Beruflich Dokumente

Kultur Dokumente

1.4.2 Resource Center Sample Spec Knockout Tank Spec 6.02

Hochgeladen von

jkhgvdj mnhsnjkhgCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

1.4.2 Resource Center Sample Spec Knockout Tank Spec 6.02

Hochgeladen von

jkhgvdj mnhsnjkhgCopyright:

Verfügbare Formate

ISCO INDUSTRIES LLC

SPECIFICATION for

HDPE METHANE CONDENSATE SUMPS (KO TANKS)

1. GENERAL

This specification shall govern the materials and fabrication of Methane

Condensate Filter Sumps or Knockout Tanks, herein referred to as KO Tanks.

2. SCOPE

The contract covers the materials and fabrication of KO Tanks.

3. MATERIALS

3.1

HDPE MATERIAL SPECIFICATION - The KO Tanks shall be made

from high density polyethylene (HDPE) resin meeting the following

requirements:

3.1.1

HDPE MATERIAL - The HDPE material supplied under this

specification shall be high density, high molecular weight, HDPE

material supplied by ISCO Industries LLC. The HDPE material

shall conform to ASTM D 3350 with a minimum cell classification

value of 345464C. All pipe and fittings supplied shall be equal to

HDPE material, which meets this same specification.

3.1.2

PHYSICAL PROPERTIES OF HDPE COMPOUND

3.1.2.1 Density - the density shall be no less than 0.955 gms/ccm as

referenced in ASTM D 1505.

3.1.2.2 Melt Index - the melt index shall be no greater than 0.15

gms/10 minutes when tested in accordance with ASTM D

1238- Condition 3.2.3.

3.1.2.3 Flex Modulus - flexural modulus shall be 110,000 to less

than 160,000 psi as referenced in ASTM D 790.

3.1.2.4 Tensile Strength at yield - tensile strength shall be 3,200 to

less than 3,500 psi as referenced in ASTM D 638.

3.1.2.5 Slow Crack Growth Resistance shall be per ASTM F 1473

(PENT test). The results shall be greater than 100 hours.

3.1.2.6 Hydrostatic Design Basis shall be 1,600 psi at 23 degrees C

when tested in accordance with ASTM D 2837.

ISCO Industries LLC 926 Baxter Avenue Louisville, KY 40204 (800) 345-ISCO July 31, 2010 Page 1 of 4

3.2

DEVIATIONS - If a contractor chooses to submit a bid that does not meet

all of the requirements of this specification, his bid shall include a written

description of the deviations with data that show the magnitude of the

deviations and the justification for the deviation from the specification.

The decision to accept material deviating from this specification shall be

the responsibility of the specifying engineer.

3.2

THIRD PARTY TESTING - The owner or the specifying engineer may

request certified lab data to verify the physical properties of materials not

meeting the requirements of this specification.

4. SUBMITTALS AND QUALITY ASSURANCE

4.1 QA/QC CERTIFICATION4.1.1 The KO Tank supplier shall submit certification that the HDPE material

meets the specifications.

4.1.2 The fabricator of the KO Tank shall submit drawings showing the position

of the inlets, outlets and the overall dimensions along with any other

special features such as sight glass, pressure gage, demister pad etc.

4.1.3 The fabricator shall submit data indicating that the buried condensate tanks

meet the requirements of ASTM F 1759, Design of High Density

Polyethylene (HDPE) Manholes for Subsurface Applications. The tanks

should be proven to have acceptable design for burial and groundwater

loading conditions. Calculations supporting these requirements will be

part of the submittal package.

4.1.4 The fabrication technician shall perform work in accordance to butt fusion

of high-density polyethylene per ASTM F 2620 and for extrusion and hot

air welding per ASTM C 1147. The fabricator shall submit the written

quality assurance program used during fabrication of the manholes. The

fabricator may be required to submit their overall QA/QC program for

fabricating thermoplastic structures, the welding certification program for

the fabrication technician, and the facility safety program.

4.1.5 The structure shall be tested with water or air when required. A written

certification shall be sent to the engineer certifying the manholes are leak

free. The test results shall become part of the submittals. An identification

plate indicating, the job number, testing data, and when built and by

whom, shall be attached to the manhole.

4.2 Approval or Rejection

4.2.1 Written approval or rejection of substitution given by the ENGINEER.

4.2.2 ENGINEER reserves he right to require proposed product to comply with

any or all requirements of specified product.

4.2.3 In the event substitution results in a change of Contract Price or time,

provisions in the Agreement will be applied for adjustment.

ISCO Industries LLC 926 Baxter Avenue Louisville, KY 40204 (800) 345-ISCO July 31, 2010 Page 2 of 4

4.2.4 Substitutions will be rejected if:

4.2.4.1 Submittal is not through the CONTRACTOR with his stamp or

approval.

4.2.4.2 Requests are not made in accordance with this Section.

4.2.4.3 In the ENGINEERS opinion, acceptance will require substantial

revision of the original design.

4.2.4.4 In the ENGINEERS opinion, substitution is not equal to original

product specified or will not perform adequately the function for which

it is intended.

4.3 THIRD PARTY TESTING-The owner or the specifying engineer may request

certified lab data to verify the physical properties of materials not meeting the

requirements of this specification.

4.4 DEVIATIONS- Procedure for requesting substitute

4.4.1 Consider after award of Contract.

4.4.2 A letter defining the deviation and justification must be sent to the

engineer. The letter must identify:

4.4.2.1 The Product

4.4.2.2 Manufacturers Name

4.4.2.3 Representative Contact Name and Telephone Number

4.4.2.4 Specification Section or drawing reference of originally specified

product

4.4.2.5 Discrete name or tag number assigned to original product in the

Contract Document.

4.4.3 Manufacturers literature clearly marked to show compliance of proposed

product with Contract Document.

4.4.4 Itemize comparison of original and proposed product addressing product

characteristics including but not necessarily limited to:

4.4.4.1 Size

4.4.4.2 Composition or material of construction

4.4.4.3 Weight

4.4.4.4 Electrical or mechanical requirements

4.4.4.5 Product Experience:

4.4.4.5.1 Location of past projects utilizing product

4.4.4.5.2 Name and telephone numbers of persons associated with

referenced projects knowledgeable concerning proposed

product.

4.4.4.5.3 Available field data and reports associated with proposed

products

4.4.4.6 Data relating to changes in construction schedule

4.4.4.7 Data relating to changes in cost.

4.4.4.8 Samples: At request of the Engineer, a full size sample may be

required. This sample maybe held by the Engineer until completion of

the project.

ISCO Industries LLC 926 Baxter Avenue Louisville, KY 40204 (800) 345-ISCO July 31, 2010 Page 3 of 4

4.5 REJECTION The high-density polyethylene manholes may be rejected for

failure to meet any of the requirements of this specification.

5. KO TANKS DETAILS

5.1

The body of the KO Tanks shall be fabricated from HDPE solid wall pipe,

with a nominal OD of 48" and DR of 32.5, extruded according to ASTM

F714. Rotational molded sections or wall thickness of less than 1.25" will

not be accepted.

5.2

The top of the KO Tanks shall be flanged for easy access. A forty-four

hole bolt pattern flange using one inch bolts will be used to secure the top.

The top will be 1.5" HDPE sheet. The seal at the top shall use a neoprene

gasket. The bottoms of the KO Tanks shall be 1.5" thick and extrusion

welded to the body.

5.3

The inlets and outlets shall be extrusion welded on the inside and outside

of the structure using good welding practice. Gussets shall be attached at

90 degrees, 180 degrees, 270 degrees, and 360 degrees around the inlets

and outlets. All KO Tanks connections larger than 4 nominal OD pipe

shall be butt fusion welded, electrofusion welded or flanged connections.

For 4 OD pipe and smaller, a threaded transition fitting can also be used

as well as the acceptable connections listed above.

5.4

KO Tanks shall be tested with 2 psi air by the fabricator and certified to

have leak free welds. Data will be supplied with the submittal. The owner

or his representative may request to observe the test.

ISCO Industries, LLC has carefully checked the accuracy and standards used in the preparation of these

sample specifications, it does not guarantee or warranty piping or manhole installations. Sample

specifications are to be used as a guide to assist engineers and owners of piping systems containing HDPE

manholes. Sample specifications do not cover all situations or applications. These specifications are not

intended to provide installation training or instructions. Since every job is different, a trained professional

engineer should be used to determine the needs of a particular job.

TECHNICAL DISCLAIMER: As used in this paragraph, Technical Information includes; but is not

limited to, technical advice, recommendations, testing, or analysis. The information in this document does

not constitute a guarantee or warranty for piping installations or products and cannot be guaranteed due to

conditions outside the control of ISCO Industries, LLC. It is vital that you test the information and products

to determine whether the information or product is suitable for your intended use and application. The use

of this document is not intended to replace the evaluation and judgment of a professional competent in this

field. Permanent field installations should be done only by those who have been properly trained and

certified as qualified. The user of this information expressly assumes and releases ISCO Industries, LLC

from all risk and liability, whether based in contract, tort, or otherwise in connection with the results

obtained for the information provided.

ISCO Industries LLC 926 Baxter Avenue Louisville, KY 40204 (800) 345-ISCO July 31, 2010 Page 4 of 4

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- 12v 6a 92 4w Tec 12706 Thermoelectric Cooler PeltierDokument5 Seiten12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltierjkhgvdj mnhsnjkhgNoch keine Bewertungen

- API 608 Floating Ball ValvesDokument2 SeitenAPI 608 Floating Ball Valvesjkhgvdj mnhsnjkhgNoch keine Bewertungen

- Cantilever Retaining Wall Design PDFDokument2 SeitenCantilever Retaining Wall Design PDFjkhgvdj mnhsnjkhgNoch keine Bewertungen

- En 12201Dokument33 SeitenEn 12201jkhgvdj mnhsnjkhgNoch keine Bewertungen

- 12v 6a 92 4w Tec 12706 Thermoelectric Cooler PeltierDokument5 Seiten12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltierjkhgvdj mnhsnjkhgNoch keine Bewertungen

- Tip Sheet 9 Web Version DocumentDokument2 SeitenTip Sheet 9 Web Version DocumentKarun NooneyNoch keine Bewertungen

- 12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltier PDFDokument5 Seiten12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltier PDFjkhgvdj mnhsnjkhgNoch keine Bewertungen

- API 608 Floating Ball ValvesDokument2 SeitenAPI 608 Floating Ball Valvesjkhgvdj mnhsnjkhgNoch keine Bewertungen

- 12v 6a 92 4w Tec 12706 Thermoelectric Cooler PeltierDokument5 Seiten12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltierjkhgvdj mnhsnjkhgNoch keine Bewertungen

- 12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltier PDFDokument5 Seiten12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltier PDFjkhgvdj mnhsnjkhgNoch keine Bewertungen

- ISO 5211 Drilling Patterns Imperial SizesDokument1 SeiteISO 5211 Drilling Patterns Imperial Sizesjkhgvdj mnhsnjkhgNoch keine Bewertungen

- ASTM Method D1945-96: Analysis of Natural GasDokument1 SeiteASTM Method D1945-96: Analysis of Natural GasJosep JaamNoch keine Bewertungen

- LowVoltage Feb19thDokument6 SeitenLowVoltage Feb19thShreyas EsheNoch keine Bewertungen

- Handling PigBasket GADokument1 SeiteHandling PigBasket GAjkhgvdj mnhsnjkhgNoch keine Bewertungen

- Audit Checklist Master-HEMSA - June2010Dokument6 SeitenAudit Checklist Master-HEMSA - June2010jkhgvdj mnhsnjkhgNoch keine Bewertungen

- MSG 00018Dokument7 SeitenMSG 00018jkhgvdj mnhsnjkhgNoch keine Bewertungen

- Lawctd 603Dokument5 SeitenLawctd 603Nguyen Anh TuanNoch keine Bewertungen

- Tolerancesspecifications & DimensionsDokument1 SeiteTolerancesspecifications & DimensionswernhowNoch keine Bewertungen

- BZC 14Dokument1 SeiteBZC 14jkhgvdj mnhsnjkhgNoch keine Bewertungen

- File 1361847746Dokument8 SeitenFile 1361847746jkhgvdj mnhsnjkhgNoch keine Bewertungen

- Carmagen 6 10Dokument3 SeitenCarmagen 6 10ikhleifNoch keine Bewertungen

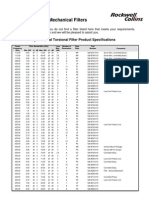

- Collins Torsional Mechanical Filters: Symmetrical Torsional Filter Product SpecificationsDokument2 SeitenCollins Torsional Mechanical Filters: Symmetrical Torsional Filter Product SpecificationsGdfsndh GfdvhjzdNoch keine Bewertungen

- 05120Dokument4 Seiten05120jkhgvdj mnhsnjkhgNoch keine Bewertungen

- Datasheet 1mbhDokument5 SeitenDatasheet 1mbhnguanjukNoch keine Bewertungen

- Semiconductor DevicesDokument524 SeitenSemiconductor Devicesapuinwork100% (1)

- Material GradesDokument2 SeitenMaterial Gradespankaj_pawar89Noch keine Bewertungen

- 164200252Dokument92 Seiten164200252jkhgvdj mnhsnjkhgNoch keine Bewertungen

- Indian Standards For Natural Gas Pipeline SystemDokument5 SeitenIndian Standards For Natural Gas Pipeline SystemNapidduNoch keine Bewertungen

- 0871Dokument1 Seite0871jkhgvdj mnhsnjkhgNoch keine Bewertungen

- 570 Examination Sample ItemsDokument3 Seiten570 Examination Sample ItemsMaria_Victoria_5742Noch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- General Architectural DraftingDokument584 SeitenGeneral Architectural Draftingayogunwusi2014100% (3)

- PHEONWJ-G-SPE-0101 0 - Structural and Piping Fabrication Quality ControlDokument11 SeitenPHEONWJ-G-SPE-0101 0 - Structural and Piping Fabrication Quality ControlIksan Adityo Mulyo100% (1)

- Certificate LetterDokument4 SeitenCertificate LetterThiyagu VasuNoch keine Bewertungen

- Technical Specification Volume II-Part IDokument244 SeitenTechnical Specification Volume II-Part Inawajha0% (1)

- Seismic Evaluation of Buildings & RetrofittingDokument17 SeitenSeismic Evaluation of Buildings & RetrofittingHage Tajang100% (1)

- Wire Reinforcement InstituteDokument6 SeitenWire Reinforcement InstituteVu NguyenNoch keine Bewertungen

- Software Testing NotesDokument164 SeitenSoftware Testing Notesvikrant_ashwarya75% (8)

- VVP Engineering Institute's Guide to Tchibechiff's Straight Line MechanismDokument14 SeitenVVP Engineering Institute's Guide to Tchibechiff's Straight Line MechanismTausif ShaikhNoch keine Bewertungen

- Multi Storey Bldg Pile Foundation DesignDokument5 SeitenMulti Storey Bldg Pile Foundation DesignIlmtalabNoch keine Bewertungen

- PCC PanelDokument9 SeitenPCC PanelSambasivarao Goriparthi0% (1)

- Hole and Shaft Basis Limits and Fits, Hole Limits and Fits, Hole and Shaft, ToleranceDokument2 SeitenHole and Shaft Basis Limits and Fits, Hole Limits and Fits, Hole and Shaft, ToleranceNagendra PrasadNoch keine Bewertungen

- QCF 42 CladdingDokument7 SeitenQCF 42 CladdingAnneBricklayerNoch keine Bewertungen

- PDH Post Tensioned Concrete Design PDFDokument8 SeitenPDH Post Tensioned Concrete Design PDFabdulmananNoch keine Bewertungen

- Final Penn Work 08 091webDokument75 SeitenFinal Penn Work 08 091webJames LowderNoch keine Bewertungen

- Section Analysis-LC 150x50x18x3.0mmDokument2 SeitenSection Analysis-LC 150x50x18x3.0mmRachelle Quilala0% (1)

- Tata ElxsiDokument185 SeitenTata ElxsiReTHINK INDIANoch keine Bewertungen

- C192PF8-RPR 0Dokument75 SeitenC192PF8-RPR 0Rolando Henry Flores CamavilcaNoch keine Bewertungen

- MS-6600 10603Dokument2 SeitenMS-6600 10603International EngineeringNoch keine Bewertungen

- B.Tech Power System Operation and Control Exam QuestionsDokument8 SeitenB.Tech Power System Operation and Control Exam QuestionsMedha AravindNoch keine Bewertungen

- Conveyors and ChutesDokument2 SeitenConveyors and ChutesGanesan Balraj50% (2)

- How To Validate Computerized SystemsDokument31 SeitenHow To Validate Computerized SystemsRahulRajGoldyNoch keine Bewertungen

- Preview of Performance Based Specifications and Control of Concrete Durability State of The Art Report RILEM TC 230 PSCDokument20 SeitenPreview of Performance Based Specifications and Control of Concrete Durability State of The Art Report RILEM TC 230 PSCSumanthNoch keine Bewertungen

- Civil Engineer Resume 1Dokument2 SeitenCivil Engineer Resume 1Nazee 122333Noch keine Bewertungen

- MGT 3202 - Engineering Management - Obe Based Course OutlineDokument13 SeitenMGT 3202 - Engineering Management - Obe Based Course OutlineMr cookNoch keine Bewertungen

- MCQsDokument53 SeitenMCQsMaddie ZonnieNoch keine Bewertungen

- Construction ProcessDokument9 SeitenConstruction ProcessSyukry Rosle100% (1)

- 12 Types of Loads Considered For Design of Bridge Structures PDFDokument11 Seiten12 Types of Loads Considered For Design of Bridge Structures PDFPritha DasNoch keine Bewertungen

- Testing Facility-Chambers and Specfication PDFDokument18 SeitenTesting Facility-Chambers and Specfication PDFAnil teaserNoch keine Bewertungen

- Mechanical Engineer Job for Locomotive DesignDokument2 SeitenMechanical Engineer Job for Locomotive DesignNaveen GNoch keine Bewertungen

- 11-Steps of Testing Process: Assess Development Plan and StatusDokument3 Seiten11-Steps of Testing Process: Assess Development Plan and StatusAbhinav DakshaNoch keine Bewertungen