Beruflich Dokumente

Kultur Dokumente

Acid Pickling Procedure Rev.c1

Hochgeladen von

hannanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Acid Pickling Procedure Rev.c1

Hochgeladen von

hannanCopyright:

Verfügbare Formate

MSET ENGINEERING CORPORATION SDN BHD

DOCUMENT TITLE: WORK PROCEDURE

DATE: 23.11.2011

DOC. REF. NO.: MSET/M2-189/WP-347

REVISION: R0

JOB NO: M2-189

SUBJECT: ACID PICKLING PROCEDURE

PAGE: 1 of 6

ACID PICKLING

PROCEDURE

PROJECT NAME:

SUPPLY OF FUEL GAS SYSTEM FOR KEBABANGAN

TOPSIDE

CLIENT:

SIME DARBY ENGINEERING SDN BHD.

OWNER:

KEBABANGAN PETROLEUM OPERATING CO.

R0

Rev.

No.

23.11.2011

Issued for Approval

Date

Description of Revision

Wan Nafiza

Prepared

by

Azizan Ariffin

Reviewed

by

Ahmad Kamal

Approved

by

MSET ENGINEERING CORPORATION SDN BHD

DOCUMENT TITLE: WORK PROCEDURE

DATE: 23.11.2011

DOC. REF. NO.: MSET/M2-189/WP-347

REVISION: R0

SUBJECT: ACID PICKLING PROCEDURE

JOB NO: M2-189

PAGE: 2 of 6

TABLE OF CONTENTS

SECTION

DESCRIPTION

1.0

SCOPE

2.0

REFERENCE

3.0

CLEANING METHOD

4.0

SAFETY

5.0

RECORD

6.0

ATTACHMENT 1- PDS AND MSDS OF PICKLING

GEL

MSET ENGINEERING CORPORATION SDN BHD

DOCUMENT TITLE: WORK PROCEDURE

DATE: 23.11.2011

DOC. REF. NO.: MSET/M2-189/WP-347

REVISION: R0

SUBJECT: ACID PICKLING PROCEDURE

JOB NO: M2-189

PAGE: 3 of 6

CHANGE RECORD

Amendment No.

Date

Responsible

Person

Description Of Change

MSET ENGINEERING CORPORATION SDN BHD

DOCUMENT TITLE: WORK PROCEDURE

DATE: 23.11.2011

DOC. REF. NO.: MSET/M2-189/WP-347

REVISION: R0

SUBJECT: ACID PICKLING PROCEDURE

1.0

JOB NO: M2-189

PAGE: 4 of 6

SCOPE

1.1

This procedure covers the scope for acid cleaning upon completion of fabrication work

and prior to function test of stainless steel material of Pressure Vessel.

2.0

REFERENCE

2.1

Clients Specification AF-KPOC-MEC-SPC-00120 - (Specification for Unfired

Pressure Vessel)

2.2

3.0

PTS 61.10.08.11 Field Inspection Prior To Commissioning Of Mechanical Equipment

CLEANING METHOD

3.1

The vessel to be cleaned shall be cleared of all welding and NDT and acid cleaning shall

be performed after hydrostatic test completed (unless it is not possible).

3.2

The internal areas of vessel shall be cleaned using chemical cleaners that do not have a

detrimental effect on the stainless steel and welded joints. The use of chemical cleaners

shall always be followed by through rinsing with water and drying.

3.3

Prior to cleaning the vessel shall be rinsed by potable water and shall not contain more

than 50 ppm chloride at ambient temperature.

3.4

After cleaning by potable water the vessel shall be flushed by air compressor to ensure

the spool are free from water.

3.5

The entire stainless steel surface shall be wetted with acid cleaning solution (Pickling

Gel) using the proper stainless steel brush. That surface shall be kept in contact with the

pickling solution for about 10-20 minutes to ensure scale removal. (Refer Datasheet

~Attachment I Technical Data & MSDS)

MSET ENGINEERING CORPORATION SDN BHD

DOCUMENT TITLE: WORK PROCEDURE

DATE: 23.11.2011

DOC. REF. NO.: MSET/M2-189/WP-347

REVISION: R0

SUBJECT: ACID PICKLING PROCEDURE

3.6

JOB NO: M2-189

PAGE: 5 of 6

After scale removal has been accomplished surfaces must be thoroughly rinsed by

potable water and/or S-Weld Neutralizer neutralizing solution to removal residual

chemical.

3.7

When cleaning is required, these operations shall be followed immediately by rinsing,

not allowed the surfaces to dry between operations.

3.8

Particular attention shall be given to low spots, crevices and similar areas. Hot drying is

not permitted.

3.9

4.0

Inspection by all party concerned to be carried out after first cleaning completed.

SAFETY

4.1

All chemicals, especially acids must be handled with care. Always take note when

mixing acid and water note, DO NOT POUR WATER INTO ACID, ALWAYS POUR

ACID INTO WATER WHILE MIXING. The personnel handling the acid or solutions

shall wear synthetic rubber apron, gloves and plastic face shield.

4.2

All personnel shall be informed of the work being carried out and the test areas shall be

cordoned off with rope and warning signboards to be displayed. Potable shower station

shall be located near the operation area for the emergency use.

4.3

5.0

Metal temperature shall be ensured to be less than 40 oC or at ambient temperature.

RECORD

5.1

The procedure shall be kept by QA/QC Engineer and shall be made available to the

respective personnel.

5.2

Cleaning certificate to be prepared by QA/QC representative and endorsed by client

representative who witness/ review the cleaning.

MSET ENGINEERING CORPORATION SDN BHD

DOCUMENT TITLE: WORK PROCEDURE

DATE: 23.11.2011

DOC. REF. NO.: MSET/M2-189/WP-347

REVISION: R0

SUBJECT: ACID PICKLING PROCEDURE

6.0

ATTACHMENT 1

(PDS AND MSDS OF PICKLING GEL)

JOB NO: M2-189

PAGE: 6 of 6

Das könnte Ihnen auch gefallen

- Robert Sorby Pyrography ManualDokument12 SeitenRobert Sorby Pyrography ManualAnonymous Hz5fBwKmR100% (2)

- Repair ProcedureDokument11 SeitenRepair Procedurebilelliuvi2100% (4)

- Unit SS Design Calculations For PrecastDokument13 SeitenUnit SS Design Calculations For PrecastKumar SureshNoch keine Bewertungen

- Feroxyle Test Procedur eDokument9 SeitenFeroxyle Test Procedur esanrexiNoch keine Bewertungen

- (AL Shabab) : Painting Procedure P-04Dokument12 Seiten(AL Shabab) : Painting Procedure P-04Omar Nabil80% (5)

- Flame Straightening S355Dokument9 SeitenFlame Straightening S355Anonymous oI04sS100% (1)

- Welding A Cast IronDokument9 SeitenWelding A Cast Ironjatin jainNoch keine Bewertungen

- Control of Welding ConsumablesDokument6 SeitenControl of Welding ConsumablesRakesh RanjanNoch keine Bewertungen

- Geotech Buried PipesDokument54 SeitenGeotech Buried Pipeserleos100% (2)

- Pickling & Passivation Procedure MainDokument6 SeitenPickling & Passivation Procedure Mainvijay padale100% (3)

- Generic Repair Procedure For Grinding and Build-UpDokument8 SeitenGeneric Repair Procedure For Grinding and Build-UpRafiqKuNoch keine Bewertungen

- Hot Dip GalvanizeDokument9 SeitenHot Dip GalvanizeDetoned StonedNoch keine Bewertungen

- GRP General Procedure (EWS)Dokument16 SeitenGRP General Procedure (EWS)Maged Ali Ragheb100% (1)

- Feroxyl and Copper Sulfate TestingDokument23 SeitenFeroxyl and Copper Sulfate TestingPrashant RaneNoch keine Bewertungen

- Pickling and Passivation Work InstructionDokument18 SeitenPickling and Passivation Work InstructionPlata Elpidio100% (1)

- Painting Procedure TemplateDokument15 SeitenPainting Procedure TemplateMohd Fadzle93% (70)

- Procedure For Surface Preparation and PaintingDokument13 SeitenProcedure For Surface Preparation and Paintingwilliamsen50% (2)

- Repair ProcedureDokument6 SeitenRepair ProcedureTomy GeorgeNoch keine Bewertungen

- Pickling & Passivation - InspectionDokument7 SeitenPickling & Passivation - InspectionBhanu Pratap ChoudhuryNoch keine Bewertungen

- Vacume Box Test ProcedureDokument5 SeitenVacume Box Test ProcedureFarhan Sheikh100% (3)

- Painting Procedure PDFDokument13 SeitenPainting Procedure PDFDominik100% (1)

- 2 Painting Insp - Report (PN-001)Dokument1 Seite2 Painting Insp - Report (PN-001)Vimin Prakash100% (3)

- 3.painting InspectionDokument2 Seiten3.painting InspectionSRINIVASAN S M100% (1)

- Blasting and Painting ProcedureDokument9 SeitenBlasting and Painting Procedureisukuru67% (12)

- 1method Statement For Passivation and PicklingDokument6 Seiten1method Statement For Passivation and PicklinggatoNoch keine Bewertungen

- Fiberglass Coating SpecDokument3 SeitenFiberglass Coating Specponnivalavans_994423100% (1)

- Pickling ProcedureDokument2 SeitenPickling Proceduremahazari100% (6)

- Saudi Aramco Test Report: Positive Material Identification (PMI) Report 24-Jul-18 MechDokument2 SeitenSaudi Aramco Test Report: Positive Material Identification (PMI) Report 24-Jul-18 MechnadeemNoch keine Bewertungen

- Pickling Passivation Procedure by JSDokument2 SeitenPickling Passivation Procedure by JSAkhilesh Kumar67% (3)

- Blasting Painting ProcedureDokument10 SeitenBlasting Painting ProcedureMohamed RizwanNoch keine Bewertungen

- Painting ProcedureDokument17 SeitenPainting Procedurestdshop75% (4)

- Gen Slab and Wall Tutorial 1492723667 PDFDokument49 SeitenGen Slab and Wall Tutorial 1492723667 PDFVijayNoch keine Bewertungen

- Shop Fabrication Procedure (Supply of Tank Option#3) PDFDokument7 SeitenShop Fabrication Procedure (Supply of Tank Option#3) PDFGATOTNoch keine Bewertungen

- Pickling and Passivation ProcedureDokument4 SeitenPickling and Passivation ProcedureWaqas Waqas89% (18)

- Gate 2004Dokument8 SeitenGate 2004Shailendra Mishra100% (1)

- Pickling Procedure 20 - 08Dokument2 SeitenPickling Procedure 20 - 08Siriepathi SeetharamanNoch keine Bewertungen

- ASSDA - Pickling and PassivationDokument2 SeitenASSDA - Pickling and Passivationippon_osotoNoch keine Bewertungen

- Painting Procedure For Field Erected Tank FINAL (13850)Dokument22 SeitenPainting Procedure For Field Erected Tank FINAL (13850)Parthiban NCNoch keine Bewertungen

- Blasting Painting ProcedureDokument4 SeitenBlasting Painting ProcedureRyanNoch keine Bewertungen

- m2-216 Vendor Document Master ListDokument1 Seitem2-216 Vendor Document Master ListhannanNoch keine Bewertungen

- Weld SurveillanceDokument33 SeitenWeld SurveillancecanakyuzNoch keine Bewertungen

- Method Statement For Tank Erection by Hydraulic JackDokument4 SeitenMethod Statement For Tank Erection by Hydraulic Jackmanish pathrabeNoch keine Bewertungen

- Pickling and Passivation 399Dokument14 SeitenPickling and Passivation 399fpiccoli_4100% (1)

- Pickling and Passivation ProcedureDokument5 SeitenPickling and Passivation ProcedureBoby Thomas100% (5)

- Building Code of Pakistan 2021Dokument614 SeitenBuilding Code of Pakistan 2021Uzair Maqbool KhanNoch keine Bewertungen

- Prequalified Minimum Preheat and Interpass TemperatureDokument3 SeitenPrequalified Minimum Preheat and Interpass TemperatureAnonymous wJGQDTH0pNoch keine Bewertungen

- Electrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedureDokument2 SeitenElectrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedurePrashant Puri100% (1)

- Painting Inspection Report Angle Bars PDFDokument1 SeitePainting Inspection Report Angle Bars PDFpstechnical_43312697Noch keine Bewertungen

- Hydroblasting and Coating Procedure of FpsoDokument33 SeitenHydroblasting and Coating Procedure of FpsoGilvan Silva100% (2)

- Procedure For Surface Preparation-Painting - For Storage TankDokument8 SeitenProcedure For Surface Preparation-Painting - For Storage Tankcristinelb50% (2)

- Painting Procedure TemplateDokument14 SeitenPainting Procedure TemplateNnamdi Celestine NnamdiNoch keine Bewertungen

- Method Statement Replace Bottom PlateDokument5 SeitenMethod Statement Replace Bottom Plateคุณพ่อน้อง บิ๊กบอส100% (6)

- Pickling and Passivity Procedure - Rev A PDFDokument7 SeitenPickling and Passivity Procedure - Rev A PDFthanh100% (1)

- 25 - Coating ProcedureDokument12 Seiten25 - Coating ProcedureMOHAMEDNoch keine Bewertungen

- Procedure For DPT PDFDokument4 SeitenProcedure For DPT PDFSaut Maruli Tua Samosir50% (2)

- Working Procedure Ls1-Ls4Dokument9 SeitenWorking Procedure Ls1-Ls4Tuğrulhan ÖzdemirNoch keine Bewertungen

- Characteristics of Steel Slags and Their Use in Cement and ConcreteDokument11 SeitenCharacteristics of Steel Slags and Their Use in Cement and ConcreteArulvijayNoch keine Bewertungen

- Vessel Fabrication Tolerances: Otherwise - Are Based by Users Ind Veuejs. Unjeu Otherwise O His S /20 /8Dokument1 SeiteVessel Fabrication Tolerances: Otherwise - Are Based by Users Ind Veuejs. Unjeu Otherwise O His S /20 /8hannan100% (1)

- EN 10204/3.1 1546708 Pag. /: Mill Test Certificate DOC - CREDIT N. M04091506NU00250Dokument4 SeitenEN 10204/3.1 1546708 Pag. /: Mill Test Certificate DOC - CREDIT N. M04091506NU00250Paviter SinghNoch keine Bewertungen

- Pickling and Passivation ProcedureDokument4 SeitenPickling and Passivation ProcedureJaroslaw Konieczny0% (1)

- m5-36 - Packing List - DeliveryDokument16 Seitenm5-36 - Packing List - DeliveryhannanNoch keine Bewertungen

- Selection of Welding ConsumablesDokument13 SeitenSelection of Welding ConsumablesbassemaeNoch keine Bewertungen

- Brochure English - Pickling, Cleaning, PassivatingDokument4 SeitenBrochure English - Pickling, Cleaning, PassivatingSerge1976100% (1)

- Pickling (Metal)Dokument2 SeitenPickling (Metal)alphadingNoch keine Bewertungen

- Sandblasting Daily ReportDokument1 SeiteSandblasting Daily Reportkaito kidNoch keine Bewertungen

- Revision Questions PA 10 Specific Page 23-12Dokument2 SeitenRevision Questions PA 10 Specific Page 23-12Bayu Falen100% (2)

- Blasting & Painting Inspection Report Format For Bottom Plate 01Dokument7 SeitenBlasting & Painting Inspection Report Format For Bottom Plate 01ABEC Trombay siteNoch keine Bewertungen

- QA-R-05 - Fitup Inspection Report (SPL) LS & CS Joints For Pressure VesselsDokument1 SeiteQA-R-05 - Fitup Inspection Report (SPL) LS & CS Joints For Pressure VesselsvinothNoch keine Bewertungen

- API Tank Estimate SheetDokument3 SeitenAPI Tank Estimate SheetKjunwolf100% (1)

- Painting ProcedureDokument4 SeitenPainting ProcedureRidoNoch keine Bewertungen

- Rust Removal Using Electrolysis 1Dokument4 SeitenRust Removal Using Electrolysis 1kelvinyeohNoch keine Bewertungen

- Blasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateDokument3 SeitenBlasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateLOPA THANDARNoch keine Bewertungen

- Format TQDokument2 SeitenFormat TQhannanNoch keine Bewertungen

- Terengganu Crude Oil Terminal (Tcot) Separation Upgrade: Request For InspectionDokument2 SeitenTerengganu Crude Oil Terminal (Tcot) Separation Upgrade: Request For InspectionhannanNoch keine Bewertungen

- Mset Engineering Corporation Sdn. BHD.: Work InstructionDokument1 SeiteMset Engineering Corporation Sdn. BHD.: Work InstructionhannanNoch keine Bewertungen

- Hardness Test Inspection Report: Weld Base MetalDokument2 SeitenHardness Test Inspection Report: Weld Base MetalhannanNoch keine Bewertungen

- Rubber Lining CoverDokument1 SeiteRubber Lining CoverhannanNoch keine Bewertungen

- Inspection and Test Plan (ITP) (Pressure Vessel)Dokument1 SeiteInspection and Test Plan (ITP) (Pressure Vessel)hannanNoch keine Bewertungen

- Nama 2011Dokument32 SeitenNama 2011hannanNoch keine Bewertungen

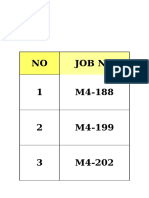

- NO Job No 1 M4-188: Senarai Kerja-Kerja BaikpulihDokument30 SeitenNO Job No 1 M4-188: Senarai Kerja-Kerja BaikpulihhannanNoch keine Bewertungen

- Metodo XenosepDokument12 SeitenMetodo XenosepJenny Chavez AlarconNoch keine Bewertungen

- 12CHEM Long Response Dot PointsDokument11 Seiten12CHEM Long Response Dot PointsJane YooNoch keine Bewertungen

- Phosphorus, Reactive, PhosVer 3 Method 8048, 02-2009, 9th EdDokument7 SeitenPhosphorus, Reactive, PhosVer 3 Method 8048, 02-2009, 9th EdzvjesosNoch keine Bewertungen

- Statically Indeterminate Members (Axially Loaded Only: F F FyDokument11 SeitenStatically Indeterminate Members (Axially Loaded Only: F F FyHafiz NordinNoch keine Bewertungen

- Phase Equilibrium Study in The CaODokument5 SeitenPhase Equilibrium Study in The CaOsattiricNoch keine Bewertungen

- 200319-Final Exam - Machine DesignDokument2 Seiten200319-Final Exam - Machine DesignJoseph RefuerzoNoch keine Bewertungen

- PCM Free Cooling With DEC PDFDokument13 SeitenPCM Free Cooling With DEC PDFqaiserNoch keine Bewertungen

- SET-2 Answer CHEMISTRY CLASS XI ASESSMENT-2Dokument7 SeitenSET-2 Answer CHEMISTRY CLASS XI ASESSMENT-2Study EasyNoch keine Bewertungen

- AbcdDokument3 SeitenAbcdNikesh ShahNoch keine Bewertungen

- GORE Automotive Vents Exterior Lighting Datasheet ENDokument4 SeitenGORE Automotive Vents Exterior Lighting Datasheet ENAaron HuangNoch keine Bewertungen

- (Outside Project Site Rental) (Barracks To Project Site) (Site Office, Stockpile, Workshop, Etc.)Dokument24 Seiten(Outside Project Site Rental) (Barracks To Project Site) (Site Office, Stockpile, Workshop, Etc.)Christian CabacunganNoch keine Bewertungen

- Four Probe MethodDokument5 SeitenFour Probe MethodSarthakJainNoch keine Bewertungen

- 1998 Zhang Biodegradability ofDokument8 Seiten1998 Zhang Biodegradability ofAlejandro Castro YaruroNoch keine Bewertungen

- Cambridge Secondary 1 Checkpoint: Cambridge Assessment International EducationDokument16 SeitenCambridge Secondary 1 Checkpoint: Cambridge Assessment International EducationAnisahNoch keine Bewertungen

- 02-Rheological Investigation of The Flotation Performance of High ClayDokument8 Seiten02-Rheological Investigation of The Flotation Performance of High Clayrolandoh1Noch keine Bewertungen

- Ok 83.28Dokument1 SeiteOk 83.28joe_frangiehNoch keine Bewertungen

- Unit-I Chemical Bonding and Molecular Structure: (18 Contact Hours)Dokument3 SeitenUnit-I Chemical Bonding and Molecular Structure: (18 Contact Hours)Imran Afzal BhatNoch keine Bewertungen

- Recent Advances in Active Metal Brazing of Ceramics and Process-S12540-019-00536-4Dokument12 SeitenRecent Advances in Active Metal Brazing of Ceramics and Process-S12540-019-00536-4sebjangNoch keine Bewertungen

- Katalog ProdukDokument20 SeitenKatalog ProdukWaridi RidiNoch keine Bewertungen

- Column Buckling - Inelastic: A Long TopicDokument43 SeitenColumn Buckling - Inelastic: A Long TopicKishore BhatNoch keine Bewertungen

- Lattice Vibrations and Free Electron TheoryDokument43 SeitenLattice Vibrations and Free Electron TheoryᎽᎪsh ᏒᎪj sᎥᏁᎶhNoch keine Bewertungen