Beruflich Dokumente

Kultur Dokumente

Performance Analysis and Parametric Variation of A Solar Adsorption Chiller

Hochgeladen von

IJIRSTOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Performance Analysis and Parametric Variation of A Solar Adsorption Chiller

Hochgeladen von

IJIRSTCopyright:

Verfügbare Formate

IJIRST International Journal for Innovative Research in Science & Technology| Volume 2 | Issue 02 | July 2015

ISSN (online): 2349-6010

Performance Analysis and Parametric Variation

of a Solar Adsorption Chiller

Parash Goyal

Student

Energy Centre

Maulana Azad National Institute of Technology, Bhopal, India

Prashant Baredar

Associate Professor

Energy Centre

Maulana Azad National Institute of Technology, Bhopal, India

Arvind Mittal

Associate Professor

Energy Centre

Maulana Azad National Institute of Technology, Bhopal, India

Abstract

Solar energy is the most promising among the available green energy sources and also the panacea to the increasing global

warming potential and ozone depletion. In the last three decades, various technologies have been invented for extracting the

latent potential of the solar energy. Among them, the one that is still unearthed and needs to be researched is the adsorption

refrigeration cycle. In the present paper, we have designed a basic adsorption chiller driven by solar thermal energy which

consists of a solar collector, an adsorbent bed, a condenser and an evaporator. The model provides a maximum COP of 0.452

with a refrigeration power of 6.78 kW. Moreover, we have provided the variation of COP system and COP cycle with time.

Here, we have also inferred the response of COP with variation in mass and collector area and we came to the conclusion that the

COP of the present system declines if the mass exceeds 15 Kg.

Keywords: Solar Adsorption Chiller, Solar Refrigeration, Parametric Variation, Cop, Solar Collector

_______________________________________________________________________________________________________

I. INTRODUCTION

Global warming, change in the seasonal cycle, limitation of primary energy compared to the need of the growing global

population, are the prime concern of the twenty first century. Cooling and refrigeration are essentials for modern days society to

provide the human comfort. In tropical countries like India, which experience extreme in the mainland, demand for electricity

shoots up due to the need for cooling. The high electricity demand not only overloads the grid but harms the environment as well

due to the burning of fossil fuels, which are the primary source of power. Most of the technologies at present for providing

cooling or refrigeration are vapor compressor technology. However, the vapor compressor refrigeration device is one of the

technologies responsible for ozone layer destruction as most of these use HCFCs and HFCs. Solar energy for cooling

applications provides an opportunity to overcome this problem. The amount of solar radiation intercepted by the Earths surface

is much higher than the annual global energy use. The energy available from the sun (82x1015 Wp) is greater than about 5200

times the global worlds need in 2006 [1]. In recent years, many promising technologies have been developed to harness the

Suns energy. These technologies help in environmental protection, economizing energy, and sustainable developments which

are the major issues of the world in the 21st century. The fact that cooling demand in summer is proportional to the availability of

solar energy has been spurring the researchers to further exploit solar energy.

In cooling applications, different types of sorption systems can be employed. Among them one is the adsorption cycles.

Adsorption refrigeration is a thermal driven refrigeration system, which can be powered by solar energy as well as waste heat

[2]. The use of thermal driven systems helps to reduce the carbon dioxide emission from combustion of fossil fuels in power

plants. Another advantage for adsorption systems compared with conventional vapor compression systems is the working fluid

used. Adsorption systems mainly use a natural working fluid such as water and ammonia, which have zero ozone depletion

potential.

Adsorption is the process by which molecules of a fluid are fixed on the walls of a solid material via connections of the Van

der Waals type [3]. The general principle of the basic adsorption refrigeration cycle is given in fig.1. The refrigeration circuit

usually consists of three main components; a solid adsorbent bed, a condenser and an evaporator. Some system employ isolating

valves between the various components and some utilize expansion valves between the condenser and the evaporator. The

adsorption refrigeration cycle relies mainly on the natural affinity of the adsorbent bed (when at low temperature) to attract the

refrigerant vapor from the evaporator thus creating a lower pressure in the evaporator. Once the adsorbent bed is close to the

saturation point, the valve between the evaporator and the absorber is closed and heat is applied to adsorbent bed, thus releasing

the refrigerant vapor which then gets collected and condensed in the condenser before returning to the evaporator. Once this

cycle is completed the heat on the adsorbent bed is removed and in some cases forced cooling is introduced onto the adsorber

All rights reserved by www.ijirst.org

30

Performance Analysis and Parametric Variation of a Solar Adsorption Chiller

(IJIRST/ Volume 2 / Issue 02 / 008)

until the adsorption conditions are established then the valve between the evaporator and the adsorbed is reopened. In the present

study, we have designed, fabricated and tested a single stage adsorption chiller.

Fig. 1: Principle of basic adsorption cycle

II. PREVIOUS WORKS

The sorption refrigeration driven by solar energy attracted broad attention because the heat supply and cool demand are very well

matched with the season and the heat quantity. Compared with the absorption system, the adsorption system that are driven by

the heat sources of lower temperatures makes the application of solar energy more feasible on the adsorption system.

The solid adsorption refrigeration technology driven by solar energy has been researched extensively since Tchernev [4]

successfully developed the refrigeration system with zeolite water as the working pair. Pons and Guilleminot in France, studied

activated carbonmethanol and zeolitewater adsorption systems driven by solar energy, in which the COP of the activated

carbonmethanol ice maker [5] is 0.120.14 with a collector area of 6m2 (four collectors) and adsorbent mass of 2024 kg/m2,

and the COP of a zeolitewater refrigerator [6] is about 0.10 with the collector area of 20m2 (24 collectors) and the adsorbent

mass of 360 kg. K. Sumathy et al. investigated an activated carbonmethanol ice maker powered by solar energy, and results

showed that the daily ice production is 45 kg and the COP is 0.10.2 [7] when the area of flat plate collector is 0.92m2. Y.K.

Tan [8-10] in South China University of Technology and Z.F. Li et al. in Guangzhou Institute of Energy Conversion [11] also

developed the solid adsorption refrigeration system driven by solar energy, which had a similar performance to the system

developed by K. Sumathy. Different from the refrigeration system with the integrated solar collectoradsorption generator, multi

types of solar energy powered adsorption refrigeration systems were developed. Iloeje et al. [12, 13] utilized a tubular type of

absorber, for which the adsorbent (such as calcium chloride, activated carbon) is filled inside the metal pipes. The concentric

tube arranged at the center of the metal pipe served as the mass transfer channel of the refrigerant, and the metal tube is boned on

the collector surface. Erhard [14] arranged the condensation part of the horizontal heat pipe inside the adsorbent bed to improve

the heat flux density. Headley et al. [15] studied the activated carbonmethanol adsorption refrigerating system utilizing the

compound parabolic concentrator (CPC) as the heat source. The system could realize refrigeration even if the solar radiation is

very feeble, but the efficiency of the refrigeration system is very low. Bansal et al. [16] studied the SrCl2-NH3 adsorption

refrigerating system driven by the vacuum tube type collector. Vasiliev [17] developed a continuous adsorption heat pump with

heat recovery process driven by solar energy and natural gas, using a parabolic concentrator for collecting the solar energy to

heat the circulating water. The system employed solar energy as a main power supply, and the natural gas served as an auxiliary

heat source when solar energy is not enough. The system can accomplish continuous refrigeration with the cycle time of 12

minutes Z.Y. Liu [18, 19] put forward the refrigeration system which combined the unit adsorption tube with the collector for the

solar energy. For such a design the adsorbent bed can be heated by solar energy directly.

On the topic of solar energy utilization, SJTU [20] developed a compound system of water heater and refrigerator driven by

solar energy to improve energy efficiency. Meanwhile, SJTU also developed the silica gelwater adsorption chiller in 2004,

which had been applied to the building and grain storage hall with solar energy as the driving power.

III. BASIC ADSORPTION REFRIGERATION SYSTEM

Adsorption refrigeration system uses solid adsorbent beds to adsorb and desorb a refrigerant in order to obtain cooling effect.

These adsorbent beds filled with solid material adsorb and desorb a refrigerant vapor in response to changes in the temperature of

the adsorbent. The basic adsorption refrigeration system, commonly referred to as the adsorption heat pump loop, or an

adsorption refrigeration circuit, mainly consists of four main components: a solid adsorbent bed, a condenser, an expansion valve

and an evaporator. The adsorbent bed desorbs refrigerant when heated and adsorb refrigerant vapor when cooled. The adsorbent

All rights reserved by www.ijirst.org

31

Performance Analysis and Parametric Variation of a Solar Adsorption Chiller

(IJIRST/ Volume 2 / Issue 02 / 008)

is packed in a hermetically sealed container painted black for solar radiation absorption at a particular temperature in compliance

with its condensing pressure.

A basic adsorption cycle consists of four thermodynamic steps.

A. Heating and Pressurization

The adsorber receives heat while being closed. The adsorbent temperature increases, which increases pressure from the

evaporation pressure to the condensation pressure. This process is equivalent to the "compression" in compression cycles. Refer

line AB in fig.2.

B. Heating, Desorption and Condensation

The adsorber continues receiving heat while being connected to the condenser. The adsorbent temperature continues increasing,

which induces desorption of vapor. This desorbed vapor gets liquefied in the condenser. This is equivalent to the "condensation"

in compression cycles. Refer line BC in fig. 2.

C. Cooling and Depressurization

During this period, low pressure vapor is entered to adsorber from evaporator. The adsorber releases heat while being closed.

The adsorbent temperature decreases, which decrease pressure from the condensation pressure down to the evaporation pressure.

This process is equivalent to the "expansion" in compression cycles. Refer line CD in fig. 2.

D. Cooling, Adsorption and Evaporation

The adsorber continues releasing heat while being connected to the evaporator. The adsorbent temperature continues decreasing,

which induces adsorption of vapor. This adsorbed vapor is vaporized in the evaporator. The evaporation heat is supplied by the

heat source at low temperature. This is equivalent to the "evaporation" in compression cycles. Refer line DA in fig. 2.

The schematic of the adsorption chiller is shown in fig. 3. In the present case we have fabricated the adsorption chiller

following the schematics shown. We have used activated carbon and methanol as the working pair.

Fig. 2: Clayperon curve of basic adsorption refrigeration cycle.

Fig. 3: Schematics of the adsorption chiller

All rights reserved by www.ijirst.org

32

Performance Analysis and Parametric Variation of a Solar Adsorption Chiller

(IJIRST/ Volume 2 / Issue 02 / 008)

IV. PERFORMANCE PARAMETERS

From the Clapeyron diagram, the total energy gained by the system during the heating period Q T will be the sum of the energy

QAB used to raise the temperature of the A.C+ methanol from point A to B and the energy QBD used for progressive heating of

the A.C to point D and desorption of methanol.

QT = QAB + QB

QAB = (mA:C CpA:C +CpmmmA)(TB -TA )

QBD = [mA:C CpA:C + Cpm{ (mmA + mmD)/ 2}](TD TB)+ (mmA - mmD)H

The gross heat released during the cooling period Qe1 will be the energy of vaporization of methanol.

Qe = (mmA - mmD) L

But the net energy actually used to produce ice Qe will be

Qe = Qe1 Qe2,

where Qe2 is the energy necessary for cooling the liquid adsorbate from the temperature at which it is condensed to the

temperature at which it evaporates.

Qe2 = (mmA - mmD) Cpm (Tc - Te)

Qice1 is the energy required to cool water from T A to 0oC and to produce ice

Qice1 = M* (L* Cpwater (TA - 0)),

where M* and L* are the mass and latent heat of fusion of ice and net cooling produced will be

Qice = M * L*

1) The collector efficiency 1=QT/ QI ,

where QI is the total solar energy input to the system during the day.

2) The cycle COP = Qe1/QT

3) The net solar COP net = Qice / QI

Here, Cp is specific heat in kJ/kgK, H is heat of desorption in kJ/kg, L is latent heat of evaporation of the methanol in kJ/kg,

M is mass in kg, Q is energy in kJ, T is temperature in C.

V. PERFORMANCE ANALYSIS

Fig. 4 shows the variation of the solar incident radiation and the ambient atmospheric temperature with the day hours. These data

simulate a summer day in May 5, 2015, for Bhopal, India.

Fig. 4: Variation of Solar radiation and ambient temperature with time

Table 1 shows the experimental results obtained from the experiments performed on the basic adsorption system. It shows the

per day solar intensity, average ambient temperature corresponding to the respective solar radiation intensity, condensation

temperature, evaporator temperature and the coefficient of performance (COP). It shows that as the ambient temperature

increases i.e. increase in solar radiation intensity, there is an increase in the condensation temperature along with a more

reduction in evaporation temperature. From the results in table it is evident that there exists a relation among the COP, T con and

Tevp. The system possesses a monthly average COP of 0.4305 calculated for the month of May.

On the basis of the experiments performed, we went for calculating hourly performance of the refrigeration system i.e.

calculating the variation of COP with time of the day. Fig. 5 shows the variation of the system COP with time of day. Also, it

shows that in a day the maximum COP value that the system achieved is 0.35. On the same lines, we draw the variation of the

COPcycle with time of the day, see fig. 6. It shows that the maximum COP value on a day can be of 0.465.

All rights reserved by www.ijirst.org

33

Performance Analysis and Parametric Variation of a Solar Adsorption Chiller

(IJIRST/ Volume 2 / Issue 02 / 008)

Date

5/5/2015

10/5/2015

15/5/2015

20/5/2015

25/5/2015

30/5/2015

Table - 1

Experimental performance of the adsorption chiller

Ambient

Condensation Evaporator

Solar Intensity

temperature

temperature

temperature

(I)

(Tamb)

(Tcon)

(Tevp)

2

MJ/ m /day

o

o

o

c

c

c

22.6

25.4

32.3

19.6

24.5

27.3

34.7

16.3

27.2

30.7

37.8

12.2

27.6

31.4

38.6

10.8

25.3

28.8

35.4

14.7

19.8

22.2

28.2

21.9

COP

0.412

0.428

0.447

0.452

0.435

0.409

Fig. 5: Variation of COP with time of the day

Fig. 6: Variation of COPcycle with time of the day

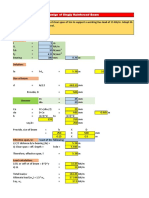

Fig. 7 shows the response surface of the COP of refrigerator as a function of mass and collector area using statistical software

(Minitab), multiple regression method is used in this software As shown in the figure, the optimum value of the COP lies in the

region where the collector area is from 3 to 4.5 m2, and mass from 10 to 15 kg. The COP decreases beyond 5 m2. This is due to

the fact that the cooling production does not increase much once the water temperature reaches above 100 oC which is attained if

the collector area is beyond 5 m2. Hence, with further increase in the water temperature as a result of increasing collector area,

the cooling production remains stable, but the COP decreases. The figure shows also that the COP and cooling production

increases as long as the adsorbent mass is less than 15 kg. The increase in adsorbent mass indicates more methanol being

adsorbed initially. Hence, during desorption phase, more methanol vapor can be desorbed, which produces more cooling and

thereby results in high COP. On the other hand, if the mass of adsorbent is increased to more than 15 kg, the COP as well as the

cooling production decreases. This is because with the given heat input, only the bed could be heated, and this is not sufficient to

desorb the required amount of methanol.

All rights reserved by www.ijirst.org

34

Performance Analysis and Parametric Variation of a Solar Adsorption Chiller

(IJIRST/ Volume 2 / Issue 02 / 008)

Fig. 7: Response surface of the COP of refrigerator as a function of mass and collector area

VI. CONCLUSIONS

Adsorption cooling systems have received significant interest during the last few decades in order to satisfy the market demand

of cooling systems and cope with the current environmental issues. In the present study we excogitated, fabricated and tested a

solar adsorption refrigerator which uses activated carbon and methanol as the working pair. This system was tested for the

meteorological conditions of MANIT, Bhopal. Maximum COP and refrigeration power of the modelled chiller was calculated to

be 0.452 that occurred on 20th of May and 6.78 kW respectively. From the experiments performed we can conclude that on a

particular day COP follows a parabolic curve which attains its peak near 13:00 hrs. Also we can conclude that COPcycle follows

an approx. constant curve for a duration of 5 hours. The maximum value of COP cycle s 0.465. Moreover, we can infer that if the

collector area is increased then the COP would increase but simultaneously we have to maintain the generating temperature as if

it crosses the optimum generating temperature the COP value will start declining. It is found that the present model is capable of

operating only in night time with fairly good performance. Hence this system suffers from intermittency i.e. not capable of

providing cooling for the 24 hours of the day. Hence, for this generally two stage adsorption systems are employed in order to

overcome the intermittent nature.

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

[18]

[19]

[20]

Habib K, Saha BB, Chakraborty A, Oh ST, Koyama S. (2013) Study on solar driven combined adsorption refrigeration cycles in tropical climate. Applied

Thermal Engineering; 50(2): 15821589 http://dx.doi.org/10.1016/j.applthermaleng.2011. 11.042.

Sumathy K, Yeung KH, Yong L. (2003) Technology development in the solar adsorption refrigeration systems. Prog Energy Combust Sci; 29 (4): 30127,

http://dx.doi.org/10.1016/S0360-1285(03)00028-5.

Dieng AO, Wang RZ. (2001) Literature review on solar adsorption technologies for ice-making and air conditioning purposes and recent developments in

solar technology. Renew Sustain Energy Rev; 5(4):31342, http://dx.doi.org/ 10.1016/S1364-0321(01)00004-1.

Tchernev, D. (1985) Heat pump energized by low-grade heat sources. US Patent PCT/US85/00783.

Pons, M. and Guilleminot, J.J. (1986) Design of an experimental solar-powered, solid-adsorption ice maker. ASME Journal of Solar Energy Engineering,

108, 332337.

Grenier, P., Guilleminot, J.J. and Meunier, F. (1988) Solar powered solid adsorption cold store. Solar Energy Engineering, 110, 192197.

Sumathy, K. and Li, Z.F. (1999) Experiments with solar-powered adsorption ice maker. Renewable Energy, 16, 704707.

Feng, Y. and Tan, Y.K. (1990). The experimental research on the adsorption refrigeration for the recovery of the waste heat in industries. Energy

Conservation Technology, (4), 13, ISSN: 10026339 (in Chinese).

Feng, Y. and Tan, Y.K. (1990). The research for the adsorption refrigeration cycle with activated carbon-methanol as the working pair. Journal of

Refrigeration, (1), 15, ISSN: 02534339 (in Chinese).

Feng, Y. and Tan, Y.K. (1991) Research on the heat and mass transfer performance for the adsorption refrigeration systems. Journal of Chemical Industry

and Engineering, 42(3), 342347, ISSN: 0438-1157 (in Chinese).

Li, Z.F., Huang, Z.C. and Liu, G.X. (1991). The principle and experimental research on the solid adsorption refrigeration powered by the solar energy.

Journal of Refrigeration, 1, 2126, ISSN: 0253-4339 (in Chinese).

Enibe, S.O. and Iloeje, O.C. (1997) Design optimization of the flat plate collector for a solid absorption solar refrigerator. Solar Energy, 60(2), 7787.

Enibe, S.O. and Iloeje, O.C. (1997) Transient analysis and performance prediction of a solid absorption solar refrigerator. Solar Energy, 60(1), 4359.

Erhard, D., Spindler, K. and Hahne, E. (1998) Test and simulation of a solar powered solid sorption cooling machine. International Journal of Refrigeration,

21(2), 133141.

Headley, S., Kothdiwal, A.F., McDoom, I.A. et al. (1994) Charcoal-methanol adsorption refrigerator powered by a compound parabolic concentrating solar

collector. Solar Energy, 53(2), 191197.

Bansal, N.K., Blumenberg, J., Kavasch, H.J. et al. (1997) Performance testing and evaluation of solid absorption solar cooling unit. Solar Energy, 61(2),

127140.

Vasiliev, L.L. (2005) Heat pipes in modern heat exchangers. Applied Thermal Engineering, 25(1), 119.

Liu, Z.Y., Lu, Y.Z. and Zhao, J.X. (1998) Zeolite-active carbon compound adsorbent and its use in adsorption solar cooling tube. Solar Energy Materials

and Solar Cells, 52, 4553.

Liu, Z.Y., Lu, Y.Z. and Wang, Y.T. (2000) Experimental research on a novel solar powered refrigerating pipe. Acta Energiae Solaris Sinica, 21(1), 8288,

ISSN: 0254-0096 (in Chinese).

Wang, R.Z., Li, M., Xu, Y.X. and Wu, J.Y. (2000). An energy efficient hybrid system of solar powered water heater and adsorption ice maker. Solar

Energy, 68(2), 189195.

All rights reserved by www.ijirst.org

35

Das könnte Ihnen auch gefallen

- The Effect of Diverse Recording Devices On Forensic Speaker Apperception SystemDokument9 SeitenThe Effect of Diverse Recording Devices On Forensic Speaker Apperception SystemIJIRSTNoch keine Bewertungen

- Postprocessing of Compacted Images Through Consecutive DenoisingDokument4 SeitenPostprocessing of Compacted Images Through Consecutive DenoisingIJIRSTNoch keine Bewertungen

- Experimental Analysis of Friction Stir Processing of Tig Welded Aluminium Alloy 6061Dokument7 SeitenExperimental Analysis of Friction Stir Processing of Tig Welded Aluminium Alloy 6061IJIRSTNoch keine Bewertungen

- Manganese: Affecting Our Environment (Water, Soil and Vegetables)Dokument7 SeitenManganese: Affecting Our Environment (Water, Soil and Vegetables)IJIRSTNoch keine Bewertungen

- Custom ROMDokument3 SeitenCustom ROMIJIRSTNoch keine Bewertungen

- Patterns of Crop Concentration, Crop Diversification and Crop Combination in Thiruchirappalli District, Tamil NaduDokument10 SeitenPatterns of Crop Concentration, Crop Diversification and Crop Combination in Thiruchirappalli District, Tamil NaduIJIRSTNoch keine Bewertungen

- Multi-Physics Based Simulations of A Shock Absorber Sub-SystemDokument7 SeitenMulti-Physics Based Simulations of A Shock Absorber Sub-SystemIJIRSTNoch keine Bewertungen

- Development of Satellite Data For Infrastructure Updation and Land Use/Land Cover Mapping - A Case Study From Kashipur & Chhatna Block, Bankura & Purulia District, West BengalDokument7 SeitenDevelopment of Satellite Data For Infrastructure Updation and Land Use/Land Cover Mapping - A Case Study From Kashipur & Chhatna Block, Bankura & Purulia District, West BengalIJIRSTNoch keine Bewertungen

- Vibration Analysis of Composite Leaf Spring by Finite Element MethodDokument7 SeitenVibration Analysis of Composite Leaf Spring by Finite Element MethodIJIRSTNoch keine Bewertungen

- Physico-Chemical Analysis of Selected Ground Water Samples in and Around Nagapattinam District, TamilnaduDokument3 SeitenPhysico-Chemical Analysis of Selected Ground Water Samples in and Around Nagapattinam District, TamilnaduIJIRSTNoch keine Bewertungen

- Satellite Dish Positioning SystemDokument5 SeitenSatellite Dish Positioning SystemIJIRST100% (1)

- Performance Analysis of Organic Rankine Cycle (ORC) Working On Different Refrigerant Fluids Having Low Boiling PointDokument5 SeitenPerformance Analysis of Organic Rankine Cycle (ORC) Working On Different Refrigerant Fluids Having Low Boiling PointIJIRSTNoch keine Bewertungen

- Study On Performance Evaluation of Forced Convection Solar Dryer For Turmeric (Curcuma Longa L.)Dokument10 SeitenStudy On Performance Evaluation of Forced Convection Solar Dryer For Turmeric (Curcuma Longa L.)IJIRSTNoch keine Bewertungen

- Arduino-UNO Based Magnetic Field Strength MeasurementDokument4 SeitenArduino-UNO Based Magnetic Field Strength MeasurementIJIRSTNoch keine Bewertungen

- Analysis of Agent Oriented Software EngineeringDokument5 SeitenAnalysis of Agent Oriented Software EngineeringIJIRSTNoch keine Bewertungen

- Currency Recognition Blind Walking StickDokument3 SeitenCurrency Recognition Blind Walking StickIJIRSTNoch keine Bewertungen

- Experimental Investigation On Concrete by Replacement of Sand by Silica Sand and Artificial SandDokument6 SeitenExperimental Investigation On Concrete by Replacement of Sand by Silica Sand and Artificial SandIJIRSTNoch keine Bewertungen

- Rock Deformation by Extesometers For Underground Powerhouse of Sardar Sarovar Project (Gujarat)Dokument5 SeitenRock Deformation by Extesometers For Underground Powerhouse of Sardar Sarovar Project (Gujarat)IJIRSTNoch keine Bewertungen

- Development of Tourism Near Loktak Lake (Moirang) in Manipur Using Geographical Information and Management TechniquesDokument4 SeitenDevelopment of Tourism Near Loktak Lake (Moirang) in Manipur Using Geographical Information and Management TechniquesIJIRSTNoch keine Bewertungen

- Experimental Investigation On The Effect of Use of Bottom Ash As A Replacement of Fine AggregatesDokument7 SeitenExperimental Investigation On The Effect of Use of Bottom Ash As A Replacement of Fine AggregatesIJIRSTNoch keine Bewertungen

- Induction Motor Drive Using SPWM Fed Five Level NPC Inverter For Electric Vehicle ApplicationDokument7 SeitenInduction Motor Drive Using SPWM Fed Five Level NPC Inverter For Electric Vehicle ApplicationIJIRSTNoch keine Bewertungen

- Reconfigurable Manufacturing Systems Using The Analytical Hierarchical Process (AHP) - A ReviewDokument3 SeitenReconfigurable Manufacturing Systems Using The Analytical Hierarchical Process (AHP) - A ReviewIJIRSTNoch keine Bewertungen

- Intelligent Irrigation SystemDokument5 SeitenIntelligent Irrigation SystemIJIRSTNoch keine Bewertungen

- Efficient Revocation of Data Access in Cloud Storage Based On ABE-SchemeDokument6 SeitenEfficient Revocation of Data Access in Cloud Storage Based On ABE-SchemeIJIRSTNoch keine Bewertungen

- Literature Review For Designing of Portable CNC MachineDokument3 SeitenLiterature Review For Designing of Portable CNC MachineIJIRSTNoch keine Bewertungen

- Impact of Different Soils and Seismic Zones On Varying Height of Framed StructuresDokument8 SeitenImpact of Different Soils and Seismic Zones On Varying Height of Framed StructuresIJIRSTNoch keine Bewertungen

- Women Protection Mechanism With Emergency Communication Using Hand Waving PatternDokument5 SeitenWomen Protection Mechanism With Emergency Communication Using Hand Waving PatternIJIRSTNoch keine Bewertungen

- Comparative Study of Inner Core, Peripheral and RC Shear Wall SystemDokument8 SeitenComparative Study of Inner Core, Peripheral and RC Shear Wall SystemIJIRSTNoch keine Bewertungen

- Infiltration, Permeability, Liquid Limit and Plastic Limit of SoilDokument12 SeitenInfiltration, Permeability, Liquid Limit and Plastic Limit of SoilIJIRSTNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Boll Duplex Type 2.04.5Dokument2 SeitenBoll Duplex Type 2.04.5Phung Van HiepNoch keine Bewertungen

- Engineering Mechanics (2009 Course) : Multiple Choice QuestionsDokument6 SeitenEngineering Mechanics (2009 Course) : Multiple Choice QuestionsDigamNoch keine Bewertungen

- The Extended Rayleigh-Ritz Method For An Analysis of Nonlinear VibrationsDokument7 SeitenThe Extended Rayleigh-Ritz Method For An Analysis of Nonlinear VibrationsGuilherme NagaeNoch keine Bewertungen

- Hydraulic Circuit DesignDokument17 SeitenHydraulic Circuit DesignansarALLAAH100% (1)

- 3P04 Tutorial 1 SensorFlow 2008Dokument28 Seiten3P04 Tutorial 1 SensorFlow 2008Khaled KamalNoch keine Bewertungen

- Modified Asphalt Binders: Need of Present PavementsDokument85 SeitenModified Asphalt Binders: Need of Present PavementsPalika ChopraNoch keine Bewertungen

- Baird Uc TedDokument17 SeitenBaird Uc TedJeffFordNoch keine Bewertungen

- Man P2862 Le ProjectDokument406 SeitenMan P2862 Le ProjectMuhammad Subhan IrfandyNoch keine Bewertungen

- What is TDB, TWB & PsychrometricsDokument1 SeiteWhat is TDB, TWB & PsychrometricsYasna Guiñez HerreraNoch keine Bewertungen

- 114-3 Unit Assembling Check Sheet KOMATSU ENGINE 114-3-87874Dokument12 Seiten114-3 Unit Assembling Check Sheet KOMATSU ENGINE 114-3-87874เชิดศักดิ์ สอาดศรีNoch keine Bewertungen

- Earthquake Resistant Design of Structures PDFDokument3 SeitenEarthquake Resistant Design of Structures PDFPraveen JainNoch keine Bewertungen

- CraneDokument16 SeitenCraneAdrian Franco MolinaNoch keine Bewertungen

- CPS Refrigerant Leak Detector LS790BDokument20 SeitenCPS Refrigerant Leak Detector LS790BRichard WeimerNoch keine Bewertungen

- DM25-SP Series: Atlas Copco Blasthole DrillsDokument4 SeitenDM25-SP Series: Atlas Copco Blasthole DrillsKOMATSU SHOVELNoch keine Bewertungen

- Bottom Blowdown: Download The (295 KB) Try Answering The For This Tutorial View The Complete Collection ofDokument8 SeitenBottom Blowdown: Download The (295 KB) Try Answering The For This Tutorial View The Complete Collection ofsenaNoch keine Bewertungen

- Oldsmobile Engine DecoderDokument5 SeitenOldsmobile Engine DecoderJohn PerzyloNoch keine Bewertungen

- Ra92060 2006-12 PDFDokument36 SeitenRa92060 2006-12 PDFabdelrhmangbr86Noch keine Bewertungen

- Shankar DurgamDokument9 SeitenShankar DurgamasdfNoch keine Bewertungen

- Ejercicios CORIOLIS PDFDokument2 SeitenEjercicios CORIOLIS PDFAlejandro CGNoch keine Bewertungen

- Wire Rope Inspection Checklist FormDokument1 SeiteWire Rope Inspection Checklist FormРашад ИбрагимовNoch keine Bewertungen

- Singly Reinforced Beam ExcelDokument3 SeitenSingly Reinforced Beam ExcelVEERKUMAR100% (3)

- Directional Controls: Solenoid Operated Directional Control ValvesDokument16 SeitenDirectional Controls: Solenoid Operated Directional Control Valvesreincidentesk8Noch keine Bewertungen

- Strength & failure modes of concreteDokument12 SeitenStrength & failure modes of concretemaneeshaNoch keine Bewertungen

- Pressure Vessel Rupture 1571662927 PDFDokument9 SeitenPressure Vessel Rupture 1571662927 PDFbilalak1990Noch keine Bewertungen

- Stress Analysis Bolted JointDokument11 SeitenStress Analysis Bolted JointGustavoYippeekayyayGusNoch keine Bewertungen

- Unitor Udf 2100 Ultrasonic Cleaner 230VDokument2 SeitenUnitor Udf 2100 Ultrasonic Cleaner 230Vankarthik11Noch keine Bewertungen

- Printable Flashcard On API 570 Flashcards - Free Flash CardsDokument3 SeitenPrintable Flashcard On API 570 Flashcards - Free Flash Cardstipu321Noch keine Bewertungen

- Al Self Priming PumpDokument15 SeitenAl Self Priming PumpHalley ElangovanNoch keine Bewertungen

- "View" "Slide Show.": Resources Chapter MenuDokument62 Seiten"View" "Slide Show.": Resources Chapter Menuelty TanNoch keine Bewertungen

- Stainless Steel Float Level Switch and Mechanical Float Switch for Tank Level MonitoringDokument1 SeiteStainless Steel Float Level Switch and Mechanical Float Switch for Tank Level MonitoringErick Nacor ArevaloNoch keine Bewertungen