Beruflich Dokumente

Kultur Dokumente

2322 Weekly Check

Hochgeladen von

R ShindeOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

2322 Weekly Check

Hochgeladen von

R ShindeCopyright:

Verfügbare Formate

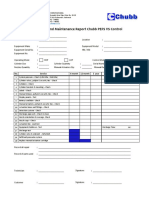

New York State Department of Environmental Conservation

Part 232BPerchloroethylene Dry Cleaning

Weekly Leak Inspection and Operation and Weekly Maintenance

Checklists For 3rd-and 4th-Generation Perc Dry-Cleaning Machines

Complete separate checklists for each machine in the facility each week. This checklist covers five (5) weeks of weekly

inspections; use one sheet per month. Completed forms must be kept on-site for at least five (5) years.

Facility Name:_________________________________________________________________________________

City:

State:

Zip Code:

Address:

Telephone Number:(______)_____________________

NYSDEC ID No.:__________________________________________

Machine #:____________

Machine Type: ~ Third-Generation

~ Fourth Generation

Checklist covers ____/____/____ through ____/____/____

Operator Name:________________________________________ Certification #: ____________________________

Operator Signature: _____________________________________

Leak Detection device used B Halogen leak detector (Abeeper@):

Make: ________________________

Model: ________________________

Has halogen leak detector been properly calibrated for Perc sampling according to the manufacture=s instructions prior to

performing the leak check?

~ Yes ~ No

Part I - Weekly Leak Inspection Checklist

The dry-cleaning system must be thoroughly inspected for vapor leaks using the device indicated. The dry cleaning system

includes, but is not limited to, dry cleaning equipment; filter or purification systems; waste holding, treatment, or disposal

systems; Perc supply systems; dip tanks; pumps; gaskets; piping, ducting, fittings, valves, or flanges that convey Perccontaminated air; and dry cleaning control systems. Perc fugitive emissions from any part of the dry cleaning system

cannot exceed 50 ppm. Any detected leak (an answer of AYes@ below) requires completion of Part IV - Emergency

Response/Corrective Action Log.

Date:

Any leaks detected with device?

___/___/___

___/___/___

___/___/___

___/___/___

___/___/___

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

The dry cleaning system also must be inspected for perceptible liquid and vapor leaks and for proper operation

while the system is operating. Any detected leak (an answer of AYes@ below) requires completion of Part IV Emergency Response/Corrective Action Log.

Any Perceptible leaks in:

___/___/___

___/___/___

___/___/___

___/___/___

___/___/___

hose and pipe connections,

fittings, couplings and valves

door gaskets and seatings

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

filter gaskets and seatings

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

pumps

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

solvent (including spent solvent)

tanks and containers

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

water separators

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

muck cookers

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

stills

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

exhaust dampers

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

diverter valves

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

cartridge filter housings

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

waste water collection and

treatment units

other area, specify:

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Form 232-2 (7/2011)

Page 1 of 2

Weekly Checklist For 3rd & 4th Generation Machines

Part II - Weekly Operation & Maintenance Tests

Note: Any question answered ANo@ requires completion of Part IV - Emergency Response/Corrective Action Log.

___/___/___

___/___/___

___/___/___

___/___/___

___/___/___

____ AM/PM

____ AM/PM

____ AM/PM

____ AM/PM

____ AM/PM

_____ <F

_____ <F

_____ <F

_____ <F

_____ <F

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Is inward air velocity for loading door

at least 100 fpm when door is open?

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Indicate velocity:

Instrument used:

~ portable velometer

~ other (Specify:_______________)

_______ fpm

_______ fpm

_______ fpm

_______ fpm

_______ fpm

________ppm

________ppm

________ppm

________ppm

________ppm

____AM/PM

____AM/PM

____AM/PM

____AM/PM

____AM/PM

Date:

Refrigerated Condensers:

time of test:

vapor stream outlet temperature:

(If greater than 45F, complete Part IV)

Secondary control system carbon

adsorbers:

Is carbon adsorber stripped or desorbed

in accordance with manufacturer=s

instructions or at least weekly ?

How stripped?

~ by operator

~ automatically or continuously

Door Fans (if so equipped):

Carbon adsorber vent test results:

time of test:

instrument used:

~ colorimetric tube

~ other (Specify:________________)

Part III - Weekly Emergency Preparedness Checklist

Note: Any entry of ANo@ requires completion of Part IV - Emergency Response/Corrective Action Log.

Date:

___/___/___

___/___/___

___/___/___

___/___/___

___/___/___

Preparedness and Prevention

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

adequate spill control equipment

available

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

aisle space around dry cleaning

equipment is adequate and clear

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

spare parts for equipment repair

available

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

all parts of dry cleaning system closed

except during required operation and

maintenance activities

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

vapor proof containers for storing spillcontaminated material available

fire control equipment available and in

working order

Failure to complete this form is a violation of 6NYCRR Part 232 and could result in enforcement action, including

monetary penalties. This form must be kept on-site for at least five (5) years.

Form 232-2 (7/2011)

Page 2 of 2

Weekly Checklist For 3rd & 4th Generation Machines

Das könnte Ihnen auch gefallen

- Dredge Fox River Operators Daily ReportDokument15 SeitenDredge Fox River Operators Daily ReportPhilip NguyenNoch keine Bewertungen

- CW FUSION PM Checklist - M-QF-75-11 Rev ADokument2 SeitenCW FUSION PM Checklist - M-QF-75-11 Rev AbaileybancroftNoch keine Bewertungen

- Diesel Inspection Testing FormDokument6 SeitenDiesel Inspection Testing Form5463RNoch keine Bewertungen

- Underground Pipe CertDokument2 SeitenUnderground Pipe CertnomarblesNoch keine Bewertungen

- ChillerDokument25 SeitenChillerZebi DiansNoch keine Bewertungen

- HPLC Preventative Maintenance Check-ListDokument7 SeitenHPLC Preventative Maintenance Check-ListMubarak PatelNoch keine Bewertungen

- Lab No. Object(s) Date of Performance RemarksDokument17 SeitenLab No. Object(s) Date of Performance RemarksShehzad BachaniNoch keine Bewertungen

- Pumping Test FormDokument4 SeitenPumping Test FormdisassociatedNoch keine Bewertungen

- VRF & DX Split Type ACU Testing MethodologyDokument1 SeiteVRF & DX Split Type ACU Testing MethodologydamianNoch keine Bewertungen

- FRM Sample Report (ML)Dokument1 SeiteFRM Sample Report (ML)Isaac RosarioNoch keine Bewertungen

- LAWA Basic Commissioning Forms - CompleteDokument53 SeitenLAWA Basic Commissioning Forms - Completemohammed_hatem0% (1)

- Method Statement For Duct Leakage TestDokument5 SeitenMethod Statement For Duct Leakage Testmohd faisal jamilNoch keine Bewertungen

- Preventive Maintenance Suven Life Sciences LimitedDokument5 SeitenPreventive Maintenance Suven Life Sciences LimitedvjchandrarNoch keine Bewertungen

- VGP 2013 Annual ReportDokument9 SeitenVGP 2013 Annual ReportRiaz AhmedNoch keine Bewertungen

- IMO Test Reports LSADokument12 SeitenIMO Test Reports LSAMd AmirulNoch keine Bewertungen

- Blank Well Log PDFDokument3 SeitenBlank Well Log PDFJordi EscorciaNoch keine Bewertungen

- Lab Manual Applied Hydraulics (CE-241) : N University of Engineering and Technology, JamshoroDokument55 SeitenLab Manual Applied Hydraulics (CE-241) : N University of Engineering and Technology, JamshoroShehzad BachaniNoch keine Bewertungen

- Ops Plan TempDokument21 SeitenOps Plan TempTiago HenriquesNoch keine Bewertungen

- RPZ Testing Form 215bDokument2 SeitenRPZ Testing Form 215bSam ChoiNoch keine Bewertungen

- Reference Tank Handbook PDFDokument10 SeitenReference Tank Handbook PDFIvan AvilesNoch keine Bewertungen

- PMCL VS Control PDFDokument1 SeitePMCL VS Control PDFHandrean Yudya PratamaNoch keine Bewertungen

- GRN 6 Residential O and M Manual 01.01.23Dokument4 SeitenGRN 6 Residential O and M Manual 01.01.23kamatsho153Noch keine Bewertungen

- Esg Service Bulletin: Issue Date:IssueDokument3 SeitenEsg Service Bulletin: Issue Date:IssueDNoch keine Bewertungen

- Domestic Water Booster Test ProcedureDokument6 SeitenDomestic Water Booster Test ProcedureEduardo ChvaNoch keine Bewertungen

- Ms. Norbelene B. Siat Nestfarms, Inc.: Ion XiDokument4 SeitenMs. Norbelene B. Siat Nestfarms, Inc.: Ion XiMelvinDapitanonNoch keine Bewertungen

- PropertyRiskEngineering GAPS FireProtection InspectionMaintFrequency Chart XL Catlin USDokument9 SeitenPropertyRiskEngineering GAPS FireProtection InspectionMaintFrequency Chart XL Catlin USSteve VelardeNoch keine Bewertungen

- ProFloSe UF UseDokument2 SeitenProFloSe UF UseintermountainwaterNoch keine Bewertungen

- Hygiene Check ListDokument15 SeitenHygiene Check ListpatricioacurioNoch keine Bewertungen

- Flowmeter Preventive Maintenance FormDokument1 SeiteFlowmeter Preventive Maintenance FormWaseem TariqNoch keine Bewertungen

- Standard Field Report Standard Specification - MCE EG020 CDokument11 SeitenStandard Field Report Standard Specification - MCE EG020 CSenol LimanNoch keine Bewertungen

- Preventive Report Form PDFDokument2 SeitenPreventive Report Form PDFRicardo NapitupuluNoch keine Bewertungen

- Functional TestDokument9 SeitenFunctional TestChinith HengNoch keine Bewertungen

- HVAC Performance Test Quality Control and Inspection Report FormDokument6 SeitenHVAC Performance Test Quality Control and Inspection Report Formhasan_676489616100% (1)

- Shimadzu PdaDokument11 SeitenShimadzu PdaARAS InstrumentNoch keine Bewertungen

- FAT Procedure (B) 12.10.15Dokument5 SeitenFAT Procedure (B) 12.10.15Richard AdolfNoch keine Bewertungen

- Aramco Ticket No.: Eqpm'T Number: Service Date: Service LocationDokument4 SeitenAramco Ticket No.: Eqpm'T Number: Service Date: Service LocationArt AlbastroNoch keine Bewertungen

- PMS ChecklistDokument1 SeitePMS ChecklistKlye John Isiah IgnacioNoch keine Bewertungen

- Installation Oxygen ConcentratorDokument1 SeiteInstallation Oxygen Concentratordean HaroldNoch keine Bewertungen

- As Pub N Bagfilter Pemberitahuan Bertulispenapis Begwritten Notification Bag FilterDokument7 SeitenAs Pub N Bagfilter Pemberitahuan Bertulispenapis Begwritten Notification Bag FilterAnonymous koR9VtfNoch keine Bewertungen

- Engine Room DocumentsDokument5 SeitenEngine Room DocumentsФурад ДжакумовNoch keine Bewertungen

- Appendix B - 20100903 - 145453Dokument25 SeitenAppendix B - 20100903 - 145453AkoKhalediNoch keine Bewertungen

- Trailer PMDokument2 SeitenTrailer PMArnulfo LavaresNoch keine Bewertungen

- Calibration of Digital Burette IIIDokument10 SeitenCalibration of Digital Burette IIIWaleed MedhatNoch keine Bewertungen

- Self - Monitoring Report in The PhilippinesDokument14 SeitenSelf - Monitoring Report in The Philippinesdinaforproject2557Noch keine Bewertungen

- TP - 008 - F - Contractor Materials Test Certificate For Piping Alterations and Relocation of Heads 11.5.2021Dokument2 SeitenTP - 008 - F - Contractor Materials Test Certificate For Piping Alterations and Relocation of Heads 11.5.2021Don WaiteNoch keine Bewertungen

- U. S. Army Corps of Engineers Above-Ground Treatment System Performance ChecklistDokument8 SeitenU. S. Army Corps of Engineers Above-Ground Treatment System Performance Checklistavisek_basuNoch keine Bewertungen

- High Expansion Foam Systems: Semi-Annual InspectionDokument1 SeiteHigh Expansion Foam Systems: Semi-Annual Inspectionkirandevi1981Noch keine Bewertungen

- ERAVAP m-8018Dokument202 SeitenERAVAP m-8018jenan h.albayatiiNoch keine Bewertungen

- Triplex PUmp 01 ChecklistDokument7 SeitenTriplex PUmp 01 ChecklistMarizon ZulkarnainiNoch keine Bewertungen

- MSC.1-Circ.980-Add.1 - (Continued) (Secretariat)Dokument218 SeitenMSC.1-Circ.980-Add.1 - (Continued) (Secretariat)K.l. DhanaNoch keine Bewertungen

- S-900-1242-022 - 6a - 003 - A2 (Confined Space Entry Permit)Dokument2 SeitenS-900-1242-022 - 6a - 003 - A2 (Confined Space Entry Permit)umar saidNoch keine Bewertungen

- Testing Commisioning Report FCU: ProjectDokument2 SeitenTesting Commisioning Report FCU: Projectagun gunawanNoch keine Bewertungen

- ELFL004Dokument15 SeitenELFL004Destry YoungNoch keine Bewertungen

- Gdflo 497Dokument9 SeitenGdflo 497raritylimNoch keine Bewertungen

- Environment Audit Report Format - GPCBDokument8 SeitenEnvironment Audit Report Format - GPCBmaikalrNoch keine Bewertungen

- Pumping Test FormDokument4 SeitenPumping Test FormYogie Fian ZahriNoch keine Bewertungen

- Automotive Actuators and EVAP System TestingVon EverandAutomotive Actuators and EVAP System TestingBewertung: 4.5 von 5 Sternen4.5/5 (4)

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryVon EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNoch keine Bewertungen

- Major Process Equipment Maintenance and RepairVon EverandMajor Process Equipment Maintenance and RepairBewertung: 4 von 5 Sternen4/5 (4)

- Dual Nature of Radiation and MatterDokument5 SeitenDual Nature of Radiation and Mattercopadag753Noch keine Bewertungen

- HSE Inspection Report-07Dokument32 SeitenHSE Inspection Report-07najihahNoch keine Bewertungen

- BIO CH04 FoundationsDokument12 SeitenBIO CH04 FoundationsDyuana Stevenson0% (1)

- Website Design Proposal DentistDokument8 SeitenWebsite Design Proposal DentistNamanNoch keine Bewertungen

- 5CT PDVSA em - 18!00!05 EnglishDokument27 Seiten5CT PDVSA em - 18!00!05 EnglishJuan Gutierrez100% (1)

- Table of SpecificationDokument2 SeitenTable of SpecificationAya AlisasisNoch keine Bewertungen

- Introduction To Plant Physiology!!!!Dokument112 SeitenIntroduction To Plant Physiology!!!!Bio SciencesNoch keine Bewertungen

- Anodizing PDFDokument12 SeitenAnodizing PDFsanjay ukalkarNoch keine Bewertungen

- Paper 5Dokument4 SeitenPaper 5hbyhNoch keine Bewertungen

- Oleg Losev NegativeDokument2 SeitenOleg Losev NegativeRyan LizardoNoch keine Bewertungen

- Pega DevOps Release Pipeline OverviewDokument200 SeitenPega DevOps Release Pipeline OverviewArun100% (1)

- Lithium Dongjin 48v100ahDokument5 SeitenLithium Dongjin 48v100ahmk7718100% (1)

- Ocular Trauma - BantaDokument211 SeitenOcular Trauma - BantaLuisa Fernanda Arboleda100% (1)

- Reglos, DISPUTE FORM 2020Dokument2 SeitenReglos, DISPUTE FORM 2020Pipoy ReglosNoch keine Bewertungen

- 2002PCDFCADokument78 Seiten2002PCDFCATin NguyenNoch keine Bewertungen

- Agro Tech Foods LTDDokument17 SeitenAgro Tech Foods LTDAlmas KhanNoch keine Bewertungen

- Basic Definition of Manufacturing SystemDokument18 SeitenBasic Definition of Manufacturing SystemRavenjoy ArcegaNoch keine Bewertungen

- Times Like This Strip-by-Strip (Part 1)Dokument49 SeitenTimes Like This Strip-by-Strip (Part 1)Joseph HoukNoch keine Bewertungen

- Battle Group Builder + Commonwealth Infantry Roster - Wargames DesignDokument12 SeitenBattle Group Builder + Commonwealth Infantry Roster - Wargames DesignPete PoliNoch keine Bewertungen

- Ingles - 1 - Bach - Modulo - 2 (20 - 21)Dokument32 SeitenIngles - 1 - Bach - Modulo - 2 (20 - 21)John Alex Almeida50% (2)

- Sri Anjaneya Cotton Mills LimitedDokument63 SeitenSri Anjaneya Cotton Mills LimitedPrashanth PB50% (2)

- Set B Cluster 3 (Final) (Aug102015)Dokument4 SeitenSet B Cluster 3 (Final) (Aug102015)Kuo Sarong100% (1)

- Router Board Performance TestsDokument2 SeitenRouter Board Performance TestsedkaviNoch keine Bewertungen

- Everyday Life - B1 - ShoppingDokument7 SeitenEveryday Life - B1 - ShoppingAmi BarnesNoch keine Bewertungen

- BestPractices PDFDokument14 SeitenBestPractices PDFAnonymous tChrzngvNoch keine Bewertungen

- DNA Structure and Replication: Chapter Nine Khalid HussainDokument49 SeitenDNA Structure and Replication: Chapter Nine Khalid HussainKhalid HussainNoch keine Bewertungen

- B. Tech. - CSE - R13-Syllabus JntuaDokument132 SeitenB. Tech. - CSE - R13-Syllabus JntuaVasim AkramNoch keine Bewertungen

- FTec 150 - Intro To Meat ProcessingDokument51 SeitenFTec 150 - Intro To Meat ProcessingJessa Silvano ArgallonNoch keine Bewertungen

- PCI20107, Overview of Boiler Commissioning and Startup PDFDokument17 SeitenPCI20107, Overview of Boiler Commissioning and Startup PDFMarc AnmellaNoch keine Bewertungen

- SFA TRAINING MODULE Week 1Dokument14 SeitenSFA TRAINING MODULE Week 1Ivan Perez100% (1)