomortar ElDokument4 SeitenNitomortar ElBalasubramanian AnanthNoch keine Bewertungen

- Nitobond EPDokument3 SeitenNitobond EPArun KumarNoch keine Bewertungen

- 136Dokument4 Seiten136Mohamed ShehataNoch keine Bewertungen

- Nitoseal 290Dokument4 SeitenNitoseal 290Venkata RaoNoch keine Bewertungen

- Nitoproof 110Dokument2 SeitenNitoproof 110Jude Peter Benjamin100% (1)

- Nitocote RiDokument2 SeitenNitocote RiVenkata Rao0% (1)

- Conbextra EP Data SheetDokument4 SeitenConbextra EP Data Sheetprabhu81Noch keine Bewertungen

- Nitoflor Eu50Dokument4 SeitenNitoflor Eu50Venkata RaoNoch keine Bewertungen

- 2 Nitobond EPDokument3 Seiten2 Nitobond EPfatinaainaaNoch keine Bewertungen

- Nitomortar TC2000Dokument3 SeitenNitomortar TC2000grtunaNoch keine Bewertungen

- Supercast EPT PDFDokument2 SeitenSupercast EPT PDFmilanbrasinaNoch keine Bewertungen

- Nitocote HT120Dokument4 SeitenNitocote HT120Venkata Raju KalidindiNoch keine Bewertungen

- Nitoseal 220Dokument4 SeitenNitoseal 220Venkata RaoNoch keine Bewertungen

- 50 FS MortarDokument2 Seiten50 FS MortarjaimeschofieldNoch keine Bewertungen

- Nitoseal 200Dokument4 SeitenNitoseal 200shanon33Noch keine Bewertungen

- Nitomortar ELDokument4 SeitenNitomortar ELmilanbrasinaNoch keine Bewertungen

- Nitoseal® 200Dokument4 SeitenNitoseal® 200Venkata Raju KalidindiNoch keine Bewertungen

- Nitozinc PrimerDokument4 SeitenNitozinc Primervenkatasuri999Noch keine Bewertungen

- Expoband One : Flexible Expansion Joint MembraneDokument4 SeitenExpoband One : Flexible Expansion Joint MembraneVenkata Raju KalidindiNoch keine Bewertungen

- TDS Nitomortar TC2000 Saudi ArabiaDokument3 SeitenTDS Nitomortar TC2000 Saudi ArabiaHarry BawingNoch keine Bewertungen

- Nitotile 489Dokument2 SeitenNitotile 489Balasubramanian AnanthNoch keine Bewertungen

- Expoband OneDokument4 SeitenExpoband Oneshanon33Noch keine Bewertungen

- Fosroc Dekguard PU: Constructive SolutionsDokument4 SeitenFosroc Dekguard PU: Constructive SolutionsganmosesNoch keine Bewertungen

- Nitocote Et402Dokument4 SeitenNitocote Et402Venkata Rao100% (1)

- Cemtop 250T PDFDokument4 SeitenCemtop 250T PDFriverwilliamsNoch keine Bewertungen

- Fosroc Nukote JF80Dokument3 SeitenFosroc Nukote JF80Balasubramanian AnanthNoch keine Bewertungen

- Conbextra Cable Grout : Constructive SolutionsDokument4 SeitenConbextra Cable Grout : Constructive SolutionsAnonymous uNhWGqNzNoch keine Bewertungen

- Conbextra Cable GroutDokument4 SeitenConbextra Cable GroutVenkata RaoNoch keine Bewertungen

- Nitoproof 10Dokument2 SeitenNitoproof 10Venkata RaoNoch keine Bewertungen

- Nitoflor FC550Dokument4 SeitenNitoflor FC550Venkata Raju KalidindiNoch keine Bewertungen

- Fosroc Nukote ST: Constructive SolutionsDokument4 SeitenFosroc Nukote ST: Constructive SolutionsRaj PatelNoch keine Bewertungen

- Nitotile 489 : Constructive SolutionsDokument2 SeitenNitotile 489 : Constructive SolutionsmilanbrasinaNoch keine Bewertungen

- TDS - Mastertile 540 - WjgroutDokument2 SeitenTDS - Mastertile 540 - WjgroutVenkata RaoNoch keine Bewertungen

- Tds - Waboflex SRDokument3 SeitenTds - Waboflex SRVenkata RaoNoch keine Bewertungen

- TDS - Mastertile 40Dokument2 SeitenTDS - Mastertile 40Venkata RaoNoch keine Bewertungen

- TDS - Mastertile 30 - WPMDokument2 SeitenTDS - Mastertile 30 - WPMVenkata RaoNoch keine Bewertungen

- TDS - Mastertile 530 - RbgroutDokument1 SeiteTDS - Mastertile 530 - RbgroutVenkata RaoNoch keine Bewertungen

- TDS - Mastertile 550 - DgroutDokument3 SeitenTDS - Mastertile 550 - DgroutVenkata RaoNoch keine Bewertungen

- Rheofinish 202: Solvent Based Chemical Release AgentDokument2 SeitenRheofinish 202: Solvent Based Chemical Release AgentVenkata RaoNoch keine Bewertungen

- TDS - Wabocrete IIDokument2 SeitenTDS - Wabocrete IIKingshuk SarkarNoch keine Bewertungen

- TDS - Masterkure 107Dokument2 SeitenTDS - Masterkure 107Venkata Rao100% (1)

- TDS - Masterkure 161Dokument2 SeitenTDS - Masterkure 161Venkata Rao0% (1)

- TDS Rheomix 121Dokument3 SeitenTDS Rheomix 121Tanzeel Liaqat100% (1)

- PlastisealDokument4 SeitenPlastisealVenkata RaoNoch keine Bewertungen

- TDS - Rheomix 141Dokument4 SeitenTDS - Rheomix 141Venkata RaoNoch keine Bewertungen

- Fosroc Acid EtchDokument2 SeitenFosroc Acid EtchVenkata RaoNoch keine Bewertungen

- Proofex GPXDokument2 SeitenProofex GPXVenkata RaoNoch keine Bewertungen

- TDS - Masterkure 106Dokument2 SeitenTDS - Masterkure 106Venkata RaoNoch keine Bewertungen

- 3696 2Dokument7 Seiten3696 2Venkata RaoNoch keine Bewertungen

- ReebolDokument2 SeitenReebolVenkata RaoNoch keine Bewertungen

- Reebol WBDokument2 SeitenReebol WBVenkata RaoNoch keine Bewertungen

- Nitoprime ZincrichDokument4 SeitenNitoprime ZincrichVenkata RaoNoch keine Bewertungen

- Conbextra Cable GroutDokument4 SeitenConbextra Cable GroutVenkata RaoNoch keine Bewertungen

- Brush BondDokument4 SeitenBrush BondVenkata RaoNoch keine Bewertungen

- Nitomortar SDokument4 SeitenNitomortar SVenkata RaoNoch keine Bewertungen

- Render CureDokument2 SeitenRender CureVenkata RaoNoch keine Bewertungen

- Trafficguard UrDokument2 SeitenTrafficguard UrVenkata RaoNoch keine Bewertungen

- Assessmentof Cementand Filler Requirementsfor Grouting Sandy SoilDokument155 SeitenAssessmentof Cementand Filler Requirementsfor Grouting Sandy Soilzeme6Noch keine Bewertungen

- Aci 351.1 R-99 Grouting Bet Foundn & Bases For Support of Equipment & Machinery (PDF - Io)Dokument18 SeitenAci 351.1 R-99 Grouting Bet Foundn & Bases For Support of Equipment & Machinery (PDF - Io)Prapa KaranNoch keine Bewertungen

- Ceramic TilingDokument45 SeitenCeramic TilingFirdaus Pasro Radzi100% (2)

- Brickwork Boq FormatDokument18 SeitenBrickwork Boq FormatPankaj MalpotraNoch keine Bewertungen

- SIREG - Sleeved Grouting PipesDokument16 SeitenSIREG - Sleeved Grouting PipesMario RuggieroNoch keine Bewertungen

- Nitotile GroutDokument2 SeitenNitotile GroutVenkata RaoNoch keine Bewertungen

- Fosroc Grouting BrochureDokument9 SeitenFosroc Grouting Brochurehareesh13hNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Masonry Units and Plaster Installation Inspection SAIC-M-1009 1-Nov-09 CivilDokument4 SeitenSaudi Aramco Inspection Checklist: Masonry Units and Plaster Installation Inspection SAIC-M-1009 1-Nov-09 CivilWaleed MedhatNoch keine Bewertungen

- Floor Tiling-Method StatementDokument5 SeitenFloor Tiling-Method StatementamroNoch keine Bewertungen

- SALI EstimatesDokument56 SeitenSALI EstimatesaldwinNoch keine Bewertungen

- Elemental Bill of Quantities For 3 Bedroom Apartment BlockDokument29 SeitenElemental Bill of Quantities For 3 Bedroom Apartment BlockAliyu Shehu83% (72)

- System For Waterproofing and Installing Ceramic Tiles and Mosaics in Tanks and Swimming Pools (PDFDrive)Dokument24 SeitenSystem For Waterproofing and Installing Ceramic Tiles and Mosaics in Tanks and Swimming Pools (PDFDrive)VicktorNoch keine Bewertungen

- DR Fixit General Repair Remedial Waterproofing Guide PDFDokument40 SeitenDR Fixit General Repair Remedial Waterproofing Guide PDFandrealeger755774Noch keine Bewertungen

- Dokumen - Tips - As 39581 2007 Ceramic Tiles Guide To The Installation 39583 Guide To TheDokument8 SeitenDokumen - Tips - As 39581 2007 Ceramic Tiles Guide To The Installation 39583 Guide To TheEli MatucadNoch keine Bewertungen

- 1489571423323-Question Bank PDFDokument367 Seiten1489571423323-Question Bank PDFAshok kumar100% (1)

- Punch List B1Dokument30 SeitenPunch List B1salamankanNoch keine Bewertungen

- Helifix Crack StitchingDokument2 SeitenHelifix Crack Stitchingneel12321Noch keine Bewertungen

- BASF - APE System PDFDokument86 SeitenBASF - APE System PDFrendroedywibowoNoch keine Bewertungen

- Method - Statement - For - Granite Floor and WallDokument6 SeitenMethod - Statement - For - Granite Floor and WallobieNoch keine Bewertungen

- Repair, Retrofitting, Rehabiliation of StructuresDokument57 SeitenRepair, Retrofitting, Rehabiliation of Structures29-GouravNoch keine Bewertungen

- Methodologies For Repair of Cracks in PQC in Concrete PavementsDokument9 SeitenMethodologies For Repair of Cracks in PQC in Concrete PavementsADC PLNoch keine Bewertungen

- 2755-MCD-CON-CEP-0070 - Concrete Repair Works For Cold JointDokument19 Seiten2755-MCD-CON-CEP-0070 - Concrete Repair Works For Cold JointNURLINURLINDANoch keine Bewertungen

- Water Proofing - W02 - Work Method StatementDokument3 SeitenWater Proofing - W02 - Work Method StatementJohn Rhey Lofranco TagalogNoch keine Bewertungen

- Ultrafine Cement: Figure 1. Chemical Composition of Ultrafine Cements (CITATION Cla93 /L 1033)Dokument2 SeitenUltrafine Cement: Figure 1. Chemical Composition of Ultrafine Cements (CITATION Cla93 /L 1033)Michael Arya YutakaNoch keine Bewertungen

- Structural Elements Dead LoadDokument3 SeitenStructural Elements Dead LoadAgapito Barasi KionisalaNoch keine Bewertungen

- Report of SOYMPH Tile TentingDokument4 SeitenReport of SOYMPH Tile TentingHugo LabastidaNoch keine Bewertungen

- Water Proofing MethodologyDokument6 SeitenWater Proofing Methodologykartick adhikaryNoch keine Bewertungen

- UPDATED BoQ Document 7b-Annex C-BoQ-CPB6-Dhading Gorkha PDFDokument176 SeitenUPDATED BoQ Document 7b-Annex C-BoQ-CPB6-Dhading Gorkha PDFblueoceanNoch keine Bewertungen

- Comparative Studies of The Effectiveness of Diferent Methods For Compacting Cohesionless SoilsDokument9 SeitenComparative Studies of The Effectiveness of Diferent Methods For Compacting Cohesionless SoilsAnonymous GnfGTwNoch keine Bewertungen

- Methodology For Honeycomb RepairDokument2 SeitenMethodology For Honeycomb Repairanbunilavan50% (2)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetVon EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetBewertung: 4.5 von 5 Sternen4.5/5 (10)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeVon EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeBewertung: 4.5 von 5 Sternen4.5/5 (59)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionVon EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionBewertung: 4.5 von 5 Sternen4.5/5 (543)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Von EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Noch keine Bewertungen

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonVon EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonBewertung: 5 von 5 Sternen5/5 (2)

- To Engineer Is Human: The Role of Failure in Successful DesignVon EverandTo Engineer Is Human: The Role of Failure in Successful DesignBewertung: 4 von 5 Sternen4/5 (138)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tVon EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tBewertung: 4.5 von 5 Sternen4.5/5 (27)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosVon EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosBewertung: 5 von 5 Sternen5/5 (1)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersVon Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersBewertung: 5 von 5 Sternen5/5 (1)

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsVon EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNoch keine Bewertungen

- Electronics All-in-One For Dummies, 3rd EditionVon EverandElectronics All-in-One For Dummies, 3rd EditionBewertung: 5 von 5 Sternen5/5 (2)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialVon EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Multiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...Von EverandMultiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...Noch keine Bewertungen

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesVon EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesBewertung: 5 von 5 Sternen5/5 (1)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeVon EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeBewertung: 4.5 von 5 Sternen4.5/5 (10)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansVon EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansBewertung: 4.5 von 5 Sternen4.5/5 (21)

- Retro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsVon EverandRetro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsNoch keine Bewertungen

- Analog Design and Simulation Using OrCAD Capture and PSpiceVon EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceNoch keine Bewertungen

- Power Electronics Diploma Interview Q&A: Career GuideVon EverandPower Electronics Diploma Interview Q&A: Career GuideNoch keine Bewertungen

- Rocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyVon EverandRocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyBewertung: 4.5 von 5 Sternen4.5/5 (5)