Beruflich Dokumente

Kultur Dokumente

Inkoma Friction Locking Bushes

Hochgeladen von

RuiOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Inkoma Friction Locking Bushes

Hochgeladen von

RuiCopyright:

Verfügbare Formate

Friction locking bushes

Product description

Inkofix - friction locking bushes ISC, ISR, ISS, ISP, ISK, ISB and ISH

INKOMA-Inkofix-friction locking bushes are non-positive couplers for

the simple and problem free assembly and disassembly of machine

components.

To select the correct tension unit the transmitted torque, axial load and

available space must be considered. The static and dynamic

requirement as well as the drive characteristics need to be taken into

account.

2008.01

www.INKOMA.de

001

Friction locking bushes

Contents list

Inkofix - friction locking bushes ISC, ISR, ISS, ISP, ISK, ISB and ISH

Technical information

Load factor

Calculation for the hub

Dimensions ISC/K - Inkofix-friction locking bush

Version A

Version B

Page

003

Page

004 - 005

Dimensions ISC/L - Inkofix-friction locking bush

Version A

Version B

Page

006 - 007

Dimensions ISR - Inkofix-shrink ring

Version A

Page

008 - 009

Dimensions ISS - Inkofix-shrink disc

Version A

Page

010 - 011

Dimensions ISP - Inkofix-tension flange

Version A

Version B

Version C

Page

012 - 013

Dimensions ISK - Inkofix-shrink coupling

Page

014 - 015

Dimensions ISB - Inkofix-tension sleeve

Page

016 - 017

Dimensions ISH - Inkofix-tension set

Page

018 - 019

Application examples

Page

020

2007.01

www.INKOMA.de

002

Friction locking bushes

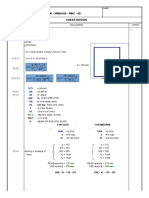

Technical information

Inkofix - friction locking bushes ISC, ISR, ISS, ISP, ISK, ISB and ISH

Type of load

Load factor

Smooth loading

e.g. electric motor, fan, blower, centrifugal pump.

Minimal shock loading

e.g. piston compressor, internal combustion

engine, mixer, machine tool, wood working

machinery, spiral conveyors, as well as all

applications with lightly varying loads.

1,5

Heavy shock loading

e.g. presses, forging, shears, conveyors, water

hydraulics, milling, rolling mills.

Calculation for the hub:

For hubs having the form of a hollow cylinder and length l1 the

following formula is valid for the stress at the internal diameter.

1 + CN 2

1 - CN2

= pN

R = -p N

Comparative stress

energy of distortion:

V =

pN

1-CN

according to the hypothesis for strain

3 + CN 4

In the formula for selecting the friction locking bushes the following

symbols are used:

The comparative stress for hub diameter relationships 0.3 <

=1 can

be estimated using the following formula:

Ta

[Nm]

operational torque

[Nm]

transmissible torque

Fax B

[kN]

operational axial loading

Fax

[kN]

max. axial load

l1

[mm]

effective axial length of friction locking bush

Lx

[mm]

available fixed length of hub

So

[-]

safety factor for ring thickness dependent

safety

[mm]

outer diameter of tension element

dW

[mm]

internal diameter of tension element,

shafts diameter

dN

[mm]

outer diameter of the hub,

internal diameter of tension element

CN

[-]

D

dN

pW

[N/mm2]

surface pressure of the shaft tension element

pN

[N/mm2]

permissible surface pressure in the tension

element hub

[N/mm2]

radial stress

[N/mm2]

comparative stress

N 0,2

[N/mm2]

yield point of hub material

W 0,2

[N/mm2]

yield point for shaft material

twi

[N/mm2]

hollow shaft tangential stress

2007.01

V =

pN

0,8 (1-CN)

If torque is supplemented by an axial loading the resulting

moment can be calculated as follows:

T <

=

Ta2 +

pN

l1 1 + So CN

Lx 0,8 (1-CN)

Fax B dW

2

[Nm]

Hub stress:

N 0,2 <= 1,35

The value Lx is the available hub length for the tension element.

The catalogue values for transmission are derived by calculation.

Test results as well as variations in coefficient of friction may

reveal small deviations from the stated transmissible values.

www.INKOMA.de

003

Friction locking bushes

Dimensions

ISC/K - Inkofix-friction locking bush

The INKOMA-Inkofix-friction locking bushes ISC/K are supplied in two

versions (A and B).

Version ISC/K-A

l

Version ISC/K-A:

Higher transmissible torque than ISC/K-B. Can be easily positioned

axially during assembly.

l3

l2

l1

Version ISC/K-B:

Cannot be moved axially during assembly and transmits rather less

torque than ISC/K-A.

dw h8

D H8

H8

Surface condition:

Shaft and hub bore: Rz <

- 16m

dw h8

Tolerances:

Greatest permitted fit:

h8 for shaft

H8 for hub

Concentricity:

Friction locking bushes ISC/K-A and ISC/K-B are self-centering.

Assembly:

1. Shaft and hub should be carefully cleaned and lightly oiled. The

values in the table for T and Fax assume assembly using oiled

components.

2. Locate the friction locking bush in the hub.

3. Slide friction locking bush with hub on the shaft into position.

4. Tighten opposite tensioning screws gradually up to the

recommended tightening torque TA using a torque wrench.

5. Check the tightening torque for all screws in the tightening

sequence.

dismounting threads

Version ISC/K-B

Note:

Oils containing molybdenum disulphide or high pressure additives

should not be used. Do not use grease. These will radically reduce the

coefficient of friction. The friction locking bushes are supplied

lubricated. Oil-free assembly will achieve different values to both the

tabled and calculated ones.

l

l3

l2

l1

D1

Explanation:

T

= maximum transmissible torque for an Inkofix-friction locking

bush

Fax = maximum axial force which may be applied to an Inkofixfriction locking bush

TA = the required tightening torque for the tensioning screws

Dis-assembly:

1. Remove tension screws

2. Three or four of the screws should be inserted to the axial

dismounting threads. Gradually tighten these in turn until the

conical ring is released.

3. The friction locking bush and the hub can now be removed.

dismounting threads

Ordering example:

Inkofix-friction locking bush

Shaft diameter

External diameter

Index of version

ISC/K 50 x 80 - A

2007.01

www.INKOMA.de

004

Friction locking bushes

Dimensions [mm]

ISC/K 20 x 47 - A

ISC/K 22 x 47 - A

ISC/K 24 x 50 - A

ISC/K 25 x 50 - A

ISC/K 28 x 55 - A

ISC/K 30 x 55 - A

ISC/K 32 x 60 - A

ISC/K 35 x 60 - A

ISC/K 38 x 65 - A

ISC/K 40 x 65 - A

ISC/K 45 x 75 - A

ISC/K 50 x 80 - A

17

17

17

17

17

17

17

17

17

17

20

20

22

22

22

22

22

22

22

22

22

22

25

25

28

28

28

28

28

28

28

28

28

28

33

33

34

34

34

34

34

34

34

34

34

34

41

41

M6

M6

M6

M6

M6

M6

M6

M6

M6

M6

M8

M8

Mass

Hub

l3

Shaft

l2

max. axial force

l1

Torque

Order code

dW x D

Operational data

Tightening torque

ISO 4762

(DIN 912)

Tension screw

TA

[Nm]

T

[Nm]

Fax

[kN]

pW

[N/mm2]

pN

[N/mm2]

[kg]

14

14

14

14

14

14

14

14

14

14

35

35

350

380

420

520

580

620

890

970

1060

1100

2100

2300

35

35

35

42

42

42

55

55

55

55

90

90

280

260

240

270

240

230

280

260

240

230

290

260

120

120

110

140

120

130

150

150

140

140

170

160

0,26

0,25

0,28

0,27

0,32

0,30

0,37

0,35

0,41

0,38

0,61

0,67

Surface pressure

between friction locking

bush and

Other sizes available, please enquire.

D1

ISC/K 20 x 47 - B

ISC/K 22 x 47 - B

ISC/K 24 x 50 - B

ISC/K 25 x 50 - B

ISC/K 28 x 55 - B

ISC/K 30 x 55 - B

ISC/K 32 x 60 - B

ISC/K 35 x 60 - B

ISC/K 38 x 65 - B

ISC/K 40 x 65 - B

ISC/K 45 x 75 - B

ISC/K 50 x 80 - B

ISC/K 55 x 85 - B

ISC/K 60 x 90 - B

ISC/K 65 x 95 - B

ISC/K 70 x 110 - B

ISC/K 75 x 115 - B

ISC/K 80 x 120 - B

ISC/K 85 x 125 - B

ISC/K 90 x 130 - B

ISC/K 95 x 135 - B

ISC/K 100 x 145 - B

ISC/K 110 x 155 - B

ISC/K 120 x 165 - B

ISC/K 130 x 180 - B

ISC/K 140 x 190 - B

ISC/K 150 x 200 - B

17

17

17

17

17

17

17

17

17

17

20

20

20

20

20

24

24

24

24

24

24

26

26

26

34

34

34

22

22

22

22

22

22

22

22

22

22

25

25

25

25

25

30

30

30

30

30

30

32

32

32

40

40

40

28

28

28

28

28

28

28

28

28

28

33

33

33

33

33

40

40

40

40

40

40

44

44

44

52

54

54

34

34

34

34

34

34

34

34

34

34

41

41

41

41

41

50

50

50

50

50

50

56

56

56

64

68

68

56

56

59

59

64

64

69

69

74

74

84

89

94

99

104

119

124

129

134

139

144

154

164

174

189

199

209

M6

M6

M6

M6

M6

M6

M6

M6

M6

M6

M8

M8

M8

M8

M8

M10

M10

M10

M10

M10

M10

M12

M12

M12

M12

M14

M14

Hub

l3

Shaft

l2

max. axial force

l1

Torque

Order code

dW x D

Operational data

Tightening torque

ISO 4762

(DIN 912)

Tension screw

TA

[Nm]

T

[Nm]

Fax

[kN]

pW

[N/mm2]

pN

[N/mm2]

[kg]

17

17

17

17

17

17

17

17

17

17

41

41

41

41

41

83

83

83

83

83

83

145

145

145

145

230

230

280

310

400

440

490

530

760

820

890

940

1700

1900

2400

2700

3200

4900

5200

5500

6600

7000

8200

10100

11000

13600

19000

21800

25600

30

30

30

30

30

30

50

50

50

50

60

90

90

90

90

120

120

120

130

130

130

170

170

200

270

270

320

220

200

220

210

200

190

210

190

190

190

230

210

210

190

200

220

200

190

200

190

200

210

190

210

190

180

190

90

90

110

110

100

100

110

110

110

100

130

130

130

120

130

140

130

120

130

130

140

150

140

140

140

130

140

0,28

0,27

0,31

0,30

0,36

0,35

0,42

0,39

0,45

0,45

0,70

0,76

0,85

0,90

0,93

1,67

1,76

1,87

1,96

2,05

2,30

2,83

3,10

3,30

5,10

5,40

5,70

Surface pressure

between friction locking

bush and

Mass

Dimensions [mm]

Other sizes available, please enquire.

2007.01

www.INKOMA.de

005

Friction locking bushes

Dimensions

ISC/L - Inkofix-friction locking bush

The INKOMA Inkofix-friction locking bushes ISC/L are supplied in two

versions (A and B).

Version ISC/L-A

l

Version ISC/L-A:

Higher transmissible torque than ISC/L-B. Can be easily positioned

axially during assembly.

dw h8

D H8

D H8

Tolerances:

Greatest permitted fit:

h8 for shaft

H8 for hub

dw h8

Version ISC/L-B:

Cannot be moved axially during assembly and transmits rather less

torque than ISC/L-A.

Surface condition:

Shaft and hub bore: Rz <

- 16m

dismounting threads

Concentricity:

Friction locking bushes ISC/L-A and ISC/L-B are self-centering.

l1

Assembly:

1.Shaft and hub should be carefully cleaned and lightly oiled. The

values in the table for T and Fax assume assembly using oiled

components.

2. Locate the friction locking bush in the hub.

3. Slide friction locking bush with hub on the shaft into position.

4. Tighten opposite tensioning screws gradually up to the

recommended tightening torque TA using a torque wrench.

5. Check the tightening torque for all screws in the tightening

sequence.

l2

l3

Version ISC/L-B

l

Dis-assembly:

1. Remove tension screws

2. Three or four of the screws should be inserted to the axial

dismounting threads. Gradually tighten these in turn until the

conical ring is released.

3. The friction locking bush and the hub can now be removed.

D1

Note:

Oils containing molybdenum disulphide or high pressure additives

should not be used. Do not use grease.These will radically reduce the

coefficient of friction. The friction locking bushes are supplied

lubricated. Oil-free assembly will achieve different values to both the

tabled and calculated ones.

dismounting threads

Explanation:

T

= maximum transmissible torque for an Inkofix-friction locking

bush

Fax = maximum axial force which may be applied to an Inkofixfriction locking bush

TA = the required tightening torque for the tensioning screws

l1

l2

l3

Ordering example:

Inkofix-friction locking bush

Shaft diameter

External diameter

Index of version

ISC/L 30 x 55 - A

2007.01

www.INKOMA.de

006

Friction locking bushes

D1

ISC/L 20 x 47

ISC/L 22 x 47

ISC/L 24 x 50

ISC/L 25 x 50

ISC/L 28 x 55

ISC/L 30 x 55

ISC/L 32 x 60

ISC/L 35 x 60

ISC/L 38 x 65

ISC/L 40 x 65

ISC/L 42 x 75

ISC/L 45 x 75

ISC/L 48 x 80

ISC/L 50 x 80

ISC/L 55 x 85

ISC/L 60 x 90

ISC/L 65 x 95

ISC/L 70 x 110

ISC/L 75 x 115

ISC/L 80 x 120

ISC/L 85 x 125

ISC/L 90 x 130

ISC/L 95 x 135

ISC/L 100 x 145

ISC/L 110 x 155

ISC/L 120 x 165

ISC/L 130 x 180

ISC/L 140 x 190

ISC/L 150 x 200

26

26

26

26

26

26

26

26

26

26

30

30

30

30

30

30

30

40

40

40

40

40

40

46

46

46

46

51

51

31

31

31

31

31

31

31

31

31

31

36

36

36

36

36

36

36

46

46

46

46

46

46

52

52

52

52

59

59

39

39

39

39

39

39

39

39

39

39

47

47

47

47

47

47

47

57

62

62

62

62

62

77

77

77

77

84

84

45

45

45

45

45

45

45

45

45

45

55

55

55

55

55

55

55

67

72

72

72

72

72

89

89

89

89

98

98

56

56

59

59

64

64

69

69

74

74

84

84

89

89

94

99

104

119

124

129

134

139

144

154

164

174

189

199

209

M6

M6

M6

M6

M6

M6

M6

M6

M6

M6

M8

M8

M8

M8

M8

M8

M8

M10

M10

M10

M10

M10

M10

M12

M12

M12

M12

M14

M14

33

33

50

50

50

50

67

67

67

67

67

92

110

120

120

120

120

190

190

190

240

240

240

280

280

350

420

450

490

Fax

[kN]

0,38

0,37

0,41

0,42

0,48

0,46

0,52

0,51

0,60

0,57

1,02

0,93

1,05

1,01

1,12

1,21

1,23

2,30

2,50

2,58

2,70

2,80

3,20

3,94

4,30

4,60

10,10

10,50

11,00

310

360

420

470

580

640

780

840

1000

1100

1900

1900

2100

2200

2400

2600

2800

5700

6200

6700

8000

8500

10000

13300

14600

19100

20400

25000

30100

31

31

35

35

41

41

50

50

50

50

90

90

90

90

90

90

90

160

160

160

180

180

180

270

270

250

300

350

350

230

220

220

230

220

200

230

200

210

200

230

230

210

210

220

200

210

220

210

200

210

200

210

210

190

210

190

190

200

100

90

100

100

110

120

110

120

120

120

140

140

130

130

140

150

140

140

140

130

140

140

150

150

140

150

140

140

150

Mass

380

430

520

580

690

750

910

1000

1200

1300

2100

2300

2500

2500

3100

3300

4000

6700

7400

7900

9500

10100

11900

15400

16900

22100

23600

30200

36400

T

[Nm]

Hub

17

17

17

17

17

17

17

17

17

17

41

41

41

41

41

41

41

83

83

83

83

83

83

145

145

145

145

230

230

pN

pW

[N/mm2] [N/mm2] [kg]

Surface pressure

between friction

locking bush and

Shaft

Fax

[kN]

Mass

T

[Nm]

Hub

TA

[Nm]

Surface pressure

between friction

locking bush and

max. axial force

l3

Operational data

Torque

l2

max. axial force

l1

ISC/L-B

Operational data

Torque

Order code

dW x D

ISC/L-A

Tightening torque

ISO 4762 (DIN 912)

Tension screw

Shaft

Dimensions [mm]

pN

pW

[N/mm2] [N/mm2] [kg]

230

210

210

220

200

220

200

200

200

200

220

220

220

220

220

210

200

220

220

200

220

200

190

200

200

220

200

190

200

95

95

100

110

110

120

110

120

120

120

140

140

140

140

140

140

130

150

140

140

160

140

140

150

180

160

140

140

150

0,42

0,40

0,44

0,43

0,52

0,49

0,56

0,55

0,64

0,61

1,09

1,00

1,10

1,07

1,20

1,29

1,31

2,44

2,60

2,73

2,80

2,99

3,20

4,14

4,52

4,84

5,00

10,50

11,00

Other sizes available, please enquire.

2007.01

www.INKOMA.de

007

Friction locking bushes

Dimensions

ISR - Inkofix-shrink ring

TV =

T2Table +

dw Fax

2

Version A

l2

l

l1

dW H7

h6

l4

dN H7

f7

The INKOMA-Inkofix-shrink ring series ISR is for friction-locked shafthub connection.

The required force for torque transmission is provided by tapered

external rings which are engaged by tensioning screws causing the

inner ring to clamp the hub firmly onto the shaft.

All INKOMA-Inkofix-shrink rings are supplied ready-to-assemble.

They can be frequently re-used if handled carefully and the conical

components are re-lubricated.

INKOMA-Inkofix-shrink rings are available for all intermediate values

of shaft diameter. The applicable transmissible torque can be derived

by interpolation.

The given values for transmissible torque are achieved for a shaft to

hub friction coefficient of = 0.15. The listed torque values are only

applicable when the recommended values for shaft and hub tolerance

are applied. Larger clearance of the fit reduces the transmitted torque.

The surface roughness should, under no circumstances exceed 15 .

To achieve the highest possible friction between shaft and hub, both

must be grease free in the area of the connection. Screws and conical

surfaces must be lubricated with grease. Socket head cap screws to

ISO 4014 (DIN 931) class 10.9 are used.

Should transmission of axial loads and torque be applied

coincidentally the values must be added vectorially.

2

grease free

greased

Assembly:

Contact surfaces of the shaft and bore should be de-greased with

solvent or degreaser. Tension screws should be tightened in two or

three stages up to the recommended tightening torque TA.

Disassembly:

Release all the screws in turn. The disc is not self-locking so

disengage this from the conical surface. Should dirt or fretting prevent

this a sharp tap from a copper or plastic hammer will effect release.

Explanation:

T = maximum transmissible torque for an Inkofix-shrink ring

Fax = maximum axial force which may be applied to an Inkofix-shrink

ring

TA = the required tightening torque for the tensioning screws

Ordering example:

Inkofix-shrink ring

Hub diameter

External diameter

Index of version

ISR 180.340 / A

2007.01

www.INKOMA.de

008

Friction locking bushes

ISR 36.72

ISR 44.80

ISR 50.90

ISR 55.100

ISR 62.110

ISR 68.120

ISR 80.155

ISR 100.175

ISR 110.190

ISR 125.220

ISR 140.245

ISR 165.290

ISR 180.340

ISR 200.355

ISR 220.370

ISR 240.410

ISR 260.440

l2

l4

T

[Nm]

181...

236

343...

403

448...

654

682...

860

966...

1446

1220...

1940

1820...

2300

2400...

3250

3300...

4300

6200...

9200

9400...

13400

16800...

19600

24000...

34000

41000...

59000

60000...

85000

93900...

130000

131000...

162000

165000...

207000

221000...

275000

18...

22

29...

30

32...

40,8

35...

46

51...

68

57...

81

75...

88

90...

108

110...

127

179...

230

232...

297

370...

392

474...

591

706...

907

1060...

1170

1286...

1625

1630...

1850

2225...

2250

2310...

2620

24

50

18

15

22

20

6xM5x16

30

60

20

17

24

25

6xM6x16

12

36

72

22

20

26

28

6xM6x20

12

44

80

24

21

28

30

8xM6x20

12

50

90

26

24

30

35

8xM6x20

12

55

100

30

26

34

35

10xM6x25

12

62

110

32

28

36

40

10xM6x25

12

68

120

36

32

40

40

10xM6x30

32

80

155

42

36

47,5

46

12xM8x35

32

100

175

50

40

55,5

55

15xM8x40

32

110

190

54

46

61

60

12xM10x45

60

125

220

60

52

68

65

14xM12x50

110

140

245

74

65

82

80

16xM12x60

110

165

290

90

80

100

95

12xM16x75

250

180

340

105

90

115

110

16xM16x80

250

200

355

115

100

125

120

18xM16x100

250

220

370

135

120

145

140

18xM16x110

250

240

410

145

130

158

150

16xM20x120

480

260

440

160

140

173

170

18xM20x130

480

Mass

ISR 30.60

19...

22

23...

27

28...

32

33...

37

38...

42

43...

48

49...

52

53...

60

60...

68

69...

80

81...

90

91...

100

101...

115

116...

130

131...

145

146...

160

161...

175

176...

190

191...

210

l1

TA

[Nm]

dN

Mass moment

of inertia

ISR 24.50

dw

Torque 1)

Order code

Operational data

Tightening torque

ISO 4014 (DIN 931)

10.9

Tension screw

max. axial force 1)

Dimensions [mm]

Fax

[kN]

J

[kg cm2]

[kg]

0,7

0,18

2,0

0,28

4,0

0,5

6,0

0,6

11,0

0,8

18,0

1,1

30,0

1,5

43,0

1,8

148,0

3,8

260,0

5,1

410,0

6,8

840,0

10,5

1610,0

16,2

3910,0

28,1

8550,0

46,2

11000,0

53,0

15170,0

65,5

25270,0

88,6

35880,0

108,8

1) The values for T and F can be be interpolated from d .

ax

w

Other sizes available, please enquire.

2007.01

www.INKOMA.de

009

Friction locking bushes

Dimensions

ISS - Inkofix-shrink disc

1. Degrease the shaft and hub bore.

2. Lubricate the fitting surfaces of the hub part of the shrink disc.

3. Slide the shrink disc onto the hub.

4. Slide the hub part into position on the shaft seat.

5. Lightly tighten the tension screws in clockwise sequence in a

number of stages until the recommended tightening torque TA is

achieved. The correct tension is reached when the end surfaces of

the outer ring and the inner ring coincide.

dw H7

h6

l1

dN H7

f7

Assembly:

INKOMA-Inkofix-shrink discs are supplied ready-to-assemble. They

can be frequently re-used if handled carefully and the conical

components are re-lubricated.

Version A

The INKOMA-Inkofix-shrink disc series ISS is for friction-locked shafthub connection. The required force for torque transmission is

provided by conical external and internal rings which are engaged by

tensioning screws, causing the inner ring to clamp the hub firmly onto

the shaft. The hub inner ring can be produced to intermediate sizes.

The transmissible torque value in the table can only be achieved if the

recommended tolerances between shaft and hub are provided.

Larger clearance of the fit will result in lower transmitted torque. The

surface roughness should, under no circumstances, exceed 15 . To

achieve the highest possible friction between shaft and hub, both

must be grease free in the area of the connection. Screws and conical

surfaces must be lubricated with grease. Hexagon head screws to ISO

4017 (DIN 933) class 10.9 are used. The long conical surfaces allow

very high concentricity to be achieved. These comonents are

therefore suitable for high speed rotation.

grease free

greased

Disassembly:

1. Loosen the tension screws sequentially. This should be caried out

in sequence in stages. Do not completely remove the tension

screws.

2. Fit two or three of the screws in the dismounting holes and tighten

opposites until the tension ring loosens.

3. Remove the tension ring and hub.

Explanation:

T = maximum transmissible torque for an Inkofix-shrink disc

Fax = maximum axial force which may be applied to an Inkofix-shrink

disc

TA = the required tightening torque for the tensioning screws

Ordering example:

Inkofix-shrink disc

Hub diameter

External diameter

Index for version

ISS 55.100 / A

2007.01

www.INKOMA.de

010

Friction locking bushes

Dimensions [mm]

l1

Mass

Mass moment

of inertia

dN

max. axial force 1)

dw

Torque 1)

Order code

Operational data

Tightening torque

ISO 4017

(DIN 933)

10.9

Tension screw

TA

[Nm]

T

[Nm]

Fax

[kN]

J

[kg cm2]

[kg]

ISS 12.32

10

12

11

32

5xM5x10

38

0,09

0,058

ISS 14.38

12

14

12

10

38

5xM5x10

52

0,2

0,083

ISS 16.42

14

16

15

12

42

6xM5x12

90

13

0,3

0,12

18

15

12

45

6xM5x12

0,135

15

12

48

6xM5x12

0,5

0,150

24

18

14

52

8xM5x16

0,9

0,210

30

20

16

62

8xM5x16

1,9

0,32

36

22

18

74

8xM6x16

12

3,0

0,40

44

24

20

80

8xM6x16

12

7,0

0,65

50

26

21

90

8xM6x16

12

11,0

0,86

55

29

23

100

8xM6x16

12

18,0

1,1

62

29

23

110

10xM6x16

12

26,0

1,32

68

29

23

115

10xM6x16

12

32,0

1,45

75

31

24

138

10xM8x25

32

56,0

1,80

80

31

24

145

10xM8x25

32

66,0

1,92

90

38

31

155

12xM8x25

32

137,0

3,4

100

43

36

170

15xM8x25

32

233,0

4,8

110

49

41

185

12xM10x35

60

347,0

6,0

125

53

44

215

15xM10x35

60

10...

14

16...

20

17...

25

23...

27

37...

46

41...

47

55...

72

54...

77

69...

84

73...

103

97...

133

108...

133

145...

190

170...

220

226...

280

280...

340

0,4

20

80...

112

140...

184

160...

280

280...

360

550...

740

700...

850

1100...

1540

1130...

1850

1690...

2170

1800...

3100

2700...

4300

3250...

4700

4700...

7200

5920...

8900

9050...

12600

12850...

17000

657,0

8,5

ISS 18.45

ISS 20.48

ISS 24.52

ISS 30.62

ISS 36.74

ISS 44.80

ISS 50.90

ISS 55.100

ISS 62.110

ISS 68.115

ISS 75.138

ISS 80.145

ISS 90.155

ISS 100.170

ISS 110.185

ISS 125.215

15...

16

17...

18

19...

22

24...

26

28...

32

34...

36

38...

42

42...

48

48...

52

50...

60

55...

65

60...

70

65...

75

70...

80

80...

90

90...

100

1) The values for T and F can be be interpolated from d .

ax

w

Other sizes available, please enquire.

2007.01

www.INKOMA.de

011

Friction locking bushes

Dimensions

ISP - Inkofix-tension flange

dW h7

H2

Version B

H2

H1

Fh7

dW h7

Disassembly:

1. Loosen the tension screws sequentially, in gradual stages.

2. Should the tension ring not loosen, insert screws in some of the

dismounting holes and screw in until the inner and outer rings

separate.

1. Degrease the shaft and tension flange bore.

2. Lightly engage the screws and slide into position on the shaft.

3. Lightly tighten the tension screws in clockwise sequence in gradual

stages until the recommended tightening torque TA is achieved.

4. Once the tension flange is fitted the flange component, coupling

hub, gear, sprocket, etc. can be secured to the tension flange. The

design prevents any possible distortion of the flange.

Assembly:

INKOMA-Inkofix-shrink discs are supplied ready-to-assemble. They

can be frequently re-used if handled carefully and the conical

components are re-lubricated.

Version A

The INKOMA-Inkofix-tension flange series ISP transmits torque via an

inner and outer ring using friction. The required interference is created

using conical inner and outer rings tensioned by screws. The

transmissible torque stated in the table assumes the use of the stated

tolerances for the diameters connected. Larger clearance of the fit will

reduce the torque transmissible. Surface roughness should in no

circumstances be greater than 15 . For the best friction effect

between shaft and bore the surfaces should be free of lubricant.

Screws and conical surfaces should be greased. Hexagon head

screws to ISO 4017 (DIN 933) class 10.9 are used. The ISP tension

flange is used as an economical and simple method for securing

flange like elements. The range includes units for use with our PK, LFK

and IFK couplings. Other applications include sprockets, pulleys and

gears. In most cases the outer diameter of the tension flange is

designed for compatability with the INKOMA coupling range but can

also be made with smaller outside diameters. Alternative hole patterns

for the securing of other components are also offered.

Version C

Explanation:

T = maximum transmissible torque for an Inkofix-tension flange

Fax = maximum axial force which may be applied to an Inkofixtension flange

TA = the required tightening torque for the tensioning screws

H2

Fh7

dW h7

H1

Ordering example:

Inkofix-tension flange

Shafts diameter

External diameter

Number of mounting holes

Version

F - Centering shoulder

ISP 30.110/4 B 50

2007.01

www.INKOMA.de

012

Friction locking bushes

Tension screw

H1

H2

ISP 16.60/3 1)

ISP 16.66/4

ISP 16.66/6

ISP 25.82/3

ISP 25.82/4

ISP 30.90/3 1)

ISP 30.110/3

ISP 30.110/4

ISP 30.115/3

ISP 30.115/4

ISP 35.125/3

ISP 35.130/3

ISP 35.130/4

ISP 35.145/4

ISP 40.140/3

ISP 40.140/4

ISP 40.145/3

ISP 40.145/4

ISP 40.150/3

ISP 40.150/4

ISP 45.160/3

ISP 45.160/4

ISP 50.180/3

ISP 50.180/4

ISP 50.185/3

ISP 50.185/4

ISP 60.230/4

ISP 60.230/5

ISP 60.230/6

ISP 80.290/6

16

16

16

25

25

30

30

30

30

30

35

35

35

35

40

40

40

40

40

40

45

45

50

50

50

50

60

60

60

80

25

25

25

45

45

40

50

50

50

50

55

50

50

60

60

60

60

60

60

60

70

70

80

80

80

80

100

100

100

150

48

56

56

70

70

70

90

90

98

98

100

110

110

128

115

115

120

120

130

130

135

135

152

152

150

150

200

200

200

260

60

66

66

82

82

90

110

110

115

115

125

130

130

145

140

140

145

145

150

150

160

160

180

180

185

185

230

230

230

290

14

12

12

14

14

20

25

25

16

16

35

30

30

20

40

40

35

35

30

30

45

45

50

50

60

60

70

70

70

75

16

14

14

17

17

23

28

28

19

19

38

33

33

23

43

43

38

38

33

33

48

48

53

53

65

65

75

75

75

80

M8

M6

M6

M8

M8

M12

M12

M12

M8

M8

M16

M12

M12

M8

M16

M16

M16

M16

M12

M12

M16

M16

M16

M16

M20

M20

M20

M20

M20

M20

6,6

6,6

9

9

14

14

9

9

18

14

14

9

18

18

18

18

14

14

18

18

18

18

22

22

22

22

22

22

6xM5x10

6xM5x10

6xM5x10

8xM5x16

8xM5x16

8xM5x16

8xM5x16

8xM5x16

8xM5x16

8xM5x16

8xM6x16

8xM6x16

8xM6x16

8xM6x16

8xM6x16

8xM6x16

8xM6x16

8xM6x16

8xM6x16

8xM6x16

10xM6x16

10xM6x16

10xM6x20

10xM6x20

10xM6x20

10xM6x20

10xM6x20

10xM6x20

10xM6x20

10xM8x25

Mass moment

of inertia

max. axial force

dW

Torque

Order code

Operational data

Tightening torque

ISO 4017

(DIN 933)

10.9

Preferred dimensions

TA

[Nm]

T

[Nm]

Fax

[kN]

J

[kg cm2]

[kg]

7

7

7

7

7

7

7

7

7

7

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

32

125

90

90

340

340

830

982

982

680

680

1385

1195

1195

850

2460

2460

2220

2220

1920

1920

3000

3000

4100

4100

5200

5200

9800

9800

9800

13600

16

13

13

27

27

55

65

65

45

45

79

68

68

49

123

123

111

111

96

96

133

133

164

164

208

208

327

327

327

340

1,4

1,7

1,7

4,9

4,9

10

28

28

21,5

21,5

65

66

66

68

118

118

119

119

117

117

226

226

402

402

538

538

1500

1500

1500

4061

0,29

0,30

0,30

0,53

0,53

0,89

1,73

1,73

1,22

1,22

3,10

2,90

2,90

2,44

4,44

4,44

4,19

4,19

3,90

3,90

6,54

6,54

9,21

9,21

11,73

11,73

21,27

21,27

21,27

35,90

Mass

Dimensions [mm]

1) Version C is not available.

Spacing of the mounting holes: 3 x 120 = 360 / 4 x 90 = 360 / 5 x 72 = 360 / 6 x 60 = 360

2007.01

www.INKOMA.de

013

Friction locking bushes

Dimensions

ISK - Inkofix-shrink coupling

The INKOMA-Inkofix-shrink coupling series ISK is for the rigid keyless

coupling of shafts having the same or similar diameters. The required

force for torque transmission is provided by pressure and friction via

the inside conical rings causing the inner ring to clamp firmly onto the

shafts.

All INKOMA-Inkofix-shrink couplings are delivered ready for use.

If carefully treated (with the lubrication of the conical surfaces renewed

every time), Inkofix-shrink couplings may be dismantled and

remounted as often as necessary. INKOMA-Inkofix-shrink couplings

are available for all intermediate values of shaft diameter.

The applicable transmissible torque can be derived by interpolation.

When the torque and the axial force overlap, their values must be

added vectorially.

greased

l1

The surface quality must always be better than 15 . Hexagon head

screws to ISO 4014 (DIN 931) class 10.9 are used.

The torque and axial loads indicated will be transmitted under the

following conditions:

1. the coefficient of friction between shaft and hole must be greater

than =0,15

2. the quality of the clearance of the fit between shaft and hole is as

indicated.

Greater clearance of the fit penalises torque transmission. Less

clearance of the fit enhances torque transmission.

dw Fax

2

grease free

T2Table +

dw h7

TV =

l2

l3

Assembly:

Contact surfaces of the shaft and bore should be de-greased with

solvent or degreaser. Tension screws should be tightened in two or

three stages up to the recommended tightening torque TA.

Disassembly:

The clamping force is released by loosening the screws. If necessary

remove some of the screws and use as dismounting screws.

Explanation:

T = maximum transmissible torque for an Inkofix-shrink coupling

Fax = maximum axial force which may be applied to an Inkofix-shrink

coupling

TA = the required tightening torque for the tensioning screws.

Ordering example:

Inkofix-shrink coupling

Shafts diameter

External diameter

ISK 100.195

2007.02

www.INKOMA.de

014

Friction locking bushes

Dimensions [mm]

ISK 20.50

ISK 25.60

ISK 30.72

ISK 35.80

ISK 40.94

ISK 45.102

ISK 50.110

ISK 60.120

ISK 65.140

ISK 80.160

ISK 90.180

ISK 100.195

ISK 115.220

ISK 120.256

ISK 135.285

ISK 150.300

ISK 165.325

ISK 180.350

ISK 200.375

ISK 220.410

ISK 240.430

1) The

24

l1

22

l2

27,5

l3

5xM5x20

Mass

ISK 16.46

40

Mass moment

of inertia

ISK 13.43

10...

12

13...

15

16...

18

19...

22

23...

27

28...

32

33...

37

38...

42

43...

48

49...

52

52...

60

61...

68

69...

80

81...

90

91...

100

101...

115

116...

130

131...

145

146...

160

161...

175

176...

190

191...

210

211...

230

231...

250

max. axial force 1)

ISK 10.40

dw 2)

Torque 1)

Order code

Operational data

Tightening torque

ISO 4014

(DIN 931)

10.9

Tension screw

TA

[Nm]

T

[Nm]

Fax

[kN]

J

[kg cm2]

[kg]

30...

36

70...

90

180...

210

230...

330

370...

520

580...

820

900...

1310

1400...

1890

2050...

2725

2900...

3210

3460...

5200

5420...

7230

8340...

11800

12800...

16100

16800...

22430

23600...

36800

37500...

54600

56300...

71400

78500...

88300

89700...

119900

121300...

165400

167200...

206600

210000...

264000

278000...

335000

0,4

0,20

11...

12

19...

23

24...

30

32...

39

41...

51

55...

70

74...

90

96...

114

119...

123

131...

173

178...

212

242...

295

320...

358

370...

450

468...

640

648...

840

860...

985

994...

1100

1115...

1370

1390...

1740

1770...

1960

1990...

2295

2400...

2680

0,7

0,29

1,1

0,37

1,7

0,48

4,0

0,75

9,0

1,2

16,0

1,7

31,0

2,4

47,0

3,1

75,0

4,1

110,0

4,9

241,0

8,1

464,0

11,6

851,0

16,8

1243,0

20,7

2203,0

28,6

4278,0

44,5

6804,0

58,0

10533,0

74,9

15245,0

91,8

22596,0

116,7

32219,0

142,7

52880,0

195,4

66718,0

220,1

43

30

28

33,5

6xM5x25

46

34

32

37,5

6xM5x30

50

40

37

44

6xM6x30

13

60

44

41

48

6xM6x35

13

72

48

45

52

8xM6x40

13

80

56

52

61,5

8xM8x45

32

94

58

54

63,5

9xM8x50

32

102

68

64

75

8xM10x50

60

110

74

70

81

9xM10x60

60

120

78

74

85

9xM10x60

60

140

92

86

100

9xM12x70

110

160

104

98

112

12xM12x75

110

180

120

112

130

12xM16x90

250

195

128

120

138

12xM16x90

250

220

140

132

150

12xM16x100

250

256

164

150

177

12xM20x120

480

285

178

164

191

15xM20x120

480

300

194

180

207

15xM20x140

480

325

204

190

217

15xM20x140

480

350

224

210

237

15xM20x150

480

375

244

230

259

15xM24x160

840

410

280

260

295

10

16xM24x180

840

430

300

280

315

12

18xM24x200

840

values for T and Fax can be be interpolated from dw.

diameter dw when ordering. Other diameters are available with additional price. Please enquire.

2) State

2007.01

www.INKOMA.de

015

Friction locking bushes

Dimensions

ISB - Inkofix-tension sleeve

The INKOMA-Inkofix-tension sleeves are shaft-hub connections

suitable for high torque transmission. The self centering feature

guarantees concentric running.

The force necessary for torque transmission through the non positive

connection is generated by pressure and friction via the conical ring

between the hub and the shaft. The sleeves are delivered ready for

installation. i.e. the conical surfaces are suitably greased and the

contact surface coated with a light film of oil.

The hub and shaft must be cleaned thoroughly. To achieve concentric

running and the stated figures for torque transmission, the tolerances

for the shaft and the bore of the hub must be as indicated in the table.

The surface finish should be <15 m. Since the bore of the hub tends

to be expanded by the pressure of the tension sleeve, care should be

taken to maintain this within the eleastic limit of the material. i.e. the

wall thickness of the hub must be adequate.

Using the formula for thick walled tubes under internal pressure an

equation can be derived with sufficient security.

D H7

dN

C

C

dw h8

0,2 + pN

0,2 - pN

l1

> D

dN =

l2

0,2 = Limit of elasticity of the hub material

= Permitted surface pressure in the bore of the hub

= Factor for friction locking bush width

e.g. C=1 when hub width = friction locking bush width and

C=0,6 when hub width = 2x friction locking bush width

pN

C

The limit of elasticity of the hub material must always be higher than

the pressure generated by the tension set inside the bore of the hub.

If carefully treated (with the lubrication of the conical surfaces renewed

every time), friction locking bushes may be dismantled and

remounted as often as necessary, provided the operating surfaces are

free from notches and scratches.

The clamping force can be easily released by use of the threaded

dismantling hole.

Before re-use the parts of the friction locking bush must be cleaned

and the screws and conical surfaces re-lubricated.

When the torque and the axial force overlap, their values must be

added vectorially.

TR =

T2Table +

dw Fax

2

grease free

greased

TR is the resulting reduced transmissible torque. All friction locking

bushes are delivered ready for installation. Friction locking bushes

series ISB are equipped with screws quality ISO 4762 (DIN 912) class

12.9.

The friction locking bush should be initially aligned by slightly

screwing in opposite sets of screws in turn. Thereafter the screws can

be sequentially tightened in 3-4 equal steps until the indicated

tightening torque TA is achieved.

Explanation:

T = maximum transmissible torque for an Inkofix-tension

sleeve

Fax = maximum axial force which may be applied to an Inkofixtension sleeve

TA = the required tightening torque for the tensioning screws

Ordering example:

Inkofix-tension sleeve

Shafts diameter

External diameter

ISB 100.145

2007.02

www.INKOMA.de

016

Friction locking bushes

Dimensions [mm]

ISB 50.80

ISB 55.85

ISB 60.90

ISB 65.95

ISB 70.110

ISB 75.115

ISB 80.120

ISB 85.125

ISB 90.130

ISB 95.135

ISB 100.145

ISB 110.155

ISB 120.165

ISB 130.180

ISB 140.190

ISB 150.200

ISB 160.210

ISB 170.225

ISB 180.235

ISB 190.250

ISB 200.260

ISB 220.285

ISB 240.305

ISB 260.325

ISB 280.355

ISB 300.375

ISB 320.405

ISB 340.425

ISB 360.455

ISB 380.475

ISB 400.495

ISB 420.515

ISB 440.545

ISB 460.565

ISB 480.585

ISB 500.605

50

55

60

65

70

75

80

85

90

95

100

110

120

130

140

150

160

170

180

190

200

220

240

260

280

300

320

340

360

380

400

420

440

460

480

500

80

85

90

95

110

115

120

125

130

135

145

155

165

180

190

200

210

225

235

250

260

285

305

325

355

375

405

425

455

475

495

515

545

565

585

605

44

44

44

44

60

60

60

60

60

70

70

70

70

79

79

79

79

92

92

102

102

108

108

180

206

206

206

206

263

263

263

263

263

263

263

263

40

40

40

40

50

50

50

50

50

60

60

60

60

65

65

65

65

78

78

88

88

96

96

176

202

202

202

202

220

220

220

220

220

220

220

220

52

52

52

52

70

70

70

70

70

82

82

82

82

93

93

93

93

108

108

118

118

124

124

200

226

226

226

226

258

258

258

258

258

258

258

258

2007.01

8xM8x40

9xM8x40

10xM8x40

10xM8x40

10xM10x50

10xM10x50

10xM10x50

10xM10x50

12xM10x50

12xM12x60

12xM12x60

12xM12x60

12xM12x60

12xM14x70

12xM14x70

12xM14x70

12xM14x70

12xM16x80

12xM16x80

12xM16x90

12xM16x90

12xM16x100

12xM16x100

12xM20x140

14xM20x140

14xM20x140

14xM20x140

14xM20x140

20xM22x160

20xM22x160

20xM22x160

20xM22x160

20xM22x160

20xM22x160

20xM22x160

20xM22x160

Mass

l2

Mass moment

of inertia

l1

Hub

Shaft

max. axial force

dw

Torque

Order code

Operational data

Tightening torque

ISO 4762

(DIN 912)

12.9

Tension screw

TA

[Nm]

T

[Nm]

Fax

[kN]

pW

[N/mm2]

pN

[N/mm2]

J

[kg cm2]

[kg]

41

41

41

41

83

83

83

83

83

145

145

145

145

230

230

230

230

355

355

355

355

355

355

690

690

690

690

690

930

930

930

930

930

930

930

930

3400

4740

5760

6250

10290

11300

12400

13500

15850

19100

21500

26100

32800

41000

52000

59800

67300

77400

88200

104000

115400

151400

182300

340000

477000

510000

600000

630000

910000

980000

1110000

1160000

1300000

1360000

1520000

1590000

136

172

192

193

274

301

310

317

352

402

430

475

546

630

743

800

842

855

980

1100

1160

1376

1521

2620

3410

3410

3750

3750

3750

5090

5090

5500

5940

5940

6370

6370

184

189

186

172

198

157

191

142

184

150

163

159

171

166

178

187

187

154

157

159

151

167

163

220

205

210

215

200

225

215

220

210

220

210

215

205

91

96

98

92

101

98

102

98

102

106

93

89

98

96

106

109

110

97

98

98

96

102

106

170

170

165

170

160

180

170

180

170

170

170

170

170

13,0

18,0

22,0

28,0

49,0

57,0

65,0

77,0

94,0

126,0

171,0

230,0

291,0

419,0

515,0

617,0

732,0

1123,0

1325,0

1910,0

2192,0

3435,0

4387,0

7146,0

11794,0

14702,0

19649,0

22957,0

42920,0

49491,0

57210,0

65692,0

80340,0

88913,0

100209,0

112425,0

1,2

1,4

1,6

1,7

2,3

2,4

2,5

2,7

3,0

3,7

4,4

5,1

5,6

6,8

7,4

7,9

8,4

11,3

12,3

15,5

16,3

21,2

23,3

33,0

46,0

51,0

52,0

62,0

102,0

107,0

113,0

119,0

131,0

134,0

140,0

146,0

www.INKOMA.de

Surface pressure

between friction

locking bush and

017

Friction locking bushes

Dimensions

ISH - Inkofix-tension set

INKOMA-Inkofix-tension sets are shaft-hub connections suitable for

high torque transmission.They are not self centering.

The force necessary for torque transmission through the non positive

connection is generated by pressure and friction via the conical ring

between the hub and the shaft. The sleeves are delivered ready for

installation. i.e. the conical surfaces are suitably greased and the

contact surface coated with a light film of oil.

The hub and shaft must be cleaned thoroughly. To achieve concentric

running and the stated figures for torque transmission, the tolerances

for the shaft and the bore of the hub must be as indicated in the table.

The surface finish should be <15 m.

Since the bore of the hub tends to be expanded by the pressure of the

tension sleeve, care should be taken to maintain this within the

eleastic limit of the material. i.e. the wall thickness of the hub must be

adequate.

Using the formula for thick walled tubes under internal pressure, an

equation can be derived with sufficient security.

l2

l1

l

dN

0,2 = Limit of elasticity of the hub material

= Permitted surface pressure in the bore of the hub

= Factor for friction locking bush width

e.g. C=1 when hub width = friction locking bush width and

C=0,6 when hub width = 2x friction locking bush width

pN

C

The limit of elasticity of the hub material must always be higher than

the pressure generated by the tension set inside the bore of the hub

If carefully treated (with the lubrication of the conical surfaces renewed

every time), friction locking bushes may be dismantled and

remounted as often as necessary, provided the operating surfaces are

free from notches and scratches.

The clamping force can be easily released by use of the threaded

dismantling hole. Before re-use, the parts of the friction locking bush

must be cleaned and the screws and conical surfaces re-lubricated.

When the torque and the axial force overlap, their values must be

added vectorially.

TV =

T2Table +

dw Fax

2

dw h8

C

C

D H7

> D

dN =

0,2 + pN

0,2 - pN

grease free

greased

TR is the resulting reduced transmissible torque. All friction locking

bushes are delivered ready for installation. Friction locking bushes

series ISH are equipped with screws quality ISO 4762 (DIN 912).

The friction locking bush should be initially aligned by slightly

screwing in opposite sets of screws in turn. Thereafter the screws can

be sequentially tightened in 3-4 equal steps until the indicated

tightening torque TA is achieved.

Explanation:

T = maximum transmissible torque for an Inkofix-tension set

Fax = maximum axial force which may be applied to an Inkofixtension set

TA = the required tightening torque for the tensioning screws

Ordering example:

Inkofix-tension set

Shafts diameter

External diameter

ISH 100.145

2011.01

www.INKOMA.de

018

Friction locking bushes

l1

l2

ISH 20.47

ISH 22.47

ISH 24.50

ISH 25.50

ISH 28.55

ISH 30.55

ISH 32.60

ISH 35.60

ISH 38.65

ISH 40.65

ISH 42.75

ISH 45.75

ISH 48.80

ISH 50.80

ISH 55.85

ISH 60.90

ISH 65.95

ISH 70.110

ISH 75.115

ISH 80.120

ISH 85.125

ISH 90.130

ISH 95.135

ISH 100.145

ISH 110.155

ISH 120.165

ISH 130.180

ISH 140.190

ISH 150.200

ISH 160.210

ISH 170.225

ISH 180.235

ISH 190.250

ISH 200.260

20

22

24

25

28

30

32

35

38

40

42

45

48

50

55

60

65

70

75

80

85

90

95

100

110

120

130

140

150

160

170

180

190

200

47

47

50

50

55

55

60

60

65

65

75

75

80

80

85

90

95

110

115

120

125

130

135

145

155

165

180

190

200

210

225

235

250

260

20

20

20

20

20

20

20

20

20

20

24

24

24

24

24

24

24

28

28

28

28

28

28

33

33

33

38

38

38

38

44

44

52

52

17

17

17

17

17

17

17

17

17

17

20

20

20

20

20

20

20

24

24

24

24

24

24

26

26

26

34

34

34

34

38

38

46

46

26

26

26

26

26

26

26

26

26

26

32

32

32

32

32

32

32

38

38

38

38

38

38

45

45

45

50

50

50

50

58

58

66

66

M6

M6

M6

M6

M6

M6

M6

M6

M6

M6

M8

M8

M8

M8

M8

M8

M8

M10

M10

M10

M10

M10

M10

M12

M12

M12

M12

M12

M12

M12

M14

M14

M14

M14

Hub

Shaft

max. axial force

dw

Torque

Order code

Operational data

Tightening torque

ISO 4762

(DIN 912)

Tension screw

TA

[Nm]

T

[Nm]

Fax

[kN]

pW

[N/mm2]

pN

[N/mm2]

[kg]

14

14

14

14

14

14

14

14

14

14

35

35

35

35

35

35

35

70

70

70

70

70

70

125

125

125

125

125

125

125

190

190

190

190

320

340

420

440

550

590

780

830

1000

1100

1850

1950

2100

2100

2800

3000

3800

5600

6100

6500

7900

8300

9900

11900

13000

16300

22000

26000

30500

35000

43500

50000

62000

70000

32

32

35

35

39

39

47

47

55

55

87

87

87

87

100

100

115

160

160

160

180

180

200

230

230

270

340

370

400

440

510

550

650

700

250

220

230

220

220

210

210

210

220

210

270

260

230

230

250

230

240

260

250

230

240

230

240

240

220

230

200

210

210

220

210

220

200

200

110

110

110

110

105

110

120

120

130

130

160

160

150

150

160

150

160

160

150

150

160

160

170

170

160

170

150

150

160

160

160

170

150

160

0,24

0,23

0,26

0,25

0,30

0,29

0,34

0,32

0,36

0,34

0,60

0,57

0,62

0,60

0,63

0,69

0,73

1,26

1,33

1,40

1,49

1,53

1,62

2,01

2,15

2,35

3,51

3,85

4,07

4,30

5,78

6,05

8,25

8,65

Surface pressure

between friction

locking bush and

Mass

Dimensions [mm]

Other sizes available, please enquire.

2007.01

www.INKOMA.de

019

Friction locking bushes

Application examples

Inkofix - friction locking bushes ISC, ISR, ISS, ISP, ISK, ISB and ISH

The INKOMA-Inkofix-friction locking bushes ISC are self centering

universal friction locking bushes for keyless shaft-hub connection.

They are supplied in two versions (A and B).

ISC-A

ISC-B

ISR

ISS

ISC/K-A and ISC/K-B see page 04 - 05

ISC/L-A and ISC/L-B see page 06 - 07

Inkofix-shrink ring ISR and Inkofix-shrink disc ISS are for frictionlocked shaft-hub connection.

ISR see page 08 - 09

ISS see page 10 - 11

ISP

Inkofix-tension flanges ISP are primarily intended for use with our

PK, Lineflex and Inkoflex couplings.

ISP see page 12 - 13

ISK

Inkofix-shrink couplings ISK are for the rigid keyless coupling of

shafts with the same or similar diameters.

ISK see page 14 - 15

Inkofix-tension bushes ISB transmit high torques with precise

concentricity.

Inkofix-tension bushes ISH transmit moderate torque with normal

concentricity.

ISB

ISH

ISB see page 16 - 17

ISH see page 18 - 19

2008.01

We reserve the right to make technical

changes. For current information go to

www.inkoma.de or your local sales office.

INKOMA - GROUP Headoffice

Neue Reihe 44

D-38162 Schandelah

Phone: +49/ (0)53 06-92 21- 0

Fax:

+49/ (0)53 06-92 21-50

E-Mail:

info@inkoma.de

020

Das könnte Ihnen auch gefallen

- C95 Eu PDFDokument36 SeitenC95 Eu PDFMihaela PopNoch keine Bewertungen

- SKF OK Couplings CatalogueDokument28 SeitenSKF OK Couplings Cataloguemihalikj2190Noch keine Bewertungen

- Cas Quil HosDokument4 SeitenCas Quil HosLuisSilvaNoch keine Bewertungen

- H1000e K FJDokument8 SeitenH1000e K FJSyarif HidayatullahNoch keine Bewertungen

- SKF Shaft CouplingsDokument24 SeitenSKF Shaft CouplingsEmilio PortelaNoch keine Bewertungen

- ShaftsDokument0 SeitenShaftslindanoraNoch keine Bewertungen

- 1.0 Beam DesignDokument17 Seiten1.0 Beam DesignklynchelleNoch keine Bewertungen

- BSP 05 UK (Nov-11) PDFDokument20 SeitenBSP 05 UK (Nov-11) PDFhepcomotionNoch keine Bewertungen

- Electrovalva SMC - Eng 3 - 1 - 2 - 1 - SY3000-5000-7000-9000Dokument234 SeitenElectrovalva SMC - Eng 3 - 1 - 2 - 1 - SY3000-5000-7000-9000Canea Mihai CaiusNoch keine Bewertungen

- Hydraulic Cylinders CH: - Big Bore Sizes To Iso 6020-3 - Nominal Pressure 16 Mpa (160 Bar) - Max 25 Mpa (250 Bar)Dokument6 SeitenHydraulic Cylinders CH: - Big Bore Sizes To Iso 6020-3 - Nominal Pressure 16 Mpa (160 Bar) - Max 25 Mpa (250 Bar)Stoianovici CristianNoch keine Bewertungen

- DesignDokument4 SeitenDesignJigneshkumar PatelNoch keine Bewertungen

- Thomson Roundrail 1NC SpecsheetDokument2 SeitenThomson Roundrail 1NC SpecsheetElectromateNoch keine Bewertungen

- MBB50 50Dokument45 SeitenMBB50 50dgfggfhghgdfhtNoch keine Bewertungen

- 10.piston CylinderDokument19 Seiten10.piston Cylinderprihartono_diasNoch keine Bewertungen

- Brosura FrankenDokument28 SeitenBrosura FrankenTraian-Vasile MaximNoch keine Bewertungen

- 2012 LMT Onsrud Production Cutting Tools Aluminum PDFDokument1 Seite2012 LMT Onsrud Production Cutting Tools Aluminum PDFguru2368Noch keine Bewertungen

- cp1210 SpecsDokument2 Seitencp1210 Specsyoucef alimNoch keine Bewertungen

- Moment Connection Design Hea220Dokument56 SeitenMoment Connection Design Hea220Atul WanodeNoch keine Bewertungen

- Thomson Roundrail 1CA SpecsheetDokument2 SeitenThomson Roundrail 1CA SpecsheetElectromateNoch keine Bewertungen

- Deep Beam TypicalDokument6 SeitenDeep Beam TypicalArpit SinghNoch keine Bewertungen

- Alignment of CouplingDokument24 SeitenAlignment of Couplinger_sanjaypatelNoch keine Bewertungen

- Dynamic Bar Brochure InchDokument12 SeitenDynamic Bar Brochure InchJonathan PlataNoch keine Bewertungen

- Butterfly Valves Series BF-03-M2 Full Lug and BF-04-M2 Wafer Specification SheetDokument2 SeitenButterfly Valves Series BF-03-M2 Full Lug and BF-04-M2 Wafer Specification SheetWattsNoch keine Bewertungen

- As TDS 60Hz MetricDokument4 SeitenAs TDS 60Hz MetricMarko Antonio AguilarNoch keine Bewertungen

- Converting Excavator Buckets From J-Series Base Assemblies To The K-SeriesDokument28 SeitenConverting Excavator Buckets From J-Series Base Assemblies To The K-Seriespacman2803Noch keine Bewertungen

- 003 SPH MED I 2022 Yohana1Dokument3 Seiten003 SPH MED I 2022 Yohana1multisolusindoniagaNoch keine Bewertungen

- CCL Post Tension Ing Civil 28.04.10Dokument35 SeitenCCL Post Tension Ing Civil 28.04.10Wang JueNoch keine Bewertungen

- KF Series Ball Valve PDFDokument20 SeitenKF Series Ball Valve PDFbloggerparthiNoch keine Bewertungen

- Api Plan 11Dokument6 SeitenApi Plan 11johnsaballaNoch keine Bewertungen

- JS4BD-KA Series R-410A High Efficiency Air Conditioner: Technical SpecificationsDokument4 SeitenJS4BD-KA Series R-410A High Efficiency Air Conditioner: Technical SpecificationsKokoNoch keine Bewertungen

- Rotary IndexingDokument10 SeitenRotary IndexingdeadmatrixNoch keine Bewertungen

- K-XCT300iSM v2 PDFDokument656 SeitenK-XCT300iSM v2 PDFaitorNoch keine Bewertungen

- ELINE Ball Screw AssembliesDokument24 SeitenELINE Ball Screw AssembliesAnonymous PIqdeNp8Noch keine Bewertungen

- Indian Railways Presented by Y.K.Jha Sse/Nc/AiiwDokument9 SeitenIndian Railways Presented by Y.K.Jha Sse/Nc/Aiiwdhanalakshmi k sNoch keine Bewertungen

- Indian Railways Presented by Y.K.Jha Sse/Nc/AiiwDokument9 SeitenIndian Railways Presented by Y.K.Jha Sse/Nc/Aiiwdhanalakshmi k sNoch keine Bewertungen

- Generator Testing Manual For Rotor & ExciterDokument20 SeitenGenerator Testing Manual For Rotor & ExciterRakesh KumarNoch keine Bewertungen

- Thomson Roundrail 1DC SpecsheetDokument2 SeitenThomson Roundrail 1DC SpecsheetElectromateNoch keine Bewertungen

- ABS Submersible Wastewater Pump AS 0530-0841: ApplicationsDokument4 SeitenABS Submersible Wastewater Pump AS 0530-0841: Applicationsas3ateNoch keine Bewertungen

- K3XTBDokument8 SeitenK3XTBSAKDA MAPRADITKULNoch keine Bewertungen

- Case 446 Accessories Parts ManualDokument32 SeitenCase 446 Accessories Parts ManualDan Carson0% (1)

- Catalogo Cardan250fDokument56 SeitenCatalogo Cardan250fk86_oliverosNoch keine Bewertungen

- TTM Post TensioningDokument103 SeitenTTM Post Tensioninghorea67100% (2)

- Accouplement MecDokument19 SeitenAccouplement MecAli Ben Belgacem MahroukNoch keine Bewertungen

- Conveyor Pulley DesignDokument2 SeitenConveyor Pulley DesignZoebair100% (1)

- Prisma Technical GuideDokument61 SeitenPrisma Technical Guidenooruddinkhan1Noch keine Bewertungen

- Rubber Design Vibration and Noise ControlDokument14 SeitenRubber Design Vibration and Noise Controlcvishwas1159Noch keine Bewertungen

- Flange Leakage 6Dokument2 SeitenFlange Leakage 6hamid sobirinNoch keine Bewertungen

- BIG Kaiser Accessories Vol. 2Dokument24 SeitenBIG Kaiser Accessories Vol. 2lizarazojavierNoch keine Bewertungen

- Regrease FittingsDokument1 SeiteRegrease FittingsLenin CarrazcoNoch keine Bewertungen

- Service Manual: Fm/Am Compact Disc PlayerDokument52 SeitenService Manual: Fm/Am Compact Disc PlayerGsmHelpNoch keine Bewertungen

- Chapter 1Dokument94 SeitenChapter 1rethinamkNoch keine Bewertungen