Beruflich Dokumente

Kultur Dokumente

ELK 1401 289 Manuscript 1

Hochgeladen von

raghwendra123Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ELK 1401 289 Manuscript 1

Hochgeladen von

raghwendra123Copyright:

Verfügbare Formate

1

High dynamic performance of BLDC motor with

front end converter using FPGA based controller

for electric vehicle application

Praveen YADAV1, Rajesh POOLA 2, Khaja NAJUMUDEEN3

1,2

5

6

7

Department of Electrical Engineering, Motilal Nehru National Institute of

Technology, Allahabad, India.

Faculty at Department of Electrical and Electronics Engineering, Dhanalakshimi

Srinivasan College of Engineering, Coimbatore, India.

E-mail:praveeny84@gmail.com,ecarajesh@gmail.com,

10

kaja.najumudeen06@gmail.com

11

12

Abstract:

13

This paper focus on a novel operation of Brushless dc (BLDC) motor fed by

14

Proportional Integral (PI) controlled buck-boost converter supplemented with battery to

15

provide required power to drive BLDC motor. The operational characteristics of proposed

16

BLDC motor drive system for constant as well as step changes in dc link voltage of front

17

end converter, controlled by Xilinx System Generator (XSG) based PI controller, for two

18

quadrant operations are derived. Thus Field Programmable Gate Array (FPGA) based PI

controller manages the energy flow through battery and the front end converter. Moreover,

speed to voltage conversion logic, made to control BLDC motor through PI controller,

improves the performance and gives optimum control under the unstable driving situation

or varying load condition when complete system becomes a subject of application to

Electric Vehicles (EVs) and Hybrid Electric Vehicles (HEVs). The dual closed loop

control implemented, for end to end speed control of proposed drive system, facilitates the

system with high accuracy integrated with excellent dynamic and steady state performance.

In this paper, the proposed controller has been designed for 5 kW/480 V BLDC motor

drive system. The feasibility of the proposed dual loop control topology for BLDC motor

10

drive system is validated and verified with extensive dynamic simulation in

11

MATLAB/SIMULINK and XSG environment.

12

Keywords: BLDC motor drive, EVs, FPGA, front end converter, HEVs, PI controller,

13

Xilinx system generator (XSG).

14

Nomenclature:

Vdc = output voltage of buck boost

converter

Vin = dc input voltage to buck boost

converter

R = load resistance

iLo

range of variation of inductor

current

Vco = range of variation of dc link

D = duty cycle

voltage

fs = switching frequency

ia, ib, ic = a, b and c phase currents

Ls = inductance of the stator windings

r = angular velocity of rotor

Vab, Vbc = ab and bc phase to phase

Ea, Eb, Ec = a, b and c phase

voltage

electromotive forces

Rs = resistance of the stator windings

Te = electromagnetic torque

= amplitude of the flux induced by the

Vn = maximum voltage from buck boost

permanent magnets of the rotor in the

converter

stator phase

k = kth sample

P = number of pole pairs

1. Introduction

1

Since last two decades the issues like sustainable development and environmental

pollution due to vehicular emission are accelerating the modern science and technology

and have given thrust to the research on Electric Vehicles (EVs) and Hybrid Electric

Vehicle (HEVs). Brushless DC motor drives have been found more suitable for EVs,

HEVs and other low power applications [1, 2, 3]. BLDC motor has many advantages over

the conventional induction and DC motors; such as better speed and torque characteristics,

high efficiency and reliability, low electromagnetic interference (EMI), high power to

weight and torque to current ratio, long operation life etc. [4,5]. Compared to induction

machine BLDC motor have lower inertia, allowing for faster dynamic response to

10

reference commands. Moreover the advancement in the power electronic devices and

11

DSP/FPGA based processors have added more features to these motor drives to make them

12

more prevalent in industrial installation [6-8]. Hysteresis current control and pulse

width modulation (PWM) control coupled with continuous control theory produced

the most widely used BLDC motor control techniques. The control of BLDC motor in

medium as well as high speed applications is much easier as compared to induction

motors. Hysteresis current control is essential in achieving adequate control of

instantaneous torque and hence yielding faster speed response. Digital PWM control

technique implemented for speed control of BLDC motor have maximum speed error

below 5% [9-10]. So this control technique is not suited for application which

requires high precision. Conduction angle control and current mode control of BLDC

motor also have significant error in speed control, though less than digital PWM

10

control [11]. Conventional BLDC motors with six switch inverter, excited through bipolar

11

based soft switching currents, are suitable for low/medium power and medium speed

12

applications as well. In order to use these motors effectively at their optimal efficiency and

13

in safe operating zone they must be driven at their nominal power requirement [12]. Power

14

electronic converters provide the featured solution to meet the demand of the regulated

15

electrical power for efficient and dynamic operation of BLDC motor drives. Most of the

16

controllers designed for speed control of BLDC motors consider the unidirectional power

17

flow converter as it facilitates the easy control and reduced cost of the drives [13].

18

Moreover the use of the battery to feed to front end converter of BLDC motor drive, not

19

only removes the lack of specific power, but also enables an excellent performance of the

20

drive system in both acceleration and regenerative braking in EVs applications [14].The

21

converter also adjusts the dc input voltage to the front end converter of BLDC motor

22

verses the motor speed in order to reduce the ripple of the motor current waveform [15].

This fact is of a particular importance in case of slotless axial-flux PMDC motor drives,

which have been proposed recently for medium-speed and high torque motor drive

applications such as the direct driving of EVs wheel [16]. Conventional proportional

integral (PI) control technology is not meeting the requirement of very fast dynamic

response of the EVs under rapid changes in operating modes of the drive system. The

evolution of high speed and high density FPGA based processor is now providing the best

alternative to the ASIC and microprocessor based implementation of complex control

algorithm. The improved and appreciable dynamic and steady state performance of BLDC

motors supplemented with FPGA based controller will make them suitable for position

10

control

11

healthcare/biomedical equipments, speed control and torque control in various industrial

12

drives and process control applications.

in

machine

tools,

robotics

and

high

precision

servos,

aerospace,

13

In this paper, a novel FPGA based dual speed control technique has been proposed

14

targeting very precise speed control applications. The complete paper is structured as

15

follows. The overall work is briefly introduced in the section 2. Section 3 deals with the

16

mathematical modeling of buck boost converter, induction profile of BLDC motor and

17

front end converter. Proposed dual loop speed control, designed to meet transient and

18

steady state constraint with an objective of excellent speed control of BLDC motor drive

19

system, is discussed in details in section 4. Section 5 deals with simulation analysis of

20

proposed control strategy in MATLAB/SIMULINK and Xilinx system generator

21

environment and performance evaluation of the entire drive system under steady state and

dynamic conditions. Finally conclusions are made with discussion of the results and merits

of the proposed control scheme in section 6.

2. Structure of the proposed controlled dc-dc converter fed BLDC motor drive

Figure 1 shows front end converter fed BLDC motor drives with dual control loop

designed on FPGA processor to control the variable dc link voltage and hence to achieve

the desired speed control. The battery used to feed the buck-boost converter circuit, acts as

source and sink during acceleration and regeneration mode of EVs respectively. The

validation of the proposed model for EVs application governs the choice of buck-boost

converter for this application. Additionally, the selection of buck-boost converter reduces

10

the switching losses of VSI operated at low frequency for electronic commutation of

11

BLDC motor drive [17]. The discrete rotor position, sensed through hall sensor, is fed back

12

to FPGA processor-

13

(i) wherein, speed to voltage conversion is carried out. Voltage error

14

equivalence, Ve(k),of speed error, Ne(k) is given to PI controller which

15

generates the control signal, D for the operation of buck-boost converter.

16

(ii) to generate switching signal Mi at a frequency, f for the operation of front

17

end converter.

18

3. Mathematical modeling

19

3.1. Buck-boost converter

20

21

The equation (1) governs the relation between input (Vin) and output voltage (Vdc)

during continuous conduction mode of buck boost converter [18].

Vin * D

1 D

Vdc

The value of the inductance L0 is given by (2)

L0

The value of the capacitance C0 is given by (3)

C0

1 D *Vin

iL0 f s

D

V

Rf s c 0

V0

(1)

(2)

(3)

6

7

8

3.2. The Induction profile of BLDC motor drive system

The motor under investigation is a Permanent Magnet Synchronous Machine (PMSM)

10

with the permanent magnet mounted on the rotor and concentrated stator windings

11

resulting in trapezoidal induced back EMFs with maximum possible width of flat top

12

portion [19]. To ensure the smooth torque production a constant current is forced through

13

each phase winding during the interval when the back EMF is at its maxima as shown in

14

Figure 2. For the unipolar excitation with soft switching current, positive current flows

15

through the phase windings for positive back EMFs with each conduction period lasting

16

for 120. However, no current flows through phase windings when back EMFs vary with

time. This results in two phases conducting at a time and producing the torque. So for

trapezoidal variation of induced back EMFs and with an assumption that phase

inductances are constant, the equation governing the above described induction profile of

BLDC motor in abc reference frame [20] are given by

dia

1

2Vab Vbc 3Rsia pr (2Ea Eb Ec )

dt 3Ls

(4)

dib

1

Vab Vbc 3Rs ib pr ( Ea 2 Eb Ec )

dt Lq

(5)

dic

di di

a b

dt

dt dt

(6)

E i Ebib Ecic

Te a a

(7)

3.3. Front end converter

10

Figure 3 shows three phase front end converter for speed control of BLDC motor

11

drive system through electronic commutation. Each leg has two IGBT switches,

12

accompanied by anti parallel flywheel diodes, which are complement in their switching

13

action. For understanding the underlying principles involved in working of this front end

14

converter circuit, phase A is taken under consideration.

15

From Figure 3, the voltage VaN across phase A with respect to neutral point (N) of dc link

16

capacitor [21] is expressed by Eq. (8)

17

VaN

4 Vdc

1

1

1

1

cos ot cos 3ot cos 5ot cos 7ot cos 9ot ...

2

3

5

7

9

(8)

The voltage VnN, between neutral of stator winding and neutral point (N) of dc link

capacitor, is given by (9)

VnN

So, the voltage Van that appears across phase A with respect to windings neutral n, is

given by (10)

Van VaN VnN

VaN

It can be inferred from equation (11) that the most dominant 3rd order harmonics is

eliminated.

10

4 Vdc 1

1

cos3

cos9ot ....

o

2 3

9

4 Vdc

1

1

cos ot cos 5ot cos 7ot ....

2

5

7

(9)

(10)

(11)

4. Proposed dual loop speed control

11

When precise speed control becomes the prime concern, then multiple pathways

12

become an essential ingredient to achieve the stated objective. Here in the proposed BLDC

13

drive system the speed is being controlled

14

15

16

17

1. by controlling the input voltage to the front end converter with the help of proposed

PI controller and

2. by triggering the switching pulse of front end converter proportional to EMF

detection

10

The design of efficient controllers is needed for the optimal operation of power converters

to improve the close loop dynamic and steady state performance of BLDC drive system.

Conventional way of implementing digital controller based on FPGA and developing

control algorithm using high level language like Verilog Hardware Description Language

(VHDL) is a cumbersome and tedious job. Newly evolved FPGA based Xilinx System

Generator provides a very realistic solution for the aforesaid problem. Automatic code

generation, dedicated hardware intellectual properties of the Xilinx block sets for FPGA

core and simulation of real time physical system in safer environmental zone makes it

appropriate platform for our research. So designing the controller based on FPGA (Xilinx

10

system generator, a type of real time digital simulator) ensures a very rapid prototyping to

11

our proposed methodology [22].

12

The subject of application of proposed BLDC drive system to EVs and HEVs,

13

where predominantly step changes in speed occur, governs the selection of PI controller for

14

excellent dynamic response of the system with zero steady state error. Here discrete time

15

FPGA based PI controller is controlling the DC link voltage to the front end converter and

16

thus speed of the BLDC drive system. So the dynamics of the entire drive system is

17

completely governed by controller.

18

19

4.1.

Modelling of XSG based digital PI controller

In Figure 4, if Nr(k), Nr*(k) and Ne(k) denote the actual rotor speed, reference speed

20

and speed error respectively, input to the speed to voltage converter is given by (12)

21

Ne (k ) Nr *(k ) Nr (k )

(12)

11

And voltage error Ve(k), equivalent to speed error is given by (13)

V

Ve (k ) n * N e (k )

N

The output, switching command U (k), of PI controller at kth instant is expressed as

U k U k 1 K p Ve (k ) Ve (k 1) Ki Ve (k ) Ve (k 1) * k

Where PI controller constant KP = 0.6 and KI= 5 and k is sampling interval.

Control signals D, for the operation of buck-boost converter, are generated by comparison

of U (k) with 20 kHz triangular wave.

4.2. Delay control of switching sequences in front end converter

(13)

(14)

The second way to control the speed of motor is to vary the triggering rate of switches.

10

The speed of the motor can be changed here by manipulating the time interval between

11

switching of different phases. To control speed via this method, the circuitry required is

12

shown in Figure 5.

13

To achieve variable rate of switching between the different phases switching pulses are

14

generated in synchronism with discrete rotor position sensed by the hall sensor. As shown

15

in Figure 6, the hall sensor will detect discrete rotor position after every 60 degree rotation

16

and will produce pulses which are converted into equivalent back EMF signals by decoder.

17

Firing circuit with back EMF signal produces the switching pulses, shown in Table 1, for

18

the front end converter.

12

So, the change in speed is accompanied by electronic commutation where the

inductance energy of any one phase reaches the maximum value during each 30 electrical

degree, inductance holds this energy for next 120 electrical degrees and which finally is

released in next 30 electrical degrees through anti parallel fly wheel diode. This

commutation process for phase A is shown in Figure 7.

5. Description of simulation setup and performance evaluation of the proposed

7

8

9

10

11

12

control scheme.

To validate the proposed methodology, extensive dynamic simulations are carried out in

1. MATLAB/SIMULINK environment using power system toolbox for power

circuitry in floating point representation.

2. XSG environment using Xilinx block set tools for control circuit in fixed point

representation.

13

The overall block diagram with closed loop control using proposed FPGA based PI

14

controller is shown in Figure 8 which outlined the communication between FPGA

15

based PI controller and rest of electric drive system. The control circuit consists of

16

three parts

17

1. Speed to voltage conversion

18

2. PI controller and saturation.

19

3. Delay control of switching in front end converter

20

21

And the power circuit consists of

1. Buck Boost converter

13

2. VSI fed BLDC drive system

Reference speed is digitally set and actual rotor speed is sensed and speed to voltage

conversion logic loop, shown in Figure 8, is used to convert speed error into voltage

equivalence error which is further utilized by proposed PI controller to generate gate

signal for discrete IGBT switch used in buck boost converter. IGBT switch is rated

for 60 A, 700V and 20 kHz frequency. In this way voltage is drawn from power

converter for the desired speed response of BLDC drive system. Simulation results

and performance of proposed system are discussed in later section.

The detailed data of power circuit considered for simulation are given in Table 2.The

10

performance of the BLDC motor drive system categorized into steady state and

11

dynamic performance. The performance indices:

12

Primary-(a) Percentage average speed error (b) Maximum speed ripples (c)

13

Percentage maximum speed error and

14

Secondary-(a) Stator back EMFs E(V) (b) Stator current I(A) (c) Electromagnetic

15

torque Te(N-m) (d) DC link voltage Vdc(V) from buck boost converter, are selected to

16

study the effectiveness of proposed control scheme.

17

5.1. Steady state analysis

18

This analysis is aimed to determine if the actual motor speed reaches commanded

19

speed at steady state. Based on the speed error and its voltage equivalence correct

20

proposed controller execute the steps required to decide the duty cycle required for

21

IGBT switch of buck boost converter in next cycle.

14

5.1(a). Speed ripple and percentage speed error calculation

The average speed error and maximum speed error are the function of speed ripples.

It is therefore essential to find out the speed ripples at steady state for both, the

dynamic and steady state performance evaluation.

%Average Speed Error =

%Maximum Speed Error =

Average speed ripple

*100

Average speed

Maximum speed ripple

*100

Reference speed

The results, shown in Figure 9 (a)-(c), illustrate that the ability of proposed

controller in tracking the commanded speed is reasonably good under different sets

of operating condition. Results, in reference to Figure 9(a)-(c) and Table 3, are

10

11

12

13

14

15

16

summarized as below1. It is very clear that average speed lies very close to commanded speed and

maximum speed ripple is well below 6 rpm.

2. The percentage average speed error and percentage maximum speed error are

always less than 1%.

3. It is also notable that average error and maximum error are decreasing

reasonably fast with increase in commanded speed.

17

4. For lower speed range (900-1100 rpm), ripples are almost constant, during

18

steady state, in their magnitude. Due to this reason average error and

15

maximum error are almost equal to each other which can be seen from Table

3.

3

4

From Table 3 a chart have been shown in Figure 10, in order to give a clear

insight about the effectiveness of the proposed control scheme. Chart is drawn for

1. Percentage average error Vs average speed and

2. Percentage Maximum speed error Vs reference speed

From chart it can clearly be seen that average as well as maximum speed error

keep on decreasing with increase in reference speed.

Further the steady state performance of proposed control scheme for BLDC

10

drive, against constant load of 3 N-m, at two different commanded speed, are also

11

shown in Figure 11 -12.

12

It can be seen form Figures 11(a) and 12(a) that controller is sufficiently fast in

13

tracking reference speed in approximately 0.25 sec. The enlarged view of back EMFs

14

and phase current are shown in Figures 11(b)-(c) and 12(b)-(c), which are constant

15

for preset load of 3 N-m. Since the load is assumed to be constant as shown in Figures

16

11(d) and 12(d), the phase current is also constant. The dc link voltage follows the

17

changes made in commanded speed as can be observed from Figures 11(e) and 12(e).

18

5.2. Dynamic performance

19

In order to test the dynamic performance of the proposed control scheme, the

20

desired response of BLDC drive system is investigated under sudden change in

16

reference speed, issued at t = 1.5 sec. The response of the system is shown in Figure 13

(a) and an enlarged view of speed response, after step change in commanded speed, is

shown in Figure 13 (b).

The results depicted in Figure 13 (b) show that the actual speed attains steady

state value very close to commanded speed, in less than 40 ms, after a step change in

reference or commanded speed (3000 to 1500 rpm) is enforced.

The enlarged view of actual speed spectrum is also shown in Figure 13 (c)-(d) to

assess the average and maximum speed ripple at steady state under issued change in

commanded speed. The effectiveness and efficiency of the proposed control scheme in

10

terms of chosen performance indices such as average and maximum speed error,

11

maximum speed ripple has been presented in Table 3. It can clearly be observed from

12

Figure 13 (c)-(d) and Table 3 that maximum speed ripple stays well within 5 rpm and

13

percentage average error and percentage maximum error stays less than or equal to

14

0.23 and 0.26 respectively. Thus the simulation results validate the utility and

15

effectiveness of the proposed control scheme in terms of precise tracking of reference

16

speed. Furthermore, the time taken by the controller to track the commanded speed,

17

after the system has been subjected to a step change in speed, is less than 40 ms,

18

which is appreciably fast response of controller.

19

Moreover, for a step change in commanded speed issued at t = 1.5 s and t = 1.6 s,

20

the dynamic behavior of the proposed BLDC drive system is investigated against

21

secondary performance indices which are shown in Figure 14 (i) (a). It can be

17

observed from Figure 14 (i) (c) that, under the issued changes, the electromagnetic

torque regains its steady state value with acceptable values of overshoot in less than

0.5 s after the commanded speed has been changed. As the load torque has been

assumed to be constant this makes stator phase current also constant, which can be

easily seen from Figure 14 (i) (b). It can also be seen from Figure 14 (i) (d) that the dc

link voltage exactly follows the corresponding changes made in commanded speed.

Any change in reference speed is followed by actual speed and the corresponding

change

in

stator

phase

back

EMF

is

shown

in

Figure

14

(ii).

6. Conclusions

The Dual loop control scheme, based on FPGA, for speed control of BLDC

motor, targeting precise speed control and medium power application such as EVs

and HEVs, has been presented in this paper. The proposed control scheme has

following advantages

1. Simulation results discussed so far illustrate the effectiveness of control

scheme in tracking the commanded speed in a very less time and quiet less

speed ripple as well.

2. The main attractive feature of the proposed work is the easy and quick

realization in real time applications when this control logic is implemented

on XSG platform.

3. The Proposed FPGA based PI controller is sufficiently fast in its action of

generating the desired DC link voltage, from buck boost converter, and

hence the desired speed control.

18

4. Moreover the average speed error and maximum speed error are

evaluated in order to determine certain more application of proposed

system. So the observed dynamic performance of BLDC drive system has

demonstrated the ability of proposed control scheme to be selectively used

for application which requires very high speed accuracy along with fast

dynamic response such as biomedical /health care equipments, printing

technology, aerospace applications.

This controller provides far superior performance when proposed drive system is

used for high speed application over the classical zero crossing sensorless approach which

is applicable only in low speed applications. Indeed, the availability of discrete rotor

position through Hall Effect sensor and disturbance torque information greatly improves

the efficiency and robustness of the system, while decreasing the acoustic noise. This

paper, thus, illustrate feasibility of an accurate speed controller along with the estimator

portion of the controller. The implementation of dual control loop to control speed either

via changing DC link voltage with PI controller or by changing the time interval for

conduction state of phases facilitates end to end speed control. Hence the proposed model

realized the speed controller for a brushless DC Motor, which is demanded increasingly,

using the FPGA based control scheme. Finally the performance of the system is evaluated

in MATLAB/SIMULINK software integrated with Xilinx System Generator.

19

References

[1] B. Singh, S. Singh, State of art on permanent magnet brushless DC motor Drives,

Journal of Power Electronics, Vol. 9, pp. 1-17, 2009.

[2] N.P. Shah, A.D. Hirzel, B. Cho, Transmissionless Selectively Aligned SurfacePermanent-Magnet BLDC Motor in Hybrid Electric Vehicles, IEEE Transactions on

Industrial Electronics, Vol. 57, pp. 669-677, 2010.

[3] F.L. Luo, H.G. Yeo, Advanced PM brushless DC motor control and system for

electric vehicles, IEEE Conference Record of the Industry Applications, Vol. 2, pp. 13361343, 2000.

[4] A.A. Rajan, R.D. Raj, S. Vasantharathna, Fuzzy based reconfigurable controller for

BLDC motor, Computing International Conference on Communication and Networking

Technologies, pp. 1-7, 2010.

[5] B. Singh, B.P. Singh, S.K. Dwivedi, A state of art on different configurations of

permanent magnet brushless machines, IE (I) Journal, Vol. 78, pp. 63-73,2006.

[6] K.R. Rajagopal, A. Nair, Design and development of a TMS320F2812 DSP controller

based PM BLDC motor drive, International Conference on Electrical Machines and

Systems, pp. 776-780, 2010.

[7] T.P. Banerjee, J.R. Choudhury, S. Das, A. Abraham, Hybrid Intelligent Predictive

Control System for High Speed BLDC Motor in Aerospace Application, 3rd International

Conference on Emerging Trends in Engineering and Technology, pp.258-262, 2010.

20

[8] J. Gunhee, M.G. Kim, A bipolar-starting and unipolar-running method to drive a hard

disk drive spindle motor at high speed with large starting torque, IEEE Transactions on

Magnetics, Vol. 41, pp. 750-755, 2005.

[9] A. Sathyan, N. Milivojevic, Y.J. Lee, M. Krishnamurthy, A. Emadi, An FPGA-Based

Novel Digital PWM Control Scheme for BLDC Motor Drives, IEEE Transactions on

Industrial Electronics, Vol. 56, pp. 3040-3049, 2009.

[10] N. Milivojevic, M. Krishnamurthy, Y. Gurkaynak, A. Sathyan, Y.J. Lee, A. Emadi,

Stability Analysis of FPGA-Based Control of Brushless DC Motors and Generators Using

Digital PWM Technique, IEEE Transactions on Industrial Electronics vol. 59, pp. 343351, 2012.

[11] F. Rodriguez, A. Emadi, A Novel Digital Control Technique for Brushless DC Motor

Drives, IEEE Transactions on Industrial Electronics, Vol. 54, pp. 2365-2373, 2007

[12] M.R. Feyzi, M. Niapour, S.A. Kh, F. Nejabatkhah, S. Danyali, A. Feizi, Brushless

DC motor drive based on multi-input DC boost converter supplemented by hybrid

PV/FC/battery power system, 24th Canadian Conference on Electrical and Computer

Engineering, pp. 442-446, 2011.

[13] B. Singh, S. Singh, Single-phase power factor controller topologies for permanent

magnet brushless DC motor drives, IET Power Electronics, Vol. 3, pp. 147-175, 2010.

[14] J. Dixon, I. Nakashima, E.F. Arcos, M. Ortuzar, Electric Vehicle Using a

Combination of Ultra capacitors and ZEBRA Battery, IEEE Transactions on Industrial

Electronics, Vol. 57, pp. 943- 949, 2010.

21

[15] M. Amari, J. Ghouili, F.N. Bacha, high-frequency unidirectional DC-DC converter

for fuel-cell electrical vehicles, 24th Canadian Conference on Electrical and Computer

Engineering, pp. 1451-1458, 2011.

[16] M. Aydin, S. Huang, T.A. Lipo, Torque quality and comparison of internal and

external rotor axial flux surface-magnet disc machines, The 27th Annual Conference of

the IEEE Industrial Electronics Society (IECON), Vol. 2, pp. 1428-1434, 2001.

[17] V. Bist, B. Singh, An Adjustable-Speed PFC Bridgeless BuckBoost Converter-Fed

BLDC Motor Drive, IEEE Transactions on Industrial Electronics, Vol. 61, pp. 2665-2677,

2014.

[18] J. Chen, D. Maksimovic, R. Erickson, A new low-stress buck-boost converter for

universal-input PPC applications, Sixteenth Annual IEEE Applied Power Electronics

Conference and Exposition (APEC), pp. 343-349, 2001.

[19] T. Gopalarathnam, H.A. Toliyat, A new topology for unipolar brushless DC motor

drive with high power factor, IEEE Transactions on Power Electronics, Vol. 18, pp. 13971404, 2003.

[20] D. Grenier,. L.A. Dessaint, O. Akhrif, Y. Bonnassieux, B.L. Pioufle, Experimental

Nonlinear Torque Control of a Permanent Magnet Synchronous Motor Using Saliency,

IEEE Transactions on Industrial Electronics, Vol. 44, pp. 680-687, 1997

[21] H. Farahani, H. Sarabadani, Modulation Index Effect on the 5-Level SHE-PWM

Voltage Source Inverter, Scientific Research Engineering, Vol. 3, pp. 187-194, 2011.

[22] J. Belanger, P. Venne, J.N. Paquin, The What, Where, and Why of Real-Time

Simulation, Planet RT, 2010.

22

List of Figures

BUCK-BOOST

CONVERTER

BATTERY

FRONT END

CONVERTER

BLDC MOTOR

Mi, f

Ea

FPGA PROCESSOR

Nr

Figure 1. Block diagram of the proposed drive system

UNIPOLAR Excitation

Phase A

180

360

Magnitude

Phase B

Stator Phase Back EMFs

Phase Current

Output Torque

Phase C

Torque

30

90 150 210 270

Rotor angle(deg)

330

Figure 2. Induction profile of BLDC drive system showing Back-EMFs, Phase

current and output torque waveform with unipolar excitation

23

C1

T1

T3

T5

DC input

voltage

Ra

N

PMSM

La

Ea

Rb

Lb Eb

Rc

Lc Ec

C2

T2

T4

T6

Figure 3. Circuit topology of a voltage control three phase inverter

speed

sensor,

Nr(k)

Ref.

Speed,

Nr*(k)

Control

signal

(D)

+ Ne(k) Speed to Ve(k) PI U(k) PWM

voltage

controller

generator

conversion

FPGA PROCESSOR

Figure 4. Block diagram of proposed speed control algorithm.

Hall

sensor

Decoder

Equivalent

EMF s

signal Firing

circuit

FPGA PROCESSOR

Figure 5. Switching signal generator for VSI.

Control

signal

(mi,f)

24

0

1

Ha

60 1200

120 1800

0 600

1

1

Hb

Ha 1

Ha 0

H

Hc 1

300 3600

H 0

b

Hc 0

180 2400

Ha

Hb

240 3000

Hc

H

a

1

H

b 1

H

c

0

Figure 6. State representation of hall sensor functionality

C1

T1

Ra

DC input

voltage

NA

Hc

b

Hc 0

Hb

Hc

Ha 0

Ha

NA

H

a

0

H

b 1

H

c

1

La

Ea

C2

T6

Figure 7. Equivalent circuit of phase A of BLDC drive system

25

Figure 8. Simulation circuit diagram in MATLAB/SIMULINK and Xilinx System

Generator environment

Nr(rpm)

905

900

895

(a)

Nr(rpm)

1005

1000

995

(b)

Nr(rpm)

1107

1102

1097

755

759.5

764

768.5

(c)

773

Time(ms)

777.5

Figure 9 (a)-(c). Simulated speed response of considered BLDC drive for reference

speed of (a) 900 rpm (b) 1000 rpm (c) 1100 rpm, at 30% of rated load condition.

26

0.7

%Avg. speed error vs Avg.

Speed (rpm)

%Avg. / %Maximum Error

0.6

0.5

%Max. speed error vs Ref.

speed (rpm)

0.4

0.3

0.2

0.1

0

0

500

1000

1500

2000

2500

3000

3500

Speed (rpm)

Figure 10. Performance evaluation of proposed control scheme in terms of average

and maximum error at different commanded speed.

27

(a)

Speed

Nr(rpm)

2500

Steady

state

0

(b)

Back EMF

(c)

Current

(d)

Torque

(e)

DC Link Voltage

Ea(V)

150

0

-150

Ia(A)

3

0

-3

Te(N-m)

4

2

0

Vdc(V)

350

0

0

0.25

0.5

0.75

1.0

1.25

Time(s)

1.5

1.75

2.0

2.25

2.5

Figure 11. Steady state performance of proposed BLDC motor drive at 2000 rpm and

at 30% of full load condition

28

Speed

(a)

Nr(rpm)

3500

Steady

state

0

Ea(V)

250

(b)

Back EMF

(c)

Current

(d)

Torque

(e)

Dc link voltage

-250

Ia(A)

4

2

0

-2

-4

Te(N-m)

2

0

Vdc(V)

500

250

0

0

0.25

0.5

0.75

1.0

1.25

Time(s)

1.5

1.75

2.0

2.25

2.5

Figure 12. Steady state performance of proposed BLDC motor drive at 3000 rpm and

at 30% of full load condition.

29

3200

Nr(rpm)

2800

2400

2000

1600

1200

.25

.50

.75

1.0

1.25

1.5

1.75

(a) Time(s)

2.0

2.25

2.5

2.75

Nr(rpm)

3000

1500

1.460

3007.7

1.480

1.520

1500

1.540

X axis: Time(ms)

1 div-2.25 ms

Nr(rpm)

Nr(rpm)

X axis: Time(ms)

1 div-2.25 ms

1.500

(b) Time(s)

2995.7

755

766.25

(c) Time(ms)

1495

777.5

2000

(d)

2011.25

Time(ms)

2022.5

Figure 13. Simulated result, at 30% of full load condition (a) for a step change in

reference speed from 3000 to 1500 rpm, (b) enlarged view for step change showing

response time and tracking, (c)-(d) zoomed view of actual speed to account for ripples

30

Speed

(a)

Nr(rpm)

3500

2000

Transient region

0

(b)

Current

(c)

Torque

Ia(A)

4

2

0

-2

-4

Te(N-m)

Transient region

0

(d)

DC link voltage

Vdc(V)

500

250

0

0

Step Change (480

0.25

0.5

1.0

0.75

1.25

1.5

1.75

320)V

2.0

2.25

2.5

Time(s)

(i)

Enlarged View of Back EMF

Ea(V)

300

Dynamic region

-300

1.4

1.5

1.525

1.55

Time(s)

1.575

1.6

1.7

(ii)

1

Figure 14. (i) Dynamic performance of proposed BLDC motor drive during step

change in speed (ii) Enlarged view of back EMF for phase A, at step change in

commanded speed issued at t = 1.5 and t = 1.6, at 30% of rated load.

31

List of Tables

Table 1. Switching states of the VSI feeding a BLDC motor drive based on the Hall-

effect position signals

State of switches

T1

T2

T3

T4

T5

T6

NA

0-60

60-120

120-180

180-240

240-300

300-360

NA

4

5

Table 2. Parameters of power circuit considered for simulation

S.No.

1

2

3

4

5

6

7

8

9

10

11

12

Parameter

BLDC MOTOR DRIVE

No. of pole pairs

Rated Power (Prated)

Rated Torque (Trated)

Rated DC Link Voltage

(Vrated)

Torque Constant (Kt)

Voltage Constant

Stator Phase Resistance (Rs)

Stator Phase Inductance (Ls)

BUCK BOOST CONVERTER

Buck Boost Inductor (L0)

Buck Boost Capacitor (C0)

Input Voltage (Vin)

Switching Frequency(fs)

Numerical Value

2

5 KW

10 N.m

480 V

1.4 N.m/A

160 V/k rpm

2.85 ohm

8.5 mH

20 mH

800 uF

12 V

20 kHz

32

Table 3. Summary of Simulated Results

Nr*

(rpm)

Navg

(rpm)

%Average

error

|Maximum

speed ripple|

%Maximum

error

900

898.35

0.623

5.62

0.624

1000

999.80

0.40

4.0

0.40

1100

1101.35

0.42

4.62

0.42

Dynamic

1500

1500.1

0.23

3.9

0.26

performance

3000

3001.7

0.11

4.5

0.15

Performance

indices

Steady state

Proposed

control

technique

performance

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Support of Roof and Side in Belowground Coal MinesDokument5 SeitenSupport of Roof and Side in Belowground Coal MinesNavdeep MandalNoch keine Bewertungen

- User Manual ManoScanDokument58 SeitenUser Manual ManoScanNurul FathiaNoch keine Bewertungen

- An1914 PDFDokument56 SeitenAn1914 PDFUpama Das100% (1)

- Sensory Play Activities Kids Will LoveDokument5 SeitenSensory Play Activities Kids Will LoveGoh KokMingNoch keine Bewertungen

- 67 9268Dokument34 Seiten67 9268Salvador ReyesNoch keine Bewertungen

- Accuracy of Transferring Analog Dental Casts To A Virtual ArticulatorDokument9 SeitenAccuracy of Transferring Analog Dental Casts To A Virtual ArticulatorNetra TaleleNoch keine Bewertungen

- RegistryDokument4 SeitenRegistryRajan KhandelwalNoch keine Bewertungen

- Manual Safety Installation Operations Tescom en 123946Dokument23 SeitenManual Safety Installation Operations Tescom en 123946Karikalan JayNoch keine Bewertungen

- A A ADokument5 SeitenA A ASalvador__DaliNoch keine Bewertungen

- Test Bank For Macroeconomics 8th Canadian Edition Andrew AbelDokument16 SeitenTest Bank For Macroeconomics 8th Canadian Edition Andrew AbelstebinrothNoch keine Bewertungen

- AWANA Handbook 2010-2011Dokument8 SeitenAWANA Handbook 2010-2011carriepratchard100% (1)

- 1st Quarter 2016 Lesson 5 Powerpoint With Tagalog NotesDokument25 Seiten1st Quarter 2016 Lesson 5 Powerpoint With Tagalog NotesRitchie FamarinNoch keine Bewertungen

- A Review of Automatic License Plate Recognition System in Mobile-Based PlatformDokument6 SeitenA Review of Automatic License Plate Recognition System in Mobile-Based PlatformadiaNoch keine Bewertungen

- Centiloquium of PtolemyDokument37 SeitenCentiloquium of PtolemyNatasa Karalic Koprivica100% (9)

- CESC Performance Task Quarter 1Dokument3 SeitenCESC Performance Task Quarter 1MarinaM.CubiaNoch keine Bewertungen

- CSMP77: en Es FRDokument38 SeitenCSMP77: en Es FRGerson FelipeNoch keine Bewertungen

- Transformational and Charismatic Leadership: The Road Ahead 10th Anniversary EditionDokument32 SeitenTransformational and Charismatic Leadership: The Road Ahead 10th Anniversary Editionfisaac333085Noch keine Bewertungen

- MikroekonomiDokument1 SeiteMikroekonomiYudhaPrakosoIINoch keine Bewertungen

- Defining The Market Research Problem & Developing An ApproachDokument77 SeitenDefining The Market Research Problem & Developing An ApproachSakshi Bhati I H21O41Noch keine Bewertungen

- Erp FinalDokument33 SeitenErp FinaltenetchatNoch keine Bewertungen

- Unit 9 TelephoningDokument14 SeitenUnit 9 TelephoningDaniela DanilovNoch keine Bewertungen

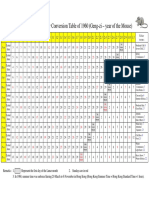

- Gregorian-Lunar Calendar Conversion Table of 1960 (Geng-Zi - Year of The Mouse)Dokument1 SeiteGregorian-Lunar Calendar Conversion Table of 1960 (Geng-Zi - Year of The Mouse)Anomali SahamNoch keine Bewertungen

- Tia Portal V16 OrderlistDokument7 SeitenTia Portal V16 OrderlistJahidul IslamNoch keine Bewertungen

- Module 8 - Facilitating Learner - Centered TeachingDokument4 SeitenModule 8 - Facilitating Learner - Centered TeachingSheila Mae Paltep100% (3)

- Shaheed Suhrawardy Medical College HospitalDokument3 SeitenShaheed Suhrawardy Medical College HospitalDr. Mohammad Nazrul IslamNoch keine Bewertungen

- Computer Forensics ReportDokument7 SeitenComputer Forensics ReportMatias IacobuzioNoch keine Bewertungen

- 2018-3-27 MIDAS Civil Presentation Curved BridgesDokument57 Seiten2018-3-27 MIDAS Civil Presentation Curved BridgesShishir Kumar NayakNoch keine Bewertungen

- Abbreviations For O&G IndustryDokument38 SeitenAbbreviations For O&G IndustryMike George MeyerNoch keine Bewertungen

- Useful C Library FunctionDokument31 SeitenUseful C Library FunctionraviNoch keine Bewertungen