Beruflich Dokumente

Kultur Dokumente

V1i3 Ijertv1is3128

Hochgeladen von

parth daxiniOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

V1i3 Ijertv1is3128

Hochgeladen von

parth daxiniCopyright:

Verfügbare Formate

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 1 Issue 3, May - 2012

Computer Aided Analysis of Multiple Cylindrical Shell Structure

Using Different Parameters

1

Ravindra Rai

ME-(CASDD) Student

Department of CE,U.E.C,

Ujjain,Madhya Pradesh,India

Dr. Umesh Pendharkar

Professor

Department of CE,U.E.C,

Ujjain,Madhya Pradesh,India

ABSTRACT

Shell structures are widely used in the field o f

civil, mechanical, , aeronautical and marine engineering.

Shell technology has been enhanced by the development

of new materials and prefabrication schemes. Despite the

mechanical advantages and aesthetic values offered by

the shell structures, the relative degree of unacquaintance with shell behavior and design is high. The

construction of a reinforced concrete shell involves many

problems, the design and construction of form work,

reinforcement selection etc. More than almost any other

structural system, shells depend upon the ability of the

engineer to foresee the design problems. Most of the early

shells built were single or multi-barrel cylindrical shells.

The work provides analysis comparison of multiple

cylindrical shells with varying parameters of radius and

thickness.

1. INTRODUCTION

by type of load action, by type of material used

(concrete, steel), etc. This great variability and range of

shell performance presents many practical difficulties

in their design. In the work one type of concrete multi

cylindrical shell loaded with live (snow load) and dead

load only. It has been considered that thin shell

structures transfer their loading by means of the

membrane tensional and compression forces that act in

the walls of the shell. Also it is known that shells have

very high efficiency under symmetrical loading and

support. Transfer of asymmetrical loading and local

load is not desirable. In real life, shell structures are

used mainly as chimneys, tanks, pipelines, silos,

hangers, sports auditoriums, exhibition halls, industrial

buildings and a variety of other large span structures

where uninterrupted floor space is required. Shell roofs

are architecturally very expressive and have been used

for domes by Romans Recent advances include the

construction of shell structures using prefabricated

shell elements.

2. SOFTWARE USED

A Shell in the technical language may be defined as a

curved structural member in which the thickness is

small compared to the radius and other dimension.

Shell or skin space roof are preferable to plane roofs

since they can be used to cover large floor spaces with

economical use of materials of construction. The use of

curved space roofs requires 25 to 40% less materials

than that of the plane elements. Structurally the shell

roofs are superior since the whole cross section is

uniformly stressed due to the direct forces with

negligible effects & due to this aspect the thickness of

shells is usually very small in the range of 75 mm to

150 mm. Shell structures are very broad topic. Shells

differ in their shape (cylindrical, spherical, parabolic,

etc.), in the way in which their walls are stiffened

(laterally, longitudinally, with orthogonal stiffeners),

www.ijert.org

Among the features introduced by the analysis engine

of SAP2000 are modal analys is, static and dynamic

analys is, linear and nonlinear analysis, and pushover

analys is. The analytical modeling used in this software

is the member type model which means that beams or

columns are modeled using single elements. The

layered shell modeling can be possible in SAP2000

which allows any number of layers to be defined in the

thickness direction, each with an independent location,

thickness, behavior, and material. Material behavior

may be non linear. The hysteretic response of the

concentrated plasticity at ends of a member can be

described by a moment curvature relationship.

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 1 Issue 3, May - 2012

SAP2000 can specify for each material one or more

stress-strain curves that are used to generate nonlinear

hinge properties in frame elements. The different

curves can be used for different parts of a frame cross

section. For steel and other metal materials, SAP2000

typically only specify one stress-strain curve. A variety

of cross sections are available in SAP2000 element

library. These sections include rectangular sections as

used for modeling the beams and columns of the RC

buildings. SAP2000 provides the tools needed for

pushover analysis as material nonlinearity at discrete,

user-defined hinges in frame elements. The hinge

properties are created based on pushover analysis

regulations found in performance-based guidelines.

Default hinge properties are provided based on FEMA356 criteria. Display capabilities in the graphical user

interface to generate and plot pushover curves,

including demand and capacity curves in spectral

ordinates. Capabilities in the graphical user interface to

plot and get information about the state of every hinge

formed at each step in the pushover analysis.

3. METHODS OF ANALYSIS

3.1 Membrane Theory

The shells whose L/R ratio is less than 0.5 can be

analysed reasonably accurately by Membrane theory

provided the edges of such shells are afforded

unyielding supports.

3.2 Beam Method

the multiple shell structure. For analysis two parameter

have been change first one is thickness and second is

radius, on the basis of different radius and thickness for

same chord width, length and material of shell,

following results are formed and compare the results

for different models.

5. PROPERTY AND DIMENSIONS OF

MODELS

Span in X direction

11 m

Span in Y direction

Live load

Grade of Concrete

Type of Steel

Column Height

11 m

0.6 kN/m2

M-25

HYSD bars

5.0 m

Column Size

Column Support condition

Beam Size

Varying Thickn esses for Radius =

8.56m of bay

Number

0.3 m X 1.0 m

Fixed

0.30 m x 0.50 m

0.08m, 0.12m

3 bay

Semi central angle (Typ e-A)

Semi central angle (Typ e-B)

Semi central angle (Typ e-C)

40

0

31

0

57

Radius of model (Type-A)

10.83m

Radius of model (Type-B)

Radius of model (Type-C)

8.56m

6.53m

The shell whose L/R ratio is greater than or equal to

can be analysed accurately by Beam method.

3.3 Analytical method

The shells not falling in the above mentioned two

categories have to be analysed by any accepted

Analytical method. After determining the dimensions

L i.e. span, R i.e. radius and (2h) i.e. thickness of the

shell, the two mutually independent ratios are obtained

. These ratios viz. and k being known as parameters

were first introduced by Aas-Jakobsen, in order to

make all computations dimensionless and of the same

order of magnitude. The stress distribution in a shell is

a function of these two parameters.

Fig.1.1 basic dimensions of multi-bay cylindrical shell

4. MODELING

For the analysis of multiple cylindrical shell following

dimension are considered which is tabulated in table

In the current study main goal is parametric analysis of

www.ijert.org

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 1 Issue 3, May - 2012

The analyses of all the models of shell is done only for

dead load of the structure and result of support reaction

obtain from analysis are listed in table below.

6.2 Model Type (A)

with central rise is 1.5m and 120 mm th ickness

of shell value of maximu m mo ment portion is shown

in fig 1.4 and max. mo ment of particu lar member

shown in table.1.

Fig.1.2 3D- model of multi-bay cylindrical shell

Structure

Fig.1.4:- Portion of Maximum Moment(A)

Table 1:- Element Max. Mome nts

Fig.1.3 Front perspective view of modeled multiple

shell structure

6. ANALYSIS RESULT

The linear static analys is is adopted for analysis of

multiple cylindrical shell using structural engineering

software SAP-2000 due to static load only. the

following analysis result, stresses and force contour are

obtain from the analysis for varying thickness and

radius for fixed length and chord width of the model

which are presented below.

6.1 RESULT COMPARISON BETWEEN MODEL TYPE

A , B and C

Area

OutputCase

Mmax

Text

Text

KN-m/ m

DEAD LOAD

12.67

DEAD LOAD

12.71

DEAD LOAD

11.96

16

DEAD LOAD

11.94

17

DEAD LOAD

11.93

18

DEAD LOAD

11.48

27

DEAD LOAD

11.04

28

DEAD LOAD

11.05

29

DEAD LOAD

10.97

6.3 Model Type (B)

with central rise is 2m and 120 mm thickness

of shell value of maximum moment portion is

shown in fig 1.5 and max. moment of particular

member shown in table.2.

For showing comparison between all the models

consider following conditions.

1. Take all models having same thickness

with different radius.

2. Take a single model having same radius

with different thickness of shell element.

www.ijert.org

Fig.1.5:- Portion of Maximum Moment(B)

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 1 Issue 3, May - 2012

6.5 MAXIMUM ELEMENT FORCES

Table 2 :- Element Max. Moments

Area

OutputCase

Mmax

Text

Text

KN-m/ m

The portion of max. force for different shell models are

shown in tabulated below with their element number .

DEAD LOAD

10.21

DEAD LOAD

10.26

DEAD LOAD

9.87

16

DEAD LOAD

9.78

Area

OutputCase

Fmax

17

DEAD LOAD

9.78

Text

Text

KN/ m

18

DEAD LOAD

9.64

44

DEAD LOAD

140.33

27

DEAD LOAD

9.18

66

DEAD LOAD

155.93

28

DEAD LOAD

9.31

77

DEAD LOAD

153.58

29

DEAD LOAD

9.34

6.5.a

Model Type (A): 1.5 m rise 120mm thick

Table4:-Element Max. Forces

6.5.b

6.4 Model Type (c)

With central rise is 3m and 120 mm thickness

of shell value of maximum moment portion is

shown in fig below and max. Moment of particular

member shown in table

Model Type (B) : 2.0 m rise 120mm thick

Table 5:- Element Max. Forces

6.5.c

Area

Output Case

Fmax

Text

Text

KN/ m

44

DEAD LOAD

127.31

66

DEAD LOAD

140.62

77

DEAD LOAD

138.75

Model Type (C) : 3.0 m rise 120mm thick

Table 6:- Element Max. Forces

Fig.1.6:- Portion of Maximum Moment(C)

Area

OutputCase

Fmax

Text

Text

KN/ m

Table 3 :- Element Max. Moments

44

DEAD LOAD

114.57

Area

Output Case

Mmax

66

DEAD LOAD

125.43

Text

Text

KN-m/ m

77

DEAD LOAD

124.08

DEAD LOAD

6.89

DEAD LOAD

7.41

DEAD LOAD

7.41

16

DEAD LOAD

6.99

17

DEAD LOAD

7.44

18

DEAD LOAD

7.43

27

DEAD LOAD

6.96

28

DEAD LOAD

7.45

29

DEAD LOAD

7.45

6.6 MAXIMUM S TRESS ES

The portion of maximum stress in shell models

are present by element having maxi. value show

below in table.

6.6.a Model Type (A)

1.5 m rise 120mm thick

www.ijert.org

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 1 Issue 3, May - 2012

Table7:- Element Max. Stresses

Area

Output Case

Smax Top

Text

Text

KN/ m2

DEAD LOAD

19371.36

12

DEAD LOAD

12772.05

DEAD LOAD

7366.47

13

DEAD LOAD

5992.26

6.6.b

Model Type (B)

2.0 m rise 120mm thick

Fig 1.7:- comparison between max. moment contour

Table 8:- Element Max. Stresses

Table 9: Element Forces - Area Shells

Area

Output Case

Smax Top

Text

Text

KN/ m2

DEAD LOAD

17055.73

Area

Output Case

12

DEAD LOAD

11302.02

Text

Text

% difference

between both model

DEAD LOAD

6917.11

Self weight

41.39

5633.65

Self weight

42.50

Self weight

45.29

16

Self weight

42.80

17

Self weight

44.54

18

Self weight

46.37

27

Self weight

44.37

28

Self weight

46.72

29

Self weight

47.14

13

6.6.c

DEAD LOAD

Model Type (C)

3.0 m rise 120mm thick

Table7.11:- Element Max. Stresses

Area

Output Case

Smax Top

Text

Text

KN/m2

1

DEAD LOAD

12603.79

12

DEAD LOAD

8594.11

2

DEAD LOAD

1785.91

13

DEAD LOAD

5078.41

6.7 TAKE A SINGLE MODEL HAVING

DIFFERENT THICKNESS OF SHELL

ELEMENT:

Now show the result for varying thickness we

consider shell element with central rise is 1.5m having

thickness of element 120mm and 80 mm respectively

for two different model and the result obtained form

the analys is for max. moment ,max. force and max.

stress. In the shell element are shown below.

www.ijert.org

Fig 1.8: comparison between elements force

Contour

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 1 Issue 3, May - 2012

In all models of having same thickness and

different radius the portion of max. mo ment is

same but the magnitude of max. mo ment reduced

when the rise of shell will be increase or radius

will be decrease.

The portion of max. forces is lies at that portion

where two shells are jo in with each other.

The forces formed in the shell elements is

reduced when increase the size of the shell.

The portion of max. stresses in mu ltip le shell is

lies at the corner of shell where it connect with

the column .

The stresses formed in the shell models will be

reduced when the rise of shell increas ed.

In the simply way when we increased the rise of

shell mo ment ,fo rces and stresses in the shell

element will be increased but the portion of all

the result will be different.

Considered models havi ng same radius wi th

di fferent thickness:

When worked on the above condition and

compare the result for model having radius 10.56m

with rise 1.5m and varies thicknesses 120mm to

80mm. It is found that the portion of maxi. Mo ment,

maxi. Forces and maxi. Stresses is remain ing same

but due to reduction in thicknes s all mo ment ,forces

and stresses reduced. and now we reach to following

conclusion that for shell construction always use liter

section.

Table 10: Element Forces - Area Shells

Area

Output Case

Text

Text

% difference

between both

model

44

Self weight

39.16

55

Self weight

38.96

66

Self weight

38.86

77

Self weight

38.96

Fig 1.9 comparison b/w elements max. stresses

of element

Table 11: Element Stresses - Area Shells

Area

Output Case

Text

Text

% difference

between both

model

Self weight

12

Self weight

3.54

Self weight

12.10

13

Self weight

13.22

REFERENCES:

28.67

7. CONCLUSION :

Considered all model having di fferent radi us and

same thickness.

Fro m the analysis of all the model it is find out

the portion of max. element mo ment , max.

element fo rces and max. stresses due to self

weight of structure and reach the following

conclusion.

The portion of max. mo ment formed at the

middle (end and start) element of the end shell.

www.ijert.org

[1.] Bathe, K. J. and E. N. Dvorkin. 1986."A

Formulat ion of General Shell Elements -- The

Use of Mixed Interpolation of Tonsorial

Co mponents". Int. Journal for Nu merical

Methods in Engineering, Vo l. 22, No. 3. pp. 697722.

[2.] Zienkiewicz, O.C. 1977. The Finite Element

Method. McGraw-Hill Book Co mpany.

[3.] N.Krishna Raju Advanced Reinforced

Concrete Design based on IS-456-2000 (2nd

Ed ition ).

[4.] Membrane theory of cylindrical shells , K.C.

Roy , Indian concrete journal , Vol. 23, 1949.

[5.] An Analytical and Experimental Investigation

of the Behavior of thin Cylindrical Shell Roof

Structures M. Smolira, University of London

Ph.D. Thesis Part 1 and 2 ,1949.

[6.] Theory and Design of Cylindrical Shell

Structures by R.S. Jenkins, Lund and

Hu mphries and Co. Ltd. London 1947.

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 1 Issue 3, May - 2012

[7.] Distribution method for Circular Cylindrical

Shell Roofs by Yit zhaki North Holland

Publishing Co., A msterdam ,Holland

[8.] Cylindrical Th in Concrete Shells Jose Antonio

Lo zano Galant May 2009 ,TRITA-BKN. Master

Thesis 277, 2009 ISSN 1103-4297 ,ISRN

KTH/ BKN/ EX-277-SE.

[9.] Design aids for fixed support reinforced concrete

cylindrical shells under uniformly distributed

loads Dept. of Ocean Engineering, Ind ian

Institute of Technology Madras, Chennai 600

036, India.

[10.] Design of cylindrical concrete shell roofs

prepared by the committee masonry and

reinforced concrete of the structural d ivision

through its subcommittee on thin shell design.

R.F.Bleich ,Mario G.salvadori., A lfred l Prame.

[11.] Thin Shell Concrete Structure Design and

Construction, Jessica Mandrick, E90 Pro ject

Proposal Swarth more College,Depart ment of

Engineering.

[12.] Integrated Modeling, Finite -Element Analysis,

and Engineering Design for Thin-Shell

Structures using Subdivision Fehmi Cirak,

M ichael J. Scott, Erik K. Antonsson, Michael

Ort iz and Peter Schroder.

[13.] Practical design of cylindrical shell roofs

V.K.Chavan.

www.ijert.org

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Is 4326 1993 - Code of Practice For Earthquake Resistant Design and Construction of BuildingsDokument37 SeitenIs 4326 1993 - Code of Practice For Earthquake Resistant Design and Construction of BuildingsAmit SinghNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Foundation SettlementDokument25 SeitenFoundation Settlementnivarn88% (8)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Beam PDFDokument11 SeitenBeam PDFparth daxiniNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Effect of Elastic Properties On The Behaviour of Beams: Rakesh PatelDokument11 SeitenEffect of Elastic Properties On The Behaviour of Beams: Rakesh Patelparth daxiniNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Minimum Steel 7 1Dokument2 SeitenMinimum Steel 7 1parth daxiniNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Gujarati Grammar Most Important Material 2014 Part ADokument56 SeitenGujarati Grammar Most Important Material 2014 Part Avipul0457Noch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Pushover Analysis of Existing Reinforced Concrete Framed StructuresDokument9 SeitenPushover Analysis of Existing Reinforced Concrete Framed Structuresparth daxiniNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- 05 FloatDokument26 Seiten05 Floatparth daxiniNoch keine Bewertungen

- International Journal of EngineeringDokument10 SeitenInternational Journal of Engineeringparth daxiniNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Evaluation of Response Reduction Factor For RC Elevated Water TanksDokument12 SeitenEvaluation of Response Reduction Factor For RC Elevated Water Tanksparth daxiniNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Model TB-16Dokument20 SeitenModel TB-16xuanphuong2710Noch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- LG Sigma+EscalatorDokument4 SeitenLG Sigma+Escalator강민호Noch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Pt. Trijaya Agro FoodsDokument18 SeitenPt. Trijaya Agro FoodsJie MaNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Alpha Sexual Power Vol 1Dokument95 SeitenAlpha Sexual Power Vol 1Joel Lopez100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Asuhan Keperawatan Pada Klien Dengan Proses Penyembuhan Luka. Pengkajian Diagnosa Perencanaan Implementasi EvaluasiDokument43 SeitenAsuhan Keperawatan Pada Klien Dengan Proses Penyembuhan Luka. Pengkajian Diagnosa Perencanaan Implementasi EvaluasiCak FirmanNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

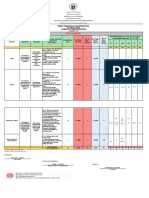

- Revised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10Dokument6 SeitenRevised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10May Ann GuintoNoch keine Bewertungen

- Manual: Functional SafetyDokument24 SeitenManual: Functional SafetymhaioocNoch keine Bewertungen

- Countable 3Dokument2 SeitenCountable 3Pio Sulca Tapahuasco100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Health and Safety For The Meat Industry: Guidance NotesDokument198 SeitenHealth and Safety For The Meat Industry: Guidance NotesPredrag AndjelkovicNoch keine Bewertungen

- Jurnal Ekologi TerestrialDokument6 SeitenJurnal Ekologi TerestrialFARIS VERLIANSYAHNoch keine Bewertungen

- MV Lec PDFDokument102 SeitenMV Lec PDFJonas Datu100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Agile ModelingDokument15 SeitenAgile Modelingprasad19845Noch keine Bewertungen

- QuinnmcfeetersresumeDokument1 SeiteQuinnmcfeetersresumeapi-510833585Noch keine Bewertungen

- Catálogo MK 2011/2013Dokument243 SeitenCatálogo MK 2011/2013Grupo PriluxNoch keine Bewertungen

- Introduction To M365 PresentationDokument50 SeitenIntroduction To M365 Presentationlasidoh0% (1)

- ARC-232, Material Construction 2Dokument4 SeitenARC-232, Material Construction 2danishali1090Noch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Kefauver Harris AmendmentsDokument7 SeitenKefauver Harris AmendmentsAnil kumarNoch keine Bewertungen

- Internet Bill FormatDokument1 SeiteInternet Bill FormatGopal Singh100% (1)

- Brochure International ConferenceDokument6 SeitenBrochure International ConferenceAnubhav Sharma sf 12Noch keine Bewertungen

- 1996 OKI LCD Driver Controller DatabookDokument232 Seiten1996 OKI LCD Driver Controller Databookpiptendo100% (1)

- Innovativ and Liabl :: Professional Electronic Control Unit Diagnosis From BoschDokument28 SeitenInnovativ and Liabl :: Professional Electronic Control Unit Diagnosis From BoschacairalexNoch keine Bewertungen

- Optimal Dispatch of Generation: Prepared To Dr. Emaad SedeekDokument7 SeitenOptimal Dispatch of Generation: Prepared To Dr. Emaad SedeekAhmedRaafatNoch keine Bewertungen

- 2013 Cases Penned by Justice BernabeDokument11 Seiten2013 Cases Penned by Justice BernabeJoan PabloNoch keine Bewertungen

- Engine Controls (Powertrain Management) - ALLDATA RepairDokument3 SeitenEngine Controls (Powertrain Management) - ALLDATA RepairRonald FerminNoch keine Bewertungen

- Calculus HandbookDokument198 SeitenCalculus HandbookMuneeb Sami100% (1)

- Lec. 2Dokument22 SeitenLec. 2محمدNoch keine Bewertungen

- Public Access - The GauntletDokument1 SeitePublic Access - The GauntletTesting0% (2)

- Asan Visa Ae102901499Dokument2 SeitenAsan Visa Ae102901499hardeep ranaNoch keine Bewertungen

- N50-200H-CC Operation and Maintenance Manual 961220 Bytes 01Dokument94 SeitenN50-200H-CC Operation and Maintenance Manual 961220 Bytes 01ANDRESNoch keine Bewertungen

- Project Manager PMP PMO in Houston TX Resume Nicolaas JanssenDokument4 SeitenProject Manager PMP PMO in Houston TX Resume Nicolaas JanssenNicolaasJanssenNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)