Beruflich Dokumente

Kultur Dokumente

Protecting Prestressing Strand and Improving Bond with Nano Coating

Hochgeladen von

Kyle BuschOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Protecting Prestressing Strand and Improving Bond with Nano Coating

Hochgeladen von

Kyle BuschCopyright:

Verfügbare Formate

Oliva, Anderson, Tejedor, Busch & Principe-Martinez

2013 PCI/NBC

PROTECTING PRESTRESSING STRAND IN TRANSPORTATION

STRUCTURES AND IMPROVING STRAND-CONCRETE BONDING

Michael G. Oliva, Professor of Civil Engineering, University of Wisconsin, Madison

Marc Anderson, Professor of Civil Engineering, University of Wisconsin, Madison

Isabel Tejedor, Research Scientist, University of Wisconsin, Madison

Kyle Busch, Student, Civil and Envr. Engr., University of Wisconsin, Madison

Carla Principe-Martinez, Grad Student, Civil and Envr. Engr., University of

Wisconsin, Madison

ABSTRACT

Corrosion of steel strands in prestressed concrete may significantly

reduce the structural capacity of prestressed elements and lead to costly

maintenance and repairs. Epoxy coating of strands is not an effective

measure for corrosion protection and inflicts a loss in bond between the

steel and concrete. A novel inorganic nanoporous coating has been

developed as an alternative for protecting prestressing strands. Methods

of applying the coating and levels of corrosion resistance have been

analyzed via electrochemical tests, comparing corrosion pitting potentials

of coated and uncoated samples. Tests conducted include small scale

pull-out tests to analyze the effect on bond strength and electrochemical

tests to show that the inorganic coating offers good corrosion protection

to steel wires in strand. The corrosion tests showed improved resistance of

the coated wires as compared to uncoated. The pull-out tests revealed an

increase in maximum load for coated wires when compared to uncoated

wires. This suggests an increased ability for the steel to maintain

chemical adhesion to concrete as a result of the novel coating.

Performance results for corrosion and pullout are provided for the nanocoated strand and uncoated strand.

Keywords: Strand, Corrosion, Bond, Prestressing, Bridges, Coating

[Type text]

Oliva, Anderson, Tejedor, Busch & Principe-Martinez

2013 PCI/NBC

INTRODUCTION

The objective of the work described here was to prove the viability of thin nanoporous

inorganic coatings in protecting steel prestressing strands from corrosion. Corrosion of

steel in pre-stressed concrete, particularly in highway bridges where coatings are not

used, can be a severe problem that leads to loss in structural capacity due to both the

reduction of cross-sectional area of the steel and the loss in bond between the damaged

steel tendon and the concrete which surrounds it. The nano coating is intended to

improve corrosion resistance and simultaneously increase the bond capacity between

concrete and strand.

The useful life of prestressed concrete members in transportation structures can be

seriously affected by deterioration due to corrosion of the steel strand. This is more

severe in bridge structures close to marine environments where seawater is present and in

cold regions where de-icing salts are used during the winter period since pre-tensioned

members use uncoated strands or bars1 .

The loss of even one or a few strands has an impact on prestressed members since their

ability to sustain load relies on the tensile strength of the tendons. Weakening of the steel

and resultant concrete cracking can cause loss of prestress transfer and failure of the

member. For example the girder in Figure 1 shows clear signs of concrete spalling caused

by the corrosion products of rusting strand in the US-45 Bridge in Milwaukee.

Figure 1. Strand and rebar deterioration in US 45 bridge in Milwaukee.

In addition to safety concerns for highway bridges and other prestressed structures, the

cost of corrosion is a major problem. The annual direct cost of corrosion in highway

bridges in the United States is estimated at $8.3 billion including replacement and

maintenance2. The deteriorating effects and high costs of corrosion on pre-stressed

concrete members have led to the development of a number of corrosion protection

1

Oliva, Anderson, Tejedor, Busch & Principe-Martinez

2013 PCI/NBC

methods. However, these methods are not without flaws and their use is limited. The

most common approaches are: concrete sealers and barriers, chemical stabilization,

electrochemical protection, and epoxy coatings on steel. An ultimate alternative is to

replace the steel with materials such as stainless steel or fiber-reinforced plastic.

Epoxy-coated reinforcement (ECR) is used extensively in construction to protect steel

from corrosion. Epoxy coating works by preventing chloride and moisture from reaching

the surface of the steel. Some studies have shown favorable results, while other research

has documented poor performance. A study by Clear found that ECR typically

outperformed uncoated reinforcement, but the increased performance was not long term3.

Clear determined that the increase in life of ECR in northern U.S. and Canadian

environments would be in the range of only 3 to 6 years in most instances, rather than the

more than 40 years previously estimated. This was attributed to the progressive loss of

coating adhesion to the steel and under-film corrosion.

The ability of a prestressed member to sustain service loads and control cracking also

depends on the attained transfer lengths. The latter term refers to the length of strand over

which the prestress is effectively transferred into the concrete. This length is in turn

partially dependant on the bond strength of the steel tendon to the concrete. The nature of

bond strength is complex and varies throughout the length of the member. Because of the

complexity and importance of the steel-concrete bond, many researchers and agencies

have developed several methods for predicting bond. The North American Strand

Producers (NASP) Bond Test is one of the most studied methods and has been compared

to other methods such as the Moustafa Method and found to be more repeatable.

The novel strand coating used in this project to provide corrosion protection and

improved concrete bond is a sol-gel, a liquid containing very small, suspended particles.

The sol is zirconium-based (ZrO2). Zirconium was chosen as a possible candidate for

strand applications due to its corrosion-resistant properties4. The sol-gel process (using a

substance that is in both liquid and solid phases) involves the formation of an oxide

network and the gelation of sol in a liquid medium5.

The application of sol-gels to steel has shown the ability to increase steels resistance to

corrosion. Dip-coating was chosen as the method of application for the sol-gel here, with

each layer of applied sol having a thickness of 0.4 0.6 nanometers. After deposition on

the steel substrate, the nano-particles form an integrated protective network through a

heat sintering process.

Lengths of Grade 270 low relaxation 0.6 inch diameter strand were donated by three

manufacturers for corrosion and bond testing. They will be referred to as strand

manufacturers A, B, and C. For simplicity all testing was done on single wires removed

from the (0.6 and 0.5 diameter) strand.

Oliva, Anderson, Tejedor, Busch & Principe-Martinez

2013 PCI/NBC

CORROSION TESTING

Setup:

Electrochemical techniques are often used to provide preliminary evaluation of corrosion

resistance and involve accelerated tests that are analogous to long-term corrosion

development in the field. The results are useful in comparing relative corrosion pitting

potentials of metals in a corrosive environment. The corrosion resistance of the coated

wires was compared to that of the uncoated. Specifically, the potentiodynamic anodic

polarization technique was used here and includes a three-electrode system to determine

the required voltage to cause a rapid and sudden increase in current that signals the start

of pitting corrosion.

A three electrode test cell consists of the working electrode (the strand wire) and a

counter electrode. A third electrode (a reference) is included to reduce the effect of

additional polarizations in the cell6. In this case the potential of the working electrode is

measured with respect to the reference electrode. The counter electrode in this cell

completes the circuit and transmits current to or from the working electrode. The

electrolyte solution used during the tests was 0.23M NaCl in a Ca(OH)2 saturated

solution. This solution has a pH of 12.4, and is meant to simulate an environment similar

to concrete. Figure 2 shows an electrochemical cell used for the tests, the electrode

arrangement and electrolyte container. The electrodes were connected to a multichannel

potentiostat which applies the voltage sweep and measures the current produced in the

cell.

Figure 2. Three-Electrode Cell used for the polarization Experiments

Oliva, Anderson, Tejedor, Busch & Principe-Martinez

2013 PCI/NBC

Figures 3, 4 & 5. (clockwise from top right): In-situ electrochemical test setup, strain

gauge bonded to steel wire, and three-electrode potentiodynamic anodic polarization test

surrounding tensioned wire.

A novel test setup was required to perform corrosion tests on wires that were under stress

levels typical for strand in prestressed members. This test setup included a steel frame to

support the tensioned wire as shown in Figures 3-5. The wires were stressed to 216 ksi in

the frame. The tension was held at a relatively constant 216 ksi level until the completion

of each corrosion test and was monitored by a strain gage on each wire.

Three wires from manufacturer C were first tested in an uncoated condition and coated

condition, but in an unstressed state. Then three coated and uncoated C-type wires were

tested for corrosion resistance while under high tension stress.

Oliva, Anderson, Tejedor, Busch & Principe-Martinez

2013 PCI/NBC

Results:

During the corrosion tests, an increasing voltage is applied to the cell until a spike in the

current flow is detected. This spike occurs when pitting corrosion initiates. A high

applied positive voltage at the pitting corrosion potential (i.e. the spike in current)

indicates a more corrosion-resistant coating. The test method involves applying a

potential to the reference electrode and measuring the current at the counter electrode in

the presence of a steel wire, which acts as the working electrode7.

Unstressed wires:

The graphs of Figure 6 show the pitting corrosion potential, or

the maximum mV applied to each of the unstressed wire specimens before pitting

corrosion started. A higher positive value of voltage indicates higher resistance to

corrosion. Clearly the coated wires withstand a higher average positive voltage before the

pitting corrosion initiates. The pitting corrosion potentials are listed in Table 1.

blue

red

Figure 6. Test results showing pitting corrosion potential for test specimens.

Oliva, Anderson, Tejedor, Busch & Principe-Martinez

2013 PCI/NBC

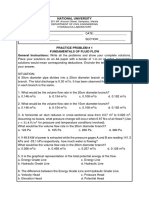

Table 1. Critical pitting corrosion potential values unstressed wires8.

TEST

Type A Uncoated

(2 test average))

Type A Coated

(3 test average)

Type B Uncoated

(3 test average)

Type B Coated

(3 test average)

Type C Uncoated

(3 test average)

Type C Coated

(3 test average)

Critical Pitting

Corrosion Potential

(mV)

-110

28

-160

236

-113

503

Table 2: Critical pitting corrosion potential values for Type C wires under stress.

TEST

No Tension - Uncoated

1 - Coated

2 - Coated

5 - Coated

3 - Uncoated

4 - Uncoated

6 - Uncoated

Critical Pitting

Corrosion Potential

(mV)

-106

52

-57

-281

-227

-237

-278

Stressed wires:

All of the corrosion tests with prestress applied were conducted on

wires from manufacturer C. Three repetitions of corrosion tests on uncoated samples

were performed, and three repetitions on coated samples were performed. One test was

run on an unstressed and uncoated wire for comparison. The actual voltage versus current

plots are shown in Figure 7. The pitting potential is taken as the voltage measured from

the x-intercept of the curve tangent line, after the curve lifts off the x-axis. Visually it is

approximately where the curves lift off the x-axis. The actual corrosion potential values,

measured from the tangent intersect, are listed in Table 2.

Discussion:

The electrochemical tests show that the nanoporous zirconium coating provides

an increase in the ability of steel wires comprising pre-stressing strand to resist corrosion.

For both the unstressed and stressed tests the potential of the coated wires was higher

compared to uncoated.

Oliva, Anderson, Tejedor, Busch & Principe-Martinez

2013 PCI/NBC

Figure 7. Corrosion tests: applied voltage (x-axis) and resulting current (y-axis), for Type

C wires while under stress; Tests #1-#6 are all on tensioned wires.

The first two tests of tensioned coated samples provided more positive pitting potential

values than those for uncoated samples. However, the increase in potential between

coated and uncoated wires is not as large as that seen for non-tensioned samples. Clearly

the tensioned condition is increasing the susceptibility to corrosion of both the coated and

uncoated wires, but the coated wires perform better.

Test 5 of a stressed coated sample, performed just as poorly as the uncoated samples.

This occurred because the steel wire accidentally reached its yield point during tensioning

prior to Test 5. This test was the only test of the six in-situ tests during which the strain

gauge did not perform properly, either due to an electrical issue or a loss in bond between

the gauge and the wire. Excessive load was accidentally applied and the steel had yielded

prior to the realization that the strain gauge and the steel wire total stretch were not

compatible. The occurrence of yielding was verified by the approximate maximum

pressure in the hydraulic jack and by the permanent elongation in the wire. Although

Test 5 does not contribute another data point to show the viability of the coating on

normal wires, this test incidentally shows that the nanoporous coating is not good beyond

the yield point - the wire behaves as if it were uncoated. This means that the coating film

is less ductile than the steel and fails at a certain point prior to the breaking point of the

wire.

Oliva, Anderson, Tejedor, Busch & Principe-Martinez

2013 PCI/NBC

BOND TESTING

While the coatings should be effective as a corrosion protection method they should also

not be detrimental to the bond between strand and concrete which serves to transfer

prestress to the concrete member. The steel-concrete bond was evaluated using pull-out

tests.

Setup:

Wire pullout tests, from concrete, were loosely based on the NASP Bond Test described

in the NCHRP 603 Report. That test consisted of pulling complete steel strand from a

concrete mortar cylinder and measuring the force required to achieve sufficient slip of the

strand relative to the mortar.

The setup described in the NASP Bond Test specifications and the small-scale tests used

on the individual wires differed in four aspects: (1) test specimen, (2) size of the concrete

mortar cylinder, (3) casting of the mortar and (4) the testing frame.

Figure 8. (a) NASP Bond Test setup and (b) Small-Scale Bond Test setup

A comparison of the two test setups is shown in Figure 8. The NASP Bond Test requires

the test specimen to be a 32 inch long 7-wire strand with an embedment length of 16

inches. The small-scale counterpart used a single 13.5inch long center wire obtained from

the 7-wire strand. The embedment length was 8 inches with a de-bonded section of 1inch

at the end.

The wire was secured to the top grip on the moving crosshead of the Sintech hydraulic

test machine and the steel frame enclosing the test cylinder was anchored at bottom grip.

8

Oliva, Anderson, Tejedor, Busch & Principe-Martinez

2013 PCI/NBC

A dial gage was attached to the wire with a holder so that the plunger is in contact with

the bottom of the mortar cylinder to measure wire pullout. The rate of applied

displacement on the top wire was set at 0.1in/min.

Results:

Three results are reported from the bond tests: pull-out force at 0.1 in of slip, maximum

pull-out force, and mortar strength. Table 3 summarizes the preliminary bond test results

for all the wires.

Table 3. Bond test results for wires (4 tests each)

Test

Bare wire A

Coated wire A

Bare wire B

Coated wire B

Bare wire C

Coated wire C

Pull-out Force at

Max Load (lb)

0.1 (lb)

150 (avg)

512 (avg)

std dev = 74

std dev = 177

245 (avg)

1227 (avg)

std dev = 129

std dev = 311

443 (avg)

474 (avg)

std dev = 104

std dev = 73

197 (avg)

868 (avg)

std dev = 43

std dev = 138

256 (avg)

445 (avg)

std dev = 48

std dev = 41

178 (avg)

799 (avg)

std dev = 70

std dev = 192

fc (psi)

4580

4580

5155

5155

5060

5060

The type A coated wires showed an increase of 63% in pull-out force at 0.1 inches of slip

with respect to bare wire. The max pull-out load had a 140% increase. The coated type B

wire actually had a lower pullout force at 0.1 inch, 44% of the uncoated value. The

maximum load, however, showed an 83% increase. The coated type C wire also had a

reduced pullout force at 0.1 inch slip, 70% of the uncoated wires force, but had the

maximum load increased by 80% compared to the uncoated.

While the force at 0.1 inch of slip is a standard reference value used in measuring strand

bond, it is an arbitrary reference value and does not seem to be an appropriate measure

for wire bond. The 0.1 inch reference value was employed by NASP because of low

variability in results at that level. The pull-out tests here were not meant to prove

appropriate pull-out strength for in-service conditions, but rather to make relative

comparisons of overall strength due to surface bonding of the materials. For in-service

conditions, the use of full seven-wire strand provides additional bond strength due to

mechanical interlock and increased friction.

The load versus slip plots for the wires show a linear behavior, past the 0.1 inch limit, up

to the maximum capacity as visible in Figure 9 for the coated wire C. The maximum

resisting load developed by the wires that were coated increased by 80 to 140% when

9

Oliva, Anderson, Tejedor, Busch & Principe-Martinez

2013 PCI/NBC

compared to the uncoated wire capacities. A comparison of the maximum bond loads is

shown in Figure 10.

Figure 9. Load and slip or extension plot for coated wire C in pullout test.

Figure 10. Comparison of wire pullout forces.

10

Oliva, Anderson, Tejedor, Busch & Principe-Martinez

2013 PCI/NBC

CONCLUSIONS AND RECOMMENDATIONS

The results in this report on preliminary testing are encouraging and intriguing. The

wires with nanoporous coatings show an improvement in corrosion resistance and also an

increase in the steel-concrete bond strength, ensuring satisfactory transfer of prestress.

Further efforts are needed to completely prove the qualities of the coatings and a specific

focus is required to make the coating process practical for industry.

The coatings provide a substantial increase in corrosion resistance for the Grade 270

pretressing wire, as measured by accelerated tests, when under the long term tension

stress levels expected in prestressed concrete members as compared to the uncoated

strand that are now commonly used in prestressed concrete bridge girders.

Unlike other coatings, such as epoxy, the nanoporous coating does not reduce the

strength of the steel-concrete bond but was shown to actually improve bond by 80 to

140%. This extra bond could improve transfer lengths in girders and may impact the

shear strength at the ends of girders.

A natural concern might be related to the toughness of the thin nano coatings and whether

they can experience handling conditions without damage. Although testing has not yet

been conducted, the nanoporous coating is expected to be tougher......since it is a ceramic

material with a greater hardness than steel.

The next step in this research should focus on how to best pre-treat the steel wires prior to

coating and on how to devise an industrial process applying the coatings. Then future

research should also determine how resistant the coating is to physical abrasion and the

bond characteristics of the full 7 wire strand rather than individual wires.

REFERENCES

1. Nmai, C.K., and D. M. Suchorski, Reinforcement for Concrete Materials and

Applications, American Concrete Institute, ACI Education Bulletin E2-00, 2000

2. Koch, G.H., M. P. H. Brongers, N. G. Thompson, Y. P. Virmani, and J. H. Payer,

Corrosion Costs and Preventive Strategies in the United States, National Association

of Corrosion Engineers (NACE), Publication No. FHWA-RD-01-156, 2000

3. Clear, K.C.,Effectiveness of Epoxy-coated Reinforcing Steel, Concrete

International, vol. 14, no. 5, pp. 58, 1992, pp602.

4. Anderson, M. A., Gieselmann, M. J., & XU, Q., Titania and Alumina Ceramic

Membranes, Journal of Membrane Science, 39, 1988, pp243-258.

5. Wang, D., & Bierwagen, G. P., 2009, Sol-gel Coatings on Metals for Corrosion

Protection, Progress in Organic Coatings, 64, 2009, pp327-338.

6. Oldham, K.B., and J. C. Myland, Fundamentals of Electro Chemical Science,

Academic Press, Inc., 1994.

7. Genesca, J., Mendoza, J., Duran, R., & Garcia, E., Conventional DC Electrochemical

Techniques in Corrosion Testing, Manuscript submitted for publication, Metallurgical

Engineering, UNAM City University, Mexico City, Mexico.

11

Oliva, Anderson, Tejedor, Busch & Principe-Martinez

2013 PCI/NBC

8. Prncipe-Martnez , C. S., Corrosion Protection of Prestressing Strand in

Transportation Structures and Strand-Concrete Bond Improvement, University of

Wisconsin Madison, 2012.

12

Das könnte Ihnen auch gefallen

- CEE 699 Spring 2013Dokument38 SeitenCEE 699 Spring 2013Kyle BuschNoch keine Bewertungen

- Review ActDokument3 SeitenReview ActHD MOVIESNoch keine Bewertungen

- Mci BavarianDokument13 SeitenMci BavarianmuqeetNoch keine Bewertungen

- Outokumpu Corrosion Management News Acom 1and2 Edition 2002Dokument24 SeitenOutokumpu Corrosion Management News Acom 1and2 Edition 2002turboconchNoch keine Bewertungen

- CP Criteria 01Dokument15 SeitenCP Criteria 01Sheik DawoodNoch keine Bewertungen

- Abaqus AnalysisDokument12 SeitenAbaqus AnalysisMohan BhalmeNoch keine Bewertungen

- Corrosion influence on bond in reinforced concreteDokument9 SeitenCorrosion influence on bond in reinforced concretepinarinciNoch keine Bewertungen

- Laboratory Simulation of Corrosion Damage in Reinforced ConcreteDokument9 SeitenLaboratory Simulation of Corrosion Damage in Reinforced Concretejorge mario martinez gameroNoch keine Bewertungen

- 2 PDFDokument11 Seiten2 PDFbaneNoch keine Bewertungen

- Coated Stainless Steel 441 As Interconnect Material For Solid Oxide Fuel Cells Evolution of Electrical PropertiesDokument7 SeitenCoated Stainless Steel 441 As Interconnect Material For Solid Oxide Fuel Cells Evolution of Electrical PropertiesJags BuddyNoch keine Bewertungen

- protección catódica 05-r25Dokument28 Seitenprotección catódica 05-r25andres floridoNoch keine Bewertungen

- 2012 11 Full Paper BROESDER Coatings-And-cathodic-disbondmentDokument7 Seiten2012 11 Full Paper BROESDER Coatings-And-cathodic-disbondmentkakrasana100% (1)

- Microstructure Properties Corrosion Characterization Welded Joint Novel Welding ProcessDokument12 SeitenMicrostructure Properties Corrosion Characterization Welded Joint Novel Welding ProcessRami GhorbelNoch keine Bewertungen

- Chloride-Induced Steel Corrosion in Concrete: Part 2 - Gravimetric and Electrochemical ComparisonsDokument9 SeitenChloride-Induced Steel Corrosion in Concrete: Part 2 - Gravimetric and Electrochemical ComparisonsMatthew SmithNoch keine Bewertungen

- Assessment of Corrosion Rate in Prestressed Concrete With Acoustic EmissionDokument13 SeitenAssessment of Corrosion Rate in Prestressed Concrete With Acoustic Emissionjesé m.Noch keine Bewertungen

- 1 s2.0 S1018363916300332 MainDokument5 Seiten1 s2.0 S1018363916300332 MainFernando LariosNoch keine Bewertungen

- Materials ScienceDokument5 SeitenMaterials SciencepewinataliyaNoch keine Bewertungen

- Las ss400Dokument19 SeitenLas ss400FikrimbarrNoch keine Bewertungen

- Corrosion CinéticaDokument9 SeitenCorrosion CinéticaOscar David Madera OzunaNoch keine Bewertungen

- Reinforced Concrete Corrosion GuideDokument8 SeitenReinforced Concrete Corrosion GuideOpany JuliusNoch keine Bewertungen

- Designing Cathodic Protection for Concrete StructuresDokument9 SeitenDesigning Cathodic Protection for Concrete StructureslokenderchaturvediNoch keine Bewertungen

- Corrosion Inhibitors PDFDokument9 SeitenCorrosion Inhibitors PDFmanil_5100% (1)

- Reliability of Acoustic Emission As A Technique To Detect Corrosion and Stress Corrosion Cracking On Prestressing Steel StrandsDokument15 SeitenReliability of Acoustic Emission As A Technique To Detect Corrosion and Stress Corrosion Cracking On Prestressing Steel Strandsmankari.kamal.18022963Noch keine Bewertungen

- Numerical Study of R.C. Beams Strengthening by External Steel PlateDokument9 SeitenNumerical Study of R.C. Beams Strengthening by External Steel PlateAJER JOURNALNoch keine Bewertungen

- Developing Cathodic Protection Based On Disbondment GeometryDokument8 SeitenDeveloping Cathodic Protection Based On Disbondment GeometryMarcelo Varejão CasarinNoch keine Bewertungen

- Raupauch Macrocell 2001Dokument8 SeitenRaupauch Macrocell 2001Antony Jacob AshishNoch keine Bewertungen

- Experimental Study On The Effects of Corrosion in Reinforced Concrete Incorporating Steel Fiber and Ultra-Fine SlagDokument6 SeitenExperimental Study On The Effects of Corrosion in Reinforced Concrete Incorporating Steel Fiber and Ultra-Fine SlagIJRASETPublicationsNoch keine Bewertungen

- A Comparative Research On Corrosion Behavior of A Standard, Crack-Free and Duplex Hard Chromium CoatingsDokument6 SeitenA Comparative Research On Corrosion Behavior of A Standard, Crack-Free and Duplex Hard Chromium CoatingsKarthi SundarNoch keine Bewertungen

- Csec2013 Gen 147Dokument11 SeitenCsec2013 Gen 147김대경Noch keine Bewertungen

- Fatigue in High Strength BoltDokument10 SeitenFatigue in High Strength BoltEgyptian ResearcherNoch keine Bewertungen

- Corrosion Monitoring of Reinforced Concrete StructDokument29 SeitenCorrosion Monitoring of Reinforced Concrete StructAafan ShahidNoch keine Bewertungen

- Structural Integrity of Steel Pipeline With Clusters of Corrosion DefectsDokument16 SeitenStructural Integrity of Steel Pipeline With Clusters of Corrosion DefectsVinícius WendelNoch keine Bewertungen

- Tensile Armor Wires Submitted To Slow Strain Rate Tests in A Corrosive EnvironmentDokument11 SeitenTensile Armor Wires Submitted To Slow Strain Rate Tests in A Corrosive EnvironmentPedro OliveiraNoch keine Bewertungen

- Shridevi 2020 IOP Conf. Ser. Mater. Sci. Eng. 989 012024Dokument11 SeitenShridevi 2020 IOP Conf. Ser. Mater. Sci. Eng. 989 012024ron_danyNoch keine Bewertungen

- Cathodic Protection of Steel in Concrete Using Magnesium Alloy AnodeDokument7 SeitenCathodic Protection of Steel in Concrete Using Magnesium Alloy AnodeFa HedaiatNoch keine Bewertungen

- Baek 2014Dokument42 SeitenBaek 2014Edmar Souza SilvaNoch keine Bewertungen

- Multiple Corrosion Protection Systems for Reinforced Concrete: A ReviewDokument3 SeitenMultiple Corrosion Protection Systems for Reinforced Concrete: A ReviewHD MOVIESNoch keine Bewertungen

- PhDThesis - Bruno PedrosaDokument298 SeitenPhDThesis - Bruno Pedrosam.w.wintermansNoch keine Bewertungen

- Mechanical Properties of Reinforcing Steel Bars Corroded at Different LevelsDokument13 SeitenMechanical Properties of Reinforcing Steel Bars Corroded at Different LevelsJorge BlancoNoch keine Bewertungen

- Life Cycle Analysis of Steel Railway BridgesDokument53 SeitenLife Cycle Analysis of Steel Railway BridgesRaees MazharNoch keine Bewertungen

- 10.1.1.144.9002 SW FatigueDokument13 Seiten10.1.1.144.9002 SW Fatigueb_wooNoch keine Bewertungen

- M 024102112Dokument11 SeitenM 024102112AJER JOURNALNoch keine Bewertungen

- Electrical Resistivity Measurement of Concrete - Wikipedia - PDF (NON CONTACTDokument4 SeitenElectrical Resistivity Measurement of Concrete - Wikipedia - PDF (NON CONTACTjucar fernandezNoch keine Bewertungen

- Pipeline CorrosionDokument3 SeitenPipeline Corrosion1 BRONAL SIREGARNoch keine Bewertungen

- Engineering Failure Analysis: Robert Kruzel, Malgorzata Ulewicz TDokument6 SeitenEngineering Failure Analysis: Robert Kruzel, Malgorzata Ulewicz TSmruti Ranjan PattanayakNoch keine Bewertungen

- Analysis of The Behaviour of Stainless Steel Bolted ConnectionsDokument11 SeitenAnalysis of The Behaviour of Stainless Steel Bolted ConnectionsSam SamouraNoch keine Bewertungen

- Corrosion A RiviewDokument28 SeitenCorrosion A RiviewsitiNoch keine Bewertungen

- Cathodic Protection With Localised Galvanic Anodes in Slender Carbonated Concrete ElementsDokument17 SeitenCathodic Protection With Localised Galvanic Anodes in Slender Carbonated Concrete ElementsTarek ChikerNoch keine Bewertungen

- SSRN Id4446360Dokument9 SeitenSSRN Id4446360Almas XamiNoch keine Bewertungen

- Optimising Electrochemical Remediation For Historic Steel Framed StructuresDokument10 SeitenOptimising Electrochemical Remediation For Historic Steel Framed StructuresAliNoch keine Bewertungen

- Local Mechanical Properties of Radial Friction Welded Supermartensitic StainlessDokument16 SeitenLocal Mechanical Properties of Radial Friction Welded Supermartensitic StainlessC_rovereNoch keine Bewertungen

- Eddy Current MeasurementsDokument4 SeitenEddy Current MeasurementsBassam AbdelazeemNoch keine Bewertungen

- Corrugated Metal Culverts - Durability in New Zealand ConditionsDokument3 SeitenCorrugated Metal Culverts - Durability in New Zealand Conditionslouis donyNoch keine Bewertungen

- Fulltext - Example IIDokument11 SeitenFulltext - Example IIManolo GipielaNoch keine Bewertungen

- Effect of Material of Deck On Response of Cable-Stayed Bridges To Live LoadsDokument2 SeitenEffect of Material of Deck On Response of Cable-Stayed Bridges To Live Loadsjuan carlos molano toroNoch keine Bewertungen

- Aci - 108-M04Dokument9 SeitenAci - 108-M04Denglei TangNoch keine Bewertungen

- Corrosion and its Consequences for Reinforced Concrete StructuresVon EverandCorrosion and its Consequences for Reinforced Concrete StructuresNoch keine Bewertungen

- Composite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)Von EverandComposite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)Bewertung: 4 von 5 Sternen4/5 (10)

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesVon EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesBewertung: 4.5 von 5 Sternen4.5/5 (16)

- Cathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesVon EverandCathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesBewertung: 4.5 von 5 Sternen4.5/5 (5)

- Enamel DD3009 - EN PDFDokument8 SeitenEnamel DD3009 - EN PDFAnand GuptaNoch keine Bewertungen

- Design of An Enclosed Football StadiumDokument32 SeitenDesign of An Enclosed Football StadiumHani100% (1)

- Chapter 2 Kinematics: Quick Check (Page 23)Dokument4 SeitenChapter 2 Kinematics: Quick Check (Page 23)muhammad aliNoch keine Bewertungen

- Basics Concrete Construction (2015) PDFDokument76 SeitenBasics Concrete Construction (2015) PDFwonNoch keine Bewertungen

- Science: Quarter 2 - Module 2: Chemical BondingDokument25 SeitenScience: Quarter 2 - Module 2: Chemical BondingPsycho Kpop OtakuNoch keine Bewertungen

- A Review of Theories of The L-H TransitionDokument74 SeitenA Review of Theories of The L-H TransitionpincoNoch keine Bewertungen

- 416e, 422e, and 428e Esquema HidraulicoDokument38 Seiten416e, 422e, and 428e Esquema HidraulicostalinNoch keine Bewertungen

- Sujet Dexamen Rattrapage Angalais GM Avec Corrige 2011-2012Dokument4 SeitenSujet Dexamen Rattrapage Angalais GM Avec Corrige 2011-2012redouane lotfiNoch keine Bewertungen

- Catalogue Air Cooled Chiller Ewad D SS PDFDokument43 SeitenCatalogue Air Cooled Chiller Ewad D SS PDFTamNoch keine Bewertungen

- Instrumentation & Measurements: Ruqia IkramDokument16 SeitenInstrumentation & Measurements: Ruqia Ikramjawad khalidNoch keine Bewertungen

- Applied Chemistry ProblemsDokument24 SeitenApplied Chemistry ProblemsKenneth C.LinojNoch keine Bewertungen

- Analysis of Deformation of Vertically Loaded Piles - Mark F. RandolphDokument13 SeitenAnalysis of Deformation of Vertically Loaded Piles - Mark F. RandolphJHIH KAI CHANGNoch keine Bewertungen

- 3311071.017 DometicRooftopACMechanicalComfortSingleZoneControl SVM AMER (En) 2012 01Dokument63 Seiten3311071.017 DometicRooftopACMechanicalComfortSingleZoneControl SVM AMER (En) 2012 01Adrian LedesmaNoch keine Bewertungen

- Radiation Safety Course Powerpoint PresentationDokument59 SeitenRadiation Safety Course Powerpoint PresentationJayesh100% (1)

- Batchelor Vs Stewartson Flow Structures in A Rotor Statotr CavityDokument58 SeitenBatchelor Vs Stewartson Flow Structures in A Rotor Statotr CavitykoolwaveoceanicNoch keine Bewertungen

- Water Retaining Structures August 2004 12Dokument252 SeitenWater Retaining Structures August 2004 12GO100% (3)

- Centrifugal Aftermarket Solutions BrochureDokument8 SeitenCentrifugal Aftermarket Solutions BrochureJose Renato MendesNoch keine Bewertungen

- Photodegradation and Photoprotection of Wood SurfaceDokument14 SeitenPhotodegradation and Photoprotection of Wood Surfaceichsan hakimNoch keine Bewertungen

- Pump Test Experiment InstructionsDokument10 SeitenPump Test Experiment Instructionsmohamadreza1368Noch keine Bewertungen

- Practice Problem No. 1 Hydraulics Fundamentals of Fluid FlowDokument2 SeitenPractice Problem No. 1 Hydraulics Fundamentals of Fluid FlowCharlamagne MirandaNoch keine Bewertungen

- Scientific Devices (B) Pvt. LTD.: Instruction Manual FOR by - Pass RotameterDokument5 SeitenScientific Devices (B) Pvt. LTD.: Instruction Manual FOR by - Pass RotameterfaqdaniNoch keine Bewertungen

- Forensic Ballistics 5Dokument8 SeitenForensic Ballistics 5johnpaulacostaNoch keine Bewertungen

- Problem 1Dokument3 SeitenProblem 1DANIEL DAVID VALENCIA HARRISNoch keine Bewertungen

- PHYSICS 3 LENSESDokument32 SeitenPHYSICS 3 LENSESCrisanta LeonardoNoch keine Bewertungen

- 9702 Scheme of Work (For Examination From 2022) - 3Dokument1 Seite9702 Scheme of Work (For Examination From 2022) - 3DuckyNoch keine Bewertungen

- Lab 1 - CompactionDokument5 SeitenLab 1 - CompactionPrantik MaityNoch keine Bewertungen

- Tie Requirements For RC Columns Bresler Gilbert ACI SJ 1961Dokument16 SeitenTie Requirements For RC Columns Bresler Gilbert ACI SJ 1961oggy1844Noch keine Bewertungen

- Arc Physics PDFDokument22 SeitenArc Physics PDFScott TrainorNoch keine Bewertungen

- Solutions To MCAT TPR Practice Test 1 23690Dokument83 SeitenSolutions To MCAT TPR Practice Test 1 23690Tony Adeosun75% (8)