Beruflich Dokumente

Kultur Dokumente

1 PB

Hochgeladen von

SariaKhanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

1 PB

Hochgeladen von

SariaKhanCopyright:

Verfügbare Formate

1080

JOURNAL OF NETWORKS, VOL. 8, NO. 5, MAY 2013

An Intelligent Irrigation System Based on

Wireless Sensor Network and Fuzzy Control

Liai Gao

Agricultural University of Hebei, College of Mechanical and Electrical Engineering, Baoding, China

Email: gaoliai111@126.com

Meng Zhang

China Agricultural University, College of Information and Electrical Engineering, Beijing, China

Email: zm0312@126.com

Geng Chen

Agricultural University of Hebei, College of mechanical and electrical engineering, Baoding, China

Email: 1581286612@qq.com;

AbstractIn order to resolve the problems which include

loss of soil fertility and waste of water resource in

agriculture production, we design an intelligent irrigation

system based on wireless sensor networks and fuzzy control.

The system mainly consists of wireless sensor networks and

the monitoring center. All of the nodes in Monitoring area

use solar power, collect the information of soil moisture,

together with the growth information of different crops in

different periods. Soil moisture content deviation and the

rate of change of deviation are taken as input variables of

fuzzy controller, and the fuzzy control regular database is

established for the fuzzy irrigation control system. The

monitoring center receives the data transmission from

wireless sensor network node, and output information of

irrigation water demands to the relay via a wireless sensor

network to control opening and closing time of the valve in

crop areas. The experimental results show that the system

has a stable and reliable data transmission, which achieve

real-time monitoring of soil on crop growth, give a right

amount of irrigation based on crops growth information,

which has broad application prospects.

Index Termswater-saving irrigation, wireless sensor

network, fuzzy control strategy, sensor

I. INTRODUCTION

With the rapid development of agriculture in China,

the water consumption was increasing. As the shortage

and waste of the low utilization of Chinese agricultural

water

resources

were

being

existence,

the

implementations of water-saving irrigation were more

and more crucial [1]. Soil moisture content is a

prerequisite for the crop growth, while excessive soil

moisture would cause the rot of crops roots, took away a

lot of fertilizer which will cause water pollution. With the

development of computer technology and sensor

technology, monitoring and control of soil moisture

content had made great progress [2], but there remained

two main problems: First, most of irrigation control

system worked in a wired manner, using serial bus and

2013 ACADEMY PUBLISHER

doi:10.4304/jnw.8.5.1080-1087

field bus technology, therefore it had a complex wiring,

installation and maintenance costs. Second, the crop

water requirement was a physical quantity with various

environmental factors, with a strong coupling and

complexity, it was difficult to establish a precise

mathematical model, and fuzzy control has good

robustness, dynamic response, so it is very suitable for

application in irrigation systems and does not depend on

accurate mathematical model.

Experts and scholars at home and abroad have applied

wireless sensor networks and fuzzy control technology in

the irrigation system separately. Literature [3] proposed a

soil moisture detection system based on ZigBee wireless

network, and all the references only stated monitoring

soil moisture content and had no control function;

Literature [4] used WSN based on ZigBee technology in

the precision farming, which had a detailed analysis of

the deployment of wireless sensor nodes in soil

environment and the construction of the gateway and a

base station node; Literature [5] set up a small farmland

data acquisition platform using ZigBee network, and

obtained information of the solar energy, wind and

current; Literature [6] achieved a remote monitoring of

irrigation system through the distributed WSN and GPRS;

Literature[7]put the fuzzy control to the greenhouse

monitoring system; Literature [8] proposed a soil

moisture monitoring system based on ZigBee, through

controlling solenoid valve to control soil moisture rate in

irrigation area, but need the support of electric.

In summary, combined with the advantages of wireless

sensor networks and fuzzy control technologies, an

intelligent irrigation system was designed. First of all,

ZigBee wireless network technology was used in this

design. Because it had low power consumption, low cost,

free wireless communication frequency characteristics,

which could replace the wired connections in the

traditional system. With solar cell, solar energy was

collected and stored in lithium battery to provide power

supply for the system. Secondly, the environment factor

JOURNAL OF NETWORKS, VOL. 8, NO. 5, MAY 2013

of influence irrigation volume was analyzed, a reasonable

irrigation methods for crop water requirement and soil

moisture information was selected , as we all known, the

soil water environment has the characteristics of big

inertia, non-linearity and strong coupling, in this design

we introduced fuzzy intelligent control technology to

analysis and processing the soil moisture. Adopt

MATALB for the generation of the fuzzy controller and

the fuzzy control table, using Simulink for the simulation.

On the basis of the LabVIEW virtual instrument

development platform, a software program for intelligent

irrigation monitoring system was designed. Modular

design was adopted in this design; it could realize the

signal collection for real time monitoring, data display,

data processing, control signal output, and other functions.

The whole software system operation had friendly

interface, convenient development and maintenance. In a

word, the system use fuzzy control technology, sensor

technology, wireless sensor network (WSN) technology,

and agricultural irrigation technology, which can realize

the intelligent agricultural irrigation and increase the

efficiency of agricultural water.

II. SYSTEM ARCHITECTURE

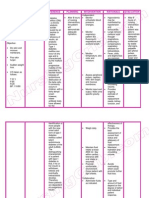

The whole monitoring system had two parts: a wireless

sensor network and monitoring center. Sensor nodes, the

controller node, soil moisture sensors, irrigation pipe,

spray irrigation and irrigation control valve were

deployed in crop-growing regions, the framework of the

monitoring system was shown in Fig. 1. ZigBee network

was adopted in mesh network topology. In order to meet

the network coverage and reduce the node energy

consumption and cost at the same time, we selected a

small amount of sensor nodes as routers, to complete the

data gathering and routing data from other equipment to

the coordinator. And most of the sensor nodes act as

terminal devices, only collect data and sent to the router

or near the coordinator; A control panel was extend to the

sensor nodes to make up for controller node, data

acquisition can be proceeding at ordinary times, control

valve can be opened to realize the irrigation when

receiving irrigation command.

Wireless sensor network consisted of sensor nodes,

routing nodes and coordinator node, distributed in all

regions of the monitoring area [9, 10]. All nodes were

powered by solar energy. Nodes used modular design,

the three kinds of nodes used common core modules, and

different nodes with different extension modules. The

temperature and humidity sensor collected temperature

and humidity information; routing nodes was responsible

for routing communication and forwarding data; the

coordinator node received data from routing node and

sent it to the host computer monitor center through

RS232 serial bus. The monitoring center could record

real-time soil moisture content uploading from all nodes,

calculate crop irrigation water requirement according to

the plant physiology characteristic in different growth

period, and output result to relay by wireless sensor

network, control opening and closing time of valve, so as

2013 ACADEMY PUBLISHER

1081

to realize the remote automatic adjustment and control for

irrigation.

Figure 1. Framework of the system

In order to solve the node energy supply problem, we

proposed a supply system based on solar energy [11],

which is composed by solar modules, Energy

management controller, and lithium battery.

The solar module can not only charge the lithium

battery, but also supply power to the sensor node;

similarly, lithium battery can supply power to the sensor

node. The microprocessor of the energy management

controller collect voltage of solar panels and lithium

battery, then transmit the feedback information to the

controlling circuit. The controlling circuit executive

power supply and charging scheme according to the

information of the microprocessor effectively solve the

problem of battery charged frequently. Under the

condition of continuous power supply, the priority for

power supply is solar panels, lithium batteries. If the

lithium battery is not saturated, the solar battery charge

for lithium batteries; when sunshine is insufficient or no

sunshine, added lithium battery power supply or power

supply separately.

III. WIRELESS SENSOR NETWORK NODES

There were three kinds of wireless sensor network

nodes: sensor nodes, route nodes and the coordinator

node. All of the nodes made cc2530 as the core, matched

by the different extension modules. The CC2530 is a true

System-on-Chip (SoC) solution specifically tailored for

IEEE 802.15.4 and ZigBee applications. It enables

ZigBee nodes to be built with very low total bill-ofmaterial costs. The CC2530 combines the excellent

performance of the leading RF transceiver with an

industry-standard enhanced 8051 MCU, 32/64/128/256

KB flash memory, 32/64/128/256 KB RAM and many

other powerful features. The CC2530 has different

running mode, makes it particularly suitable for low

power requirements of the system. Node hardware

structure diagram is shown in Fig. 2.

1082

JOURNAL OF NETWORKS, VOL. 8, NO. 5, MAY 2013

driver circuit

RTC

solenoid valve

negative pulse, and it is very suitable for the occasions

without alternating current.

CC2530

soil humidity

sensor

microprocessor

8051

IV. FUZZY CONTROL ALGORITHM

RF module

reset circuit

solar cells

energy management

controller

lithium battery

Figure 2 . The hardware structure diagram of node

A. Sensors

The type of soil moisture sensor is TDR-3A, which is

produce by Jinjiang Sunshine Technology Co., Ltd .The

sensor is an ideal instrument, which can measure soil

temperature and humidity and has the features of sealed,

waterproof, high precision. The main performance

indexes of the sensor are shown in table I.

The soil environment is a large inertia, nonlinear and

time delay system, it is very difficult to establish a precise

mathematical model, and because of the unified,

variability and complexity in the greenhouse field

conditions, it is difficult to achieve precise control if we

the traditional control method [12]. we select fuzzy

control theory of intelligent control method .Fuzzy

control theory does not need to establish accurate

mathematical model of controlled object, robust, it is

suitable for the lag, nonlinear and time-varying system,

so it is suitable for using fuzzy control strategy to realize

the controlling of the monitoring system.

Whether to construct fuzzy controller reasonably is

related to the precision of fuzzy control system, the

structure of fuzzy controller is shown in Fig. 4.

TABLE I.SENSOR TECHNOLOGY PARAMETERS

Measured

parameters

humidity

knowledge

base

Performance index

range: 0100%

accuracy: 2%

measuring field: the cylinder which diameter is 3

cm, length is 6 cm around the probe

Working voltage : 12V24V DC

Working circuit: 5070mA,

output: 4~20MA

B. Output Control Module

Irrigation actuator output control signal to the relay,

thus control irrigation time of the valve open. This paper

adopts NPN triode drives relay, the driving circuit is

shown in Fig. 3.

VCC(12V)

relay

control signal

4007

R2

8050

R1

Figure 3. The driving circuit of the relay

The type of Solenoid valve is 100-DVF which is

produced by Rain Bird Corp. It is normally in closed

solenoid valve. The function is opening and closing the

water of pipeline according to the control signal sending

by the device. The valve is equipped with a TBOS control

module, valve start-stop is controlled by positive and

2013 ACADEMY PUBLISHER

humidity

E

EC

fuzzification

fuzzy

reasoning

defuzzication

output

Figure 4. Structure of fuzzy logic controller

E is soil humidity deviation; EC is the rate of change

of deviation over time.

The reasoning process is divided into the following

steps [13]: first the continuous input, output is converted

to a fuzzy subset, its domain is defined, and fuzzy table is

set up according to the actual change range of the input

output. Establish the knowledge base through the

knowledge and experience of experts, and form the fuzzy

control rule, use fuzzy table and fuzzy control rule table,

the fuzzy control fuzzy control, into the final amount.

Calculate the amount of the corresponding fuzzy control;

finally, make fuzzy control amount defuzzification for

transforming into ultimate control parameters.

(1) The Fuzzification of Precise Variable

For the fuzzification operation of precise variable

usually include selecting fuzzy variables, quantifying

input data and determining the membership function.

Select E as the input variables, the language variables of

corresponding deviation are divided into 5 grades, which

can reflect the size: NB = negative big, NS =negative

small, Z = zero, PS = positive small, PB = positive big.

Assume that changes in humidity around 20%, the basic

domain of deviation humidity is [20, +20] , according to

the formula:

2n + 1 = km

(1)

where n is the number of elements; m is classification;

the value of k is 2.

So the fuzzy domain is (-4, -3, -2, -1, 0, 1, 2, 3, 4);

The basic domain of another input variable ECH is [-5,

+5], fuzzy domain (-4, -3, -2, -1, 0, 1, 2, 3, 4) .

JOURNAL OF NETWORKS, VOL. 8, NO. 5, MAY 2013

1083

The results of the fuzzy control is the opening time

controlled by solenoid valve, we use U as an output

variables, fuzzy linguistic variables Z (zero), DS

(short-term), ZS (middle-term), CS (Large-time). Set

the basic domain is [0,30] , the fuzzy domain (0, 1, 2, 3).

According to the formula KET = n / Z i

(2)

The quantization factor of respective variable can be

determined.

So,

the

humidity

quantitative

factor

KET1 = n / Z1 = 4 / 20 = 0.2 ;

Humidity

deviation

quantization

factor

KET2 = n / Z 2 = 4 / 5 = 0.8 ;

The

output

control

quantization

factor

KET3 = n / Z1 = 3 / 30 = 0.1 ;

Through above formula, elements of Ai , Bi , Ci in the

fuzzy domain can be calculated which is correspond to

the accurate digital quantity eTi .

Ai = KET1 eT 1

(3)

Bi = KET2 eT 2

(4)

Ci = KET3 eT 3

(5)

By this method, each variable domain ,fuzzy subset,

quantitative grade, fuzzy domain and the quantification

factor is completed, the results is shown in table II.

TABLE II. EACH VARIABLE DOMAIN, FUZZY SUBSET, QUANTITATIVE GRADE, FUZZY DOMAIN, QUANTIFICATION FACTOR

variable

domain

[-20%,+20%]

EC

[-5,+5]

[0,30]

fuzzy subset

Ai

(NB, NS, Z, PS, PL )

Bi

(NB, NS, Z, PS, PL )

Ci

(Z, DS, ZS, CS )

quantitative grade

(- 4, - 3, - 2, - 1, 0, 1, 2,

3, 4)

(- 4, - 3, - 2, - 1, 0, 1, 2,

3, 4)

(0, 1, 2, 3)

(2) Determine the membership function

This study use triangle membership function, Fuzzy

input variables membership assignment is shown in table

.

TABLE III.

fuzzy

variables

NB

NS

Z

PS

PB

FUZZY INPUT VARIABLES MEMBERSHIP ASSIGNMENT TABLE

-4

1

0

0

0

0

-3

0.5

0

0

0

0

-2

0

0.5

0

0

0

E/EC

0

0

0

1

0

0

-1

0

1

0

0

0

1

0

0

0

1

0

2

0

0

0

0.5

0

3

0

0

0

0

0.5

4

0

0

0

0

1

TABLE

Fuzzy variable

Z

DS

ZS

CS

0

1.0

0

0

0

1

0

1.0

0

0

2

0

0

1.0

0

3

0

0

0

1.0

(3) The fuzzy control rules

Formulate rules of fuzzy control principle is make the

static and dynamic characteristics of system output

response for the best [14, 15]. That is to say when the

output deviation of the system is bigger, we need to select

control variable quickly for the purpose of reducing or

even eliminating bias; when the system output deviation

is small, we must take the system stabilization as the goal

when selecting control variable, at the same time pay

attention to overshoot phenomenon. For the temperature

factor, the fuzzy control rules are as follows:

2013 ACADEMY PUBLISHER

quantification factor

0.2

0.8

0.1

If E is Ai and EC is Bi THEN U is Ci

(6)

(4) Fuzzy reasoning

The key of fuzzy controller is fuzzy reasoning; it refers

to the process of the simulation of the human brain

thinking based on fuzzy concept. In this study, Mamdani

fuzzy model is selected as reasoning method, a

corresponding membership value is obtained from the

current quantized input variables, and then from the fuzzy

control rules, we can get output control quantity of fuzzy

variable. The fuzzy control rules table is shown in table 4.

TABLE V. THE FUZZY CONTROL RULES TABLE

Fuzzy input variables membership assignment is

shown in table IV.

TABLE IV. FUZZY OUTPUT VARIABLES MEMBERSHIP ASSIGNMENT

quantitative grade

NB

NS

Z

PS

NB

Z

DS

DS

ZS

NS

Z

DS

ZS

ZS

E

Z

Z

Z

Z

ZS

PS

Z

Z

Z

Z

PB

Z

Z

Z

Z

PB

CS

CS

CS

EC

(5)Defuzzification

The output of fuzzy controller is a fuzzy set, in general,

we often require a relatively precise control signal as the

object [16]. Defuzzification is to construct mapping from

a set of fuzzy to the normal set, convert the fuzzy output

into a precise controlling quantity, it is also called

cleanness. Some method are often used, such as the

median method, gravity method, gravity method is used

in this study, the expression for the

n

i =1

i =1

zi = i A( i ) / A( i )

(7)

Among them, n is the number of fuzzy variables;

fuzzy variable; A( i ) fuzzy variable corresponding to

1084

JOURNAL OF NETWORKS, VOL. 8, NO. 5, MAY 2013

membership. After Defuzzification, we can obtain the

output of the exact amount.

B. System Simulation

This article use Simulink for the fuzzy controller

simulation. First fuzzy controller is designed based on the

theoretical design of the front; the model is shown in

Fig.5.

y1 and x1 are determined experimentally by the system.

Simulation mathematical model are created in Simulink

module in accordance with the principle of the fuzzy

controller, fuzzy controller simulation model and the PID

controller model is shown in Fig. 8.

Figure 8. The simulation model

Figure 5. The model of fuzzy control

Fuzzy rule base is designed after determining the

membership function, thereby generating fuzzy rule table,

as shown in Fig. 6.

Set humidity value is 37%, the output curve of the

fuzzy controller simulation and PID controller simulation

are shown in Fig. 9. From the simulation graph we can

see that the PID control response speed is faster than the

fuzzy control, but overshoot ratio is greater; the fuzzy

controller system has more stability relatively, it is more

suitable for greenhouse irrigation control.

Figure 6 .Fuzzy rule table

Based on the fuzzy base, we can get a surface plot of

the fuzzy control, as shown in Fig. 7.

Figure 9 .The simulation curves of PID controller and fuzzy controller

V. SOFTWARE DESIGN

Figure 7. Fuzzy control surface

Soil moisture content change is a slow and

complicated process; it has a certain relationship with the

surrounding environmental factors, it is almost

impossible to establish a precise mathematical model. so

we select formula (6) as a reference model.

y = y1 sin( t / x1 )

(8)

Wherein y is humidity change, t is valve conduction

time after conversion of irrigation quantity,

2013 ACADEMY PUBLISHER

A.Software Diagram

The software design includes the design of the ZigBee

node and the monitoring center, the architecture of the

overall software system is shown in Fig.10. The

development of node is based on the MAC and physical

layer offered by the ZigBee protocol stack, mainly relates

to the data acquisition and network frame problem [17].

Coordinator node is responsible for configuring the

network parameters, initiation network and network

maintenance work, reception of data acquisition and

transmission threshold of temperature and humidity[18].

The main task of sensor node is data acquisition and

transferring, after completing initialization protocol stack

and hardware, the terminal node start scanning channel,

and then sends the information of joining the network. If

confirmed, it began to collect data through the sensors,

and then sends to the coordinator node through the

JOURNAL OF NETWORKS, VOL. 8, NO. 5, MAY 2013

1085

wireless transmission. The flow of the node program is

shown in Fig.11.

sensor node

acquire

data

start

and

stop

the

valve

monitoring platform

coordinator node

form a

network

transmit

data to

host

comput

er

VI. EXPERIMENTAL RESULT

transmit

the

threshold

to

sensor

node

display

network

status

display

the

data

handle

and

store

data

Figure 10. Architecture of the overall software system

sensor nodes

coordinator nodes

SRART

ST ART

Initialization protocal

stack and hardware

Initialization protocal

stack and hardware

Start networing

join network

networing success

form ID

wirless

network

curves and color. The system includes a connection state,

data acquisition, data processing and alarm, data storage

and other functions. The monitoring platform is shown in

Fig. 12.

send device address

receiving data from

sensor nodes

collect data

upload data

by serial port

send data via radio

Figure 11. Flow of the node program

In order to test the validity of data transmission, we

selected an agriculture sightseeing garden located in

XuShui, Hebei province as the experimental base. The

base had 10 greenhouses with tomato as the main crops.

We selected Mar. 5, 2013 as the test date, and that day

was in the tomato blossom period. The test system

consisted of two sensor nodes and a sink node.

A Wireless Transmission Test

Wireless transmission test is divided into point-topoint and networking communication test. One

coordinator and a sensor node are opened when conduct

point-to-point communication test, the distance between

these two nodes increase from 30 mile to 300 mile, the

sensor node send a frame data to the coordinator node at

intervals of 1 minute, write down the number of packets

which the gateway node receives within one hour (out of

a total of 60).Two sensor nodes are opened when conduct

the network communication test, the distance still starts

from the 60 miles, add the distance between nodes and

coordinator node gradually,, until the two nodes are

separated by 300 m, the sensor node send a frame data to

the coordinator node at intervals of 1 minute, write down

the number of packets which the gateway node receives

within one hour (out of a total of 60). The number of

packets from coordinator node in different methods is

shown in table VI.

TABLE VI. THE NUMBER OF PACKETS IN DIFFERENT METHODS

B. Design of the Monitoring Platform

Figure 12.Wireless testing platform

The graphical programming language LabVIEW is

used for the design of the monitoring platform [19].

Graphical programming can be more intuitive and

effective to complete the test task. Designers judge

wireless sensor network state through different buttons, at

the same time, the tested results from calculation and

analysis of scientific is display through the different

2013 ACADEMY PUBLISHER

method

distance

30

60

90

120

150

180

210

240

270

300

point-to-point

networking

59

58

56

55

54

52

50

48

47

45

55

54

53

52

51

50

48

46

45

43

From table VI, we can see that the distance of network

transmission is less than point-to-point test, because all

nodes in the network send a packet to the coordinator

node after networking, resulting in data redundancy and a

lost package phenomenon, especially in the distance of

more than 200 miles, due to the influence of the obstacle,

the packet reception rate is below to 80%.

BSoil Water Content Monitoring Test

The soil moisture is set in 34% and the probe was

embed for the depth of 15 cm The soil moisture is set in

34% and the probe was embed for the depth of 15 cm.

When moisture content detected by the sensor is lower

1086

JOURNAL OF NETWORKS, VOL. 8, NO. 5, MAY 2013

than the set threshold, the control system open the

solenoid valve, after 20 minutes (this time can be setting

according to different vegetation and soil) closing

solenoid valve for water infiltration. Test again after 5

minutes, if the moisture content is still lower than the

setting threshold; continue to start the solenoid valve. The

humidity test result is shown in table VII.

TABLE VII. THE HUMIDITY TEST RESULTS

Time

9:58

10:08

10:29

11:35

12:12

12:58

13:27

14:15

14:48

15:22

16:06

16:54

humidity

Node 1

25.1

25.8

33.5

31.6

28.3

32.3

34.8

30.9

33.6

31.4

34.2

32.5

Node 2

24.3

24.9

32.9

30.9

28.1

32.1

34.6

30.5

33.1

31.0

33.9

32.1

From table VII, we can see that soil moisture content

has significant change after the irrigation for at least 10

minutes, , the system is running well in the later time, the

error between the measured soil moisture content and

value is around 2%, which indicated the system could

regulate greenhouse temperature and humidity value

according to the fuzzy control rules. That was to say,

when the plants lacked water, the valve could be opened

for irrigation. When humidity met the requirement,

irrigation would be stopped, and thereby achieved water

conservation.

Since node 1 was located in the lower part of the dense

foliage of tomato plants, the relative humidity measured

by node1 was a little higher than node 2.The measured

results basically agreed with the reality, so to achieve the

test requirements.

VII. CONCLUSIONS

Aiming at the shortcoming in the irrigation system, this

design has combined wireless sensor network with fuzzy

control system in the intelligent water-saving irrigation

system, realized a remote on-line monitoring and

controlling. Nodes in the monitoring area have used

devices of solar energy and lithium battery to provide

power, which has certain practical significance to solve

the problem of limited energy; using the set of multiple

hops network protocol to communicate, the nodes have

the feature of self-organizing, low power consumption

and high reliability. The system has adopts control

method of double input and single output fuzzy, used

Fuzzy Logic toolbox for modeling and analyzing of the

system, and demonstrated the relationship between

system input and output, made the control system much

scientific. Host computer receives soil water content

information collected by the nodes, and transmits

2013 ACADEMY PUBLISHER

information by setting a threshold of open time of

solenoid valve, so as to achieve the goal of water-saving

irrigation. The experimental results show that the system

can realize automatic real-time monitoring of soil

moisture content in crops grow, and combined with crop

growth information to irrigate moderately the system. It

has not only benefited to crop growth and development,

but also avoided the waste of water resources; finally it

can achieve better productivity, high efficiency and

quality, and water-saving.

ACKNOWLEDGMENT

This work was supported in part by a grant from the

high school scientific and technological research

guidance project in Hebei province (No.Z2011271) and

the science and technology research guidance project in

Baoding (No.13ZN022)

REFERENCES

[1] Chen Chao, W.E. Baethgen, W. Enli, Y. Qiang,

Characterizing spatial and temporal variability of crop

yield caused by climate and irrigation in the North China

Plain, Theoretical and Applied Climatology, Vol. 106, pp.

365-81, Dec. 2011.

[2] N. Philipcva, O. Nicheva, V. Kazandhiev, M. ChilikcvaLubcmircva, A computer program for drip irrigation

system design for small plots, Journal of Theoretical and

Applied Mechanics, Vol. 42, pp. 3-18, Dec. 2012

[3] Yunseop K. Evans RG, Iversen W M, Remote sensing

and control of an irrigation system using a distributed

wireless sensor network

,IEEE Trans. on

Instrumentation and Measurement, Vol. 57, pp. 13791387, 2008

[4] Jin guangzhao, Peng chenglin, Zigbee-based soil humidity

monitoring system, Transducer and Micro system

Technologies, Vol.27,pp. 92 94,2008.

[5] L. pezJ, A Wireless Sensor Networks for precision

horticulture in Southern Spain ,Computing & electronics

in Agriculture Journal, Vol. 68,pp.25-35,2009.

[6] Sun R. M. wind and water flow as energy supply for

small stationary data acquisition platforms, Computing &

Electronics in Agriculture Journal, Vol. 64, pp. 120- 132,

2008.

[7] Christos Goumopoulos, An Autonomous Wireless

Sensor/Actuator Network for Precision Irrigation in

Greenhouses, Smart Sensing Technology for Agric. &

Environ. Monitor, Springer-Verlag Berlin Heidelberg, pp.

1-20, 2012.

[8] T. Ahonen, R. Virrankoski M.Elmusrati, Greenhouse

Monitoring with Wireless Sensor Network , Mechtronic

and Embedded Systems and Applications, IEEE

Conference Publishing Services, pp. 403-408, 2008

[9] F. Ijaz, A. A. Siddiqui, IM. Byngkwan,Remote

management and control system for LED based plant

factory using ZigBee and Internet, International

Conference on Advance Communication Technology, IEEE

Conference Publishing Services, pp. 942-946, 2012

[10] N. El RAchkidy, A. Guitton , M. Misson, Pivot Routing

Improves Wireless Sensor Networks Performance,

Journal of Networks, Vol. 7, pp. 962-71, June 2012.

[11] B.D. Vick, L.K. Almas, Developing Wind and/or Solar

Powered Crop Irrigation Systems for the Great Plains,

Applied Engineering in Agriculture, Vol. 27, pp. 235-245,

March 2011.

JOURNAL OF NETWORKS, VOL. 8, NO. 5, MAY 2013

[12] P. Cepeda, P. Ponce, D. Romero, A. Molina, Fuzzy CMeans Clustering Technique applied for Modeling

Parameters of an Intelligent Greenhouse Open Control

System, Electronics, Robots and Automotive Mechanics

Conference, IEEE Conference Publishing Services,

pp.283-288,2011

[13] F. Harm, Irrigation fuzzy controller reduces tomato

cracking, International Journal of Advanced Computer

Science and Applications, Vol. 2, pp. 106-109, Nov. 2011.

[14] A. Al-Canaan, A.Khoumsi, Multimedia Web services

performance: Analysis and quantification of binary data

compression, Journal of Multimedia,Vol. 6, pp. 447-457,

2011.

[15] J. Segovia, P. Vila,, E. Calle, J.L. Marzo, Improving the

resilience of transport networks to large-scale failures,

Journal of Networks, Vol. 7, pp. 63-72, 2012.

[16] I. Kollia, Y. Kalantidis, K. Rapantzkos, A. Stafylopatis,

Improving Semantic Search in Digital Libraries Using

Multimedia Analysis, Journal of Multimedia, Vol. 7,

pp.193-204, April 2012.

[17] Fan Yang, F. W.B. Li, Active contour projection for

multimedia applications, Journal of Multimedia, Vol. 6,

pp. 170-180, April 2011.

[18] Coroama V.C, Hilty L.M, Birtel M,Effects of Internetbased multiple-site conferences on greenhouse gas

emissions, Telematics and Informatics,Vol.29, pp.362374. 2012.

[19] Buldu, Ali, A web-based controlled greenhouse system

and monitoring the system's data, International Review on

Computers and Software, vol.6, pp. 856-861, 2011.

2013 ACADEMY PUBLISHER

1087

Liai Gao received the Bachelor Degree

of Engineering in electric engineering

and the master degree respectively in

Agricultural mechanization engineering

from Agriculture University of Hebei,

Hebei, Baoding, in2003 and2006.

She is currently with electric

Department, the College of mechanical

and electrical engineering, Agriculture

University of Hebei. Her research

activity mainly focuses on wireless sensor networks, with

special interest on the use of wireless sensor networks for

intelligent detection and control technology. Now she is a Ph. D

Candidate and has published 5 papers in the core journals.

Meng Zhang received the Bachelor Degree of Engineering in

electric engineering in Agricultural mechanization engineering

from Agriculture University of Hebei, Baoding, in 2012. Now

she

is

a

graduate

student

in

College

of

Information and Electrical Engineering, China Agricultural

University, Beijing, China.

Geng Chen, he is a student in College of mechanical and

electrical engineering, Agricultural University of Hebei,

Baoding, China

Das könnte Ihnen auch gefallen

- Mid Term Assignment # 2 PsychologyDokument3 SeitenMid Term Assignment # 2 PsychologySariaKhanNoch keine Bewertungen

- ISAP2015 Technical Program Preliminary v1Dokument57 SeitenISAP2015 Technical Program Preliminary v1SariaKhan100% (1)

- Internship Report On PTCLDokument14 SeitenInternship Report On PTCLSariaKhanNoch keine Bewertungen

- 1.SC Lec1 2 5th OctDokument87 Seiten1.SC Lec1 2 5th OctSariaKhanNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Gulfpub Wo 201805Dokument81 SeitenGulfpub Wo 201805Patricia.PNoch keine Bewertungen

- Learner Cala Guide: PART A: Identification of Knowledgeable Elderly Part BDokument5 SeitenLearner Cala Guide: PART A: Identification of Knowledgeable Elderly Part BPrimrose MurapeNoch keine Bewertungen

- Play Tennis Manual PDFDokument52 SeitenPlay Tennis Manual PDFAnonymous GJuRvp9A5T100% (2)

- Secondary Scheme of Work Form 2Dokument163 SeitenSecondary Scheme of Work Form 2Fariha RismanNoch keine Bewertungen

- Certification Programs: Service As An ExpertiseDokument5 SeitenCertification Programs: Service As An ExpertiseMaria RobNoch keine Bewertungen

- Lesson 2.4Dokument8 SeitenLesson 2.4Tobi TobiasNoch keine Bewertungen

- Hurricanes Reading Comprehension FreebieDokument20 SeitenHurricanes Reading Comprehension FreebieAlex WaddellNoch keine Bewertungen

- Copper For BusbarDokument60 SeitenCopper For BusbarSunil Gadekar100% (3)

- Defining The Market Research Problem & Developing An ApproachDokument77 SeitenDefining The Market Research Problem & Developing An ApproachSakshi Bhati I H21O41Noch keine Bewertungen

- Transformational and Charismatic Leadership: The Road Ahead 10th Anniversary EditionDokument32 SeitenTransformational and Charismatic Leadership: The Road Ahead 10th Anniversary Editionfisaac333085Noch keine Bewertungen

- Rastriya Swayamsewak SanghDokument60 SeitenRastriya Swayamsewak SanghRangam Trivedi100% (3)

- Shaheed Suhrawardy Medical College HospitalDokument3 SeitenShaheed Suhrawardy Medical College HospitalDr. Mohammad Nazrul IslamNoch keine Bewertungen

- Power - of - Suffering 2Dokument21 SeitenPower - of - Suffering 2jojiNoch keine Bewertungen

- D90KSDokument1 SeiteD90KSAmilton filhoNoch keine Bewertungen

- Micromine TutorialDokument5 SeitenMicromine TutorialFerdinand Siahaan100% (1)

- Ssi-199-22 D Vikran Dolphin Rev.1Dokument2 SeitenSsi-199-22 D Vikran Dolphin Rev.1ANGEL ANTONIO GUTIERREZ CONTRERASNoch keine Bewertungen

- JIS-G3455 - Carbon Steel Pipes For High Pressure ServiceDokument27 SeitenJIS-G3455 - Carbon Steel Pipes For High Pressure ServiceHoang Tan100% (1)

- Salik Sa Mga Estudyante NG Hindi Wastong Pagsuot NG Uniporme NG Senior High School Sa Paaralang Ama Computer College Fairview CampusDokument1 SeiteSalik Sa Mga Estudyante NG Hindi Wastong Pagsuot NG Uniporme NG Senior High School Sa Paaralang Ama Computer College Fairview CampusIsrael ManansalaNoch keine Bewertungen

- Symbolic Interaction Theory: Nilgun Aksan, Buket Kısac, Mufit Aydın, Sumeyra DemirbukenDokument3 SeitenSymbolic Interaction Theory: Nilgun Aksan, Buket Kısac, Mufit Aydın, Sumeyra DemirbukenIgor Dutra BaptistaNoch keine Bewertungen

- Reading Comprehension Lesson Plan FinalDokument9 SeitenReading Comprehension Lesson Plan Finalapi-254917183Noch keine Bewertungen

- Week 5 Teradata Practice ExerciseDokument14 SeitenWeek 5 Teradata Practice ExerciseWooyeon ChoNoch keine Bewertungen

- Nexus 1500+ Power Quality Meter User Manual - E154713Dokument362 SeitenNexus 1500+ Power Quality Meter User Manual - E154713Antonio BocanegraNoch keine Bewertungen

- Extension of MDRRMO OfficeDokument12 SeitenExtension of MDRRMO OfficeJustin YuabNoch keine Bewertungen

- 2400 8560 PR 8010 - A1 HSE Management PlanDokument34 Seiten2400 8560 PR 8010 - A1 HSE Management PlanMohd Musa HashimNoch keine Bewertungen

- Paper 19 AugustDokument552 SeitenPaper 19 AugustUma Sankar Pradhan100% (1)

- Nursing Care Plan Diabetes Mellitus Type 1Dokument2 SeitenNursing Care Plan Diabetes Mellitus Type 1deric85% (46)

- Culture Performance and Economic Return of Brown ShrimpDokument8 SeitenCulture Performance and Economic Return of Brown ShrimpLuã OliveiraNoch keine Bewertungen

- PMP Exam Questions and Answers PDFDokument12 SeitenPMP Exam Questions and Answers PDFAshwin Raghav SankarNoch keine Bewertungen

- Principles of Marketing: Strategic Planning and The Marketing ProcessDokument16 SeitenPrinciples of Marketing: Strategic Planning and The Marketing ProcessAneel ZiaNoch keine Bewertungen