Beruflich Dokumente

Kultur Dokumente

Power Transformers MS 009

Hochgeladen von

Showki WaniOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Power Transformers MS 009

Hochgeladen von

Showki WaniCopyright:

Verfügbare Formate

METHOD STATEMENT FOR INSTALLATION OF

POWER TRANSFORMER

POWER GENERATION & DISTRIBUTION FACILITY

AT DALEEL FIELD(DALEEL 06-255)

Document ref: No.:

LTEM/DP/MS/ELE-09 Rev.0

Page No 1 of 6

METHOD STATEMENT

FOR

INSTALLATION OF POWER TRANSFORMER

Prepared By

(LTEM)

Reviewed

By

(LTEM)

Approved

by

(LTEM)

Approved

By

(Daleel)

Name

Date

G. Prasanth Kumar

Reddy

5.4.2

011

Devraj Kingsly

5.4.2

011

P.GovindRaj

6.4.2

011

Yousuf Al Harooni

Signature

METHOD STATEMENT FOR INSTALLATION OF

POWER TRANSFORMER

POWER GENERATION & DISTRIBUTION FACILITY

AT DALEEL FIELD(DALEEL 06-255)

LIST OF CONTENTS

1. PURPOSE

2. SCOPE

3. DOCUMENT REFERENCE

4. TOOLS AND PLANTS REQUIRED

5. RESPONSIBILITIES

6. PROCEDURE

7. INSPECTION AND TESTING

8. SAFETY

Document ref: No.:

LTEM/DP/MS/ELE-09 Rev.0

Page No 2 of 6

METHOD STATEMENT FOR INSTALLATION OF

POWER TRANSFORMER

POWER GENERATION & DISTRIBUTION FACILITY

AT DALEEL FIELD(DALEEL 06-255)

Document ref: No.:

LTEM/DP/MS/ELE-09 Rev.0

Page No 3 of 6

1.0 PURPOSE

The purpose of this method statement is to describe the procedure to be adopted

during installation of Power Transformer.

2.0 SCOPE

This procedure shall be applicable for installation and pre-commissioning of Power

Transformer of EPC of POWER GENERATION DISTRIBUTION SYSTEM at Daleel

Field.

3.0 REFERENCE

1.

2.

3.

4.

5.

Contract documents

General arrangement Drawings

Manufacturers Installation Manual

Vendor Drawing

Operation and Maintenance Manual

Any modification done as per the site condition apart from the \ifc shall be

incorporated in as built drawing.

4.0 TOOLS AND PLANTS REQUIRED

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

Oil Filtration Machine

7 ton truck

50 ton crane

Secondary Injection Kit

BDV testing Kit

Winding Resistance tester

Multimeter FLUKE MAKE

Megger 5000v

Cable jointing tool kit

Tool Box

Crimping Tool &Die Set

Torque Wrench

Compound Gauge

Temperature Gauge.

5.0 RESPONSIBLITY

5.1 QA/QC ENGINEER

a.

b.

Ensure all materials are inspected prior to utilizing at site.

Ensure the availability of required technical documents like approved method

statement, IFC Drawings at work place.

METHOD STATEMENT FOR INSTALLATION OF

POWER TRANSFORMER

Document ref: No.:

LTEM/DP/MS/ELE-09 Rev.0

POWER GENERATION & DISTRIBUTION FACILITY

AT DALEEL FIELD(DALEEL 06-255)

c.

d.

e.

Page No 4 of 6

Responsible for carrying out Stage inspections and surveillance inspections in

accordance with ITP and as per the project requirement.

Ensure the work is done by the qualified person (Ex. Cable Jointer).

Responsible for ensuring the all Testing activities are according to project

requirement.

5.2 ELECTRICAL ENGINEER

Electrical Engineer shall be overall responsible for the safe execution of

complete activity including but not limited to.

a.

b.

c.

d.

Conforming the installation works as per the schedule.

Organizing tools and equipment required for the work.

Assigning work crew.

Conforming the materials handling in safe manner.

5.3 SAFETY SUPERVISOR

The Safety supervisor shall be responsible for safe execution at site.

a. Ensure for effective tool box talk.

b. Ensure all the PPEs are available at site and are using correct PPE.

c. Ensure the first aid box available at site.

d. Ensure the adequate fire extinguishers are available at site.

e. Ensure the required warning signs and boards are available at necessary place

f. Ensure only required people are available at site.

6.0 PROCEDURE POWER TRANSFORMER INSTALLATION

6.1 General Requirements

-

Ensure the Transformer has been inspected and approved by Client.

Transformer installation, testing &commissioning work will be carried out as per the

Client &Vendor recommendation.

Under any circumstances the Power Transformer shall not be forcefully handled.

House Keeping will be done on daily basis.

6.2 Visual Inspection

After receiving the equipments it shall be inspected at store for any abnormalities

and damages. If anything found it shall be reported to Contract Manager/Stores for

necessary action.

-

Locations of cables entry for equipments shall be visually inspected with respect to

trenches, switch racks.

6.3 INSTALLATION OF POWER AND AUXILLARY TRANSFORMER

METHOD STATEMENT FOR INSTALLATION OF

POWER TRANSFORMER

POWER GENERATION & DISTRIBUTION FACILITY

AT DALEEL FIELD(DALEEL 06-255)

Document ref: No.:

LTEM/DP/MS/ELE-09 Rev.0

Page No 5 of 6

Transformer shall be either collected from the stores or other place, or received

directly from manufacturers works.

After receiving the equipments inspect for any abnormalities and damages, If any,

inform LTEM Construction Manager / Stores for necessary action.

The foundation for transformer shall be made ready before installation. Verify the

cable entry for HV, LV and control cables as per approved drawings.

Transformer weighing more than 30 tons is normally installed by specialized

erection contractor. Transformer up to 30 tons is installed by LTEM using the crane

and other lifting facilities.

Transformer shall be positioned centrally on foundation blocks, and clearances shall

be checked.

Transformer shall be finally positioned for line and level to the dimensions given in

the drawings.

Care shall be taken in positioning in relation to cable, cable duct and busbar

trunking positions.

Transformer more than 10MVA capacity are supplied with main tank separately.

Radiators and conservators and topping up oil will be supplied in separate

containers/drums.

Once the transformer is on foundation, oil in drums for topping up is tested for its

BDV and the values recorded against drum no. The top, bottom and OLTC sample

is taken and BDV recorded. If the above values are accepted, assembling of

radiators and conservator tank can be started.

It is recommended; the filling of oil shall be through a vacuum filtration plant with

heating facilities and filtered. Oil shall be circulated at least 24 hrs or until oil temp

reaches steady state value.

BDV of oil is verified once the filtration plant is off and the value recorded. Once the

transformer is cooled to ambient temp oil level is adjusted as per manufacturers

recommendation.

Trapped air in the main tank, radiators, OLTC tank is released through the air

release plugs provided. All valves except sampling & drain valves shall be opened.

HV, LV and Control cabling as applicable and terminations shall be completed as

per approved schedule.

Earthing of transformer body and neutral shall be completed.

METHOD STATEMENT FOR INSTALLATION OF

POWER TRANSFORMER

POWER GENERATION & DISTRIBUTION FACILITY

AT DALEEL FIELD(DALEEL 06-255)

Document ref: No.:

LTEM/DP/MS/ELE-09 Rev.0

Page No 6 of 6

6.4 Verification Documents

- Approved Drawings

7.0

INSPECTION AND TESTING

- Transformer Visual inspection and Storage condition.

- Transformer installation inspection as per Construction Check Sheet for Power and

Auxiliary Transformer Form No.11, 17.

- Transformer Pre-commissioning Tests as per Functional Test Sheet for Power and

Auxiliary Transformer Form No 28, 35, and 36.

8.0

-

SAFETY

Ensure that all PPEs are available with the crew involved in the job.

All equipment and tools should be checked before starting of the activity for

suitability and integrity.

Ensure that housekeeping is being carried out before and after work on a daily

basis.

Das könnte Ihnen auch gefallen

- Ch1,2,3 QuestionsDokument56 SeitenCh1,2,3 QuestionsShowki WaniNoch keine Bewertungen

- Risk MatrixDokument1 SeiteRisk MatrixShowki WaniNoch keine Bewertungen

- Add Your Title: Option Optio NDokument6 SeitenAdd Your Title: Option Optio NJoy BanikNoch keine Bewertungen

- Construction Delay Analysis Which Method UseDokument4 SeitenConstruction Delay Analysis Which Method UsetarekZADNoch keine Bewertungen

- Add Your Title: Option Optio NDokument6 SeitenAdd Your Title: Option Optio NJoy BanikNoch keine Bewertungen

- SCL Delay Protocol 2nd Edition FinalDokument84 SeitenSCL Delay Protocol 2nd Edition FinalJailanee ImakNoch keine Bewertungen

- MS-Installation 11Kv Switch Gear at Lusail-CP1Dokument6 SeitenMS-Installation 11Kv Switch Gear at Lusail-CP1Tayab Ansari100% (2)

- Final Showkat RMP QuestionsDokument22 SeitenFinal Showkat RMP QuestionsShowki WaniNoch keine Bewertungen

- Risk Management Activities For Small ProjectsDokument1 SeiteRisk Management Activities For Small ProjectsShowki WaniNoch keine Bewertungen

- Fit Ot 27-09Dokument1 SeiteFit Ot 27-09Showki WaniNoch keine Bewertungen

- LQ Form 1 Extension of Time V3 June 2015 PDFDokument1 SeiteLQ Form 1 Extension of Time V3 June 2015 PDFShowki WaniNoch keine Bewertungen

- Risk Management Register SampleDokument3 SeitenRisk Management Register SampleFabiano DamascenoNoch keine Bewertungen

- Most Confused Questions July-2019Dokument35 SeitenMost Confused Questions July-2019Showki Wani100% (1)

- Fit Ot 27-09Dokument1 SeiteFit Ot 27-09Showki WaniNoch keine Bewertungen

- Target Milestone Dates: 3.2.7 Cost/Resource LoadingDokument10 SeitenTarget Milestone Dates: 3.2.7 Cost/Resource LoadingShowki WaniNoch keine Bewertungen

- Fire Booster Sets - 30!08!07Dokument20 SeitenFire Booster Sets - 30!08!07Mahipal Singh RaoNoch keine Bewertungen

- Structured Cabling For CommunicationsDokument18 SeitenStructured Cabling For CommunicationsShowki Wani100% (3)

- SKA Project Execution PlanDokument234 SeitenSKA Project Execution PlanShowki Wani100% (2)

- PDOC 596 PEP 01 Project Execution Plan Rev 3Dokument90 SeitenPDOC 596 PEP 01 Project Execution Plan Rev 3Showki Wani80% (5)

- PDOC 596 PEP 01 Project Execution Plan Rev 3Dokument90 SeitenPDOC 596 PEP 01 Project Execution Plan Rev 3Showki Wani80% (5)

- WCCC Review CPM Schedules With P3ec 5Dokument70 SeitenWCCC Review CPM Schedules With P3ec 5Jijo PjNoch keine Bewertungen

- YPC Outreach TexasStateDokument54 SeitenYPC Outreach TexasStateShowki WaniNoch keine Bewertungen

- UploadDokument1 SeiteUploadShowki WaniNoch keine Bewertungen

- InstallationDokument6 SeitenInstallationpukazhendhiNoch keine Bewertungen

- DOE Guidance WBSDokument20 SeitenDOE Guidance WBSShowki WaniNoch keine Bewertungen

- Cdsub 65Dokument10 SeitenCdsub 65Showki WaniNoch keine Bewertungen

- Vowels: Hindi Varnamala HDokument2 SeitenVowels: Hindi Varnamala HShowki WaniNoch keine Bewertungen

- P6 Filters Most Used in Schedule ReportingDokument25 SeitenP6 Filters Most Used in Schedule ReportingShowki WaniNoch keine Bewertungen

- Why Does P6 Does Not Show Dates of The Updated Program Correctly If It Is Set As A BaselineDokument2 SeitenWhy Does P6 Does Not Show Dates of The Updated Program Correctly If It Is Set As A BaselineShowki WaniNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Specs PyrostopDokument7 SeitenSpecs PyrostopfakemasterkgpNoch keine Bewertungen

- Profil - Ball - Return AMF 82-90XL PDFDokument48 SeitenProfil - Ball - Return AMF 82-90XL PDFblurmuruganNoch keine Bewertungen

- Himel Productos 10 1Dokument58 SeitenHimel Productos 10 1yasserfouda100% (1)

- SAP Fiori ArchitectureDokument4 SeitenSAP Fiori ArchitectureaunhavcNoch keine Bewertungen

- Thesis - 051 Chapter 5 Case Study PDFDokument19 SeitenThesis - 051 Chapter 5 Case Study PDFpiangphet100% (1)

- Granite Products For Architecture and Landscape - Catalog (Blackhill Granites)Dokument19 SeitenGranite Products For Architecture and Landscape - Catalog (Blackhill Granites)Julia CampbellNoch keine Bewertungen

- (1931) Year Book of The Archite - Architectural League of New Yor PDFDokument718 Seiten(1931) Year Book of The Archite - Architectural League of New Yor PDFCHNoch keine Bewertungen

- Boiler Output Chart PDFDokument4 SeitenBoiler Output Chart PDFUsaid KhanNoch keine Bewertungen

- Importance of ByelawsDokument10 SeitenImportance of ByelawsPALKI GHAINoch keine Bewertungen

- Pre Insulated Piping Sytem HDPEDokument15 SeitenPre Insulated Piping Sytem HDPEVincent SablanNoch keine Bewertungen

- RegistryDokument4 SeitenRegistryRajan KhandelwalNoch keine Bewertungen

- Making Ubuntu Unity Look Beautiful by Enabling TransparencyDokument3 SeitenMaking Ubuntu Unity Look Beautiful by Enabling TransparencyEnlighten LightNoch keine Bewertungen

- Case Study - Floating HousesDokument6 SeitenCase Study - Floating HousesAkari MeiNoch keine Bewertungen

- How To Implement Cisco Unified SRST and MGCP Fallback - Cisco Support CommunityDokument3 SeitenHow To Implement Cisco Unified SRST and MGCP Fallback - Cisco Support CommunityRamakrishnan PisharodyNoch keine Bewertungen

- V061E12 NT Support Tool V4.6 Operation ManualDokument565 SeitenV061E12 NT Support Tool V4.6 Operation ManualRashid BasironNoch keine Bewertungen

- E3 ODE PRO Installation Manual v1.23Dokument18 SeitenE3 ODE PRO Installation Manual v1.23ハルァン ファ烏山Noch keine Bewertungen

- ENSC427 Team6 ReportDokument22 SeitenENSC427 Team6 ReportAnonymous TTVlXoNoch keine Bewertungen

- Chapter-8 (Cavity Wall)Dokument17 SeitenChapter-8 (Cavity Wall)Susma DotelNoch keine Bewertungen

- 1633725Dokument407 Seiten1633725AnoopBinuNoch keine Bewertungen

- Administrators Guide For PVSDokument261 SeitenAdministrators Guide For PVSnntien9Noch keine Bewertungen

- Art and Architecture of The Council of Europe in StrasbourgDokument2 SeitenArt and Architecture of The Council of Europe in StrasbourgCouncil of EuropeNoch keine Bewertungen

- Oscg Odoo en Simp 2015Dokument41 SeitenOscg Odoo en Simp 2015Drago K.Noch keine Bewertungen

- E1 Lab 11 5 5Dokument19 SeitenE1 Lab 11 5 5Chris LeeNoch keine Bewertungen

- GE Centricity RIS IC Solutions With VMware Site Recovery Manager WPDokument23 SeitenGE Centricity RIS IC Solutions With VMware Site Recovery Manager WPvijay_kurraNoch keine Bewertungen

- Garsia SolutionDokument7 SeitenGarsia SolutiongaghanbarianNoch keine Bewertungen

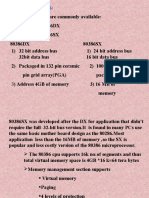

- Architecture of 80386 MicroproDokument39 SeitenArchitecture of 80386 MicroproDeepthiNoch keine Bewertungen

- Works of Pioneer Architects PDFDokument23 SeitenWorks of Pioneer Architects PDFKimNoch keine Bewertungen

- Introduction To KliaDokument9 SeitenIntroduction To Kliaanis100% (2)

- Types of FurnitureDokument19 SeitenTypes of FurnitureRuthNoch keine Bewertungen

- 04 MasonryDokument34 Seiten04 MasonrySajay PajarillagaNoch keine Bewertungen