Beruflich Dokumente

Kultur Dokumente

Brinell Hardness Test

Hochgeladen von

MYasirOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Brinell Hardness Test

Hochgeladen von

MYasirCopyright:

Verfügbare Formate

EXPERIMENT NO.

1

BRINELL HARDNESS TEST

Objectives:

To determine the deformation of metal specimen when

hardened steel specimen is pressed into it under different

normal loads.

To use the dentation to determine the properties of a metal.

Apparatus:

Brinell hardness tester

Weights

Mild steel sample

Microscope ( scale and graduated)

Steel ball (indenter)

THEORY:

Hardness is the property of a material by virtue of its ability to

resist indentation and scratching by harder bodies. It is the

resistance of a material to permanent deformation of the

surface. In other words, one can define it as the resistance of

the metal to penetration by indenter. The hardness of a surface

of the material is, of course, a direct result of inter-atomic

forces acting on the surface of the material. We must note that

hardness is not a fundamental property of a material, however,

but rather a combined effect of compressive, elastic and

plastics properties relative to mode of penetration, shape of

penetrator, etc. Hardness seems to bear a fairly constant

relationship to the tensile strength of given material and thus it

can be used as a practical non-destructive test for an

approximate idea of the value of that property and the state of

the metal near the surface.

All hardness tests are made on the surface. We may note that

in mechanical tests the bulk of material is involved.

Sometimes hardness is expressed in terms of macro hardness &

micro hardness. The macro hardness of material relates to its

resistance to larger value displacements in plastic deformation,

whereas micro hardness is the hardness of the materials in

microscopically small volumes e.g. in grain boundaries.

Hardness of material is of importance for dies and punches,

limit gauges, cutting tools, bearing surfaces etc. Softness of a

material is opposite extreme of hardness. On heating all

materials become soft.

Brinell Hardness Number:

Brinell hardness number is the hardness index, calculated by

pressing a hardened steel ball (indenter) into test specimen

under standardized hardness of metallic materials, to check

quality level of products, for uniformity of samples of metals.

The Brinell hardness number is obtained by dividing the applied

force by the spherical surface area of the indentation.

Mathematically;

BHN =

BHN =

Applied load Kg

Areaof indentation

2P

D [D D2d 2 ]

Where,

P= Applied load, D=

indentation impression

Diameter

of

steel

ball,

d=

Brinell harness tester have a scope that we calculate the

hardness number of material but it also have a demerit that it

is used to test those structure that have a rough surfaces and

hence we also separately need a microscope to check the

indentation impression and a scale to measure it. As compared

to that Rockwell is compatible easier in calculations because it

gives a hardness number on it scale we dont need separate

scale for that.

FIGURE:

Procedure:

I. 1. First we clean the specimen from grease, and all dirt.

II.

III.

IV.

Then we placed the specimen in brinell hardness tester

Then Apply the load of 3000 Kg and ball indenter we use

10 mm in diameter for a few second

Further removed the load and we get indentation

impression

V.

VI.

See this indentation impression by the help of microscope

and measure it with a scale which is engraved with a

microscope

Hence we get Hardness number of specimen

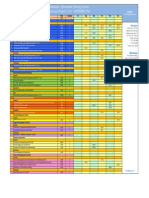

Observation and Calculation:

Sr.No

Applied

Load (P)

(Kg)

Ball Diameter

diameter( of

D)

Indent(d)

(mm)

(mm)

3000

10

3.65

Brinell

Hardnes

s

Number

(B.H.N)

280

3000

10

3.6

277

Sample Calculation:

2(3000)

B.H.N =

3.14 10[10 ( 10 )2 (3.65 )2]

3000/10.675

280 .00

So, above expression show that B.H.N is

280.00 for mild steel

Conclusion: We can calculate the mild steel hardness

number with the help of Hardness tester machine. So with the

help of that we become familiar about the brinell hardness

number of mild steel.

Das könnte Ihnen auch gefallen

- PRINCE2 Quick Reference Guide PDFDokument2 SeitenPRINCE2 Quick Reference Guide PDFLebo MaleboNoch keine Bewertungen

- Central Institute of Plastics Engineering and Technology, LucknowDokument12 SeitenCentral Institute of Plastics Engineering and Technology, Lucknowkiran yadavNoch keine Bewertungen

- EG5096 Fatigue and Fracture Mechanics Exam PaperDokument4 SeitenEG5096 Fatigue and Fracture Mechanics Exam PaperShanice McAlister-BishopNoch keine Bewertungen

- Quality Toolkit For Managers PDFDokument38 SeitenQuality Toolkit For Managers PDFMBA EngineerNoch keine Bewertungen

- Guidelines Fmea - Dyadem Press - 2003Dokument143 SeitenGuidelines Fmea - Dyadem Press - 2003Cali MelendezNoch keine Bewertungen

- Thermal Aspects in Metal CuttingDokument122 SeitenThermal Aspects in Metal CuttingSanjay NayeeNoch keine Bewertungen

- Fasl 1,2 PDFDokument3 SeitenFasl 1,2 PDFalvin tehraniNoch keine Bewertungen

- Finalized Panaflex of Vickers Hardness TestDokument2 SeitenFinalized Panaflex of Vickers Hardness TestMohsin Qazi100% (1)

- AE 2202 THERMOdynamics - 2 Mark QuestionsDokument56 SeitenAE 2202 THERMOdynamics - 2 Mark QuestionsthanikavelNoch keine Bewertungen

- Study On Mechanical Behaviour of Banana Fiber Reinforced Epoxy CompositesDokument30 SeitenStudy On Mechanical Behaviour of Banana Fiber Reinforced Epoxy Compositespramo_dassNoch keine Bewertungen

- Gas Dynamics and Jet Propulsion - 2 Marks - All 5 UnitsDokument22 SeitenGas Dynamics and Jet Propulsion - 2 Marks - All 5 UnitsMohan Prasad.M80% (10)

- Experiment # 3: Part Manufacturing Using 3D PrintingDokument12 SeitenExperiment # 3: Part Manufacturing Using 3D PrintingMuhammad FarhanNoch keine Bewertungen

- Production Technology Question PaperDokument3 SeitenProduction Technology Question PaperChirag100% (2)

- Unit 5 Balancing of Reciprocating MassesDokument43 SeitenUnit 5 Balancing of Reciprocating MassesNAVEENNoch keine Bewertungen

- Experiment No: 04 Experiment Name: Study and Observation of Compression Test of A HelicalDokument5 SeitenExperiment No: 04 Experiment Name: Study and Observation of Compression Test of A Helicalmd.Aktaruzzaman aktarNoch keine Bewertungen

- ComparatorDokument8 SeitenComparatorDr. N. S. Sriram100% (1)

- Mom Lab ManualDokument77 SeitenMom Lab ManualHammad SubhaniNoch keine Bewertungen

- Experiment No 3Dokument3 SeitenExperiment No 3pomar026100% (1)

- 53207-mt - Industrial TribologyDokument2 Seiten53207-mt - Industrial TribologySRINIVASA RAO GANTANoch keine Bewertungen

- Metrology Lab ManualDokument21 SeitenMetrology Lab ManualelavarasanNoch keine Bewertungen

- NDT Syallbus Anna University PDFDokument1 SeiteNDT Syallbus Anna University PDFSaravana Kumar MNoch keine Bewertungen

- Unit-III, Advanced Mechanisms PDFDokument41 SeitenUnit-III, Advanced Mechanisms PDFvamsi krishnaNoch keine Bewertungen

- Principles of Management P C Tripathi P N Reddy PDFDokument473 SeitenPrinciples of Management P C Tripathi P N Reddy PDFVarshaNoch keine Bewertungen

- Detc2016 59570Dokument11 SeitenDetc2016 59570Muhammad Uzair ShahNoch keine Bewertungen

- Ce 8381som Lab ManualDokument31 SeitenCe 8381som Lab ManualAERO JPR50% (2)

- Design of Machine Elements2Dokument14 SeitenDesign of Machine Elements2Satwik PriyadarshiNoch keine Bewertungen

- Additive Manufacturing: Department of Mechanical EngineeringDokument64 SeitenAdditive Manufacturing: Department of Mechanical EngineeringnareshNoch keine Bewertungen

- Production Lab Viva Question & AnswersDokument13 SeitenProduction Lab Viva Question & AnswersPradeep GsNoch keine Bewertungen

- SOM 2 MarksDokument8 SeitenSOM 2 MarksSiva ShanmugamNoch keine Bewertungen

- Lecture Notes 5 - 2 Fracture MechanicsDokument26 SeitenLecture Notes 5 - 2 Fracture MechanicsParash ChakmaNoch keine Bewertungen

- Multi Type ForkliftDokument46 SeitenMulti Type ForkliftlokeshNoch keine Bewertungen

- Rockwell Hardness TestDokument6 SeitenRockwell Hardness TestChinmay DeoNoch keine Bewertungen

- Project Report 3Dokument70 SeitenProject Report 3DhinakaranNoch keine Bewertungen

- Mos Lab ManualDokument71 SeitenMos Lab ManualAtul GaurNoch keine Bewertungen

- Mini Project ReportDokument9 SeitenMini Project ReportJayanth Gowda Virat100% (1)

- Me 8513 MM Lab 2022 OddDokument63 SeitenMe 8513 MM Lab 2022 OddVelan PrintersNoch keine Bewertungen

- Properties of MaterialsDokument35 SeitenProperties of MaterialsRyan Jeffrey Padua CurbanoNoch keine Bewertungen

- Strength of Materials Lab ManualDokument46 SeitenStrength of Materials Lab ManualgvijaymNoch keine Bewertungen

- Machine Tools LabDokument85 SeitenMachine Tools Labmohammad sammeerNoch keine Bewertungen

- 01-Industrial Visit Doc. ListDokument12 Seiten01-Industrial Visit Doc. ListNachiket Kadlag100% (1)

- Experiment No 02 To Study The Different Parts of Lathe MachineDokument4 SeitenExperiment No 02 To Study The Different Parts of Lathe MachineMuhammad SohailNoch keine Bewertungen

- Source of HeatDokument9 SeitenSource of HeatSreekumar RajendrababuNoch keine Bewertungen

- Subject Metal Cutting and Tool Design de PDFDokument2 SeitenSubject Metal Cutting and Tool Design de PDFBabuli KumarNoch keine Bewertungen

- ROE-035 Polymer Science and TechnologyDokument1 SeiteROE-035 Polymer Science and TechnologyJatin Sharma0% (1)

- Design of Form ToolsDokument2 SeitenDesign of Form ToolsSunny GaekwadNoch keine Bewertungen

- Ces511 - Structural Engineering Laboratory Lab Experiment: Bending Moment and Shear Force in Beams (Co2:Po5)Dokument13 SeitenCes511 - Structural Engineering Laboratory Lab Experiment: Bending Moment and Shear Force in Beams (Co2:Po5)elhammeNoch keine Bewertungen

- Metal Joining PrcocessDokument42 SeitenMetal Joining PrcocessDheerajSharmaNoch keine Bewertungen

- Me2303 - Design of Machine ElementsDokument14 SeitenMe2303 - Design of Machine ElementsGowtham RajNoch keine Bewertungen

- Strength of Materials/Mechanics of Solids (CE-303/DCE-303) - Short Answer Questions-UIT-RGPV BHOPALDokument4 SeitenStrength of Materials/Mechanics of Solids (CE-303/DCE-303) - Short Answer Questions-UIT-RGPV BHOPALSantosh Kumar0% (1)

- JNANASHODHADokument3 SeitenJNANASHODHASandhya GVNoch keine Bewertungen

- Lecture Notes - Metal Forming PDFDokument68 SeitenLecture Notes - Metal Forming PDFIrfan KhanNoch keine Bewertungen

- MosDokument42 SeitenMosSajjan Kumar100% (2)

- TR - Infrared Thermometer PDFDokument24 SeitenTR - Infrared Thermometer PDFchica_asNoch keine Bewertungen

- Summer Internship: Shri Sainath Electricals Pvt. LTDDokument18 SeitenSummer Internship: Shri Sainath Electricals Pvt. LTDYash Paradkar100% (1)

- Heat and Mass Transfer (Subject Code: KME 501) Unit Introduction To Heat TransferDokument2 SeitenHeat and Mass Transfer (Subject Code: KME 501) Unit Introduction To Heat TransferRajeev100% (2)

- Basic of GrindingDokument19 SeitenBasic of GrindingKaushik SreenivasNoch keine Bewertungen

- Experiment: Apparatus UsedDokument2 SeitenExperiment: Apparatus UsedamitNoch keine Bewertungen

- 3.whirling of ShaftDokument3 Seiten3.whirling of ShaftRishi ShuklaNoch keine Bewertungen

- Workshop Laboratory Manual PDFDokument95 SeitenWorkshop Laboratory Manual PDFPradipta PaulNoch keine Bewertungen

- Lab ReportDokument21 SeitenLab ReportMuhammad YasirNoch keine Bewertungen

- Brinell Hardness TestDokument7 SeitenBrinell Hardness Testharyad.tce2122065Noch keine Bewertungen

- Materials Engg Hardness TestDokument8 SeitenMaterials Engg Hardness TestSourav KayalNoch keine Bewertungen

- Value of Marginal ProductDokument5 SeitenValue of Marginal ProductMohammad BathishNoch keine Bewertungen

- 3rd Week - PTI - Kerangka Konseptual TIDokument27 Seiten3rd Week - PTI - Kerangka Konseptual TIarifNoch keine Bewertungen

- Public Training Schedule Lloyyd LRQA 2014Dokument1 SeitePublic Training Schedule Lloyyd LRQA 2014Citra FerdyanNoch keine Bewertungen

- MRP and Erp: Mcgraw-Hill/IrwinDokument31 SeitenMRP and Erp: Mcgraw-Hill/IrwinB SNoch keine Bewertungen

- 1 PBDokument12 Seiten1 PBLaras NisrinaNoch keine Bewertungen

- Powermill NCSIMUL Interface EN PDFDokument1 SeitePowermill NCSIMUL Interface EN PDFnnn765Noch keine Bewertungen

- Business Logistics/Supply Chain-A Vital SubjectDokument25 SeitenBusiness Logistics/Supply Chain-A Vital SubjectRavi100% (1)

- Solution: Behind The Supply Curve: Inputs and CostsDokument14 SeitenSolution: Behind The Supply Curve: Inputs and CostsjeninaNoch keine Bewertungen

- 4quality Tools Technique Used by Company WiproDokument10 Seiten4quality Tools Technique Used by Company WiproSushil JaiswalNoch keine Bewertungen

- Using Operations To Create Value: Eleventh EditionDokument24 SeitenUsing Operations To Create Value: Eleventh EditionOmer ChowdhuryNoch keine Bewertungen

- ERP ReportDokument11 SeitenERP ReportZarlish AnumNoch keine Bewertungen

- Setting Product StrategyDokument19 SeitenSetting Product StrategyNoora ZulfiqarNoch keine Bewertungen

- Short Run Average Costs, Marginal CostDokument21 SeitenShort Run Average Costs, Marginal CostTemitayo OguntiNoch keine Bewertungen

- Akuntansi Biaya - Tugas E4-23Dokument3 SeitenAkuntansi Biaya - Tugas E4-23Rizkya Ajrin ArtameviaNoch keine Bewertungen

- Firms and Production: Reading: Perlo Chapter 6Dokument62 SeitenFirms and Production: Reading: Perlo Chapter 6Prachi TamtaNoch keine Bewertungen

- Continual Improvement Process-1Dokument3 SeitenContinual Improvement Process-1Harrison NchoeNoch keine Bewertungen

- Principles of Total Quality ManagementDokument19 SeitenPrinciples of Total Quality ManagementAbhisek SamantaNoch keine Bewertungen

- Disclosure To Promote The Right To InformationDokument17 SeitenDisclosure To Promote The Right To InformationAnonymous NRlowQUcnNoch keine Bewertungen

- Industrial Management IPE 481: Tanveer Hossain Bhuiyan Assistant Professor, Dept. of IPE BuetDokument63 SeitenIndustrial Management IPE 481: Tanveer Hossain Bhuiyan Assistant Professor, Dept. of IPE BuetNaimul Hoque ShuvoNoch keine Bewertungen

- Farm Management (Agec3101) : Department of Agricultural EconomicsDokument52 SeitenFarm Management (Agec3101) : Department of Agricultural EconomicsDagnachew Wale100% (2)

- ProductionCost ProblemsDokument3 SeitenProductionCost ProblemsRyanNoch keine Bewertungen

- Cost CurveDokument8 SeitenCost CurveBimbo GrilloNoch keine Bewertungen

- Eas Jan 2020Dokument2.407 SeitenEas Jan 2020MalcolmNoch keine Bewertungen

- CH 16Dokument42 SeitenCH 16Abdulrahman AlotaibiNoch keine Bewertungen

- FMEADokument49 SeitenFMEAHermanManru100% (1)

- Good Manufacturing PracticesDokument1 SeiteGood Manufacturing PracticesVidya VijayanNoch keine Bewertungen

- Answer Key Bacostmx-3tay2021-Finals Quiz 2Dokument8 SeitenAnswer Key Bacostmx-3tay2021-Finals Quiz 2Marjorie Nepomuceno100% (1)