Beruflich Dokumente

Kultur Dokumente

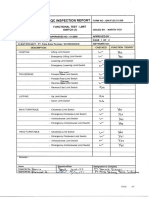

Pages From BPS 0SGA 121107 Valve & Accessories 2

Hochgeladen von

spazzbgtCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Pages From BPS 0SGA 121107 Valve & Accessories 2

Hochgeladen von

spazzbgtCopyright:

Verfügbare Formate

NRS Gate

Valve

Non-Rising Stem (NRS) Gate Valve

NF300F

Control Valves

Technical Features

Sizes available (Nominal) : 21/2/DN65, 3/DN80,

4/DN100, 5/DN125, 6/DN150, 8/DN200, 10/DN250

and 12/DN300.

Working pressure : 300 psi (21 bar)

Seat type : Resilient wedge.

Finish : Epoxy coated inside and outside.

Connections : Flange diameter and thickness according to

ANSI B16.1 Class 125. Flange drilling varies by Reference

number. See Physical Data table below.

Specifications : Design and dimensions conform to AWWA

C509.

Non-Rising Stem (NRS) Gate Valve - NF300F

Physical Data

Reference*

ANSI

NF300F-0250

NF300F-0300

NF300F-0400

NF300F-0500

NF300F-0800

NF300F-1000

NF300F-1200

PN10

PN16

NF300F-0250PN

NF300F-0300PN

NF300F-0400PN

NF300F-0500PN

NF300F-0600

NF300F-0800PN10

NF300F-0800PN16

NF300F-1000PN10

NF300F-1000PN16

NF300F-1200PN10

NF300F-1200PN16

Table E

NF300F-0250E

NF300F-0300E

NF300F-0600E

NF300F-0800E

NF300F-1000E

NF300F-1200E

Weight

(kg / lbs)

17 / 35.2

24 / 52.8

37 / 81.4

45 / 99.0

48 / 105.6

87 / 191.4

138 / 303.6

188 / 413.6

* Valve flange drilling (size and location of bolt holes and pitch circle diameter) allows mating with the following flange types :

ANSI = ANSI B16.1 Class 125

PN10 = DIN 2501, BS 4504, EN 1092 - PN10

PN16 = DIN 2501, BS 4504, EN 1092 - PN16

Table E = BS10-1962 Table E

** No Post Flange supplied with 2 & 3 sizes

NF300F

Materials List

Material

ASTM Specifications

Ductile Iron

ASTM A356 64-45-12

Ductile Iron EPDM encapsulated

Bronze

ASTM B62

Stainless Steel

AISI 420

Bronze

ASTM B62

Ductile Iron

ASTM A356 64-45-12

EPDM

Commercial

Ductile Iron

ASTM A356 64-45-12

EPDM

Commercial

Ductile Iron

ASTM A356 64-45-12

Ductile Iron

ASTM A356 64-45-12

Brass

B16, C38000

Stainless Steel

AISI 316

Carbon Steel

A307 B

2012-02-17

Description

Body

Wedge

Disc Nut

Stem

Thrust Collar

Bonnet

Gasket

Gland

O-Ring

Wrench Nut

Post Flange*

NPT Nut

Bolt on Post Flange

Bolt on Bonnet Flange

* Please note that no Post Flange is supplied with the 2 & 3 sizes

Worldwide Fire Protection

FireKing is a trademark of The Viking Corporation. Refer to Manufacturers datasheet. Specifications subject to change without notice.

Updates datasheet of 2011-04-20 (Note regarding post flanges added)

Nominal Pipe

Dimensions (mm / inch)

Size

inch Metric

L

H

D

2** DN65 190.5 / 7.50 270 / 10.60

-/3** DN80

203 / 8

296 / 11.65

-/4

DN100

229 / 9

350 / 13.78

305 / 12

5

DN125

254 / 10

410 / 16.14

305 / 12

6

DN150 267 / 10.50 455 / 17.90

305 / 12

8 DN200 292 / 11.50 545 / 21.50

305 / 12

10 DN250

330 / 13 645 / 25.40

305 / 12

12 DN300

356 / 14 730 / 28.75

305 / 12

www.vikinggroupinc.com

Non-Rising Stem (NRS) Gate Valve

NF300F

Inspection and Maintenance

1.

1.

2.

3.

4.

5.

6.

7.

8.

9.

Piping systems and valves should be

thoroughly cleaned and free from ingress of

foreign materials.

Visually inspect the valve seating and

ports for cleanliness immediately prior to

installation.

All valves should be independently

supported against movement and stress

from the connected piping system.

Ensure that the valve pressure rating is

compatible with service conditions

Operate the valve at least once from the

open to closed position.

Verify that packing nuts are tight before

pressurizing the system

Check valves must be oriented properly

for flow and gravity and must be installed

sufficiently distant from pumps or other

devices producing turbulence.

8 Gate valves are not suitable for throttling

plications.

Gate valves should be installed in the

vertical position on horizontal pipework

and in the horizontal position on vertical

pipework.

2.

3.

Valves should be inspected periodically

and should be cycled to prevent buildup of

foreign materials in the piping system and

valve body.

In the event of a packing leak adjust the

packing nuts to increase pressure on the stem

packing. Packing nuts should be tightening

evenly approximately a quarter turn in a

clockwise direction.

Always shut down the system before

repacking the valve. Valves are designed with

backseats for repacking under pressure but

this is not recommended.

Control Valves

Installation

Operation

2012-02-17

Updates datasheet of 2011-04-20 (Note regarding post flanges added)

Gate valves are manually operated multi-turn

valves and are opened by a handwheel or

other operating device, generally in a clockwise

direction and then closed counterclockwise. Gate

valves with counterclockwise opening should be

clearly identified to ensure safe operation.

Worldwide Fire Protection

FireKing is a trademark of The Viking Corporation. Refer to Manufacturers datasheet. Specifications subject to change without notice.

www.vikinggroupinc.com

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Functions of A PumpDokument178 SeitenFunctions of A PumpKetan Sarmalkar50% (2)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Fire TankDokument30 SeitenFire TankPraveen Kumar100% (1)

- Chilled Water Pump CalculationsDokument4 SeitenChilled Water Pump CalculationsNitesh SinghNoch keine Bewertungen

- Super HydraulicDokument17 SeitenSuper HydraulicDaniel Castillo Peña100% (2)

- Sava3: MP Hydraulic Lift Equipment 1 " 1 "Dokument43 SeitenSava3: MP Hydraulic Lift Equipment 1 " 1 "Coil98Noch keine Bewertungen

- Fire Fighting ValvesDokument399 SeitenFire Fighting ValvesadamcyzNoch keine Bewertungen

- Img 3Dokument1 SeiteImg 3spazzbgtNoch keine Bewertungen

- Analytical Solution For Turbulent Flow in Pipes: A. Zagustin and K. ZagustinDokument6 SeitenAnalytical Solution For Turbulent Flow in Pipes: A. Zagustin and K. ZagustinspazzbgtNoch keine Bewertungen

- Img 2Dokument1 SeiteImg 2spazzbgtNoch keine Bewertungen

- Img 1Dokument1 SeiteImg 1spazzbgtNoch keine Bewertungen

- Methode Statement Civil EnglishDokument7 SeitenMethode Statement Civil EnglishspazzbgtNoch keine Bewertungen

- Plan View Front View: Scale 2: 1 Scale 2: 1Dokument1 SeitePlan View Front View: Scale 2: 1 Scale 2: 1spazzbgtNoch keine Bewertungen

- Img 5Dokument1 SeiteImg 5spazzbgtNoch keine Bewertungen

- Img 4Dokument1 SeiteImg 4spazzbgtNoch keine Bewertungen

- Img 6Dokument1 SeiteImg 6spazzbgtNoch keine Bewertungen

- Plan View Front View: Scale 2: 1 Scale 2: 1Dokument1 SeitePlan View Front View: Scale 2: 1 Scale 2: 1spazzbgtNoch keine Bewertungen

- Foto Fabrikasi Bracket FR2 JIC Dimensional CheckDokument1 SeiteFoto Fabrikasi Bracket FR2 JIC Dimensional CheckspazzbgtNoch keine Bewertungen

- Keyboard Shortcuts (Hotkeys) For Autodesk Navisworks - Beyond Design - The Construction and BIM BlogDokument6 SeitenKeyboard Shortcuts (Hotkeys) For Autodesk Navisworks - Beyond Design - The Construction and BIM BlogspazzbgtNoch keine Bewertungen

- Test QCDokument1 SeiteTest QCspazzbgtNoch keine Bewertungen

- Plan View Front View: Scale 2: 1Dokument1 SeitePlan View Front View: Scale 2: 1spazzbgtNoch keine Bewertungen

- Plan View Front View: Scale 2: 1 Scale 2: 1Dokument1 SeitePlan View Front View: Scale 2: 1 Scale 2: 1spazzbgtNoch keine Bewertungen

- Plan View Front View: Scale 2: 1Dokument1 SeitePlan View Front View: Scale 2: 1spazzbgtNoch keine Bewertungen

- Cover ComproDokument1 SeiteCover ComprospazzbgtNoch keine Bewertungen

- Analytical Solution For Turbulent Flow in Pipes: A. Zagustin and K. ZagustinDokument6 SeitenAnalytical Solution For Turbulent Flow in Pipes: A. Zagustin and K. ZagustinspazzbgtNoch keine Bewertungen

- Warranty Claim Form PT DEC - SPK HempelDokument1 SeiteWarranty Claim Form PT DEC - SPK HempelspazzbgtNoch keine Bewertungen

- Warranty Claim Form PT DEC - Civil HempelDokument1 SeiteWarranty Claim Form PT DEC - Civil HempelspazzbgtNoch keine Bewertungen

- DS PM0202 en Co 3672Dokument4 SeitenDS PM0202 en Co 3672mkfe2005Noch keine Bewertungen

- Sample Method Statement - RevDokument8 SeitenSample Method Statement - RevspazzbgtNoch keine Bewertungen

- Methode Statement Civil EnglishDokument7 SeitenMethode Statement Civil EnglishspazzbgtNoch keine Bewertungen

- Dust Suppression Pump #2 Test RecordDokument1 SeiteDust Suppression Pump #2 Test RecordspazzbgtNoch keine Bewertungen

- Cikarang Power Station Project Babelan, Bekasi, Jakarta, IndonesiaDokument3 SeitenCikarang Power Station Project Babelan, Bekasi, Jakarta, IndonesiaspazzbgtNoch keine Bewertungen

- Pages From BPS-0SGA-121107-Valve & Accessories-2 PDFDokument3 SeitenPages From BPS-0SGA-121107-Valve & Accessories-2 PDFspazzbgtNoch keine Bewertungen

- Cikarang Power Station Project Progress ReportDokument3 SeitenCikarang Power Station Project Progress ReportspazzbgtNoch keine Bewertungen

- Cikarang Power Station Project Babelan, Bekasi, Jakarta, IndonesiaDokument2 SeitenCikarang Power Station Project Babelan, Bekasi, Jakarta, IndonesiaspazzbgtNoch keine Bewertungen

- Cikarang Power Station Project Progress ReportDokument3 SeitenCikarang Power Station Project Progress ReportspazzbgtNoch keine Bewertungen

- Work Breakdown Detail Hydrant Underground Pipe Modification in TT-04 AreaDokument1 SeiteWork Breakdown Detail Hydrant Underground Pipe Modification in TT-04 AreaspazzbgtNoch keine Bewertungen

- Persta Industrie eDokument140 SeitenPersta Industrie ezoraze32Noch keine Bewertungen

- 6-Inch-CI-50-Hz Lubi PumpDokument76 Seiten6-Inch-CI-50-Hz Lubi PumpAhmed AbarchidNoch keine Bewertungen

- Pipe Friction Loss AnalysisDokument2 SeitenPipe Friction Loss Analysissunii19847908Noch keine Bewertungen

- Module 1 Introduction To HydraulicsDokument20 SeitenModule 1 Introduction To Hydraulicsoluja93Noch keine Bewertungen

- Bermad: Level Control ValveDokument2 SeitenBermad: Level Control ValvejendrikoNoch keine Bewertungen

- Concentrate Control System: Operating, Maintenance, and Filling ManualDokument24 SeitenConcentrate Control System: Operating, Maintenance, and Filling ManualSadegh AhmadiNoch keine Bewertungen

- H - Disc Valves PDFDokument4 SeitenH - Disc Valves PDFMIDHUN RAJNoch keine Bewertungen

- Joystick Control Plumbing - H PatternDokument3 SeitenJoystick Control Plumbing - H PatternricardoNoch keine Bewertungen

- Piping and Valves Design DocDokument2 SeitenPiping and Valves Design DocДмитрий РыбаковNoch keine Bewertungen

- Operation Slew A.R.V. and Anti-Cavitation Operation: Section E - HydraulicsDokument20 SeitenOperation Slew A.R.V. and Anti-Cavitation Operation: Section E - HydraulicsMarcelo Elói De Amorim SilvaNoch keine Bewertungen

- Litostroj Power Group offers spherical valves, butterfly valves and energy dissipating valvesDokument2 SeitenLitostroj Power Group offers spherical valves, butterfly valves and energy dissipating valvesZohaibNoch keine Bewertungen

- MSS SP-89 (1998) Pipe Hangers & Supports (Fabrication & Installations)Dokument20 SeitenMSS SP-89 (1998) Pipe Hangers & Supports (Fabrication & Installations)Edwin Mariaca100% (1)

- Re92035 - 2023 06 29Dokument38 SeitenRe92035 - 2023 06 29Rafael RicardoNoch keine Bewertungen

- 047 Sec IVPipingstandardsDokument43 Seiten047 Sec IVPipingstandardsSachin MankameNoch keine Bewertungen

- Chapter 6 Water Supply and DistributionDokument20 SeitenChapter 6 Water Supply and Distributionapi-131679190Noch keine Bewertungen

- Hydraulics / Hydraulique / Hidrá Ulica: Vapormatic Quality Replacement Parts Suitable For Massey Ferguson ApplicationsDokument54 SeitenHydraulics / Hydraulique / Hidrá Ulica: Vapormatic Quality Replacement Parts Suitable For Massey Ferguson ApplicationsRetropartes AcevedoNoch keine Bewertungen

- Igtr Aurangabad Pdiar Curriculum - 0 PDFDokument33 SeitenIgtr Aurangabad Pdiar Curriculum - 0 PDFMahavir ChavdaNoch keine Bewertungen

- AC & DC Hydraulic Power Packs Compact SeriesDokument84 SeitenAC & DC Hydraulic Power Packs Compact SeriesJose Luis Rodriguez CruzNoch keine Bewertungen

- CPH Recirculation Pump & Control Valve Function Test RecordDokument2 SeitenCPH Recirculation Pump & Control Valve Function Test RecordVinoth KumarNoch keine Bewertungen

- Experiment No.1 ObjectiveDokument4 SeitenExperiment No.1 ObjectivealiNoch keine Bewertungen

- Alarm ValveDokument12 SeitenAlarm ValveMusharaf ShahNoch keine Bewertungen

- Hydronic 300 Valve Setting Instructions - M04002enDokument14 SeitenHydronic 300 Valve Setting Instructions - M04002enbdgnsNoch keine Bewertungen

- Performance of Centrifugal Pump ExperimentDokument10 SeitenPerformance of Centrifugal Pump Experimentcha100% (1)

- Lampiran Fire Fighting Pltu BelitungDokument2 SeitenLampiran Fire Fighting Pltu BelitungDangolNoch keine Bewertungen