Beruflich Dokumente

Kultur Dokumente

Rev100507

Hochgeladen von

jkhgvdj mnhsnjkhgOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Rev100507

Hochgeladen von

jkhgvdj mnhsnjkhgCopyright:

Verfügbare Formate

Revised 100507

SPECIFICATIONS - DETAILED PROVISIONS

Section 11937 - Deep Well Vertical Pumps

CONTENTS

PART 1 - GENERAL ................................................................................................................. 1

1.01 GENERAL ................................................................................................................. 1

1.02 UNIT RESPONSIBILITY ............................................................................................ 1

1.03 SUBMITTALS ............................................................................................................ 1

1.04 OPERATING CONDITIONS ...................................................................................... 2

PART 2 - PRODUCT ................................................................................................................. 2

2.01 PUMP ASSEMBLY CONSTRUCTION ...................................................................... 2

2.02 CHLORINATION PIPE .............................................................................................. 5

2.03 JOINTLESS AIR LINE TUBE..................................................................................... 6

2.04 LINE SHAFT OILER ASSEMBLY .............................................................................. 6

PART 3 - EXECUTION .............................................................................................................. 6

3.01 PUMPING UNIT - PUMP DEALER REQUIREMENTS .............................................. 6

3.02 DELIVERY ................................................................................................................. 6

3.03 PREPARATION ......................................................................................................... 6

3.04 EQUIPMENT TESTING ............................................................................................. 6

3.05 INSTALLATION ......................................................................................................... 7

3.06 FIELD ACCEPTANCE TEST ..................................................................................... 7

3.07 CERTIFICATION OF INSTALLATION....................................................................... 7

3.08 WARRANTY .............................................................................................................. 7

3.09 MAINTENANCE BOND FOR PUMPING EQUIPMENT ............................................. 8

ATTACHMENT

MANUFACTURERS CERTIFICATE OF PROPER INSTALLATION

Deep Well Vertical Pumps

Section 11937 1

SECTION 11937

DEEP WELL VERTICAL PUMPS

PART 1 - GENERAL

1.01

GENERAL

This Specification is for close-coupled deep well vertical turbine pumps including discharge

head, column and tube enclosed line-shaft assembly, strainer and oil lubrication system. All

equipment furnished under this section shall be new and of current manufacture and shall be

guaranteed free from defects in material, design, or workmanship. All parts of the pump

exposed to water shall be of stainless steel, brass, heavy cast iron, or equivalent corrosionproof material. Unless otherwise specified herein, all applicable provisions of ANSI/AWWA E101, Part A, latest edition, for Vertical Turbine Pumps, are hereby made a part of these

Specifications. The pumps shall be manufactured by Peerless, Goulds, Floway or District

approved equal.

Refer to the Detailed Well Pump Specification section and the Special Conditions for additional

requirements/information.

1.02

UNIT RESPONSIBILITY

All combinations of manufactured equipment which are approved under this specification shall

be entirely compatible and the Contractor and the listed manufacturer shall be responsible for

the compatible and successful operation of the various components of the units conforming to

the specified requirements. All necessary mountings, couplings, and appurtenances shall be

included with each unit. All materials employed in the pump equipment shall be suitable for

the intended application and shall be high grade commercial quality, free from all defects and

imperfections that might affect the serviceability of the product for the purpose for which it is

intended.

Motors shall be the "hollowshaft" type with a non-reversing ratchet and shall meet the

requirements of Section 16150 and Section 16151. Should the equipment selected by the

Contractor require revisions to the structures, piping, electrical, or other work shown on the

drawings, the Contractor shall include the cost of such revisions in his bid for the equipment,

and no extra payment shall be made for such revisions. All such revisions shall be submitted

for District approval, and shall be subject to the approval of the Engineer.

1.03

SUBMITTALS

Submittals shall be provided to the Engineer for approval prior to beginning

manufacture/construction of the pumping units in accordance with the General Conditions.

Submittals shall include:

A.

Shop Drawings including the following information:

1.

Pump name and identification number.

Deep Well Vertical Pumps

Section 11937 2

2.

Pumping unit outline diagrams.

3.

Pump detailed description and specification.

4.

Electrical data including control and wiring diagrams.

5.

Assembly and installation drawings including shaft size, coupling anchor

bolt plan, part nomenclature, materials list, outline, dimensions, and

shipping weight.

B.

Certified pump curves showing head versus capacity, bowl efficiency versus

capacity; NPSH and BHP requirements, and thrust and moment of inertia

characteristics. Each curve shall be continuous over the full operating range from

zero (0) flow up to the maximum flow permissible through each pump, and shall

be based upon the RPM listed. Each curve shall state the RPM speed of the

pumping unit, and shall be furnished full-size on 8-1/2" x 11" paper. The

Contractor shall provide pumps capable of meeting all aspects of the Detailed

Well Pump Specification section and as shown on the Drawings.

C.

Operation & Maintenance Manuals. Sets of printed instructions relating to proper

maintenance and parts lists indicating the various parts by name, number and

diagram where necessary shall be furnished in duplicate with each unit or set of

identical units as required by the General and/or Special Conditions.

Recommended spare parts lists shall be included and local supplier's name

where spare parts are available.

1.04

OPERATING CONDITIONS

The capacities, heads, efficiencies, and horsepower requirements are for completely

assembled units and are specified in the Detailed Pump Specification section. Each pumping

unit shall meet the requirements and design points as specified therein.

PART 2 - PRODUCT

2.01

PUMP ASSEMBLY CONSTRUCTION

A.

Pump Discharge Head Assembly. The pump discharge head shall be of

fabricated steel or close grained, cast iron, ASTMA48 Class 30, free of sand

holes and other defects, accurately machined and with a surface discharge.

Discharge shall be machined and drilled to ANSI standards for 125# rating and

shall be of the diameter shown on the construction drawings. The top o the

discharge head shall have a rabbet fit to accurately locate the vertical hollow

shaft driver, and have a diameter equal to the driver base diameter (BD).

Deep Well Vertical Pumps

Section 11937 3

A shaft mechanical seal assembly shall be provided; including permanent seal

housing with renewable internals (faces and springs, etc.). The seal assembly

shall be approved by the Engineer and shall be silicon carbide steel as

manufactured by Chesterton, Model No. 155 or approved equal; and specifically

selected for the fluid being pumped, and the operating pressures included.

The discharge head shall be equipped with a tube tensioning device to apply and

maintain proper tension to the shaft enclosing tube. This device shall consist of a

cast iron ASTM A48 Class 30 tube tension plate and bronze ASTM B584 alloy

C83800 combination tube tension nut and bearing. Tension shall be applied to

the shaft enclosing tube through internal threads in the top tube. After proper

tensioning, nut shall be locked into position with a steel cap screw.

B.

Outer Column Pipe. The outer column pipe shall be of ASTM A53 grade B steel

pipe or ASTM A120 in interchangeable sections not over 20 feet in length and

with the ends of each section faced parallel and machined with 8 straight threads

per inch permitting the ends to butt and insuring alignment when connected by

standard mill steel couplings. The weight of the column pipe shall be no less

than that stated in ANSI Specification E101, Section 5.1 "Standard Specifications

for Discharge Column Pipe". The column size shall be such that friction loss will

not exceed 5' per 100', based on the rated capacity of the pump. If possible, the

column size shall also be such as to provide a velocity of not less than 5' per

second at the rated capacity.

C.

Line Shaft. The top line shaft (head shaft) shall be of ASTM A108 C1045 carbon

steel which shall not exceed 10' in length. Impeller adjustment shall be provided

at the top of the head shaft by means of a bronze adjusting nut of ASTM B584

alloy C83800 which shall be positively locked in position.

The line shafts shall be of carbon steel ASTM A108 grade C1045, turned and

ground. They shall be furnished in interchangeable sections not over (10) or (20)

feet in length.

The butting faces shall be machined square to the axis of the shaft, with

maximum permissible axial misalignment of the thread axis with the shaft axis

0.002" in 6". The size of the shaft shall be no less than that determined by

ANSI/AWWA-E101 Specifications, Section 5.5 for C1045 line shaft and shall be

such that elongation due to hydraulic thrust will not exceed the axial clearance of

the impellers in the pump bowls. Maximum runout in 10' shall not exceed.005".

D.

Line Shaft Bearings. The line shaft bearings shall be of bronze ASTM B505 alloy

C84400, internally spiral grooved to allow lubricant to flow through and threaded

externally to act as enclosing tube connectors.

Deep Well Vertical Pumps

Section 11937 4

E.

Shaft Enclosing Tube. The shaft enclosing tube shall be of ASTM A120,

Schedule 80 with the ends machined square and parallel, threaded internally to

receive the line shaft bearings. Maximum tube thread runout in 5' length shall not

exceed .005". Bearing spacing shall not exceed 5'.

F.

Pump Bowls. The bowls shall be of close-grained, gray cast iron, ASTM A48

Class 30 or better, precision cast, free from blow holes, sand pockets, and other

detrimental defects. The water passageways in said bowls shall be smooth so

as to allow freedom from cavitation and permit maximum efficiency. Each bowl

shall have a rubber or bronze lateral seal ring and a side seal to prevent slippage

of water between bowl and impeller. In order to improve the guaranteed

efficiency of the design point(s), bowls sizes 4" through 20" shall be lined. Said

lining, vitreous porcelain enamel or equal, shall be of such material and applied

in such manner to produce a long effective life which shall not be applied for the

purpose of a short time gain in efficiency. Lining, identical to that furnished

hereunder, shall have been used in the field, under identical conditions, with

satisfactory results for a least a five-year period. The bowls shall be able to

withstand a minimum of 150% of the maximum pump shut-off head (zero GPM)

pressure or twice the pressure at rated capacity, whichever is greater. In no

case shall the pressure rating of the bowl be less than 300 psi. Bowl material

shall have a minimum tensile strength of 30,000 psi.

G.

Pump Impellers. Impellers shall be the totally enclosed type. The impellers shall

be constructed of ASTM B505 alloy C83800 and shall be statically balanced.

Sizes 18" and greater shall also be dynamically balanced to prevent vibration.

Impellers shall be smoothly finished on all surfaces to reduce friction losses to a

minimum. The impellers shall be accurately fitted and securely locked to the

pump shaft and vertical adjustment of the impellers shall be possible by means of

an adjustment method in the driver assembly.

H.

Impeller Lock Collets. The lock collets shall be constructed of AISIB-1113 steel

or stainless steel.

I.

Pump Shaft. The pump shaft shall be constructed of ASTM A582 grade 416

stainless steel and shall be accurately machined to a sufficient dimension to

provide smooth operation and to easily withstand torsional loads and other

stresses encountered within the pump. The pump shaft shall have adequate

bearing support at every bowl section and at the top and bottom case section,

and shall be equipped with a suitable steel coupling for connection to the line

shaft. The shaft size shall be no less than that determined by ANSI/AWWA

Specifications E101, Section A4.3 paragraph 4.3.3.

J.

Pump Bearings. The suction case section and the discharge case section

bearings shall be sleeve type constructed of bronze ASTM B505 alloy C84400.

The bowl bearings shall be sleeve type of zinc-free bronze, or equal as approved

by the engineer. Bearing area, bearing cooling, and bearing lubrication shall be

ample for long trouble-free operating life of the equipment.

Deep Well Vertical Pumps

Section 11937 5

K.

Pump Discharge Case. The discharge case shall securely fasten the top pump

bowl assembly to the column piping. This section shall be heavily reinforced with

streamlined fluid passages to allow release of fluids escaping through the throttle

bearing and oil from the line shaft bearings. The discharge case shall also be

fitted with a bronze ASTM B505 alloy C84400 tube adapter bearing of proper

size to connect the shaft enclosing tube. The discharge case shall be threaded

on the outside for column sizes up to 14 inches.

L.

Pump Suction Case. The suction case shall be threaded on the O.D. and shall

securely fasten the bottom bowl assembly to the suction bell.

M.

Suction Pipe. Provide a suction pipe, attached to the bottom of the bowls, a

minimum of 10 feet in length, or as otherwise shown on the construction

drawings, and of a diameter and weight at least equal to the outer column.

N.

Strainer. A stainless steel strainer shall be provided and attached to the suction

column pipe. The inlet area shall be equal to at least four times the suction pipe

area. The maximum opening size shall not be more than 75% of the minimum

opening of the water passage through the bowl or impeller, whichever is smaller.

O.

Thrust Caps Bearings. Upthrust loads encountered in normal service, including

start-up, shall be accommodated by suitable thrust bearings in the pump and/or

motor assembly.

P.

Pump to Motor Coupling. The pump/hollow shaft motor coupling shall be, type

416 stainless steel and shall be capable of transmitting the total torque of the unit

in either direction.

Q.

Pump Nameplate. The pump shall be supplied with an easy-to-read, corrosion

resistant nameplate. It shall contain complete pump information including: pump

manufacturer's name, serial number, pump model number, number of stages,

speed, T.D.H. and capacity in GPM at the middle design point, year

manufactured, etc. Said nameplate shall be mounted on the pump head.

2.02

CHLORINATION PIPE

A 3/4" dia. dual purpose air line / chlorination pipe of 308 or 316 stainless steel pipe shall be

furnished of sufficient length to extend from the surface to the top of the bowl assembly. Pipe

lengths shall be a minimum of 10 feet long, threaded, and shall be joined with stainless steel

couplings. The pipe shall be attached to the column assembly with 1 inch wide stainless steel

hose clamps spaced a maximum of 10 feet apart. Stub-up and cap-off pipe 6" above the pump

base plate.

Deep Well Vertical Pumps

Section 11937 6

2.03

JOINTLESS AIR LINE TUBE

A 3/8" jointless airline of soft rolled stainless steel tubing shall be furnished of sufficient length

to extend from the surface to the top of the bowl assembly. The tube shall be attached to the

column assembly with 1 inch wide stainless steel hose clamps spaced a maximum of 20 feet

apart. Stub-up and cap-off pipe 6" above the pump base plate.

2.04

LINE SHAFT OILER ASSEMBLY

Discharge head shall be equipped with a standard aluminum, four quart lockable oil reservoir

fitted with solenoid valve and sight drip oiler for lubrication of the LINE SHAFT. Solenoid valve

shall have a push-button for the purpose of manual override.

PART 3 - EXECUTION

3.01

PUMPING UNIT - PUMP DEALER REQUIREMENTS

Pump supplier shall have complete office/shop facilities located within 100 miles of the job site,

and shall have a 10 years minimum successful experience record for pump sales/service.

3.02

DELIVERY

The Contractor shall order the pump at the earliest possible time to allow time for the

preparation, submittal, approval of shop drawings, and subsequent manufacture and

installation of the pump in a timely manner.

3.03

PREPARATION

Sets of instructions for field procedures for erection, adjustments, inspection, and testing shall

be provided prior to installation of the pumps, as required by the General or Special

Conditions.

3.04

EQUIPMENT TESTING

The purpose of equipment testing is to demonstrate that the pump units meet the specified

requirements.

A.

Tests shall be performed on the actual assembled unit over the entire operating

range on the certified performance curve. Prototype model tests will not be

acceptable.

B.

All pumps 10 to 50 horsepower shall be factory-tested in accordance with the

above specifications. Pumps larger than 50 horsepower may be subject to a

"factory witness test" attended by a District representative. The District shall be

notified at least 2 weeks in advance such that a representative can witness the

pump testing. Certified test results shall be submitted to the Engineer for

approval prior to shipment.

Deep Well Vertical Pumps

Section 11937 7

C.

Pump curves shall reflect data secured during actual test runs and shall be

signed by a responsible representative of the pump manufacture. Test reports

and procedures shall conform to applicable requirements of the Hydraulic

Institute Standards.

3.05

INSTALLATION

The Contractor shall install all pumping equipment in strict accordance with the manufacturer's

instructions. Care shall be used in handling to avoid bumping, twisting, dropping, or otherwise

damaging the equipment.

All pump manufacturers shall furnish the services of factory-trained personnel as required to

examine the installation, supervise start-up of equipment installed, and repair the equipment at

no additional expense to the District.

3.06

FIELD ACCEPTANCE TEST

The contractor under this specification shall have full responsibility for the proper installation

and performance of said pumping equipment, including furnishing the services of a pumping

equipment Field Service Engineer to inspect equipment installation, and to adjust, if necessary,

any portion of the pumping equipment required herein. The manufacturers Field Service

Engineer shall assist the District in the proper conduct of pumping unit field acceptance tests.

The pump units shall perform in the field as shown on the certified pump curves furnished by

the Contractor. Tests shall also demonstrate operation without cavitation, vibration,

overheating of moving parts, and excessive noise. The Contractor and pump manufacturer

shall make necessary corrections to achieve smooth pump operation. In the event the tests

reveal noncompliance of the workmanship or equipment, the Contractor shall either make

alterations as necessary or replace the pumps in order to meet the requirements of the

specifications at no additional cost to the District.

3.07

CERTIFICATION OF INSTALLATION

The Contractor shall submit the attached Manufacturers Certificate of Proper Installation to

the District confirming that all pumping equipment was inspected, operation checked, and

installation approved in writing by the respective pumping equipment representative.

3.08

WARRANTY

All pumping equipment shall carry an extended warranty for a two year period from the date of

acceptance. All warranties shall be turned into the District prior to project completion.

Deep Well Vertical Pumps

Section 11937 8

3.09

MAINTENANCE BOND FOR PUMPING EQUIPMENT

The contractor or his supplier shall provide a maintenance bond (see EMWD standard form C14 or C-14.1) from a bonding company acceptable to the District equal to 100% of the pumping

equipment value (including motors, pumps and pump assemblies) for a two (2) year term

starting when the District has accepted the contracted work. Equipment and/or components

failing within this period due to deficiency in design, workmanship or material shall be

removed, replaced, and reinstalled at no cost to the District, and said replacement shall be

guaranteed for two years continuous service. The maintenance bond shall be submitted to the

District prior to the performance test of the pump(s).

END OF SECTION 11937

MANUFACTURER'S CERTIFICATE OF PROPER INSTALLATION

OWNER:

EQPT SERIAL NO:

EQUPT TAG NO:

EQPT/SYSTEM:

PROJECT NO:

SPEC. SECTION:

I hereby certify that the above-referenced equipment/system has been:

(Check Applicable)

Installed in accordance with Manufacturer's recommendations.

Inspected, checked, and adjusted.

Serviced with proper initial lubricants.

Electrical and mechanical connections meet quality and safety standards.

All applicable safety equipment has been properly installed.

System has been performance tested, and meets or exceeds specified

performance requirements. (When complete system of one manufacturer)

Comments:

I, the undersigned Manufacturer's Representative, hereby certify that I am (i) a duly authorized

representative of the manufacturer, (ii) empowered by the manufacturer to inspect, approve,

and operate his equipment and (iii) authorized to make recommendations required to assure

that the equipment furnished by the manufacturer is complete and operational, except as may

be otherwise indicated herein. I further certify that all information contained herein is true and

accurate.

Date:

Manufacturer:

By Manufacturers Authorized Representative:

(Authorized Signature)

[PAGE LEFT INTENTIONALLY BLANK]

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Audit Checklist Master-HEMSA - June2010Dokument6 SeitenAudit Checklist Master-HEMSA - June2010jkhgvdj mnhsnjkhgNoch keine Bewertungen

- 7 React Redux React Router Es6 m7 SlidesDokument19 Seiten7 React Redux React Router Es6 m7 Slidesaishas11Noch keine Bewertungen

- Gas Chromatography - COLIN F. POOLE 2012 PDFDokument743 SeitenGas Chromatography - COLIN F. POOLE 2012 PDFVo Manh Tien100% (1)

- ISO 5211 Drilling Patterns Imperial SizesDokument1 SeiteISO 5211 Drilling Patterns Imperial Sizesjkhgvdj mnhsnjkhgNoch keine Bewertungen

- NRSPDokument27 SeitenNRSPMuhammad Farhan67% (3)

- Wargames Illustrated #115Dokument64 SeitenWargames Illustrated #115Анатолий Золотухин100% (1)

- API 608 Floating Ball ValvesDokument2 SeitenAPI 608 Floating Ball Valvesjkhgvdj mnhsnjkhgNoch keine Bewertungen

- API 608 Floating Ball ValvesDokument2 SeitenAPI 608 Floating Ball Valvesjkhgvdj mnhsnjkhgNoch keine Bewertungen

- 12v 6a 92 4w Tec 12706 Thermoelectric Cooler PeltierDokument5 Seiten12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltierjkhgvdj mnhsnjkhgNoch keine Bewertungen

- 12v 6a 92 4w Tec 12706 Thermoelectric Cooler PeltierDokument5 Seiten12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltierjkhgvdj mnhsnjkhgNoch keine Bewertungen

- 12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltier PDFDokument5 Seiten12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltier PDFjkhgvdj mnhsnjkhgNoch keine Bewertungen

- En 12201Dokument33 SeitenEn 12201jkhgvdj mnhsnjkhgNoch keine Bewertungen

- Cantilever Retaining Wall Design PDFDokument2 SeitenCantilever Retaining Wall Design PDFjkhgvdj mnhsnjkhgNoch keine Bewertungen

- 12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltier PDFDokument5 Seiten12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltier PDFjkhgvdj mnhsnjkhgNoch keine Bewertungen

- Handling PigBasket GADokument1 SeiteHandling PigBasket GAjkhgvdj mnhsnjkhgNoch keine Bewertungen

- 12v 6a 92 4w Tec 12706 Thermoelectric Cooler PeltierDokument5 Seiten12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltierjkhgvdj mnhsnjkhgNoch keine Bewertungen

- ASTM Method D1945-96: Analysis of Natural GasDokument1 SeiteASTM Method D1945-96: Analysis of Natural GasJosep JaamNoch keine Bewertungen

- Tip Sheet 9 Web Version DocumentDokument2 SeitenTip Sheet 9 Web Version DocumentKarun NooneyNoch keine Bewertungen

- Tolerancesspecifications & DimensionsDokument1 SeiteTolerancesspecifications & DimensionswernhowNoch keine Bewertungen

- MSG 00018Dokument7 SeitenMSG 00018jkhgvdj mnhsnjkhgNoch keine Bewertungen

- Indian Standards For Natural Gas Pipeline SystemDokument5 SeitenIndian Standards For Natural Gas Pipeline SystemNapidduNoch keine Bewertungen

- LowVoltage Feb19thDokument6 SeitenLowVoltage Feb19thShreyas EsheNoch keine Bewertungen

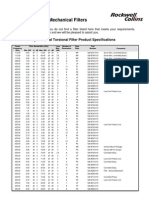

- Collins Torsional Mechanical Filters: Symmetrical Torsional Filter Product SpecificationsDokument2 SeitenCollins Torsional Mechanical Filters: Symmetrical Torsional Filter Product SpecificationsGdfsndh GfdvhjzdNoch keine Bewertungen

- BZC 14Dokument1 SeiteBZC 14jkhgvdj mnhsnjkhgNoch keine Bewertungen

- Lawctd 603Dokument5 SeitenLawctd 603Nguyen Anh TuanNoch keine Bewertungen

- Semiconductor DevicesDokument524 SeitenSemiconductor Devicesapuinwork100% (1)

- 05120Dokument4 Seiten05120jkhgvdj mnhsnjkhgNoch keine Bewertungen

- File 1361847746Dokument8 SeitenFile 1361847746jkhgvdj mnhsnjkhgNoch keine Bewertungen

- Datasheet 1mbhDokument5 SeitenDatasheet 1mbhnguanjukNoch keine Bewertungen

- Carmagen 6 10Dokument3 SeitenCarmagen 6 10ikhleifNoch keine Bewertungen

- 164200252Dokument92 Seiten164200252jkhgvdj mnhsnjkhgNoch keine Bewertungen

- 0871Dokument1 Seite0871jkhgvdj mnhsnjkhgNoch keine Bewertungen

- Material GradesDokument2 SeitenMaterial Gradespankaj_pawar89Noch keine Bewertungen

- 570 Examination Sample ItemsDokument3 Seiten570 Examination Sample ItemsMaria_Victoria_5742Noch keine Bewertungen

- List of DEA SoftwareDokument12 SeitenList of DEA SoftwareRohit MishraNoch keine Bewertungen

- Research of William Wells at HarvardDokument10 SeitenResearch of William Wells at HarvardARGHA MANNANoch keine Bewertungen

- Working With Session ParametersDokument10 SeitenWorking With Session ParametersyprajuNoch keine Bewertungen

- PSAII Final EXAMDokument15 SeitenPSAII Final EXAMdaveadeNoch keine Bewertungen

- © 2020 Lippincott Advisor Nursing Care Plans For Medical Diagnoses - Coronavirus Disease 2019 (COVID 19) PDFDokument7 Seiten© 2020 Lippincott Advisor Nursing Care Plans For Medical Diagnoses - Coronavirus Disease 2019 (COVID 19) PDFVette Angelikka Dela CruzNoch keine Bewertungen

- Mehdi Semati - Media, Culture and Society in Iran - Living With Globalization and The Islamic State (Iranian Studies)Dokument294 SeitenMehdi Semati - Media, Culture and Society in Iran - Living With Globalization and The Islamic State (Iranian Studies)Alexandra KoehlerNoch keine Bewertungen

- Chapter 1Dokument2 SeitenChapter 1Nor-man KusainNoch keine Bewertungen

- Self-Learning Module in General Chemistry 1 LessonDokument9 SeitenSelf-Learning Module in General Chemistry 1 LessonGhaniella B. JulianNoch keine Bewertungen

- Product Data: T T 13 SEER Single - Packaged Heat Pump R (R - 410A) RefrigerantDokument36 SeitenProduct Data: T T 13 SEER Single - Packaged Heat Pump R (R - 410A) RefrigerantJesus CantuNoch keine Bewertungen

- Programming Language II CSE-215: Dr. Mohammad Abu Yousuf Yousuf@juniv - EduDokument34 SeitenProgramming Language II CSE-215: Dr. Mohammad Abu Yousuf Yousuf@juniv - EduNaruto DragneelNoch keine Bewertungen

- Lte Numbering and AddressingDokument3 SeitenLte Numbering and AddressingRoderick OchiNoch keine Bewertungen

- Veolia Moray Outfalls Repair WorksDokument8 SeitenVeolia Moray Outfalls Repair WorksGalih PutraNoch keine Bewertungen

- Trabajo de Investigación FormativaDokument75 SeitenTrabajo de Investigación Formativalucio RNoch keine Bewertungen

- Modification Adjustment During Upgrade - Software Logistics - SCN WikiDokument4 SeitenModification Adjustment During Upgrade - Software Logistics - SCN Wikipal singhNoch keine Bewertungen

- Online Music Courses With NifaDokument5 SeitenOnline Music Courses With NifagksamuraiNoch keine Bewertungen

- Cats - CopioniDokument64 SeitenCats - CopioniINES ALIPRANDINoch keine Bewertungen

- Reaction CalorimetryDokument7 SeitenReaction CalorimetrySankar Adhikari100% (1)

- Sheet (1) : An Iron Ring Has A Cross-Sectional Area of 3 CMDokument2 SeitenSheet (1) : An Iron Ring Has A Cross-Sectional Area of 3 CMKhalifa MohamedNoch keine Bewertungen

- Foundry Technology GuideDokument34 SeitenFoundry Technology GuidePranav Pandey100% (1)

- tsb16 0008 PDFDokument1 Seitetsb16 0008 PDFCandy QuailNoch keine Bewertungen

- Amma dedicates 'Green Year' to environmental protection effortsDokument22 SeitenAmma dedicates 'Green Year' to environmental protection effortsOlivia WilliamsNoch keine Bewertungen

- Online Music QuizDokument3 SeitenOnline Music QuizGiang VõNoch keine Bewertungen

- Chapter 2 Literature ReviewDokument10 SeitenChapter 2 Literature ReviewSharan BvpNoch keine Bewertungen

- UK Commutator Maintenance CatalogueDokument9 SeitenUK Commutator Maintenance CatalogueCarlosNoch keine Bewertungen

- Optimum Work Methods in The Nursery Potting ProcessDokument107 SeitenOptimum Work Methods in The Nursery Potting ProcessFöldi Béla100% (1)

- Bonding in coordination compoundsDokument65 SeitenBonding in coordination compoundsHitesh vadherNoch keine Bewertungen