Beruflich Dokumente

Kultur Dokumente

Sensitivity Analysis in Pavement Performance Due To Variation in Hot Mix Asphalt Design Methodology

Hochgeladen von

Innovative Research PublicationsOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sensitivity Analysis in Pavement Performance Due To Variation in Hot Mix Asphalt Design Methodology

Hochgeladen von

Innovative Research PublicationsCopyright:

Verfügbare Formate

International Journal of Scientific Engineering and Technology

Vo lu me No.5 Issue No.1, pp: 95-104

ISSN:2277-1581

01 Jan.2016

Sensitivity Analysis in Pavement Performance Due to Variation in Hot Mix

Asphalt Design Methodology

Ahme d Mohamady, Mohamed basouny, Ayaat Ahmed Abdel- Hamid

Assistant Professor, Faculty of Engineering, Zagazig University

rosseforp , Faculty of Engineering, banha University

Abstract: The objective of this study was to develop

performance characteristics or variables (e.g., rutting,

Ilanoitanretn Roughness Index; IRI) of flexible pavements in

Egypt and to use these characteristics in the implementation of

the distress prediction models or transfer functions included in

the Mechanistic-Empirical Pavement Design Guide (MEPDG)

software. A large amount of input atad are required in order to

perform pavement design with MEPDG. These data may be

classified into traffic loads, material properties and climate

input parameters. The goal of this sensitivity analysis is to

verify that the performa nce models accurately predict

pavement distress. This research focuses on comparison

between sensitivity analysis of flexible pavement performance

predictions in MEPDG design inputs under five section

conditions, traffic volumes and AASHT, Design inputs

evaluated in the analysis include different traffic volumes (100,

50, 25, 10thousands, and the actual traffic volume) layer

thicknesses, and material properties. The design limit

sensitivity analysis adopted in this study provides practical

interpretation of sensitivity by relating a given percentage

change in a MEPDG input to the corresponding percentage

change in predicted distress/service life relative to its design

limit value. The design inputs most consistently in the highest

sensitivity categories across all distresses were the hot mix

asphalt (HMA) dynamic modulus master curve, HMA

thickness, surface shortwave absorptive.

Keywords:

Flexi ble Pavements, Pavement Design,

Mechanistic- Empirical, Rutting, IRI, AASHTO, MEPDG,

sensitivity anal

1) Introduction And Background

The 1993 AASHTO design method for pavement

design and analysis and is a largely empirical method based

primarily on the AASHO Road Test conducted in the late 1950s.

Over the years adjustments and modifications have been made in

an effort to upgrade and expand the limits over which the

AASHTO guide is valid ]1[, ]2,[ ] 3],and[4]. A 1996 workshop

meant to develop a framework for imp roving the 1993 Gu ide

recommended instead the development of a new guide based as

much as possible on mechanistic princip les. The M-E PDG

developed in NHCRP 1-37A is the result of this effort.

Following independent reviews and validations that have been

ongoing since its initial release in April, 2004, the M-E PDG is

expected to be adopted by AASHTO as the new national

pavement design guide. In this part is divided in two sections.

The first describes the AASHTO Gu ide and its revisions since

its first edition dated 1961, with the original empirical equations

derived fro m the AASHO Road Test, to its latest dated 1993

[1],[ 2], [3],and[ 4]. The second part exp lains in some detail the

new ME- PDG procedure [5]. Several researchers have studied

the AASHTO Gu ide in all its versions. This sitution summarizes

the relevant findings gathered from the literature that discuss

conflicting issues such as traffic, material p roperties,

environmental conditions, and parametric sensitivity of the

design equation. Serviceability cannot be directly measured in

the field. A panel of users is required to provide subjective

assessments of serviceability. Th is value is the Present

Serviceability Rat io (PSR). The correlation of PSR with

measured distresses is the Present Serviceability Index (PSI).

PSI is the input parameter of the design equation, not the PSR,

because determining PSR is very subjective, not to mention

expensive and time consuming. Alternative approaches are

available correlating PSI with roughness, which is a more

reliable, and more easily measured parameter than the

recommended distresses given in Eq. [1],and [14].

Traffic has been a controversial parameter in the

1993 AASHTO Guide and its earlier vers ions. The fact that it

relies on a single value to represent the overall traffic spectrum

is questionable. The method used to convert the traffic spectra

into ESA Ls by applying LEFs is also questionable. The

AASHTO LEFs consider serviceability as the damag e

equivalency between two axles. Zhang et al. (2000) have found

that Eq. (2), used to determine LEFs, is inconsistent with

capturing damage in terms of equivalent deflection, which is

easier to measure and validate. However quantifying damage

equivalency in terms of serviceability or even deflections is not

enough to represent the complex failure modes of flexible

pavements.

Today it is widely accepted that load equivalency

factors were a simp le technique for incorporating mixed traffic

into design equations and were well suited for pavement

management systems. However pavement design applications

doi : 10.17950/ ijset/v5s1/120

International Journal of Scientific Engineering and Technology

Vo lu me No.5 Issue No.1, pp: 95-104

ISSN:2277-1581

01 Jan.2016

require more co mprehensive procedures. Mechanistic-empirical

design procedures take a different approach for this problem;

different loads and axle geometrics were mechanistically

analyzed to determine directly the most critical structural

responses that were significant to performance predictions,

avoiding the shortcut of load equivalency factors.

The 1993 AASHTO Guide and its earlier versions

were developed based on results from one test site trafficked

over two years with a total of slightly over one million ESA Ls.

Fro m this test track, which was built with the same materials

varying only thicknesses, the design equation was developed.

Studies have shown that despite of the adjustments made over

the years to the design equation in attempts to expand its

suitability to different climate regions and materials, the design

of flexible pavements still lacks accuracy in performance

predictions and in ability to include different materials and their

complex behavior.

Emp irical Pavement Design Guide (M EPDG). The study

shared experiences from transportation agencies that have

performed various sensitivity analysis using the MEPDG

software, primarily related to flexib le pavement analysis.

The goal for the study was to communicate wh ich input

factors are important to the final pavement designs, so that

agencies can focus their research accordingly during the

implementation process.

What will be the impact of road traffic mix on the both

rutting depth and the IRI due to variation in AADT at

constant Agg. Size co mparing between asphalt mix

types (Marshall, super pave)?

What will be The impact of road traffic mix on the both

rutting depth and the IRI due to variation in AA DT at

constant Marshall mix type co mparing between Agg .

Size?

The M-E PDG developed in NCHRP 1-37A is a

mechanistic-emp irical (M-E) method for designing and

evaluating pavement structures. Structural responses (stresses,

strains and deflections) are mechanistically calcu lated based on

material properties, environmental conditions, and loading

characteristics. These responses are used as inputs in empirical

models to co mpute distress performance predictions. The M -E

PDG was released in draft form at the conclusion of NCHRP 137A in April, 2004 [5].

The M-E PDG still depends on empirical models to

predict pavement performance fro m calculated structural

responses and material properties. The accuracy of these models

is a function of the quality of the input information and the

calibrat ion of empirical distress models to observed field

performance. Two types of empirical models were used in the

M-E PDG. One type predicts the distress directly (e.g., rutting

model for flexib le pavements, and faulting for rig id); the other

type predicts damage which is then calibrated against measured

field distress (e.g., fatigue cracking for flexib le pavements, and

punchout for rigid).A description of the design process is

provided, followed by informat ion about the components of the

design procedure: inputs (design criteria, traffic, material

properties, and environmental conditions), pavement response

models (mechanistic structural computational tools and climate

model), emp irical performance models, and reliab ility.

The M-E approach for designing and evaluating

flexib le pavements represents a major step forward fro m purely

emp irical methods. Mechanistic models were employed for

predicting pavement responses and climatic effects on material

behavior. The pavement distresses were too complex to be

modeled by mechanistic models only. Emp irical models were

emp loyed to overcome these limitations of theory; the empirical

models establish a connection between structural responses and

performance prediction. Calibrat ion of the empirical distress

models is a crit ical requirement for quality performance predicti

What will be the impact of road traffic mix on the both

rutting depth and the IRI due to variation in AADT at

constant super pave mix type co mparing between Agg.

Size?

2) Problem Statement And Study Moti vation

This study was developed to provide information for

transportation agencies in the process of, or considering the

implementation of, the interim AASHTO Mechanistic

Page 96

3) Objecti ves Of Study

The main objectives of this study were:

The impact of road traffic mix on rutting and IRI depth

due to variation in AADT at constant Agg. Size

comparing between asphalt mix types (Marshall, super

pave).

The impact of road traffic mix on rutting depth and IRI

due to variation in AADT at both constant Marshall and

Superpave Mix types comparing between Agg. Size.

4) Research Methodolog y

The general intent of this Research is to overview the

concepts of sensitivity analysis and applications of the results in

guiding decisions during specific implementation of AASHTOs

interim MechanisticEmp irical Pavement Design Gu ide

(MEPDG). The results fro m the sensitivity studies performed

during the local calibration of the MEPDG models for are

specifically referenced. The Research underscores the

importance of sensitivity analysis as a decision support tool in

locally calibrating the MEPDG performance models and

illustrates an approach for setting up a successful sensitivity

study.

Results from the sensitivity analysis conducted for asphalt

concrete pavements will present. In addition, a discussion of

how the results will included in Egyptian specification and

design regulation including:

Assessing the quality of the prediction models and

model deficiencies,

Identifying factors that contribute most to the output

variability,

Assessing the impact of Egypt DOTspecific site and

design inputs on key design types and distress types of

interest.

doi : 10.17950/ ijset/v5s1/120

International Journal of Scientific Engineering and Technology

Vo lu me No.5 Issue No.1, pp: 95-104

Identifying the region of input factors for which the

model variat ion is maximu m.

Selecting the appropriate input level to characterize key

inputs.

4.1 Scope of work

Five main roads were to be included in this study these

roads are:- Cairo- Is mailia, Cairo - Suez ,Cairo -Alex. Desert,

Cairo-Alex. Agric, and Cairo-belbs.Tuck presents for theses

investigated roads are obtained from General Authority for

Roads and Bridges and land transport. These percents are 16.82

%, 27.8%,34.59%,34.8%,and 8.27% respectively . Four traffic

volumes were selected to be investigated in the research which

are 10.000, 25.000, 50.000, and 100.000 v/d. Aggregate size is

also a variable parameter investigated in the work. Three

aggregate sizes were considered whish are 1,3/ 4, and 1/2 .

Two methods of mix design were tested in this analysis

,Marshall and Superpave procedures.To do the intended

sensitivity analysis using MEPDG software let us understanding

the software inputs and outputs to identify the required frame o f

work.

4.1.1 The Input data to MEPDG software are: Traffic

volume, Road type (% of truck), Max. Aggregate Size M ix

types. In an effort to identify the types of input and output

parameters for the MEPDG, the M EPDG report and software

program were studied. In the following, all the required input

parameters that are needed to perform analysis using the

MEPDG software are summarized.

A goal of flexib le pavement sensitivity investigation using (all

roads) data were to Input a wide range of input values to make

initial observations of changes in performance predictions. The

as-built pavement structure assumed to be 1.9 inches asphalt

concrete surface course, 2.36 inches asphalt concrete binder

course, 2.7 inches asphalt bitumen base course , and 17.7 inches

stone type base. The inputs were organized into material, traffic,

and climate categories and graphed based on distress prediction.

IRI and total rutting were the distress models in this studied

research. The initial IRI was assumed to be 64.6 in/mile with

different value of ADT, with several aggregate sizes. Sensitivity

data outputs during a 20 year period are presented in Tables (1)

through (12) and Figures (1) through (10).

4.1.2 The Output data to MEPDG software are

a) Pavement Performance Indicators (rutting depth )

b) international roughness index, ( IRI)

A variety of structural distresses were considered in flexible

pavement design and analysis. These include:

Bottom-up fatigue (or alligator) cracking.

Surface-down fatigue (or longitudinal) cracking.

Thermal cracking.

The designer may select some or all of these performance

indicators and establish criteria to evaluate a design and make

modifications if necessary. The performance criteria for each

distress will depend on the individual highway agencys

tolerance for the amount of cracking over the design period. The

performance criteria will also depend upon the design reliability

level, wh ich in turn will be dependent upon the functional class

of the roadway.

5) Results and Anal ysis

Page 97

ISSN:2277-1581

01 Jan.2016

5.1 Introduction

The main goal of this study is to identify the pavement

performance under several mix parameters and design inputs.

So, sensitivity analysis were done using ME- PDG software the

process of varying model input parameters (subgrade type, base

type) Over a practical range and observing the relative change in

model response (e.g., HMA rutting and IRI). The locally

calibrated MEPDG models can be evaluated for reasonableness

(i.e., do pavement deterioration predictions from these models

reflect actual observed pavement deterioration).In this part we

discuss precisely about the outcome of the results that has been

accomplished for the mix design. Co mparisons of Marshall and

Superpave methods based on mix designs

The purpose of this part can be stated in the following points:1. Summarize the parameters that have a pronounced effect

on pavement design.

2. Review the co mpatibility of M EPDG soft ware results.

3. Assess the reasonableness of predicted performance

using Level 3 baseline inputs of the soft ware.

5.2 M-E PDG Sensitivity Analysis and discussion

A number of M EPDG simu lations were run using the

MEPDG input database. Level 3 analysis were used in MEPDG

software runs since typical values for AASHTO and MEPDG

default values were used for some input values related to traffic

and material properties.

The Tables (1) through (12) and Figures (1) through (10) present

the results of sensitivity analysis studies prepared For 5 roads of

Egyptian network. Th is research investigated the effect of

selected input variables on two predicted pavement distresses:

1. Total rutting, in

2. Smoothness IRI, in/ mi.

5.2.1 Effect of traffic volume on rutting depth

Tables (1) through (3) summarize the results of the

sensitivity analysis for traffic volu me on rutting depth fo r at

constant mix type for d ifferent agg size 1,3/ 4 ,and 1/ 2.Based

on the data presented in Tables (1) to (3) Figure (1) was drawn.

Fro m the curve it was clear that the rutting values increase as

truck percent increase for different traffic values. Increasing

truck percent from 8.27 %, road 5 to 34.59 %, road 3 increase

rutting depth from 0.037 inches to 0.356 inches respectively in

Marshall Method for AADT 100000 vehicle /day at max agg .

size 1. This means that increasing truck percent by 26.32%

leads to increase in rut depth by 0.319 inch, i.e. by 25.8% of its

value. However this percent become 27.2 %, 26.6 % and 26.3

% for AADT of 10000, 25000, 50000 vehicle, respectively

Tables (4) through (6) show the results of the sensitivity

analysis for traffic volu me on rutting depth with Superpave mix

design techniques for different agg size 1,3/ 4 ,and 1/ 2.Based

on the data presented in tables, Figure (2) was drawn. Fro m the

curve it was clear that the rutting value increase as truck percent

increase for different AADT value. Increasing truck percent

fro m 8.27 %, road 5 to 34.59 %, road 3 increase rutting depth

fro m 0.037 inches to 0.242 inches respectively in Superpave

Method for AADT 100000 vehicle /day at max agg. Size 1.This

means that increasing truck percent by 26.32% leads to increase

in rut depth by 0.205 inch, i.e. by 23.8% of its value. However

doi : 10.17950/ ijset/v5s1/120

International Journal of Scientific Engineering and Technology

Vo lu me No.5 Issue No.1, pp: 95-104

this percent become 25.5 %, 24.6 %, and 24.2 % for AADT of

10000, 25000, 50000 vehicle, respectively

Based on the pervious discussion it can be concluded

that , Annual Average Daily Traffic (AADT) value in all five

investigated roads have a significant effect on the predicted

pavement performance distresses AADT value affects both

rutting predictions.

5.2.2 Effect of traffic volume on IRI

Tables (7) through (9) summarize the results of the

sensitivity analysis for traffic volu me on IRI at constant mix

type for different agg size 1, 3/4, and 1/2. Based on these

results Figure (3) constructed.From the curve it was clear that

the IRI value increase as truck percent increase for different

AADT value. Increasing truck percent fro m 8.27 %, road 5 to

34.59 %, road 3 increase IRI fro m 75.7 inches/mile to 88.5

inches/mile for in Marshall Method at AADT 100000 vehicle

/day at max agg size 1.Th is means that increasing truck percent

by 26.32%leads to increase in IRI value by 12.8 inch/ mile,

about. 3% of its value. However this percent become 2.02 %,

2.3 %, and 2.7 % for AADT of 10000, 25000, 50000 vehicle,

respectively

Tables (10) through (12) show the results of the

sensitivity analysis for traffic volu me on IRI with Superpave mix

design techniques for different agg size 1, 3/ 4, and 1/ 2.Based

on the data presented in the tables Figure (4) was drawn. Fro m

the Figure it was clear that IRI value increase as truck percent

increase for different AADT value. Increasing truck percent

fro m 8.27 %, road 5 to 34.59 %, road 3 increase fro m the IRI

value fro m 75.7 inches/mile to 83.9 inches/mile respectively. in

Superpave Method for AADT 100000 vehicle /day at max agg

size 1.This means that increasing truck percent by 26.32% leads

to increase in IRI by 8.2 inch, i.e. by 2%of its value. However

this percent become 1.3 %, 1.5 %, and 1.79 % for AAD 0T of

10000, 25000, 50000 vehicle, respectively

In general, Traffic variables AADT and vehicle class

distribution have an expected influence on the predicted

pavement distresses and roughness IRI (Figures 1 through 4).

Traffic volu me was the most significant variable with a large

impact on Asphalt Concrete rutting depth (Figures 1 and 2). For

all pavement distresses and roughness IRI, values increased with

the increase of the AADT and the vehicle class distribution was

expected, with the increase of these two variables the predicted

pavement distresses and IRI increased as well. This study had

confirmed this predict ion.

5.2.3 Effect of aggregate size on rutting, and IRI for different

AADT val ues

Were investigated through There sizes as follows:

For max agg. Size 1

Table (1) and (4) su mmarize the results of the

sensitivity analysis for max agg. 1 on rutting depth with

Marshall and Superpave mix types. Based on the data presented

in theses tables the Figure (5) was drawn. Fro m the curve it was

clear that the rutting value increase as truck percent increase for

different AADT value. Increasing truck percent from 8.27 %,

Page 98

ISSN:2277-1581

01 Jan.2016

road 5 to 34.59 %, road 3 increase rutting depth from 0.037

inches to .356 inches respectively for Marshall method at AADT

100000 vehicle /day. Increasing truck percent from 8.27 %,

road 5 to 34.59 %, road 3 increase rutting depth from 0.037

inches to .242 inches respectively in Superpave method for

AADT 100000 vehicle /day constant agg. Size. Increasing truck

percent by 26.32% leads to increase in rut depth by 0.205 inch,

i.e. by 23.8% of its value in Superpave method even the rut

depth is 0.319 inch, i.e. by 25.8% of its value in Marshall

Method.

This means that large changes in input parameters produced

relatively small response of rutting performance predict ions in

Superpave method.

Tables (7) and (10) summarize the results of the

sensitivity analysis for max agg. 1 on IRI with Marshall and

Superpave mix types. Based on the data presented in tables (7)

and (10) the figure (6) was drawn.Fro m the curve it was clear

that IRI value increase as truck percent increase for different

AADT values at constant agg. size. Increasing truck percent

fro m 8.27 %, road 5 to 34.59 %, road 3 increases IRI fro m 75.7

inches/mile

to 88.5 inches/mile respectively for Marshall

Method at AADT 100000 vehicle /day. Increasing truck percent

fro m 8.27 %, road 5 to 34.59 %, road 3) increase IRI fro m 75.7

inches/mile to 83.9 inches/mile respectively in Superpave

Method for AADT 100000 vehicle /day. Increasing truck percent

by 26.32% leads to increase in IRI by 8.2 inches/mile, i.e. by 2%

of its value in Superpave method even the IRI is 12.8

inches/mile, i.e. by 3% of its value in Marshall Method. This

means that large changes in input parameters produced relatively

small response of IRI performance predict ions in Superpave

method.

For max agg. Size 3/4

Table (2) and (5) summarize the results of the

sensitivity analysis for max agg. 3/ 4 on rutting depth with

Marshall and Superpave mix types. Based on the data presented

in the tables (2) and (5) the figure (7) is drawn. Fro m the curve it

is clear that the rutting value increase as truck percent increase

for different AADT value. Increasing truck percent fro m 8.27 %,

road 5 to 34.59 %, road 3 increase rutting depth from 0.037

inches to 0.362 inches respectively for Marshall method at

AADT 100000 vehicle /day constant agg. s ize. Increasing truck

percent from 8.27 %, road 5 to 34.59 %, road 3 increase rutting

depth from 0.037 inches to 0.243 inches respectively in

Superpave method for AADT 100000 vehicle /day constant agg.

size. Increasing truck percent by 26.32% leads to increase in rut

depth by 0.206 inch, i.e. by 23.8% of its value in Superpave

method even the rut depth is 0.325 inch, i.e. by 25.8% of its

value in Marshall Method. This means that large changes in

input parameters produced relatively small response of rutting

performance predictions in Superpave method.

Table (8) and (11) summarize the results of the

sensitivity analysis for ma x agg. 3/4 on IRI with Marshall and

Superpave mix types. Based on the data presented in the tables

(8) and (11) the figure (8) was drawn. Fro m the curve it is clear

that IRI value increase as truck percent increase for different

AADT value. size. Increasing truck percent fro m 8.27 %, road 5

doi : 10.17950/ ijset/v5s1/120

International Journal of Scientific Engineering and Technology

Vo lu me No.5 Issue No.1, pp: 95-104

to 34.59 %, road 3 increases IRI fro m 75.7 inches/mile to 88.7

inches/mile respectively for Marshall method at AADT 100000

vehicle /day. Increasing truck percent from 8.27 %, road 5 to

34.59 %, road 3 increase IRI fro m 75.7 inches/mile to 83.9

inches/mile respectively in Superpave method for AADT

100000 vehicle /day .Increasing truck percent by 26.32% leads

to increase in IRI by 8.2 inches/mile, i.e. by 2% of its value in

Superpave method even the IRI is 13 inches/mile, i.e. by 3% of

its value in Marshall Method. This means that large changes in

input parameters produced relatively s mall response of IRI

performance predictions in Superpave method.

For max agg. Size 1/2

Table (3) and (6) su mmarize the results of the

sensitivity analysis for max agg. 1/ 2 on rutting depth with

Marshall and Superpave mix types. Based on the data presented

in the tables (3) and (6) the Figure (9) was drawn. Fro m the

curve it is clear that the rutting value increase as truck percent

increase for different AADT value. Size. Increasing truck

percent from 8.27 %, road 5 to 34.59 %, road 3 increase rutting

depth from 0.038 inches to 0.37 inches respectively for Marshall

method at AADT 100000 vehicle /day. Increasing truck percent

fro m 8.27 %, road 5 to 34.59 %, road 3 increase rutting depth

fro m 0.037 inches to 0.238 inches respectively in Superpave

method for AADT 100000 vehicle /day. Increasing truck percent

by 26.32% leads to increase in rut depth by 0.201 inch, i.e. by

23.7% of its value in Superpave method even the rut depth is

0.332 inch, i.e. by 25.8% of its value in Marshall Method. This

means that large changes in input parameters produced relatively

small response of rutting performance predictions in Superpave

method.

Table (9) and (12) summarize the results of the

sensitivity analysis for ma x agg. 1/2 on IRI with Marshall and

Superpave mix types. Based on the data presented in the tables

(9) and (12) the Figure (10) was drawn. Fro m the curve it was

clear that IRI value increase as truck percent increase for

different AADT value. Increasing truck percent from 8.27 %,

road 5 to 34.59 %, road 3 increases IRI fro m 75.7 inches/mile to

89 inches/mile respectively for Marshall method at AADT

100000 vehicle /day. Increasing truck percent from 8.27 %, road

5 to 34.59 %, road 3 increase IRI fro m 75.7 inches/mile to 83.7

inches/mile respectively in Superpave Method for AADT

100000 vehicle /day . Increasing truck percent by 26.32% leads

to increase in IRI by 8 inches/mile, i.e. by 1.9 % of its value in

Superpave method even the IRI is 13.3 inches/mile, i.e. by 3.1 %

of its value in Marshall Method. This means that large changes

in input parameters produced relatively small response of IRI

performance predictions in Superpave method.

Generally, the results the mid-range to the coarse side

provides the best results in terms of resistance to permanent

deformation/rutting. There are exceptions to this where dry

materials with high fines contents can reduce the amount of

permanent deformat ion. Resilient modulus results are more

scattered and tend to increase with increasing fines contents.

This increase in modulus for higher fines contents is probably

caused by the increase in density due to the fines filling the

Page 99

ISSN:2277-1581

01 Jan.2016

voids and thus giving less secondary densification. Also resilient

modulus decreases and permanent strain increases with

increasing water content. Finer grading was more affected by

increasing water content.

Previous research has revealed that fine grading have a

lower strength when wet compared with coarse grading, wh ile

the opposite is the case when dry and/or when a modifier like

cement is added (i.e. fine grading are best).The literature

reported that finer grading could be more easily constructed with

less segregation and lower total voids to minimize any further

densificat ion after opening a pavement to traffic.

Grad ing with aggregate size of 1/2, and 3/4 showed

that the best performance (least rutting) in super pave mix type

was obtained with the coarse grading with a 1. The best

performance in super pave mix type was obtained at a finer

grading with 1/2 aggregate size .Grading with aggregate size of

1, and 3/4 showed that the best performance (least rutting) in

Marshall Mix type was obtained grading with a 1/2. The best

performance in Marshall Mix type was obtained at a course

grading with 1 aggregate size

On the Tables presents the Egypt overall ranking

summary of significance of each output parameter on the

performance of flexible pavement. This study finds the most

significant variab les which impact the predictions of pavement

distresses in the republic. This study was very subjective and

depends on the variables chosen to be investigated. In this

example, based on the total ranking points (smaller nu mbers had

a higher effect), the following variab les have a significant

impact on the pavement distress prediction in Egypt: Aggregate

size, Traffic distribution (AADTT), Mix type .In the above

overall order of significance ranking the high position of the

traffic volume was surprising. This research did not investigate

how realistic ranking of the traffic volu me is as a variable for

pavement performance predictions. It is up to the republic

agency to decide if the change of traffic volu me and its range

could really affect the pavement performance.

6) Conclusions

Based on the analysis and discussion of the study results,

the following conclusion may be obtained:

1. The MEPDG distress transfer functions have been

validated for use in Egypt. The area HMA rut depth,

transverse cracking, and smoothness prediction models

(IRI) are believed to be adequate for use in Egypt . It is

recommended that Roads and Bridges Authority move

forward with using these distress prediction models in

analyzing and designing flexible pavements and HMA

overlays.

2. The MEPDG-pred icted IRI values are in good

agreement with the actual IRI values fro m all road test

for flexib le and HMA overlaid pavements.

3. Bias (systematic difference) found in MEPDG rutting

and faulting models can be eliminated by recalibrating

the MEPDG performance models to Egypt highway

conditions and materials.

doi : 10.17950/ ijset/v5s1/120

International Journal of Scientific Engineering and Technology

Vo lu me No.5 Issue No.1, pp: 95-104

4.

Irregularity trends in some of the distress measures

recorded in Egypt roads for certain pavement sections

are observed. These may need to be removed from for

verification and MEPDG local calibration.

5. MEPDG provides individual pavement layer rutting

predictions while AASHTO provides only accumulated

(total) surface rutting observed in the pavement. This

can lead to difficulties in the calibrat ion of MEPDG

rutting models for co mponent pavement layers.

6. Increasing truck percent by 26.32% leads to increase in

rut depth by 23.8% of its value in Superpave method

even the rut depth was 25.8% of its value in Marshall

Method at max. agg. Size 1.

7. Increasing truck percent by 26.32% leads to increase in

IRI by 2% of its value in Superpave method even the

IRI was 3% of its value in Marshall Method at max.

agg. Size 1.

8. Increasing truck percent by 26.32% leads to increase in

rut depth by 23.8% of its value in Superpave method

even the rut depth was 25.8% of its value in Marshall

Method at max at agg. Size 3/4.

9. Increasing truck percent by 26.32% leads to increase in

IRI by 2% of its value in Superpave method even the

IRI was 3% of its value in Marshall Method at agg. Size

3/4 .

10. Increasing truck percent by 26.32% leads to increase in

rut depth by 23.7% of its value in Superpave method

even the rut depth was 25.8% of its value in Marshall

Method at agg. Size 1/2

11. Increasing truck percent by 26.32% leads to increase in

IRI. by 1.9 % of its value in Superpave method even the

IRI was 3.1 % of its value in Marshall Method at agg.

Size 1/2

7) Recommendati ons

Based on the study analysis and conclusions, the

following reco mmendations are obtained:

1. Recalibrat ing the MEPDG performance models to

Egypt conditions is recommended to improve the

accuracy of predictions.

2. Before performing calibrat ion, it should be ensured that

pavement distress measurement units.

3. All the actual performance data should be subjected to

reasonableness check and any presence of irrational

trends or outliers in the data should be removed before

performing calibration.

ISSN:2277-1581

01 Jan.2016

iv. HRB. 1962. The AASHO Road Test. Report 7, Summary

Report, Highway Research Board Report 61G. Washington DC.

v. National Cooperative Highway Research Program (NCHRP).

(2004). Guide for Mechanistic-Empirical Design of New and

Rehabilitated

Structures.

NCHRP

Report

01-37A.

Transportation Research Board, Washington, DC.

vi. Croney, D., and Croney, P. 1991. The design and

performance of road pavements. 2nd ed. Maidenhead, UK: McGraw

Hill

International.

vii. HRB (1962) The AASHO Road Test, Report 5: Pavement

Research; Report 6: Special Studies and Report 7: Summary Report,

Highway Research Board

viii. Asphalt Institute (1991) DAMA (CP-1/1991 Revision)

Pavement Structural Analysis Using Muli-Layered Elastic Theory,

Lexington, KY.

ix. Leahy, R.B., Permanent Deformation Characteristics of

Asphalt Concrete, Ph.D. Dissertation, University of Maryland, College

Park, 1989.

x. Burmister, D.M. (1943) The Theory of Stresses and

Displacements In Layered Systems and Applications to the Design of

Airport Runways, Proceedings, Highway Research

Board, Vol. 23.

xi. Ayres, M. (1997) Development of a Rational Probabilistic

Approach for Flexible Pavement Analysis, Ph.D. Dissertation,

University of Maryland, College Park, MD.

xii. Kaloush, K. E. and Witczak, M. W. (2000). Development of a

Permanent to Elastic Strain Ratio Model for Asphalt Mixtures.

Development of the 2002 Guide for the Design of New and

Rehabilitated Pavement Structures. NCHRP 1-37 A. Inter Team

Technical Report. Sept. 2000.

xiii. Tseng, K. and Lytton, R. (1989) Prediction of Permanent

Deformation in Flexible Pavement Materials. Implication of

Aggregates in the Design, Construction, and Performance

of Flexible Pavements, ASTM STP 1016, ASTM, pp. 154-172.

xiv. Al-Omari, B., and M. I. Darter (1994). "Relationships

Between International Roughness Index and Present Serviceability

Rating,"

Transportation

Research

Record

1435,Transportation Research Board, Washington, D.C.

xv. R. Jones (2000).ISLAB2000 - Finite Element Analysis

Program for Rigid and Composite Pavements, Users Guide, ERES

Division of ARA, Inc., Champaign, IL.

xvi. Zaghloul, S., El Halim, A. A., Ayed, A., Vitillo, N., and

Sauber, R. 2006. Sensitivity analysis of input traffic levels on MEPDG

predictions. CD-ROM. Presented at 85th Annual

Transportation Research Board Meeting. Washington, DC:

Transportation

Research Board.

xvii. FHWA. 2001. Traffic Monitoring Guide. Office of Highway

Policy Information. U.S. Department of Transportation. Federal

Highway Administration. Ma

References

i. AASHTO. (1972). AASHTO Interim Guide for Design of

Pavement Structures. Washington, DC.

ii. American Association of State Highway and Transportation

Officials (AASHTO). (1986) AASHTO Guide for Design of

Pavement Structures. Washington, DC.

iii. American Association of State Highway and Transportation

Officials (AASHTO). (1993) AASHTO Guide of Pavement

Structures. Washington, DC.

Page 100

doi : 10.17950/ ijset/v5s1/120

International Journal of Scientific Engineering and Technology

Vo lu me No.5 Issue No.1, pp: 95-104

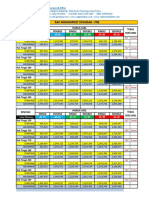

Table (1): values of

constant agg. Size 1

ISSN:2277-1581

01 Jan.2016

rutting due to variation in AADT at

Table (5): values of rutting due to variation in AADT at constant

agg Size 3/4

Table (2): values of

constant agg. Size 3/4

rutting due to variation in AADT at

Table (6): values of rutting due to variation in AADT at constant

agg Size 1/2

Table (3): values of

constant agg. Size 1/2

rutting due to variation in AADT at

Table (7): values of IRI due to variation in AADT at constant

agg Size 1

Table (4): values of rutting due to variation in AADT at constant

agg Size

Page 101

doi : 10.17950/ ijset/v5s1/120

International Journal of Scientific Engineering and Technology

Vo lu me No.5 Issue No.1, pp: 95-104

Table (8): values of IRI due to variation in AADT at constant

agg Size 3/4

ISSN:2277-1581

01 Jan.2016

Table (12): values of IRI due to variation in AADT at constant

agg Size 1/2

Table (9): values of IRI due to variation in AADT at constant

agg Size 1/2

Table (10): values of IRI due to variation in AADT at constant

agg Size 1

Figure (1): The relationship between truck percent and rutting

value with different agg. Size for Marshall.

Table (11): values of IRI due to variation in AADT at constant

agg Size 3/4

Figure (2): The relationship between truck percent and rutting

value with different agg size for Superpave

Page 102

doi : 10.17950/ ijset/v5s1/120

International Journal of Scientific Engineering and Technology

Vo lu me No.5 Issue No.1, pp: 95-104

Figure (3): The relationship between truck percent and IRI value

with different agg size fo r Marshall.

Figure (4): The relationship between truck percent and IRI value

with different agg size at Superpave mix type.

Figure (5): The relationship between truck percent and rutting

value at constant agg size co mparing between asphalt mix types

(Marshall, Superpave).

Page 103

ISSN:2277-1581

01 Jan.2016

Figure (6): The relat ionship between truck percent and IRI value

constant agg size comparing between asphalt mix types

(Marshall, Superpave).

Figure (7): The relationship between truck percent and rutting

value constant agg. Size co mparing between asphalt mix type

(Marshall, Superpave).

Figure (8): The relationship between truck percent and rutting

value constant agg size co mparing between asphalt mix types

(Marshall, Superpave).

doi : 10.17950/ ijset/v5s1/120

International Journal of Scientific Engineering and Technology

Vo lu me No.5 Issue No.1, pp: 95-104

Figure (9): The relationship between truck percent and rutting

value constant agg size co mparing between asphalt mixes types

(Marshall, Superpave)

ISSN:2277-1581

01 Jan.2016

Ahmed Mohamady Abd-Allah is currently assistant professor of

highway engineering and airports, faculty of engineering,

Zagazig University. He has a PH.D in Highway Engineering,

Cairo University, Egypt (September 2001).

His areas of interest include Pavement

Evaluation and Assessment, Pavement

Distresses and Rehabilitation, Field and

Laboratory Testing in Highway Engineering,

Pavement Management Systems, Laboratory

Testing for Highway Materials and Asphalt

Mixes, Imp roving the Properties of Highway Materials,

Behavior of Asphalt Mix Under Environ mental Effects and

Pavement Survey and Evaluation of Pavement Condition Index

(PCI).

Thesis Supervision:

19 M.Sc. Students in Highway Engineering

8 Ph.D. Students in Highway Engineering.

Mohamed Elsayed Ali BASIOUN is Dean,

Benha Faculty of Engineering since Feb.

2012 till now. Fu ll Professor, Sanitary

Engineering & Environ mental since

2008.Assistant

Professor,

Sanitary

Engineering & Environmental, fro m 2001to

2008.He is Egyptian Syndicate of

Professional

Engineers,

No.2457/ 1Engineering Sector Committee, Egyptian Supreme

Council of Universities.

Thesis Supervision:

9 M .Sc. Sanitary Eng ineering & Environ mental.

2 Ph.D. San itary Engineering & Environmental.

Figure (10): The relationship between truck percent and IRI

value constant agg size co mparing between asphalt mix types

(Marshall, Superpave).

Page 104

doi : 10.17950/ ijset/v5s1/120

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Power Transformer Protection Using Fuzzy Logic Based ControllerDokument5 SeitenPower Transformer Protection Using Fuzzy Logic Based ControllerInnovative Research PublicationsNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Case Study: Implementation of 5S Methodology in JCB Assembly Business Unit Material StorageDokument6 SeitenCase Study: Implementation of 5S Methodology in JCB Assembly Business Unit Material StorageInnovative Research PublicationsNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Experimental Study of Eccentric Loadingfor Piled Raft Foundations Settling On Slope CrestDokument5 SeitenThe Experimental Study of Eccentric Loadingfor Piled Raft Foundations Settling On Slope CrestInnovative Research PublicationsNoch keine Bewertungen

- Surveillance NetworksDokument2 SeitenSurveillance NetworksInnovative Research PublicationsNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Computational EconomicsDokument2 SeitenComputational EconomicsInnovative Research PublicationsNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- 3D Modeling of Complex Structure Based On AutoCAD VBADokument3 Seiten3D Modeling of Complex Structure Based On AutoCAD VBAInnovative Research PublicationsNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Information EngineeringDokument2 SeitenInformation EngineeringInnovative Research PublicationsNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Computational ElectromagneticsDokument3 SeitenComputational ElectromagneticsInnovative Research PublicationsNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Wearable ComputingDokument3 SeitenWearable ComputingInnovative Research PublicationsNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Role of Coaching Institutes in IndiaDokument5 SeitenRole of Coaching Institutes in IndiaInnovative Research PublicationsNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Comparative Print Quality Analysis of Screen Printing and Liquid Ink Based Digital Printing MachinesDokument3 SeitenComparative Print Quality Analysis of Screen Printing and Liquid Ink Based Digital Printing MachinesInnovative Research PublicationsNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Online Laboratory: Roy G. Perry College of Engineering Prairie View A&M University Prairie View, TX 77446Dokument2 SeitenOnline Laboratory: Roy G. Perry College of Engineering Prairie View A&M University Prairie View, TX 77446Innovative Research PublicationsNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Experimental Study About Soil Improvement With Glass FibersDokument5 SeitenExperimental Study About Soil Improvement With Glass FibersInnovative Research PublicationsNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Smart Monitoring of Faults in Power Transformers and Maintenance Based On Wi-FiDokument6 SeitenA Smart Monitoring of Faults in Power Transformers and Maintenance Based On Wi-FiInnovative Research PublicationsNoch keine Bewertungen

- Information Security in Cloud Computing: A Systematic Literature Review and AnalysisDokument6 SeitenInformation Security in Cloud Computing: A Systematic Literature Review and AnalysisInnovative Research PublicationsNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- CFD Analysis of A 210 MW Tangential Fired BoilerDokument6 SeitenCFD Analysis of A 210 MW Tangential Fired BoilerInnovative Research PublicationsNoch keine Bewertungen

- Onapsis Webcasttopnotes FinalDokument17 SeitenOnapsis Webcasttopnotes FinalnizartcsNoch keine Bewertungen

- ASM 12cDokument304 SeitenASM 12cFrank Hack100% (2)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- TIA WARDAH Knowledge Management CycleDokument8 SeitenTIA WARDAH Knowledge Management CycleDwi Tamara TressantyNoch keine Bewertungen

- Cambridge International AS & A Level: Computer Science 9608/23Dokument16 SeitenCambridge International AS & A Level: Computer Science 9608/23IGCSENoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- CH 3 SQLDokument44 SeitenCH 3 SQLRobel HaftomNoch keine Bewertungen

- HC110110017 Link State Routing With OSPFDokument29 SeitenHC110110017 Link State Routing With OSPFjscansinoNoch keine Bewertungen

- Tutorial SAP200 Through Truss BridgeDokument7 SeitenTutorial SAP200 Through Truss BridgeAdam JrNoch keine Bewertungen

- Pybom00616420000017511 PDFDokument2 SeitenPybom00616420000017511 PDFPraveen VankalakuntiNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- CIS Microsoft SQL Server 2019 Benchmark v1.0.0 PDFDokument100 SeitenCIS Microsoft SQL Server 2019 Benchmark v1.0.0 PDFConciencia ImmortalNoch keine Bewertungen

- 6bk1200 0aa20 0aa0 Sicomp Imc 01s Siemens Panel ManualDokument130 Seiten6bk1200 0aa20 0aa0 Sicomp Imc 01s Siemens Panel Manualkarim100% (2)

- Rak Minimarket Standar - P90: Single Double Single Double Single Double Rincian Harga Jual Tebal ShelvingDokument6 SeitenRak Minimarket Standar - P90: Single Double Single Double Single Double Rincian Harga Jual Tebal ShelvingAndi HadisaputraNoch keine Bewertungen

- WB1093D 8800controller 0808Dokument7 SeitenWB1093D 8800controller 0808vinaypratsinghNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- SAP User Access Request Form: New Change DeleteDokument2 SeitenSAP User Access Request Form: New Change Deleteanil007rajuNoch keine Bewertungen

- LabVIEW Core 3 2013 - Course ManualDokument135 SeitenLabVIEW Core 3 2013 - Course Manualtalaindio100% (2)

- Kamran Ahmed: Work ExperienceDokument4 SeitenKamran Ahmed: Work ExperienceMisbhasaeedaNoch keine Bewertungen

- Huawei IAD Product DatasheetDokument4 SeitenHuawei IAD Product DatasheetHarjinder SinghNoch keine Bewertungen

- Capstone User Guide (UI-5400)Dokument189 SeitenCapstone User Guide (UI-5400)Fernando Andres JegzNoch keine Bewertungen

- Installing The BIRT Viewer in Tomcat and JbossDokument3 SeitenInstalling The BIRT Viewer in Tomcat and Jbosstoba_sayed100% (2)

- DE8691 UmDokument29 SeitenDE8691 UmMuốn Làm Hòn ĐáNoch keine Bewertungen

- Release Notes Csi Bridge 2017 V 1900Dokument9 SeitenRelease Notes Csi Bridge 2017 V 1900Ihab El AghouryNoch keine Bewertungen

- ABB-free@home: System ManualDokument76 SeitenABB-free@home: System ManualJoão Carlos OliveiraNoch keine Bewertungen

- StarschemaDokument4 SeitenStarschemaapi-2504106440% (1)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Project Management: Lecture Notes 2Dokument40 SeitenProject Management: Lecture Notes 2RuchiraniKulatungaNoch keine Bewertungen

- Algorithms PDFDokument116 SeitenAlgorithms PDFFoucault Mukho HyanglaNoch keine Bewertungen

- Catia SymbolsDokument9 SeitenCatia SymbolsAmolPagdalNoch keine Bewertungen

- fmd-3200 3300Dokument10 Seitenfmd-3200 3300Jose Julius Paloma Jr.Noch keine Bewertungen

- SAP ABAP Interview Questions Top 50Dokument7 SeitenSAP ABAP Interview Questions Top 50pal singhNoch keine Bewertungen

- S - 4 HANA Credit CardDokument14 SeitenS - 4 HANA Credit CardSurani shaiNoch keine Bewertungen

- NSG9000 MHZ 6-12Dokument3 SeitenNSG9000 MHZ 6-12RobertNoch keine Bewertungen

- BhsInggris The WorldWideWeb2Dokument2 SeitenBhsInggris The WorldWideWeb2Daniel TendeanNoch keine Bewertungen