Beruflich Dokumente

Kultur Dokumente

Sample: Job Safety Analysis

Hochgeladen von

HesanRajarani0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

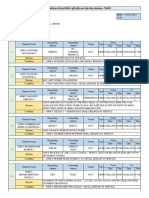

117 Ansichten5 SeitenThis document analyzes potential job safety risks and hazards that may occur during shifting operations and provides contingency plans. Key risks addressed include transport delays, missing equipment, insufficient space or equipment on site, hydraulic or electrical failures, and issues with module weight or transporter loading. Contingency plans involve spare parts, backup equipment, flexible subcontractors, early mobilization, weight checks, and emergency response procedures. The goal is to anticipate problems and have solutions in place to maintain job safety.

Originalbeschreibung:

ergkjr

Originaltitel

JSA Shifting

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document analyzes potential job safety risks and hazards that may occur during shifting operations and provides contingency plans. Key risks addressed include transport delays, missing equipment, insufficient space or equipment on site, hydraulic or electrical failures, and issues with module weight or transporter loading. Contingency plans involve spare parts, backup equipment, flexible subcontractors, early mobilization, weight checks, and emergency response procedures. The goal is to anticipate problems and have solutions in place to maintain job safety.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

117 Ansichten5 SeitenSample: Job Safety Analysis

Hochgeladen von

HesanRajaraniThis document analyzes potential job safety risks and hazards that may occur during shifting operations and provides contingency plans. Key risks addressed include transport delays, missing equipment, insufficient space or equipment on site, hydraulic or electrical failures, and issues with module weight or transporter loading. Contingency plans involve spare parts, backup equipment, flexible subcontractors, early mobilization, weight checks, and emergency response procedures. The goal is to anticipate problems and have solutions in place to maintain job safety.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 5

Job Safety Analysis

Shifting operations

When things can happen

Potential risk / hazard

a)

During mobilisation and demobilisation of the

individual transporters to site

b)

Transporters are involved in an accident

Transporters get held up in customs or at JPJ

(Malaysian Public road department) roadblock

1)

Some transporters get held up at another job

d)

Flat tyres occur during mobilisation

SA

c)

a)

2)

Some transporter connection parts are missing

During assembly and dismantling of the

transporters at site

b)

JOB SAFETY ANALYSIS

Shifting works

How to avoid / counter re-act / plan

contingency

Mobilisation of roadable trandsporters only done

I)

during daylight hours

Make sure transporters in good conditions prior

II)

to dispatch

Use realiable subcontractor for mobilisation of

III)

non roadable transporters (PST-Es)

Mobilisation done at least 2 days prior to actual

I)

requirement on site

Double check paperwork at least 1 month prior

II)

to dispatch

Have at least 10 axle lines spare which can be

I)

mobilised at any time

Mobilisation done at least 2 days prior to actual

II)

requirement on site

Mobilisation can continue with a few flat tyres on

I)

each transporter

II) At least 3 spare tyres are to be mobilised

Transporter assembly done in time to allow last

I)

minute dispatch of small parts

PL

E

No

Not sufficient assist equipment (eg crane,

forklift) available at site

II)

Insist on flexibility from independent

subcontractors to use each other's tools/parts

Make sure not all transporters arrive at the same

time

Carefully plan quantity of assist equipment

II)

required and closely follow up

Client to dedicate certain quantity of assist

III)

equipment for this purpose

I)

Updated: 12/1/2011

Page 1 of 5

Job Safety Analysis

Shifting operations

When things can happen

How to avoid / counter re-act / plan

contingency

Potential risk / hazard

a)

Not sufficient space under module to position

transporters

I)

PL

E

No

II)

b)

Module supports are not positioned in a straight

line

I)

During positioning, pick up & testing of the

transporters underneath the cargo

c)

Not enough supports or support beams

available on top of the transporters

SA

3)

II)

d)

e)

JOB SAFETY ANALYSIS

Shifting works

Hydraulic hose bursts

Major powerpack failure

I)

Clearly request and monitor the required space

Double check space available at least 2 days

prior to positioning date

The supports are to be very precicely positioned

in line for positioning of long trailers with

sufficient gaps

Client to have a set of jacks on standby for last

minute required changes

Mobilise at least 2 pcs additional beams other

than required for contingency purpose

II)

Have sufficient hardwood jacking timber on

standby for last minute adjustments/shimming

I)

Close off the partition involved to be able to

continue job. Complete proper repair after

testing

II)

Test all hydraulic systems to maximum pressure

prior to positioning transporters under the decks

Mobilise a number of hoses which are most

likely to give way

Designate a hydraulic hose shop in the vicinity

IV)

for quick repairs

Have sufficient contingency built in to be able to

I)

continue the job with one powerpack less

III)

Updated: 12/1/2011

Page 2 of 5

Job Safety Analysis

Shifting operations

When things can happen

Potential risk / hazard

3)

Center of gravity not in position as expected

resulting in overloading of certain transporters

f)

( continued)

During positioning, pick up

& testing of the transporters underneath the cargo

Module heavier than expected

SA

g)

h)

JOB SAFETY ANALYSIS

Shifting works

How to avoid / counter re-act / plan

contingency

Be ready for last minute adjustments of

I)

transporter configurations

Be ready to mobilise additional transporters in

II) case problem can not be solved by change of

transporter configurations

Client to double check and closely monitor their

III) weight control reports and center of gravity

calculations

Be ready prepared for last minute changes in

IV) the hydraulic grouping of the transporters'

suspension cylinders

Initially plan transporter loading to maximum

I)

90% of maximum loading

Be ready to mobilise additional transporters in

II) case problem can not be solved by change of

transporter configurations

Client to double check and closely monitor their

III) weight control reports and center of gravity

calculations

PL

E

No

Powerpack on-board computer failure

I)

Have spare computers/parts on standby on site

Have electronic expert on standby on site for

emergency cases

Continue testing at manual override mode and

III)

make proper repair prior to transportation

II)

Updated: 12/1/2011

Page 3 of 5

Job Safety Analysis

Shifting operations

Potential risk / hazard

i)

Control box failure

j)

Tyre failure

( continued)

During positioning, pick up

& testing of the transporters underneath the cargo

3)

When things can happen

4)

Transporter related incidents

b)

I)

Close off the partition involved to be able to

continue job if feasible , if not replace the hose

II)

Test all hydraulic systems to maximum pressure

prior to positioning transporters under the decks

Hydraulic hose bursts

SA

a)

How to avoid / counter re-act / plan

contingency

I) Have at least 1 control box on standby

II) Have sufficient connection cables on standby

Have electronic expert on standby for

III)

emergency cases

Continue testing with the flat tyre and change

I)

tyre after testing

Check tyre pressures prior to placing

II)

transporters underneath the decks

Check transporter path for sharp objects prior to

III)

placing transporter underneath the decks

PL

E

No

Major powerpack failure

Mobilise a number of hoses which are most

likely to give way

IV) Have a oil splil absorbent kit on standby

Designate a hydraulic hose shop in the vicinity

V)

for quick repairs

Have sufficient contingency built in to be able to

I)

continue the job with one powerpack less

III)

I)

c)

JOB SAFETY ANALYSIS

Shifting works

Powerpack on-board computer failure

Have spare computers/parts on standby on site

Have electronic expert on standby on site for

emergency cases

III) Continue at manual override mode if possible

II)

Updated: 12/1/2011

Page 4 of 5

Job Safety Analysis

Shifting operations

No

When things can happen

Potential risk / hazard

I)

Control box failure

II)

PL

E

d)

III)

I)

e)

Tyre failure

II)

4)

( continued)

Transporter related

incidents

III)

Wheels dig into ground during low speed, high

angle manoeuvering

SA

f)

g)

Not enough pulling force to initially move the

deck

I)

II)

III)

I)

II)

III)

IV)

JOB SAFETY ANALYSIS

Shifting works

How to avoid / counter re-act / plan

contingency

Have at least 1 control box on standby for each

system (being Goldhofer and SPMT)

Have sufficient connection cables on standby

Have electronic expert on standby for

emergency cases

Continue with the flat tyre if feasible, if not

change it

Check tyre pressures prior to placing

transporters underneath the decks

Check transporter path for sharp objects prior to

placing transporter underneath the decks

Client to place steel plates under each deck at

transporter position to avoid digging in during

transporter positioning

Client to place steel plates under each deck's

final position at transporter position to avoid

digging in during deck positioning

Have sufficient earth moving machines on

standby

Plan to have at least 5% of total weight as

pulling force available

Double check whether all drive axles are

functioning properly

Have a number of equipment and heavy duty

trucks on standby to assist pulling

Maximise movement on steel plates

Updated: 12/1/2011

Page 5 of 5

Das könnte Ihnen auch gefallen

- Port Terminals System - Conveyor and Equipment MaintenanceVon EverandPort Terminals System - Conveyor and Equipment MaintenanceNoch keine Bewertungen

- Sample: Job Safety AnalysisDokument7 SeitenSample: Job Safety AnalysisHesanRajaraniNoch keine Bewertungen

- Job Safety Analysis: No When Things Can Happen Potential Risk / Hazard How To Avoid / Counter Re-Act / Plan ContingencyDokument3 SeitenJob Safety Analysis: No When Things Can Happen Potential Risk / Hazard How To Avoid / Counter Re-Act / Plan ContingencyHesanRajaraniNoch keine Bewertungen

- Section 4 - SAFE OPERATING PRACTICESDokument48 SeitenSection 4 - SAFE OPERATING PRACTICESAnoop PrajapatiNoch keine Bewertungen

- Shipboard File List For Oil Tankers 02.05.13Dokument11 SeitenShipboard File List For Oil Tankers 02.05.13Shoaib hossain100% (1)

- NLT (LH) Method of Statement (MOS)Dokument13 SeitenNLT (LH) Method of Statement (MOS)chiat mingNoch keine Bewertungen

- Safety Briefing For Sheet Piling Works and Safe Work ProcedureDokument7 SeitenSafety Briefing For Sheet Piling Works and Safe Work ProcedureMin Min Soe100% (1)

- Unit-I One MarksDokument32 SeitenUnit-I One MarksDeepak PooranachandranNoch keine Bewertungen

- STANDART PROCEDUR1 TankDokument6 SeitenSTANDART PROCEDUR1 TankvayakunNoch keine Bewertungen

- Questions On Marine OperationDokument10 SeitenQuestions On Marine OperationMahdi Bordbar100% (1)

- Training Manual Article 1.10, Truck OpsDokument33 SeitenTraining Manual Article 1.10, Truck OpsIvan ValenzuelaNoch keine Bewertungen

- Method Statement: Please Read This Document Carefully in Conjunction With The Risk AssessmentDokument15 SeitenMethod Statement: Please Read This Document Carefully in Conjunction With The Risk AssessmentShrikant BudholiaNoch keine Bewertungen

- Method Statement For Delivery and UndloadingDokument9 SeitenMethod Statement For Delivery and UndloadingshareyhouNoch keine Bewertungen

- 2 Second Sem - t206 Emergencies - Unit 1 - Emergency DrillsDokument14 Seiten2 Second Sem - t206 Emergencies - Unit 1 - Emergency DrillsALTAF SiddiquiNoch keine Bewertungen

- MS-Concourse Roof - Rev. DDokument10 SeitenMS-Concourse Roof - Rev. DJosephChongNoch keine Bewertungen

- 2006 US Army StudentGuides SEE Student Guide 43pDokument43 Seiten2006 US Army StudentGuides SEE Student Guide 43pLo Shun FatNoch keine Bewertungen

- BRE PilingDokument10 SeitenBRE PilingRavi SalimathNoch keine Bewertungen

- Bltn149 - Multiple Crane LiftsDokument2 SeitenBltn149 - Multiple Crane LiftsLaughlikesiao HeheNoch keine Bewertungen

- SOP Renuka WarehouseDokument4 SeitenSOP Renuka WarehouseSagnik ChakrabortyNoch keine Bewertungen

- ISCM1 Summary 2Dokument16 SeitenISCM1 Summary 2aboubakrNoch keine Bewertungen

- CPCS A56 Dump Truck Articulated Chassis Theory Test AnswersDokument7 SeitenCPCS A56 Dump Truck Articulated Chassis Theory Test AnswersAdam Adrian80% (30)

- Crash TenderDokument8 SeitenCrash TenderVikash Kumar SinghNoch keine Bewertungen

- E 29 GP 002 Lifting and Hoisting RecordingDokument12 SeitenE 29 GP 002 Lifting and Hoisting RecordingIbama MirillaNoch keine Bewertungen

- Past Years TPT250Dokument12 SeitenPast Years TPT250Ain hsyx100% (1)

- Engine Room CraneDokument22 SeitenEngine Room CraneNarendra KatdareNoch keine Bewertungen

- CPCS A62 Crane Lifting Operations Supervisor Theory Test AnswersDokument7 SeitenCPCS A62 Crane Lifting Operations Supervisor Theory Test AnswersLulezim Skeja100% (1)

- Imcasf 11 02Dokument7 SeitenImcasf 11 02manglesh1Noch keine Bewertungen

- TM 9-802 GMC Dukw-353Dokument402 SeitenTM 9-802 GMC Dukw-353Advocate100% (5)

- Lesson Plan: United States Marine CorpsDokument40 SeitenLesson Plan: United States Marine CorpsAmoah EmmanuelNoch keine Bewertungen

- MOS 2x15T EOTC Robotic ShopDokument17 SeitenMOS 2x15T EOTC Robotic ShopJohn Rey PerlasNoch keine Bewertungen

- Orals Past PapersDokument34 SeitenOrals Past PapersHoward Markham100% (1)

- Unit 2 Safety and Emergency ProceduresDokument10 SeitenUnit 2 Safety and Emergency ProceduresmarpelNoch keine Bewertungen

- Loading Unloading ReportDokument12 SeitenLoading Unloading ReportFatihah SyuhadahNoch keine Bewertungen

- AUTO 2301 Assignment Mac 19Dokument1 SeiteAUTO 2301 Assignment Mac 19Norhaslina binti Abdul AzizNoch keine Bewertungen

- 1102-ERFC-CM (SCLC) - CS-0001701 (Marked)Dokument1 Seite1102-ERFC-CM (SCLC) - CS-0001701 (Marked)Gary LoNoch keine Bewertungen

- Dersnot 5003 1681217027Dokument3 SeitenDersnot 5003 1681217027Baha SevinçNoch keine Bewertungen

- Stacker Access SopDokument19 SeitenStacker Access SopIzaac ErenstNoch keine Bewertungen

- Appendix B: Practical Exercises and SolutionsDokument12 SeitenAppendix B: Practical Exercises and SolutionsLo Shun FatNoch keine Bewertungen

- Dump TruckDokument4 SeitenDump TruckHugo RodriguezNoch keine Bewertungen

- Method Statement of Casing FrameDokument9 SeitenMethod Statement of Casing FrameKuber Jawaharpur EHSNoch keine Bewertungen

- Deck SMSDokument15 SeitenDeck SMSЕвгений ЕвгенийNoch keine Bewertungen

- DownloadDokument10 SeitenDownloadKitKat ShArryNoch keine Bewertungen

- MS.041211. Van Doorn Dismantle Liebherr 132HCDokument26 SeitenMS.041211. Van Doorn Dismantle Liebherr 132HCPradeep BalasubramaniamNoch keine Bewertungen

- 2006 US Army LessonPlans C01 Crane PMCS 27pDokument27 Seiten2006 US Army LessonPlans C01 Crane PMCS 27pLo Shun FatNoch keine Bewertungen

- 360 Digger QuestionsDokument7 Seiten360 Digger QuestionsIonela-Roxana MihuNoch keine Bewertungen

- S 6CT.29aF RA For Cargo Tank Entry On Chemical TankersDokument1 SeiteS 6CT.29aF RA For Cargo Tank Entry On Chemical TankersWILLIAMNoch keine Bewertungen

- Emergency Response Procedures (ERP)Dokument9 SeitenEmergency Response Procedures (ERP)Mickey Ch100% (1)

- Risk Assessment and Control Form (Crane Operation)Dokument4 SeitenRisk Assessment and Control Form (Crane Operation)khurramNoch keine Bewertungen

- Convoy Commanders GuideDokument20 SeitenConvoy Commanders GuideAbel PodaNoch keine Bewertungen

- Fafeco Manual CN03Dokument29 SeitenFafeco Manual CN03Arabinda SahooNoch keine Bewertungen

- 4.1 Written Test PDFDokument10 Seiten4.1 Written Test PDFxxxx100% (3)

- JSA - Trench Works - Road CuttingDokument1 SeiteJSA - Trench Works - Road Cuttingmurali100% (3)

- PERMANENT Means of AccessDokument13 SeitenPERMANENT Means of AccessGemstarManeshNoch keine Bewertungen

- Improved Ribbon Bridge Operational TestDokument113 SeitenImproved Ribbon Bridge Operational TestAndria Maree JonesNoch keine Bewertungen

- Exam Questions For Obtaining Aircraft Licenses and Ratings: PPL (A) - Operational ProceduresDokument0 SeitenExam Questions For Obtaining Aircraft Licenses and Ratings: PPL (A) - Operational ProceduresJose DiasNoch keine Bewertungen

- 1.0 Execution Method Statement Preparatory Works: Documents YES NODokument1 Seite1.0 Execution Method Statement Preparatory Works: Documents YES NOMuhammed Shafeek K TNoch keine Bewertungen

- Critical Lift ChecklistDokument4 SeitenCritical Lift ChecklistUdha Pengen SuksesNoch keine Bewertungen

- Lifting Procedure: 1.0 GeneralDokument4 SeitenLifting Procedure: 1.0 GeneralMagdy BakryNoch keine Bewertungen

- Bulk Material Handling: Practical Guidance for Mechanical EngineersVon EverandBulk Material Handling: Practical Guidance for Mechanical EngineersBewertung: 5 von 5 Sternen5/5 (1)

- Declaration of Conformity467Dokument1 SeiteDeclaration of Conformity467HesanRajaraniNoch keine Bewertungen

- Template 3 Risk and Mitigation Table Part 2 Appendix BDokument9 SeitenTemplate 3 Risk and Mitigation Table Part 2 Appendix BHesanRajaraniNoch keine Bewertungen

- Task 2 (A) (Answers) : Project A - TV StationDokument3 SeitenTask 2 (A) (Answers) : Project A - TV StationHesanRajaraniNoch keine Bewertungen

- PST SLE Declaration PDFDokument10 SeitenPST SLE Declaration PDFHesanRajaraniNoch keine Bewertungen

- Noble Denton Guidelines For LoadoutsDokument36 SeitenNoble Denton Guidelines For LoadoutsBoyNoch keine Bewertungen

- 2 Maize Milling Business Plan SampleDokument22 Seiten2 Maize Milling Business Plan SamplechowNoch keine Bewertungen

- RCR Presentation RevisedDokument30 SeitenRCR Presentation RevisedHesanRajaraniNoch keine Bewertungen

- OperatorsDokument10 SeitenOperatorsHesanRajaraniNoch keine Bewertungen

- DLT Climbing Jack Operating SequenceDokument21 SeitenDLT Climbing Jack Operating SequenceBoyNoch keine Bewertungen

- 29149Dokument1 Seite29149HesanRajaraniNoch keine Bewertungen

- Chemicals UsageDokument1 SeiteChemicals UsageHesanRajaraniNoch keine Bewertungen

- Ns Vitamin e - Repair Cream Brochure 2015Dokument4 SeitenNs Vitamin e - Repair Cream Brochure 2015BoyNoch keine Bewertungen

- 29149Dokument1 Seite29149HesanRajaraniNoch keine Bewertungen

- 2015 CIMA Professional Qualification SyllabusDokument51 Seiten2015 CIMA Professional Qualification SyllabusvictorpasauNoch keine Bewertungen

- Soil Training Manual Text PDFDokument30 SeitenSoil Training Manual Text PDFHesanRajaraniNoch keine Bewertungen

- Quotation - Timun - 3000 Polybags GantungDokument1 SeiteQuotation - Timun - 3000 Polybags GantungHesanRajaraniNoch keine Bewertungen

- Open and Closed FractureDokument22 SeitenOpen and Closed FractureHesanRajaraniNoch keine Bewertungen

- Shifting Route Sec 2 To Sec 1Dokument1 SeiteShifting Route Sec 2 To Sec 1HesanRajaraniNoch keine Bewertungen

- Business Law RajDokument10 SeitenBusiness Law RajHesanRajaraniNoch keine Bewertungen

- Introduction Using Analysis Tools For TESCODokument16 SeitenIntroduction Using Analysis Tools For TESCOSiew PhingNoch keine Bewertungen

- NAAM QuotationDokument2 SeitenNAAM QuotationHesanRajaraniNoch keine Bewertungen

- What Is Critical WritingDokument4 SeitenWhat Is Critical Writingnicholaz53Noch keine Bewertungen

- Req T QuotationDokument5 SeitenReq T QuotationHesanRajaraniNoch keine Bewertungen

- HarryDokument2 SeitenHarryHesanRajaraniNoch keine Bewertungen

- Project Bukit PelandukDokument9 SeitenProject Bukit PelandukHesanRajaraniNoch keine Bewertungen

- Job Desc - Operations ManagerDokument1 SeiteJob Desc - Operations ManagerHesanRajaraniNoch keine Bewertungen

- Topic 1 Distinctive Characteristics of Small Business ManagementDokument8 SeitenTopic 1 Distinctive Characteristics of Small Business ManagementHesanRajaraniNoch keine Bewertungen

- Critique Research PaperDokument13 SeitenCritique Research PaperMadhusudan BistaNoch keine Bewertungen

- 314 944 1 PBDokument16 Seiten314 944 1 PBHesanRajaraniNoch keine Bewertungen

- UWG IT Security PlanDokument111 SeitenUWG IT Security PlanManuel SantanaNoch keine Bewertungen

- FTV2.3 Power Supply Repair Method: Chapter 09 PageDokument25 SeitenFTV2.3 Power Supply Repair Method: Chapter 09 Pageabousalman63Noch keine Bewertungen

- 03TaskPerformance1 PECHONDokument4 Seiten03TaskPerformance1 PECHONAbug Jaime Jr.Noch keine Bewertungen

- Er Shutdown For 15.12.21 Rev1Dokument8 SeitenEr Shutdown For 15.12.21 Rev1Gitesh PatelNoch keine Bewertungen

- Safety and Security: by Walusimbi KennethDokument55 SeitenSafety and Security: by Walusimbi KennethSolángé MirembeNoch keine Bewertungen

- Iec 61000-2-13-2005Dokument46 SeitenIec 61000-2-13-2005D SaiRajaNoch keine Bewertungen

- HP Accessories IT Show 2012Dokument2 SeitenHP Accessories IT Show 2012John TanNoch keine Bewertungen

- Qcomm LTE Log Packet Information 80 VP457 5 C LTE LPID PDFDokument232 SeitenQcomm LTE Log Packet Information 80 VP457 5 C LTE LPID PDFMichał Ujma100% (1)

- MasterFormat - Wikipedia, The Free EncyclopediaDokument3 SeitenMasterFormat - Wikipedia, The Free EncyclopediaMartin SabahNoch keine Bewertungen

- PIN Diagram of Intel 8085 Microprocessor - Lecture 3Dokument14 SeitenPIN Diagram of Intel 8085 Microprocessor - Lecture 3ojasbhosale07Noch keine Bewertungen

- Engineering Works (India) : Ideas With InnovationsDokument8 SeitenEngineering Works (India) : Ideas With InnovationschougulenkNoch keine Bewertungen

- Brief History of Electric Traction in India PDFDokument7 SeitenBrief History of Electric Traction in India PDFg.sravan278Noch keine Bewertungen

- PS2103 Electrical Transients in Power SystemsDokument4 SeitenPS2103 Electrical Transients in Power Systemssathishkumar3ramasamNoch keine Bewertungen

- Bluetooth Low Energy Device: Using The MT8852B To Test A Controlled Through A Proprietary InterfaceDokument7 SeitenBluetooth Low Energy Device: Using The MT8852B To Test A Controlled Through A Proprietary InterfaceAlberto SaldivarNoch keine Bewertungen

- Imp Call Flow Training NotesDokument37 SeitenImp Call Flow Training Notesjimmi9719Noch keine Bewertungen

- Release Note Ver 1.0Dokument2 SeitenRelease Note Ver 1.0Nkenchor OsemekeNoch keine Bewertungen

- Activity Refine Your Time EstimatesDokument54 SeitenActivity Refine Your Time EstimatesTAgore Ravi Teja100% (4)

- 04098159Dokument3 Seiten04098159Murali GolveNoch keine Bewertungen

- Best Thesis Topics For Mechanical EngineeringDokument7 SeitenBest Thesis Topics For Mechanical EngineeringDaniel Wachtel100% (1)

- Electrical Findings 6Dokument13 SeitenElectrical Findings 6Lester Musca100% (1)

- Search: Skip To Content Using Gmail With Screen ReadersDokument11 SeitenSearch: Skip To Content Using Gmail With Screen ReadersKavitha100% (1)

- Principles of Data VisualizationDokument2 SeitenPrinciples of Data VisualizationAAKASHNoch keine Bewertungen

- Ethics in Ict An Australian Perspective PDFDokument2 SeitenEthics in Ict An Australian Perspective PDFAndrew0% (1)

- New Text DocumentDokument2 SeitenNew Text DocumentpshtiwanNoch keine Bewertungen

- B230/B237/D042 Service ManualDokument1.312 SeitenB230/B237/D042 Service ManualSutan HarrymanNoch keine Bewertungen

- Unit IiiDokument40 SeitenUnit IiiVENU VNoch keine Bewertungen

- Manufacturing Capabilities in Microsoft Dynamics NAVDokument3 SeitenManufacturing Capabilities in Microsoft Dynamics NAVAtanacia Ilagan100% (1)

- C2-RS232-RS422-RS485-phan 3Dokument25 SeitenC2-RS232-RS422-RS485-phan 3Duc Tri Bui100% (2)

- Motor Es CatDokument42 SeitenMotor Es CatfelixezamoraNoch keine Bewertungen

- Society of International Gas Tanker & Terminal Operators (Sigtto)Dokument8 SeitenSociety of International Gas Tanker & Terminal Operators (Sigtto)Mohamed MekkyNoch keine Bewertungen