Beruflich Dokumente

Kultur Dokumente

B4 Stress Analysis

Hochgeladen von

NaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

B4 Stress Analysis

Hochgeladen von

NaCopyright:

Verfügbare Formate

STRESS ANALYSIS OF PIPING SYSTEMS

STRESS ANALYSIS OF PIPING SYSTEMS

B.139

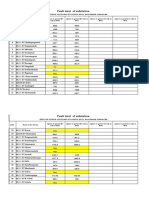

TABLE B4.4c SIFs for Class 3000 Half-Couplings (Branch Pipe Schedule 80) (Run Pipe Size:

NPS 1 to 8 (DN 40 to 200))

1 in = 25.4 mm

2. Stresses due to occasional loads. The sum of the longitudinal stresses due to

pressure, weight, and other sustained loads and of the stresses produced by

occasional loads such as earthquake or wind shall not exceed 1.33Sh. Earthquake

and wind loads need not be considered as acting simultaneously.

3. Stress range due to expansion loads. The displacement stress range SE shall not

exceed SA:

(B4.28)

where SE =

Sb = resultant bending stress, psi

= [(iiMi )2 +(ioMo)2]1/2/Z

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

STRESS ANALYSIS OF PIPING SYSTEMS

GENERIC DESIGN CONSIDERATIONS

B.140

TABLE B4.4d SIFs for Class 3000 Half-Couplings (Branch Pipe Schedule 80) (Run Pipe Size:

NPS 10 to 24 (DN 250 to 600))

1 in = 25.4 mm

Mi = in-plane bending moment, in lb

Mo = out-of-plane bending moment, in lb

ii = in-plane stress intensification factor obtained from Fig. B4.5a (see also

figure note 10)

io = out-of-plane stress intensification factor obtained from Fig. B4.5a (see

also figure note 10)

St = torsional stress, psi

= Mt/(2Z)

Mt = torsional moment, in lb

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

STRESS ANALYSIS OF PIPING SYSTEMS

STRESS ANALYSIS OF PIPING SYSTEMS

B.141

TABLE B4.4e SIFs for Class 6000 Half-Couplings (Branch Pipe Schedule 160) (Run Pipe Size:

1 to 8 in (DN 40 to 200))

1 in = 25.4 mm

SA =

=

=

Sc =

f=

allowable displacement stress range

f(1.25Sc + 0.25Sh)

f[1.25(Sc + Sh) - SL] when Sh > SL

basic allowable stress at minimum metal temperature, psi

stress range reduction factor per Table B4.2

ASME B31.4 Liquid Transportation Systems for Hydrocarbons, Liquid Petroleum

Gas, Anhydrous Ammonia, and Alcohols Piping Code.10 The scope of ASME B31.4,

Liquid Transportation Systems for Hydrocarbons, Liquid Petroleum Gas, Anhydrous

Ammonia, and Alcohols, governs piping transporting liquids such as crude oil,

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

STRESS ANALYSIS OF PIPING SYSTEMS

B.142

GENERIC DESIGN CONSIDERATIONS

TABLE B4.4f SIFs for Class 6000 Half-Couplings (Branch Pipe Schedule 160) (Run Pipe Size:

10 to 24 in (DN 250 to 600))

1 in = 25.4 mm

condensate, natural gasoline, natural gas liquids, liquefied petroleum gas, liquid

alcohol, liquid anhydrous ammonia, and liquid petroleum products between producers

lease facilities, tank farms, natural gas processing plants, refineries, stations, ammonia

plants, terminals, and delivery and receiving points. Excluded from B31.4 are auxiliary

piping such as water, air, steam, lubricating oil, gas, and fuel; piping with an internal

gauge pressure at or below 15 psi (103.5 kPa) regardless of temperature; piping with

an internal gauge pressure above 15 psi (103.5 kPa) and a temperature below -20F

(-29C) or above 250F (121C); and piping for petroleum refinery, gas transmission

and distribution, ammonia refrigeration, and so on, that is covered by other ASME

B31 sections.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

STRESS ANALYSIS OF PIPING SYSTEMS

STRESS ANALYSIS OF PIPING SYSTEMS

B.143

The limits of calculated stresses are as follows:

1. Stresses due to sustained loads. The sum of the longitudinal stresses due to pressure,

weight, and other sustained external loads shall not exceed 0.75SA, where SA =

0.72Sy (specified minimum yield strength).

2. Stresses due to occasional loads. The sum of the longitudinal stresses produced

by pressure, live and dead loads, and those produced by occasional loads, such as

wind or earthquake, shall not exceed 0.8Sy.

3. Stresses due to expansion loads

a. Restrained lines. The net longitudinal compressive stress due to the combined

effects of temperature rise and fluid pressure shall be computed from the equation.

(B4.29)

where SL

SH

T1

T2

E

=

=

=

=

=

=

=

longitudinal compressive stress, psi

hoop stress due to fluid pressure, psi

temperature at time of installation, F

maximum or minimum operating temperature, F

modulus of elasticity, psi

linear coefficient of thermal expansion, in/(in F)

Poissons ratio = 0.30 for steel

Then the equivalent tensile stress is calculated as

(B4.30)

where Seqiv = the equivalent tensile stress, psi. Beam bending stresses shall be

included in the longitudinal stress for those portions of the restrained line

which are supported aboveground.

b. Unrestrained lines. Stresses due to expansion for those portions of the piping

without substantial axial restraint shall be combined in accordance with the

following equation:

(B4.31)

where SE = stress due to expansion, psi

Sb = [(iiMi)2 +(ioMo2) ]1/2/Z

= equivalent bending stress, psi

St = Mt/(2Z) = torsional stress, psi

Mi = in-plane bending moment, in lb

Mo = out-of-plane bending moment, in lb

Mt = torsional moment, in lb

ii = in-plane stress intensification factor obtained from Fig. B4.5a

io = out-of-plane stress intensification factor obtained from Fig. B4.5a

Z = section modulus of pipe, in3

ASME B31.5 Refrigeration Piping Code.11 The scope of this code covers refrigerant

and secondary coolant piping for temperatures as low as -320F (196C). Excluded

from this code are piping designed for external or internal gauge pressure not exceeding

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

Das könnte Ihnen auch gefallen

- Attachment B - Flange CheckDokument1 SeiteAttachment B - Flange CheckNaNoch keine Bewertungen

- Static & Dynamic Analysis of Piping SystemDokument105 SeitenStatic & Dynamic Analysis of Piping Systemkarthikeashwar100% (4)

- CompreDokument3 SeitenCompreNaNoch keine Bewertungen

- CompreDokument3 SeitenCompreNaNoch keine Bewertungen

- A88516875 Slug Flow AnalysisDokument7 SeitenA88516875 Slug Flow AnalysisNaNoch keine Bewertungen

- Evaluating Dynamic Stresses of A PipelineDokument8 SeitenEvaluating Dynamic Stresses of A PipelinejasminNoch keine Bewertungen

- Forces and Moments (Api-617Dokument3 SeitenForces and Moments (Api-617NaNoch keine Bewertungen

- A135810286 Compressor Stress Analysis PresentationDokument25 SeitenA135810286 Compressor Stress Analysis PresentationNaNoch keine Bewertungen

- Steam 1Dokument4 SeitenSteam 1NaNoch keine Bewertungen

- Steam 1Dokument5 SeitenSteam 1NaNoch keine Bewertungen

- Steam 1Dokument5 SeitenSteam 1NaNoch keine Bewertungen

- Steam 1Dokument5 SeitenSteam 1NaNoch keine Bewertungen

- Steam 1Dokument5 SeitenSteam 1NaNoch keine Bewertungen

- Steam 1Dokument4 SeitenSteam 1NaNoch keine Bewertungen

- LANL EngDokument3 SeitenLANL EngNaNoch keine Bewertungen

- LANL EngDokument3 SeitenLANL EngNaNoch keine Bewertungen

- LANL EngDokument4 SeitenLANL EngNaNoch keine Bewertungen

- Steam 1Dokument5 SeitenSteam 1NaNoch keine Bewertungen

- LANL EngDokument3 SeitenLANL EngNaNoch keine Bewertungen

- LANL EngDokument3 SeitenLANL EngNaNoch keine Bewertungen

- B4 Stress AnalysisDokument5 SeitenB4 Stress AnalysisNaNoch keine Bewertungen

- LANL EngDokument3 SeitenLANL EngNaNoch keine Bewertungen

- LANL EngDokument3 SeitenLANL EngNaNoch keine Bewertungen

- Stress B4Dokument5 SeitenStress B4NaNoch keine Bewertungen

- Code Requirements: Safe-Shutdown Earthquake (SSE), Which Is Defined As The Maximum PossibleDokument4 SeitenCode Requirements: Safe-Shutdown Earthquake (SSE), Which Is Defined As The Maximum PossibleNaNoch keine Bewertungen

- Stress B4Dokument7 SeitenStress B4NaNoch keine Bewertungen

- Stress Analysis of Piping Systems: & PV Code, 1998. (Courtesy of ASME.)Dokument5 SeitenStress Analysis of Piping Systems: & PV Code, 1998. (Courtesy of ASME.)NaNoch keine Bewertungen

- Stress B4Dokument5 SeitenStress B4NaNoch keine Bewertungen

- 2) Stress Analysis 2Dokument30 Seiten2) Stress Analysis 2Dennis Padec BwochengoNoch keine Bewertungen

- Extracted Page From Stress B4Dokument3 SeitenExtracted Page From Stress B4NaNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- ZTE Rectifier SettingsDokument4 SeitenZTE Rectifier SettingsRicardo Chavarria50% (2)

- 1SCA022620R7200 Ozxt2 Terminal SetDokument2 Seiten1SCA022620R7200 Ozxt2 Terminal SetJorge Salas CabanaNoch keine Bewertungen

- Current Affairs - Sept 2014Dokument202 SeitenCurrent Affairs - Sept 2014kumar1987Noch keine Bewertungen

- Glaunach Silencer HandbookDokument67 SeitenGlaunach Silencer Handbookriff100% (4)

- 3RH29111FA22 Datasheet enDokument6 Seiten3RH29111FA22 Datasheet enFlavioNoch keine Bewertungen

- Comparison Data LED Lights Vs Incandescent & CFL BDokument7 SeitenComparison Data LED Lights Vs Incandescent & CFL BidealparrotNoch keine Bewertungen

- 4045HMC85Dokument2 Seiten4045HMC85فتحي الجمل فتحي الجملNoch keine Bewertungen

- PB0101-2 Raymond HP BM Coal Pet CokeDokument2 SeitenPB0101-2 Raymond HP BM Coal Pet CokeswatkoolNoch keine Bewertungen

- Fault Level of SubstationDokument2 SeitenFault Level of SubstationrtadNoch keine Bewertungen

- uPVC Pressure Pipes CatalogueDokument30 SeitenuPVC Pressure Pipes CatalogueanishsrNoch keine Bewertungen

- Xylem Company Profile 2012 PortableDokument26 SeitenXylem Company Profile 2012 Portablegeorge_efstratiadisNoch keine Bewertungen

- Doosan DX225LCA Electric Circuit 110705Dokument1 SeiteDoosan DX225LCA Electric Circuit 110705Eduardo Ariel Bernal97% (30)

- T-23 BOQ (Katol)Dokument40 SeitenT-23 BOQ (Katol)rajesh kumarNoch keine Bewertungen

- JSA TemplateDokument3 SeitenJSA TemplateJob MateusNoch keine Bewertungen

- BBBBDokument16 SeitenBBBBLidetu AbebeNoch keine Bewertungen

- Solutions To The Problems of The Theoretical CompetitionDokument16 SeitenSolutions To The Problems of The Theoretical CompetitionDejan DjokićNoch keine Bewertungen

- Column Piping Stress AnalysisDokument6 SeitenColumn Piping Stress Analysissj22Noch keine Bewertungen

- AS5780-Core Requirement Specification For Aircraft Gas Turbine Engine LubricantsDokument9 SeitenAS5780-Core Requirement Specification For Aircraft Gas Turbine Engine LubricantsJicheng PiaoNoch keine Bewertungen

- Overfill - Valve - 442B Size 4Dokument3 SeitenOverfill - Valve - 442B Size 4j8164322Noch keine Bewertungen

- Pulsar Extreme 3200CDokument28 SeitenPulsar Extreme 3200CGuillermoNoch keine Bewertungen

- Plug in Electric Vehicles in Smart Grids Integration TechniquesDokument355 SeitenPlug in Electric Vehicles in Smart Grids Integration Techniqueseng_alhemyari100% (3)

- A1000Dokument2 SeitenA1000nitin hadkeNoch keine Bewertungen

- Marine Engine Imo Tier LL and Tier LLL ProgrammeDokument220 SeitenMarine Engine Imo Tier LL and Tier LLL ProgrammeMuhammad Farhanuddien AnharNoch keine Bewertungen

- GATE Chemical Engineering 2002Dokument10 SeitenGATE Chemical Engineering 2002rahulsaini855Noch keine Bewertungen

- L1 ML Waves IDokument67 SeitenL1 ML Waves ISadiq QocayevNoch keine Bewertungen

- Data - Sheet - IG060NK37VB8 Limit SwitchDokument2 SeitenData - Sheet - IG060NK37VB8 Limit SwitchJenő SerkediNoch keine Bewertungen

- Specific Gravity ASTM D 70-3Dokument8 SeitenSpecific Gravity ASTM D 70-3Altaf HossainNoch keine Bewertungen

- 5070 s03 QP 1 PDFDokument16 Seiten5070 s03 QP 1 PDFAnonymous wFLGHQ6ARNoch keine Bewertungen

- Studying The Operation of A Smart Grid With The MyGrid MiniSystem For NI MyDAQ (Piomeer Release)Dokument4 SeitenStudying The Operation of A Smart Grid With The MyGrid MiniSystem For NI MyDAQ (Piomeer Release)Jobin VargheseNoch keine Bewertungen