Beruflich Dokumente

Kultur Dokumente

7541 1462 5100 1 Syllabus

Hochgeladen von

sumikannuOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

7541 1462 5100 1 Syllabus

Hochgeladen von

sumikannuCopyright:

Verfügbare Formate

Syllabus

Engineering Technology

University of North Texas

Course Title: Nontraditional

Manufacturing Processes

Course Prefix and Course Number:

MSES 5100

Semester: Spring, 2010

The Engineering Technology Department, in cooperation with the Office

of Disability Accommodation, complies with the Americans with

Disabilities Act in making reasonable accommodations for qualified

students with disabilities. Please present your written accommodation

request to the instructor prior to the fourth day.

SAFETY CATEGORY: 1

Final Examination : Wednesday, 5/12/10 1:30-3:30pm

ENGINEERING TECHNOLOGY

COLLEGE OF ENGINEERING

UNT RESEARCH PARK

University of North Texas

Engineering Technology

940/565-2022

DATE PREPARED: 1/13/10

PREPARED BY: Phillip R.

Foster

COURSE NUMBER, TITLE, CREDIT HOURS:

MSES 5100, Nontraditional Manufacturing Processes. 3 hours

DESCRIPTION:

Analysis of selected contemporary and emerging manufacturing/production processes

utilizing high-level automation, productivity-enhancing technologies and/or specialty

technologies; emphasis on process structure, organization, economics and application

within the industrial environment.

REQUIRED TEXTBOOK:

None

SUPPLEMENTAL TEXTS AND MATERIALS:

Oberg, E., et al., Machinerys Handbook, 28th Ed., NY: Industrial Press, 2008., ISBN:

9780-8311-2800-5

Weller, E., (ed.), Nontraditional Machining Processes, 2nd Ed., Dearborn: Society of

Manufacturing Engineers., 1984., ISBN 0-87263-133-8 (Out of Print but text will be

loaned for additional depth appropriate pages/lecture noted in assignment column of

course outline)

COURSE OBJECTIVES: At the conclusion of this course, the student will (be able to):

1. Acquire functional understanding of nontraditional manufacturing equipment.

2. Understand terminology used in nontraditional manufacturing industries.

3. Explore, from computational and theoretical points of view, those concepts

prerequisite to the study of advanced manufacturing systems.

INSTRUCTIONAL OBJECTIVES

1. Tech briefs are to be completed, adhering to the format in the working syllabus, and

submitted at designated dates.

2. Quizzes shall consist of free response items from the previous week or previous weeks

Page 2

University of North Texas

Engineering Technology

lecture ( as announced by the professor).

3. The two examinations will be forced response items and non-cumulative with

reference to semester's content. The items will solicit detailed technical information as

well as more broadly-based generalizations regarding processing capabilities,

advantages and disadvantages.

4. The Power Point Presentation assignment shall be prepared, adhering to the

instructions in the working syllabus, and presented to the class.

LEARNING STRATEGIES: Lecture, demonstration

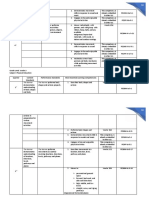

COURSE OUTLINE:

Week

1

MLK Holiday

The University is closed.

Lecture

Assignments

Introduction, Organization of Course, Policies, The

Nature of Nontraditional Manufacturing Processes

The course introduction includes: course prerequisites, specifics concerning all course

assignments, and evaluation methods. Policies discussed include: attendance and

scholastic dishonesty. The initial technical lecture addresses the nature of nontraditional

manufacturing processes in terms of mechanical, electrical, thermal and chemical

energy.

3

Abrasive Jet Machining; Water Jet Machining

37-52; 65-69; TB#1

The lecture addresses Abrasive Jet Machining and Water Jet Machining in terms of:

operational principles and characteristics; process hardware, parameters and

capabilities; typical application examples; and, advantages and disadvantages of the

technology.

4

Abrasive Water Jet Machining; Abrasive Flow Machining

52-61; TB #2

The lecture addresses Abrasive Water Jet Machining and Abrasive Flow Machining in

terms of: operational principles and characteristics; process hardware, parameters and

capabilities; typical application examples; and, advantages and disadvantages of the

technology.

5

Ultrasonic Machining; Ultrasonic Welding

15-37; TB #3

The lecture addresses Ultrasonic Machining and Ultrasonic Welding in terms of:

operational principles and characteristics; process hardware, parameters and

capabilities; typical application examples; and, advantages and disadvantages of the

technology.

Page 3

University of North Texas

Engineering Technology

6

Chemical Machining; Electro Stream Drilling

221-261; TB #4

The lecture addresses Chemical Machining and Electro Stream Drilling in terms of:

operational principles and characteristics; process hardware, parameters and

capabilities; typical application examples; and, advantages and disadvantages of the

technology.

7

Electromechanical Machining

TB #5

The lecture addresses Electromechanical Machining in terms of: operational principles

and characteristics; process hardware, parameters and capabilities; typical application

examples; and, advantages and disadvantages of the technology.

8

Prep for Midterm Exam; Electrochemical Grinding;

Electrochemical Discharge Grinding

94-108

The lecture addresses Electrochemical Grinding and Electrochemical Discharge

Grinding in terms of: operational principles and characteristics; process hardware,

parameters and capabilities; typical application examples; and, advantages and

disadvantages of the technology.

9

Midterm Exam

10

Review Midterm Results; Electric Discharge Machining

162-201

The lecture addresses, in an item by item format, the Midterm Examination taken the

previous class meeting. Included are item explanations, calculations, and class grade

distribution. The lecture addresses Electric Discharge Machining in terms of:

operational principles and characteristics; process hardware, parameters and

capabilities; typical application examples; and, advantages and disadvantages of the

technology.

11

Thermal Energy Methods; Electric Discharge Wire Cutting

202-204; 216-218

The lecture addresses Thermal Energy Methods and Electric Discharge Wire Cutting in

terms of: operational principles and characteristics; process hardware, parameters and

capabilities; typical application examples; and, advantages and disadvantages of the

technology.

12

Electron Beam Welding

PPT

The lecture addresses Electron Beam Welding in terms of: operational principles and

characteristics; process hardware, parameters and capabilities; typical application

examples; and, advantages and disadvantages of the technology.

Page 4

University of North Texas

Engineering Technology

13

Electron Beam Machining; Plasma Arc Cutting

121-137; 205-216;

PPT

The lecture addresses Electron Beam Machining and Plasma Arc Cutting in terms of:

operational principles and characteristics; process hardware, parameters and

capabilities; typical application examples; and, advantages and disadvantages of the

technology.

14

Laser Processing

137-162; PPT

The lecture addresses Laser Processing in terms of: operational principles and

characteristics; process hardware, parameters and capabilities; typical application

examples; and, advantages and disadvantages of the technology.

15

Prep for Final Exam; Electric Discharge Grinding

97-100; PPT

The lecture addresses Electric Discharge Grinding in terms of: operational principles

and characteristics; process hardware, parameters and capabilities; typical application

examples; and, advantages and disadvantages of the technology.

16

Final Exam

5/12/10 1:30-3:30pm

ORAL COMMUNICATION USAGE: Power Point Presentation

WRITTEN COMMUNICATION USAGE: Tech Briefs

GRADING ELEMENTS AND WEIGHTS:

Tech Briefs

Quizzes

Power Point Presentation

Midterm Examination

Final Examination

5%

25%

20%

25%

25%

GRADING POLICIES:

Timetable for submission of assignments is provided on pp. 3-5 of the syllabus; no late

assignments are accepted. Quiz and examination performance interpretations are based

on maximum scores accrued by students, not maximum points possible. Letter grades are

determined using the following scale:

90% to 100%

A

80% to 89.99%

B

70% to 79.99%

C

60% to 69.99%

D

Below 60%

F

Page 5

University of North Texas

Engineering Technology

CLASS POLICIES:

1.

All rules relating to academic dishonesty will be enforced in accordance with

University policies. Cheating on quizzes, examinations and laboratory assignments,

and plagiarism on various papers and reports are types of disciplinary misconduct for

which penalties are assessed under the UNT Code of Student Conduct and Discipline.

Be advised that the instructor of this course supports and fully implements this policy.

The following actions will be taken when evidence of such misconduct is observed.

The student will be presented with the evidence of misconduct and given an

opportunity to explain same. Based on the outcome of this private conference, the

matter will be either dropped or the student will be given a grade of "F" in the course

and be referred to the Dean of Students for further action.

2.

During the course, handouts will be provided to enhance the presentation of

certain concepts. These materials are provided strictly for instructional purposes and

may other wise be restricted

3.

This syllabus is subject to change at any time during the semester with changes to

be announced in class.

4.

Each student should retain graded lecture notes, pop quizzes, homework, tests,

software-generated files, and laboratory reports to document errors in recorded

grades.

5.

Requests for review of graded work must be submitted during the lecture in which

such work is returned to the students. The request should be accompanied by a written

justification of the request including any supporting data.

6.

There is no limit to the use of calculators for lecture, labs, quizzes, tests, or

examinations. No computers are permitted in any quiz, test or examination.

7.

Should you have a complaint regarding an aspect of this course, you should first

discuss your complaint with the instructor. If you wish to carry it further, contact the

Program Coordinator by calling (940) 565-2022. To further pursue your complaint,

contact the Department Chair at (940) 565-2022, but ONLY after first discussing your

concern with the previous two individuals.

8.

Material Safety Data Sheets (MSDS) are maintained on file in the department for

your review. Access to these documents may be provided by the instructor of this

course, or the Program Coordinator. Seek initial access through the instructor.

Page 6

University of North Texas

Engineering Technology

Power Point Presentation

Topical Area: An approved nontraditional manufacturing process

Format: Similar to lectures, i.e., address the following:

Operational Principles

Operational Characteristics

Process Hardware

Process Parameters

Process Capabilities

Application Examples

Process Summary

Advantages

Disadvantages

Include with Narrative: Pictures, charts, graphs (animation if you wish), sources

Length: 30 Minutes

Submit .PPT on a CD at conclusion of presentation; presentations will be made during

the last four meetings of the semester

Page 7

University of North Texas

Engineering Technology

Tech Brief

Procedure: Read an article or report pertaining to some aspect of non-traditional

manufacturing. The publication date should be no earlier than 2008. Compose a

condensed, factual Tech Brief descriptive of the major thrust of the article or report. It

should be word processed and about one or two paragraphs in length, single spaced. Do

not copy from the source document. Adhere to the example shown below for format.

Deviations from the format will not receive credit.

Tech Brief #1

MFET 3110

Section 001

John Doe

10/10/10

Source: Kennicott, Thomas. Transfer Machines in the 80s. Manufacturing

Engineering, 1982, pp.111-112.

Thrust: High speed precision machining operations that once required separate special machines

are now routinely performed on multi-station, transfer-type systems. This allows the manufacture

of different parts, models, or families of parts on the same machining system. Further flexibility

is evident in the non-synchronous transfer concept in which production continues even though

one or more individual machines in the system are down. Increased flexibility is manifest in

faster change-over, automated tool change capability, and overall improvement in machine

utilization. Transfer machining systems are particularly suited to computer numerical control

(CNC) equipment.

Page 8

Das könnte Ihnen auch gefallen

- Energy Storage Devices for Electronic Systems: Rechargeable Batteries and SupercapacitorsVon EverandEnergy Storage Devices for Electronic Systems: Rechargeable Batteries and SupercapacitorsBewertung: 5 von 5 Sternen5/5 (1)

- MMET 303 Fluid Mechanics and Power SyllabusDokument5 SeitenMMET 303 Fluid Mechanics and Power SyllabusJNoch keine Bewertungen

- Schaums Outline of Thermodynamics for Engineers, Fourth EditionVon EverandSchaums Outline of Thermodynamics for Engineers, Fourth EditionBewertung: 5 von 5 Sternen5/5 (5)

- Protecciones California State U EEE145 SyllabusDokument7 SeitenProtecciones California State U EEE145 Syllabusjorge gonzalezNoch keine Bewertungen

- Reliability Investigation of LED Devices for Public Light ApplicationsVon EverandReliability Investigation of LED Devices for Public Light ApplicationsNoch keine Bewertungen

- Class Syllabus ME850 AFDokument8 SeitenClass Syllabus ME850 AFMd Shafinur MuradNoch keine Bewertungen

- Renewable Energy Production and Distribution Volume 2: Solutions and OpportunitiesVon EverandRenewable Energy Production and Distribution Volume 2: Solutions and OpportunitiesMejdi JeguirimNoch keine Bewertungen

- Studyguide Ead 410 2013Dokument29 SeitenStudyguide Ead 410 2013Herless FloresNoch keine Bewertungen

- Managing the Testing Process: Practical Tools and Techniques for Managing Hardware and Software TestingVon EverandManaging the Testing Process: Practical Tools and Techniques for Managing Hardware and Software TestingBewertung: 4 von 5 Sternen4/5 (8)

- ELEC5205 2014 Semester 2 StudentDokument4 SeitenELEC5205 2014 Semester 2 StudentAlexander MartinNoch keine Bewertungen

- Applied Mechanics W/Lab MET 2026: Pellissippi State Community College Master SyllabusDokument5 SeitenApplied Mechanics W/Lab MET 2026: Pellissippi State Community College Master SyllabusAbdelhay Mohamed HassanNoch keine Bewertungen

- WE5300 Syllabus F2019Dokument6 SeitenWE5300 Syllabus F2019Manohar ChamanaNoch keine Bewertungen

- ELSD310B Electrical System DesignDokument3 SeitenELSD310B Electrical System DesignKendall BirjueNoch keine Bewertungen

- Ome 2016 08 Eml4500 Machine Design 1 CaiDokument4 SeitenOme 2016 08 Eml4500 Machine Design 1 CaiMadison CallowayNoch keine Bewertungen

- ME3450 Syllabus 2011 Fall v3Dokument7 SeitenME3450 Syllabus 2011 Fall v3petkirstNoch keine Bewertungen

- Ele 225Dokument4 SeitenEle 225Ahmad AbdelhakNoch keine Bewertungen

- Eml 3015 Syl Lab Us Fall 2018Dokument5 SeitenEml 3015 Syl Lab Us Fall 2018Bethany KellyNoch keine Bewertungen

- Office Hours: Mon 11:00 Am-Noon, Wed 1:00 pm-2:00 Pm-Or by AppointmentDokument9 SeitenOffice Hours: Mon 11:00 Am-Noon, Wed 1:00 pm-2:00 Pm-Or by AppointmentabukiNoch keine Bewertungen

- CASE STUDY PreziDokument16 SeitenCASE STUDY PreziTrisha Mae TrinidadNoch keine Bewertungen

- Power Electronics: University of AlcaláDokument9 SeitenPower Electronics: University of AlcaláHassanNoch keine Bewertungen

- Coursework TwoDokument5 SeitenCoursework TwoPa1 Kumar MNoch keine Bewertungen

- Syllabus ELEC 423 Power Distribution Spring 2012 MaleDokument4 SeitenSyllabus ELEC 423 Power Distribution Spring 2012 MaleMusa'bNoch keine Bewertungen

- 221 Outline-Fall 2014Dokument4 Seiten221 Outline-Fall 2014vince273Noch keine Bewertungen

- ENGG378-948 SubjectOutline - 2012Dokument4 SeitenENGG378-948 SubjectOutline - 2012spakfillaNoch keine Bewertungen

- Electrical DesignDokument10 SeitenElectrical DesignMiko QuijanoNoch keine Bewertungen

- Course Profile Elec Eng 2011 Circuit AnalysisDokument8 SeitenCourse Profile Elec Eng 2011 Circuit AnalysisLarry Gerard AquinoNoch keine Bewertungen

- ELEC273outline 2022Dokument5 SeitenELEC273outline 2022Tom ONoch keine Bewertungen

- COMP1154 Course Outline ModDokument5 SeitenCOMP1154 Course Outline Modquantum111Noch keine Bewertungen

- School of Electrical, Electronics and Computer Engineering: Mapúa Institute of TechnologyDokument5 SeitenSchool of Electrical, Electronics and Computer Engineering: Mapúa Institute of TechnologyMichael Calizo PacisNoch keine Bewertungen

- ECTE324 Subject OutlineDokument20 SeitenECTE324 Subject OutlineTuanHungNoch keine Bewertungen

- MECH 411 Course Outline - Fall 2016Dokument4 SeitenMECH 411 Course Outline - Fall 2016JohnNoch keine Bewertungen

- UTM Master of EngineeringDokument2 SeitenUTM Master of EngineeringSaravanan KerishnanNoch keine Bewertungen

- Elec4612 S2 2010Dokument6 SeitenElec4612 S2 2010Dhiraj SharmaNoch keine Bewertungen

- Prontuario INEL 4115Dokument3 SeitenProntuario INEL 4115luis PerezNoch keine Bewertungen

- ELEN90055 Control Systems: Credit Points: Level: Commencement Date & LocationDokument3 SeitenELEN90055 Control Systems: Credit Points: Level: Commencement Date & LocationtefsgNoch keine Bewertungen

- ELEC2133Summer 2013 2014Dokument10 SeitenELEC2133Summer 2013 2014Sydney FinestNoch keine Bewertungen

- Course End Survey - PsocDokument3 SeitenCourse End Survey - Psochareesh.makesuNoch keine Bewertungen

- EGRB 102 Syllabus (Spring 2015)Dokument6 SeitenEGRB 102 Syllabus (Spring 2015)unknown racerx50Noch keine Bewertungen

- Mse 2201Dokument7 SeitenMse 2201Netsanet GetnetNoch keine Bewertungen

- Ee 117L - ObeDokument5 SeitenEe 117L - ObeMichael Calizo PacisNoch keine Bewertungen

- 2.2. Teaching - Learning Processes (100) 2.2.1. Describe Processes Followed To Improve Quality of Teaching & LearningDokument8 Seiten2.2. Teaching - Learning Processes (100) 2.2.1. Describe Processes Followed To Improve Quality of Teaching & LearningMalleswara RaoNoch keine Bewertungen

- Che 413Dokument6 SeitenChe 413Charlie GalanNoch keine Bewertungen

- Elet4612k IndustrialautomationandprocesscontrolDokument6 SeitenElet4612k IndustrialautomationandprocesscontrolpasinduNoch keine Bewertungen

- SGP Course FileDokument108 SeitenSGP Course FilePrathap Vuyyuru100% (1)

- Process Control SyllabusDokument4 SeitenProcess Control Syllabuslogan6167Noch keine Bewertungen

- High Voltage Engineering OutlineDokument8 SeitenHigh Voltage Engineering OutlineZafar Ali KhanNoch keine Bewertungen

- Thesis On Chemical Engineering PDFDokument7 SeitenThesis On Chemical Engineering PDFxnehytwff100% (2)

- ECE 2208 - Lab ManualDokument71 SeitenECE 2208 - Lab ManualpythagoraNoch keine Bewertungen

- MEng Module Specification Northshore Curriculum PDFDokument10 SeitenMEng Module Specification Northshore Curriculum PDFhpathirathne_1575733Noch keine Bewertungen

- CHNG2801 2014 Semester 1 StudentDokument4 SeitenCHNG2801 2014 Semester 1 StudentRiley Murray RumingNoch keine Bewertungen

- Using A Mechanical Engineering Laboratory Course For AssessmentDokument18 SeitenUsing A Mechanical Engineering Laboratory Course For Assessmentray malonjaoNoch keine Bewertungen

- Meem 4200-5290 - Principles of Energy Conversion: Energy Conversions - The EbookDokument5 SeitenMeem 4200-5290 - Principles of Energy Conversion: Energy Conversions - The EbookMohamed Al-OdatNoch keine Bewertungen

- Power System Planning and OperationDokument2 SeitenPower System Planning and OperationDrGopikrishna Pasam100% (4)

- Course Outline: EMG 002 - Energy Modeling ProjectDokument6 SeitenCourse Outline: EMG 002 - Energy Modeling ProjectAnkit BansalNoch keine Bewertungen

- MAE 361 Syllabus 2019Dokument5 SeitenMAE 361 Syllabus 2019Gloria HolguinNoch keine Bewertungen

- Affiliated Institutions B.E. Electrical and Electronics Engineering R - 2013 Program Educational ObjectivesDokument110 SeitenAffiliated Institutions B.E. Electrical and Electronics Engineering R - 2013 Program Educational ObjectivesdineshpeterNoch keine Bewertungen

- Syllabus (Summer A) EML3001-LABDokument5 SeitenSyllabus (Summer A) EML3001-LABangelNoch keine Bewertungen

- EExxx SyllabusDokument3 SeitenEExxx SyllabusPapa SunshineNoch keine Bewertungen

- 2 - Learner Guide For Electrical Protection IV - 2016BDokument9 Seiten2 - Learner Guide For Electrical Protection IV - 2016BSboNoch keine Bewertungen

- Ele846 - W2016Dokument3 SeitenEle846 - W2016gui0381Noch keine Bewertungen

- BE Mech II Yr A Sec Production Tech ATT PercentageDokument6 SeitenBE Mech II Yr A Sec Production Tech ATT PercentagesumikannuNoch keine Bewertungen

- Agenda: Team Orientation DayDokument3 SeitenAgenda: Team Orientation DaysumikannuNoch keine Bewertungen

- Integrated Product and Process Development Unit I A. IntroductionDokument19 SeitenIntegrated Product and Process Development Unit I A. IntroductionsumikannuNoch keine Bewertungen

- Dr. Mahalingam College of Engineering and Technology, Pollachi - 642 003Dokument1 SeiteDr. Mahalingam College of Engineering and Technology, Pollachi - 642 003sumikannuNoch keine Bewertungen

- Dr. Mahalingam College of Engineering and Technology, PollachiDokument1 SeiteDr. Mahalingam College of Engineering and Technology, PollachisumikannuNoch keine Bewertungen

- Apt I NumbersDokument2 SeitenApt I NumberssumikannuNoch keine Bewertungen

- Ivyeara&b Hostel Stdnts DataDokument2 SeitenIvyeara&b Hostel Stdnts DatasumikannuNoch keine Bewertungen

- Block Diagram: NAME: E.Pradeep ROLL NO.:10E627Dokument3 SeitenBlock Diagram: NAME: E.Pradeep ROLL NO.:10E627sumikannuNoch keine Bewertungen

- Lec 28Dokument13 SeitenLec 28sumikannuNoch keine Bewertungen

- BE SW EEE Opting - List 2010 2015Dokument5 SeitenBE SW EEE Opting - List 2010 2015sumikannuNoch keine Bewertungen

- DR - Mahalingam College of Engineering & Technology, Pollachi - 3Dokument12 SeitenDR - Mahalingam College of Engineering & Technology, Pollachi - 3sumikannuNoch keine Bewertungen

- Itc LTD Interview QuestionsDokument2 SeitenItc LTD Interview QuestionssumikannuNoch keine Bewertungen

- Block Diagram: NAME: N.Pavitra ROLL NO.:10E626Dokument3 SeitenBlock Diagram: NAME: N.Pavitra ROLL NO.:10E626sumikannuNoch keine Bewertungen

- Block Diagram: NAME: B.Muthukannan ROLL NO.:10E622Dokument3 SeitenBlock Diagram: NAME: B.Muthukannan ROLL NO.:10E622sumikannuNoch keine Bewertungen

- Bank Po General English Model QuestionsDokument7 SeitenBank Po General English Model QuestionssumikannuNoch keine Bewertungen

- C - Question Paper Quark Media House India Pvt. LTD.: 1. What Is The Output of The Following CodeDokument9 SeitenC - Question Paper Quark Media House India Pvt. LTD.: 1. What Is The Output of The Following CodesumikannuNoch keine Bewertungen

- SampleDokument4 SeitenSamplesumikannuNoch keine Bewertungen

- Results (Provisional) : PSG College of TechnologyDokument1 SeiteResults (Provisional) : PSG College of TechnologysumikannuNoch keine Bewertungen

- PE MELCs Grade 3Dokument4 SeitenPE MELCs Grade 3MARISSA BERNALDONoch keine Bewertungen

- Retail Banking Black BookDokument95 SeitenRetail Banking Black Bookomprakash shindeNoch keine Bewertungen

- Measuring Temperature - Platinum Resistance ThermometersDokument3 SeitenMeasuring Temperature - Platinum Resistance Thermometersdark*nightNoch keine Bewertungen

- Cam 18 Test 3 ListeningDokument6 SeitenCam 18 Test 3 ListeningKhắc Trung NguyễnNoch keine Bewertungen

- Data Asimilasi Untuk PemulaDokument24 SeitenData Asimilasi Untuk PemulaSii Olog-olog PlonkNoch keine Bewertungen

- Modern and Nonlinear OpticsDokument181 SeitenModern and Nonlinear Opticssoma_venuNoch keine Bewertungen

- Convection Transfer EquationsDokument9 SeitenConvection Transfer EquationsA.N.M. Mominul Islam MukutNoch keine Bewertungen

- Jan 25th 6 TicketsDokument2 SeitenJan 25th 6 TicketsMohan Raj VeerasamiNoch keine Bewertungen

- Ajmera - Treon - FF - R4 - 13-11-17 FinalDokument45 SeitenAjmera - Treon - FF - R4 - 13-11-17 FinalNikita KadamNoch keine Bewertungen

- Open Letter To Hon. Nitin Gadkari On Pothole Problem On National and Other Highways in IndiaDokument3 SeitenOpen Letter To Hon. Nitin Gadkari On Pothole Problem On National and Other Highways in IndiaProf. Prithvi Singh KandhalNoch keine Bewertungen

- Fundamentals of Signal and Power Integrity PDFDokument46 SeitenFundamentals of Signal and Power Integrity PDFjaltitiNoch keine Bewertungen

- Draft JV Agreement (La Mesa Gardens Condominiums - Amparo Property)Dokument13 SeitenDraft JV Agreement (La Mesa Gardens Condominiums - Amparo Property)Patrick PenachosNoch keine Bewertungen

- 1995 Biology Paper I Marking SchemeDokument13 Seiten1995 Biology Paper I Marking Schemetramysss100% (2)

- 07 GDL Web-Site 04 (2021-2022) For 15284Dokument2 Seiten07 GDL Web-Site 04 (2021-2022) For 15284ABCDNoch keine Bewertungen

- Hazardous Locations: C.E.C. ClassificationsDokument4 SeitenHazardous Locations: C.E.C. ClassificationsThananuwat SuksaroNoch keine Bewertungen

- Epreuve Anglais EG@2022Dokument12 SeitenEpreuve Anglais EG@2022Tresor SokoudjouNoch keine Bewertungen

- Chinese Paper Cutting Work SheetDokument4 SeitenChinese Paper Cutting Work Sheet黃梓Noch keine Bewertungen

- Implications of A Distributed Environment Part 2Dokument38 SeitenImplications of A Distributed Environment Part 2Joel wakhunguNoch keine Bewertungen

- Soujanya Reddy (New)Dokument6 SeitenSoujanya Reddy (New)durgaNoch keine Bewertungen

- Iaea Tecdoc 1092Dokument287 SeitenIaea Tecdoc 1092Andres AracenaNoch keine Bewertungen

- 3 Diversion&CareDokument2 Seiten3 Diversion&CareRyan EncomiendaNoch keine Bewertungen

- CiscoDokument6 SeitenCiscoNatalia Kogan0% (2)

- FpsecrashlogDokument19 SeitenFpsecrashlogtim lokNoch keine Bewertungen

- Draft PDFDokument166 SeitenDraft PDFashwaq000111Noch keine Bewertungen

- Project Formulation and Appraisalpdf PDFDokument12 SeitenProject Formulation and Appraisalpdf PDFabhijeet varadeNoch keine Bewertungen

- Walking in Space - Lyrics and Chord PatternDokument2 SeitenWalking in Space - Lyrics and Chord Patternjohn smithNoch keine Bewertungen

- Previous Year Questions - Macro Economics - XIIDokument16 SeitenPrevious Year Questions - Macro Economics - XIIRituraj VermaNoch keine Bewertungen

- Grid Pattern PortraitDokument8 SeitenGrid Pattern PortraitEmma FravigarNoch keine Bewertungen

- Practising Modern English For Life Sciences Students Caiet Exercitii-1Dokument77 SeitenPractising Modern English For Life Sciences Students Caiet Exercitii-1Robert BobiaNoch keine Bewertungen

- BLP#1 - Assessment of Community Initiative (3 Files Merged)Dokument10 SeitenBLP#1 - Assessment of Community Initiative (3 Files Merged)John Gladhimer CanlasNoch keine Bewertungen

- Generative AI: The Insights You Need from Harvard Business ReviewVon EverandGenerative AI: The Insights You Need from Harvard Business ReviewBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Cyber War: The Next Threat to National Security and What to Do About ItVon EverandCyber War: The Next Threat to National Security and What to Do About ItBewertung: 3.5 von 5 Sternen3.5/5 (66)

- Chaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyVon EverandChaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyBewertung: 3.5 von 5 Sternen3.5/5 (111)

- Scary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldVon EverandScary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldBewertung: 4.5 von 5 Sternen4.5/5 (55)

- Algorithms to Live By: The Computer Science of Human DecisionsVon EverandAlgorithms to Live By: The Computer Science of Human DecisionsBewertung: 4.5 von 5 Sternen4.5/5 (722)

- The E-Myth Revisited: Why Most Small Businesses Don't Work andVon EverandThe E-Myth Revisited: Why Most Small Businesses Don't Work andBewertung: 4.5 von 5 Sternen4.5/5 (709)

- The Future of Geography: How the Competition in Space Will Change Our WorldVon EverandThe Future of Geography: How the Competition in Space Will Change Our WorldBewertung: 4 von 5 Sternen4/5 (6)

- Digital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyVon EverandDigital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyBewertung: 4 von 5 Sternen4/5 (51)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyVon EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyNoch keine Bewertungen

- System Error: Where Big Tech Went Wrong and How We Can RebootVon EverandSystem Error: Where Big Tech Went Wrong and How We Can RebootNoch keine Bewertungen

- Mini Farming: Self-Sufficiency on 1/4 AcreVon EverandMini Farming: Self-Sufficiency on 1/4 AcreBewertung: 4 von 5 Sternen4/5 (76)

- AI Superpowers: China, Silicon Valley, and the New World OrderVon EverandAI Superpowers: China, Silicon Valley, and the New World OrderBewertung: 4.5 von 5 Sternen4.5/5 (399)

- The Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumVon EverandThe Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumBewertung: 3 von 5 Sternen3/5 (12)

- Excel Essentials: A Step-by-Step Guide with Pictures for Absolute Beginners to Master the Basics and Start Using Excel with ConfidenceVon EverandExcel Essentials: A Step-by-Step Guide with Pictures for Absolute Beginners to Master the Basics and Start Using Excel with ConfidenceNoch keine Bewertungen

- HBR's 10 Must Reads on AI, Analytics, and the New Machine AgeVon EverandHBR's 10 Must Reads on AI, Analytics, and the New Machine AgeBewertung: 4.5 von 5 Sternen4.5/5 (69)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindVon EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNoch keine Bewertungen

- Learn Python Programming for Beginners: Best Step-by-Step Guide for Coding with Python, Great for Kids and Adults. Includes Practical Exercises on Data Analysis, Machine Learning and More.Von EverandLearn Python Programming for Beginners: Best Step-by-Step Guide for Coding with Python, Great for Kids and Adults. Includes Practical Exercises on Data Analysis, Machine Learning and More.Bewertung: 5 von 5 Sternen5/5 (34)

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveVon EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveNoch keine Bewertungen

- Evaluation of Some SMS Verification Services and Virtual Credit Cards Services for Online Accounts VerificationsVon EverandEvaluation of Some SMS Verification Services and Virtual Credit Cards Services for Online Accounts VerificationsBewertung: 5 von 5 Sternen5/5 (2)

- The Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldVon EverandThe Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldBewertung: 4.5 von 5 Sternen4.5/5 (107)

- Solutions Architect's Handbook: Kick-start your career as a solutions architect by learning architecture design principles and strategiesVon EverandSolutions Architect's Handbook: Kick-start your career as a solutions architect by learning architecture design principles and strategiesNoch keine Bewertungen

- The Bitcoin Standard: The Decentralized Alternative to Central BankingVon EverandThe Bitcoin Standard: The Decentralized Alternative to Central BankingBewertung: 4.5 von 5 Sternen4.5/5 (41)

- 100M Offers Made Easy: Create Your Own Irresistible Offers by Turning ChatGPT into Alex HormoziVon Everand100M Offers Made Easy: Create Your Own Irresistible Offers by Turning ChatGPT into Alex HormoziNoch keine Bewertungen