Beruflich Dokumente

Kultur Dokumente

Castrol Tribol 800

Hochgeladen von

Cardoso MalacaoCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Castrol Tribol 800

Hochgeladen von

Cardoso MalacaoCopyright:

Verfügbare Formate

Product Data

Castrol Tribol 800 Range

Synthetic Gear Oils

DESCRIPTION

Castrol Tribol 800 synthetic gear oils have been developed for the lubrication of heavily loaded gears, bushings and

bearings which may operate over a broad range of temperatures from ambient to elevated temperatures (>80oC/176oF).

They are particularly intended to extend the service life of both lubricant and machine parts where unusually high

operating and oil reservoir temperatures are encountered.

The high performance characteristics of Tribol 800 are achieved with select polyalkylene glycol (PAG) based synthetic

fluids. They feature chemical and thermal stability, high viscosity index, water solubility, and compatibility with metals

and elastomers most commonly used in machine construction.

The naturally high resistance to oxidation of the synthetic base fluid is further enhanced by inhibitors. Corrosion

protection is very effective even in the presence of water. Also a package of high performance additives act in

combination for superior anti-wear and Extreme Pressure (EP) performance.

APPLICATION

The Tribol 800 range are especially suited to reservoirs and circulation systems operating at high temperatures because

of heat generated in severe service or high temperatures in the application. Tribol 800 is intended for all types of heavily

loaded gears including spur, bevel and worm gears.

Although well suited for all types of gearing and bearings, the Tribol 800 range are particularly effective in controlling

wear and reducing friction between sliding surfaces. In addition, they possess a high degree of affinity for cupric metal

alloys.

ADVANTAGES

Shear stability - the synthetic base offers high viscosity index (VI) without the addition of VI improvers. In service, VI

improvers can shear, lowering oil viscosity and reducing protection critical for gear sets and bearings. The naturally

high VI of Tribol 800 assures full protection for components over a wide range of operating temperatures, speed,

and load conditions.

Long life, extended drain intervals are possible because of the natural aging and oxidation resistance of the

synthetic base fluid. Advanced Tribol lubrication technology forms friction-fighting, anti-wear films that can

significantly reduce local operating temperatures as gear teeth or bearing surfaces come into contact.

More protection for components in severe service. The extended EP performance of Tribol 800 offers protection

beyond the capabilities of conventional petroleum oils.

Wear protection under conditions of extreme temperature fluctuation and high loads.

High efficiency and lower oil temperature, especially in worm gear units.

High corrosion protection of cast and steel surfaces through special additive packages, even in the presence of

water.

Compatibility with non-ferrous metals through well-formulated synergistic additives.

Potential energy savings as a result of a lower coefficient of friction.

Reduction of maintenance costs as a result of significantly increased life of the lubricant.

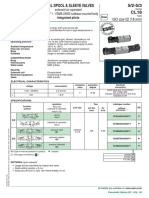

TYPICAL CHARACTERISTICS

Test

ISO viscosity group

AGMA Lubricant Number

Specific gravity @ 60F

Kinematic Viscosity

@ 40C

Method

ASTM D 2422

ASTM D 1298

ASTM D 445

@ 100C

Viscosity Index

ASTM D 2270

Units

3

g/cm

2

mm /s

2

mm /s

800/100

100

3EP

1.03

-

800/150

150

4EP

1.03

-

800/220

220

5EP

1.04

-

800/320

320

6EP

1.04

-

800/460

460

7EP

1.04

-

800/680

680

8EP

1.05

-

800/1000

1000

8AEP

1.06

-

800/2200

2200

1.06

-

100

150

220

320

460

680

1000

2200

20

29

38

59

80

113

157

372

205

225

225

253

254

271

284

325

Flash Point, COC

Pour Point

Copper Corrosion

(3 hrs @ 100C)

Rust Test Procedure A

(24 hrs Distilled Water)

ISO 2592/ASTM D92

ISO 3016/ ASTM D97

ISO 2160/

ASTM D130

ISO 7210/

ASTM D665

C

C

280

-42

280

-36

290

-33

290

-30

290

-30

290

-27

300

-24

271

-21

1a

1a

1a

1a

1a

1a

1a

1a

Pass

Pass

Pass

Pass

Pass

Pass

Pass

Pass

0.35

0.35

0.35

0.35

0.35

0.35

0.34

Four Ball Wear Test

(40 kg, 75C/167F,

1800 rpm, 1 hr) Scar

Diameter

Four Ball

Extreme Pressure Test

Load Wear Index

Weld Load

Four ball wear test

Wear scar diameter

Falex Wear Test,

ASTM D 2670, wear

teeth

FZG Test, (A/8.3/90)

FZG micropitting test

Foam Sequence I

ASTM D 2783

DIN 51350-03-B

DIN 51354

FVA No. 54

mm

Kg

kg

35

200

35

200

35

200

35

200

35

200

35

200

35

200

97

315

+2

+2

+2

+2

mm

0.27

+2

+2

+2

+2

>12

>10

ISO 6247 / ASTM

mls

0/0

D892

The viscosity-temperature relationship of these synthetic fluids is not a straight line function on the

viscosity-temperature diagram used in Test Methods ASTM D341 and DIN 51536

Subject to usual manufacturing tolerances.

Additional Information

Tribol 800 synthetic gear oils are water soluble and so spills may be cleaned up with water. They are NOT compatible

with mineral (petroleum) based lubricants. Condensation water may be absorbed without the damage of corrosion or a

change in viscosity.

Cleaning lubrication systems with a flushing oil or Tribol 800 prior to the first filling is recommended. To achieve long

drain cycles and obtain the economic advantages, systems must be free of contaminants.

The Tribol 800 range is compatible with most seals including Viton A and nitrile or Buna N (NBR). 800s are NOT

compatible with neoprene (polychloroprene) and butadiene seals - mixed polymers, stryenebutadienes, polystyrene, or

methacrylates.

Castrol Tribol 800 Series

1/12/2005, Global Version Number 1.0

Tribol 800 Series and the Castrol logo are trademarks of Castrol Limited.

All reasonable care has been taken to ensure that the information contained in this publication is accurate as of the date of printing. However, such

information may, nevertheless, be affected by changes in the blend formulation occurring subsequent to the date of printing. Material Safety Data Sheets

are available for all Castrol Ltd products. The MSDS must be consulted for appropriate information regarding storage, safe handling and disposal of a

product.

Castrol Industrial North America Inc. 150 West Warrenville Road, 605 3E Naperville, IL 60563

Tel: (877) 641 1600 Fax: (877) 648 9801

www.castrol.com/industrial

Das könnte Ihnen auch gefallen

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityVon EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityBewertung: 3 von 5 Sternen3/5 (4)

- Castrol Tribol 1421Dokument3 SeitenCastrol Tribol 1421gregcrNoch keine Bewertungen

- 5354 Greases 2010 03Dokument6 Seiten5354 Greases 2010 03Gajendra SorenNoch keine Bewertungen

- GulfSea Synth Gear Oil Series PDFDokument2 SeitenGulfSea Synth Gear Oil Series PDFObydur RahmanNoch keine Bewertungen

- Engine Oil 15W 40 PDFDokument2 SeitenEngine Oil 15W 40 PDFAngela Jackson100% (1)

- Mobilgrease 28Dokument3 SeitenMobilgrease 28adelfawzy1234Noch keine Bewertungen

- Technical Benefits MeretaDokument12 SeitenTechnical Benefits MeretaJuan Antonio MarinNoch keine Bewertungen

- Mobil SHC™ Gear SeriesDokument4 SeitenMobil SHC™ Gear SeriesJeefNoch keine Bewertungen

- Shell Turbo T PDFDokument3 SeitenShell Turbo T PDFrehmanNoch keine Bewertungen

- Mobil Rarus 800 Series FactsheetDokument2 SeitenMobil Rarus 800 Series FactsheetSiswantoro Adi WibowoNoch keine Bewertungen

- Mobilgrease XHP 322 Special PdsDokument2 SeitenMobilgrease XHP 322 Special Pdsppanagos5664Noch keine Bewertungen

- GulfSea Synth Gear Oil PG 220 PDFDokument2 SeitenGulfSea Synth Gear Oil PG 220 PDFObydur RahmanNoch keine Bewertungen

- Amsoil Racing Grease g1243Dokument2 SeitenAmsoil Racing Grease g1243amsoilromaniaNoch keine Bewertungen

- Geo Sng-4 Sae 40-Pi SheetDokument2 SeitenGeo Sng-4 Sae 40-Pi SheetDana Group - Valvoline LubricantNoch keine Bewertungen

- Chainguard 280 TDSDokument2 SeitenChainguard 280 TDSTeófilo LimasNoch keine Bewertungen

- Grease SPDokument2 SeitenGrease SPmuhammad arifNoch keine Bewertungen

- Aeroshell GreasesDokument4 SeitenAeroshell GreasesCleiton Luiz CordeiroNoch keine Bewertungen

- Endurance 8000Dokument2 SeitenEndurance 8000Azra JajčaninNoch keine Bewertungen

- Petronas Grease LiX 2-380 and MEPDokument2 SeitenPetronas Grease LiX 2-380 and MEPChristianEspinal100% (1)

- GL XX Mobil SHC Grease 460 WTDokument3 SeitenGL XX Mobil SHC Grease 460 WTRakka HardiyantaNoch keine Bewertungen

- Mobil - Glygoyle - 460Dokument3 SeitenMobil - Glygoyle - 460the anhNoch keine Bewertungen

- Glxxmorgoil Series OilsDokument4 SeitenGlxxmorgoil Series OilsAxel Mahya AvichenaNoch keine Bewertungen

- .Au ProductsAndServices Pages LubricantProDokument3 Seiten.Au ProductsAndServices Pages LubricantProabid azizNoch keine Bewertungen

- Mobilgrease HTR, HTM, HTS and HTF: GreaseDokument2 SeitenMobilgrease HTR, HTM, HTS and HTF: GreaseCARLOS ALBERTO GalaNoch keine Bewertungen

- (EN) Tribol 1100Dokument2 Seiten(EN) Tribol 1100gerardoctavaraNoch keine Bewertungen

- Mobilgrease HT Series Mobilgrease HT Series Mobilgrease HT Series Mobilgrease HT SeriesDokument3 SeitenMobilgrease HT Series Mobilgrease HT Series Mobilgrease HT Series Mobilgrease HT SeriesAyon HossenNoch keine Bewertungen

- Mobilith SHC GreaseDokument3 SeitenMobilith SHC Greasealexander900616Noch keine Bewertungen

- Mobilgear SHC 3200 6800 PdsDokument2 SeitenMobilgear SHC 3200 6800 PdsMohamed SalemNoch keine Bewertungen

- Turbo Range BrochureDokument6 SeitenTurbo Range Brochuresatya_chagantiNoch keine Bewertungen

- Amsoil Water Resistant Lithium g1281Dokument2 SeitenAmsoil Water Resistant Lithium g1281amsoilromaniaNoch keine Bewertungen

- GL XX Mobil Glygoyle SeriesDokument5 SeitenGL XX Mobil Glygoyle SeriesignaciovidalNoch keine Bewertungen

- Mobilgrease XHP 460Dokument3 SeitenMobilgrease XHP 460Jaime Miloz Masle JaksicNoch keine Bewertungen

- Shell Tivela S 220: Advanced Synthetic Gear OilsDokument2 SeitenShell Tivela S 220: Advanced Synthetic Gear OilsViruzfhmNoch keine Bewertungen

- ExxonMobil Mobil Glygoyle 320Dokument5 SeitenExxonMobil Mobil Glygoyle 320Haitham yousifNoch keine Bewertungen

- Aceite Rotork DTE 10M Series PdsDokument2 SeitenAceite Rotork DTE 10M Series PdsAlex PalaciosNoch keine Bewertungen

- Tribol 890Dokument2 SeitenTribol 890Rodrigo Andres Vallejo CastroNoch keine Bewertungen

- GL XX Mobil SHC Grease 460 WTDokument3 SeitenGL XX Mobil SHC Grease 460 WTMallikarjunareddy PNoch keine Bewertungen

- Aurelia: Trunk Piston Oil For Medium Speed EnginesDokument2 SeitenAurelia: Trunk Piston Oil For Medium Speed EnginesFreddy FarukNoch keine Bewertungen

- Pehp9544 PDFDokument4 SeitenPehp9544 PDFg665013100% (1)

- Castrol Spheerol EPLDokument2 SeitenCastrol Spheerol EPLDiego GalvanNoch keine Bewertungen

- Omala s4 GXDokument2 SeitenOmala s4 GXjeffturboNoch keine Bewertungen

- High Temperature-Grease-pds-EngDokument3 SeitenHigh Temperature-Grease-pds-Engdavide comuzziNoch keine Bewertungen

- Mobil Dte Ex Heavy BB, Aa, HHDokument2 SeitenMobil Dte Ex Heavy BB, Aa, HHMachineryengNoch keine Bewertungen

- Shell Argina T Oils: Medium-Speed Diesel Engine OilDokument3 SeitenShell Argina T Oils: Medium-Speed Diesel Engine OilDucVikingNoch keine Bewertungen

- LMX GreaseDokument2 SeitenLMX GreaseOscar CruzNoch keine Bewertungen

- Agip AcerDokument2 SeitenAgip AcerJas SumNoch keine Bewertungen

- Compressor OilsDokument4 SeitenCompressor OilsGaurav NimNoch keine Bewertungen

- Aurelia Ti 3030 - TDSDokument2 SeitenAurelia Ti 3030 - TDSnoar anwarNoch keine Bewertungen

- Shell Tellus Oils PBLAD - 2Dokument3 SeitenShell Tellus Oils PBLAD - 2Ard SaleelNoch keine Bewertungen

- Mobilgear 600 XP SeriesDokument3 SeitenMobilgear 600 XP SeriesRay Cepeda MenaNoch keine Bewertungen

- 26 GlxxengrsespolyrexemDokument3 Seiten26 GlxxengrsespolyrexemVirender KumarNoch keine Bewertungen

- Mobiltemp SHC 22 and 100Dokument4 SeitenMobiltemp SHC 22 and 100Hugo PinargoteNoch keine Bewertungen

- Turbo T TDSDokument2 SeitenTurbo T TDSDinesh NathNoch keine Bewertungen

- Shell Gadus S5 T460:: Shell Stamina Grease HDSDokument2 SeitenShell Gadus S5 T460:: Shell Stamina Grease HDSPablo Soler SalazarNoch keine Bewertungen

- Mobiltemp SHC 100 Special and 460 SpecialDokument3 SeitenMobiltemp SHC 100 Special and 460 SpecialHugo PinargoteNoch keine Bewertungen

- VALVOLINE HD - Synthetic - Gear - Oil - 80W-140-PI - SheetDokument2 SeitenVALVOLINE HD - Synthetic - Gear - Oil - 80W-140-PI - SheetJUAN BAUTISTANoch keine Bewertungen

- Castrol Aircol SR 68Dokument1 SeiteCastrol Aircol SR 68gerardoctavaraNoch keine Bewertungen

- Cat HYDO Advanced 10 Datasheet 2Dokument2 SeitenCat HYDO Advanced 10 Datasheet 2solamente10Noch keine Bewertungen

- Tellus 46Dokument3 SeitenTellus 46Vani YolganNoch keine Bewertungen

- WKM Valves (Codes How To Order)Dokument1 SeiteWKM Valves (Codes How To Order)Cardoso MalacaoNoch keine Bewertungen

- JAPY Pump HT0Dokument1 SeiteJAPY Pump HT0Cardoso MalacaoNoch keine Bewertungen

- KSB Acto ActuatorsDokument16 SeitenKSB Acto ActuatorsCardoso MalacaoNoch keine Bewertungen

- ABB Electronic Timer CT-SDS.22Dokument11 SeitenABB Electronic Timer CT-SDS.22Cardoso MalacaoNoch keine Bewertungen

- ISO Size 02 (18 MM) : Air Operated ISO 15407-1 - VDMA 24563 Subbase-Mounted BodyDokument2 SeitenISO Size 02 (18 MM) : Air Operated ISO 15407-1 - VDMA 24563 Subbase-Mounted BodyCardoso MalacaoNoch keine Bewertungen

- IMBIL INI32125.1 Data-SheetDokument4 SeitenIMBIL INI32125.1 Data-SheetCardoso MalacaoNoch keine Bewertungen

- ASCO ConnectorsDokument4 SeitenASCO ConnectorsCardoso MalacaoNoch keine Bewertungen

- HARRIS Shipbuilding-CatalogDokument76 SeitenHARRIS Shipbuilding-CatalogCardoso MalacaoNoch keine Bewertungen

- Solenoid Air Operated ISO 15407-1 - VDMA 24563 Subbase-Mounted BodyDokument4 SeitenSolenoid Air Operated ISO 15407-1 - VDMA 24563 Subbase-Mounted BodyCardoso MalacaoNoch keine Bewertungen

- Sulzer-Moret 121 NFDDokument89 SeitenSulzer-Moret 121 NFDCardoso MalacaoNoch keine Bewertungen

- ATLAS COPCO Air Compressors GA30-90 GA37 110VSDDokument9 SeitenATLAS COPCO Air Compressors GA30-90 GA37 110VSDCardoso MalacaoNoch keine Bewertungen

- Threaded Protection Tube Design Per DIN 43772 Form 5, 8 Model TW45Dokument7 SeitenThreaded Protection Tube Design Per DIN 43772 Form 5, 8 Model TW45Cardoso MalacaoNoch keine Bewertungen

- Monitoring Relays True RMS 3-Phase, 3-Phase+N, Multi-Function Types DPB01, PPB01Dokument5 SeitenMonitoring Relays True RMS 3-Phase, 3-Phase+N, Multi-Function Types DPB01, PPB01Cardoso MalacaoNoch keine Bewertungen

- LP 30 Self Monitoring Level ProbeDokument2 SeitenLP 30 Self Monitoring Level ProbeCardoso MalacaoNoch keine Bewertungen

- Avery Tronix Load Cell T302Dokument4 SeitenAvery Tronix Load Cell T302Cardoso MalacaoNoch keine Bewertungen

- IMBIL Slurry Pumps General Technical CatalogueDokument39 SeitenIMBIL Slurry Pumps General Technical CatalogueCardoso MalacaoNoch keine Bewertungen

- IMBIL Slurry Pumps Model IS ME 50 X 38 Performance CurveDokument2 SeitenIMBIL Slurry Pumps Model IS ME 50 X 38 Performance CurveCardoso MalacaoNoch keine Bewertungen

- BS5467 Copper Conductor Single Core 1.9-3.3 KVDokument2 SeitenBS5467 Copper Conductor Single Core 1.9-3.3 KVCardoso MalacaoNoch keine Bewertungen

- Plate Heat Exchanger Model M15-MFG - ASTM B265 Gr1 TitaniumDokument1 SeitePlate Heat Exchanger Model M15-MFG - ASTM B265 Gr1 TitaniumCardoso MalacaoNoch keine Bewertungen

- SAUER - DAFOSS Series 20 - 27Dokument12 SeitenSAUER - DAFOSS Series 20 - 27Cardoso Malacao100% (1)

- Hardox 550 Uk Data SheetDokument2 SeitenHardox 550 Uk Data SheetCardoso MalacaoNoch keine Bewertungen

- KONECRANES SMV 45 GC4S Technical Data-Sheet + Machine Drawing + Features Included in Our Offer (Maequi Lda)Dokument4 SeitenKONECRANES SMV 45 GC4S Technical Data-Sheet + Machine Drawing + Features Included in Our Offer (Maequi Lda)Cardoso Malacao0% (1)

- Technical Specs Ethanol Sugauli - FinalDokument108 SeitenTechnical Specs Ethanol Sugauli - FinalCardoso MalacaoNoch keine Bewertungen

- ATOSs Valves DHI-0711Dokument4 SeitenATOSs Valves DHI-0711Cardoso MalacaoNoch keine Bewertungen

- Mobrey 9000 Series Pressure TransmittersDokument6 SeitenMobrey 9000 Series Pressure TransmittersCardoso MalacaoNoch keine Bewertungen

- Stieber Clutch Bearings CatalogueDokument96 SeitenStieber Clutch Bearings CatalogueCardoso MalacaoNoch keine Bewertungen

- Krohne TD Optitemp Tra TcaDokument60 SeitenKrohne TD Optitemp Tra TcaCardoso MalacaoNoch keine Bewertungen

- CAPRARI Pumps Mec-ADokument46 SeitenCAPRARI Pumps Mec-ACardoso Malacao100% (1)

- PARKER PS1-E11 Technical Datasheet PDFDokument1 SeitePARKER PS1-E11 Technical Datasheet PDFCardoso MalacaoNoch keine Bewertungen

- Tschan CouplingsDokument19 SeitenTschan CouplingsCardoso MalacaoNoch keine Bewertungen

- Handout Temperature and Heat 1Dokument10 SeitenHandout Temperature and Heat 1NinaRicaR.RamosNoch keine Bewertungen

- Low Voltage FuseDokument27 SeitenLow Voltage FuseDE VERA, KENNETH GABRIEL D.Noch keine Bewertungen

- Tube FlaringDokument7 SeitenTube FlaringDan WolfNoch keine Bewertungen

- Chapter 10 Buckling and Stress Stiffening 1Dokument9 SeitenChapter 10 Buckling and Stress Stiffening 1Quân TrịnhNoch keine Bewertungen

- Leseprobe Design of Steel Plated Structures With Finite ElementsDokument19 SeitenLeseprobe Design of Steel Plated Structures With Finite ElementsWang MaxNoch keine Bewertungen

- Design Calculation of Spherical MSM Slide Guide (T) Bearing - 1800 KN (GB7) PDFDokument6 SeitenDesign Calculation of Spherical MSM Slide Guide (T) Bearing - 1800 KN (GB7) PDFDusmantaKumarSahooNoch keine Bewertungen

- Chemical Engineering LawsDokument4 SeitenChemical Engineering LawsAbhijit MoreNoch keine Bewertungen

- Nano World - Lesson With Answer KeyDokument26 SeitenNano World - Lesson With Answer KeyAngelie JalandoniNoch keine Bewertungen

- Manan and Gaurav - NDTDokument35 SeitenManan and Gaurav - NDTManan Depala100% (1)

- Quantum Materials Science EngineeringDokument2 SeitenQuantum Materials Science Engineeringvisheshp961Noch keine Bewertungen

- Padhle 10th - Human Eye & The Colourful WorldDokument14 SeitenPadhle 10th - Human Eye & The Colourful WorldDipak PatelNoch keine Bewertungen

- Metallic BondingDokument15 SeitenMetallic Bondingwidya sariNoch keine Bewertungen

- Pengelasan - 2 - Materials - 1Dokument82 SeitenPengelasan - 2 - Materials - 1Reza Rachman DarmawanNoch keine Bewertungen

- Circular Tube End Plate Calculation PDFDokument4 SeitenCircular Tube End Plate Calculation PDFALPHYL BALASABASNoch keine Bewertungen

- Ipc2012 90674Dokument6 SeitenIpc2012 90674Marcelo Varejão CasarinNoch keine Bewertungen

- Analysisof Design Parameterson Substation Earth Grid Safety LimitsDokument13 SeitenAnalysisof Design Parameterson Substation Earth Grid Safety LimitsFESCO WAPDANoch keine Bewertungen

- Albond HS CastableDokument2 SeitenAlbond HS CastableGurdeep Sungh AroraNoch keine Bewertungen

- Tarea 2 GeodinamicaDokument11 SeitenTarea 2 GeodinamicaCarlos David Valencia0% (1)

- Notes 03Dokument18 SeitenNotes 03agnivnath77Noch keine Bewertungen

- Best Fab NotesDokument27 SeitenBest Fab NotesJohn WellingtonNoch keine Bewertungen

- Unit 1 - How To Access The Portal: Assignment 0Dokument6 SeitenUnit 1 - How To Access The Portal: Assignment 0Arslan HassanNoch keine Bewertungen

- CSV Aug09 PDFDokument43 SeitenCSV Aug09 PDFtreda23Noch keine Bewertungen

- TDS Y3000p-2021.2Dokument6 SeitenTDS Y3000p-2021.2jituniNoch keine Bewertungen

- Properties of EVM Compounds in Relation To The Vinyl Acetate Content of The PolymerDokument10 SeitenProperties of EVM Compounds in Relation To The Vinyl Acetate Content of The PolymerabiliovieiraNoch keine Bewertungen

- Prof. Dr. Ramli Ibrahim Dr. Norlaili Abu BakarDokument24 SeitenProf. Dr. Ramli Ibrahim Dr. Norlaili Abu BakarNurshuhada NordinNoch keine Bewertungen

- (Volume 2) David Halliday, Robert Resnick - Physics - Part II 2 (1978, Wiley) - Libgen - LiDokument646 Seiten(Volume 2) David Halliday, Robert Resnick - Physics - Part II 2 (1978, Wiley) - Libgen - LicrmzNoch keine Bewertungen

- (2021-01) Recent Progress in Tin-Based Perovskite Solar CellsDokument40 Seiten(2021-01) Recent Progress in Tin-Based Perovskite Solar Cells黃凱稜Noch keine Bewertungen

- Certificate FF 16662Dokument3 SeitenCertificate FF 16662Ionela IonelaNoch keine Bewertungen

- CHEE 305: Transport Phenomena: Chapter 6: Pipe Flow William M. Chirdon, PH.DDokument48 SeitenCHEE 305: Transport Phenomena: Chapter 6: Pipe Flow William M. Chirdon, PH.DStephen AuNoch keine Bewertungen

- Lecture # 2 Cement HydrationDokument142 SeitenLecture # 2 Cement HydrationmsbNoch keine Bewertungen