Beruflich Dokumente

Kultur Dokumente

Measuring Instruments For Temperature: Resistance Thermometers

Hochgeladen von

Amin Hasan AminOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Measuring Instruments For Temperature: Resistance Thermometers

Hochgeladen von

Amin Hasan AminCopyright:

Verfügbare Formate

Measuring instruments for temperature

Resistance thermometers

Technical description

Measuring instruments for temperature

Sense

Resistance thermometer

Match

Electric transmitter

Catalog FI 01, Section 2

Output

Control

Electric

indicator

limit monitor

recorder

Catalog

controller

MP 31

MP 20

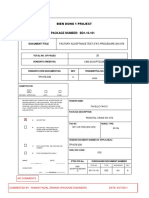

Fig. 2/44 Instrument combination for measuring and controlling temperature, with resistance thermometer as sensor

Design and mode of operation

Measuring resistors of class B are supplied. A range of resistors

of class A or 1/3 to 1/10 class B is available on request.

A resistance thermometer comprises

the measuring resistor (metal; platinum, Pt or nickel, Ni) and

the mounting and connection parts required in each case.

The resistance changes with temperature according to a certain,

reproducible series of calibration data. The changes in resistance are transmitted as changes in voltage to indicators,

recorders or controllers directly via copper wires or via transmitters. The type of measuring circuit depends on the instrument to

be connected and the required measuring range.

Measuring resistors

are suitable for

temperatures from

made of platinum

made of nickel

-200 to +850 C

(-328 to +1562 F)

-60 to +150 C

(-76 to 302 F),

briefly up to 180 C

(356 F).

Error limits to DIN EN 60 751 (IEC 751)

The resistance thermometers are divided into two classes

according to their error limits:

Class

Error limits in C

0.15 + 0.002 ^t ^ 1)

0.3 + 0.005 ^t ^

) ^t ^ is the numerical value of the temperature in C without consideration of the sign

The measuring resistors are balanced at 0 C (32 F) to

100 c 0.12 c. The basic calibration data of the resistors (i.e.

the dependence of the resistance on temperature) and the permissible deviations are defined in DIN EN 60 751 (IEC 751).

Calibration data for platinum measuring resistors

(to DIN EN 60 751)

C (F)

-200 (-328)

-180 (-292)

-160 (-256)

-140 (-220)

-120 (-184)

-100 (-148)

-80 (-112)

-60 (-76)

-40 (-40)

-30 (-22)

-20 (-4)

-10 (14)

0 (32)

10 (50)

20 (68)

30 (86)

40 (104)

50 (122)

60 (140)

80 (176)

100 (212)

120 (248)

140 (284)

160 (320)

180 (356)

200 (392)

220 (428)

c

18.52

27.10

35.34

43.88

52.11

60.26

68.33

76.33

84.27

88.22

92.16

96.09

100.00

103.90

107.79

111.67

115.54

119.40

123.24

130.90

138.51

146.07

153.58

161.05

168.48

175.86

183.19

C (F)

240 (464)

260 (500)

280 (536)

300 (572)

320 (608)

340 (644)

360 (680)

380 (716)

400 (752)

420 (788)

440 (824)

460 (860)

480 (896)

500 (932)

520 (968)

540 (1004)

560 (1040)

580 (1076)

600 (1112)

620 (1148)

640 (1184)

660 (1220)

700 (1292)

750 (1382)

800 (1472)

850 (1562)

c

190.47

197.71

204.90

212.05

219.15

226.21

233.21

240.18

247.09

253.96

260.78

267.56

274.29

280.98

287.62

294.21

300.75

307.25

313.71

320.12

326.48

332.79

345.28

360.64

375.70

390.48

Fig. 2/45 Components and circuitry of a resistance thermometer

In the standard version, the measuring resistors are embedded

in ceramic. In the case of special vibration resistance requirements, the Pt measuring resistors are double-wound and fused

into glass.

Single and double resistance thermometers are available.

Siemens FI 01 2003

2/59

Measuring instruments for temperature

Resistance thermometers

Technical description

To protect the measuring resistor for industrial measurements

and to enable easy replacement, it is fixed in a measuring insert

(Fig. 2/45) which in turn is fitted in a protective tube. The measuring insert is spring-mounted in the connection head of the

protective tube using two screws. The internal conductor in the

measuring insert connects the measuring resistor to the terminals on the terminal block.

Measuring ranges for Pt100 resistance thermometers

(to DIN 43 701)

C

-220 to +50

0 to 40

0 to 200

50 to 150

-100 to +50

0 to 60

0 to 300

100 to 200

200 to 400

-30 to +60

0 to 100

0 to 400

-30 to +150

0 to 120

0 to 500

300 to 600

-20 to +20

0 to 150

0 to 600

400 to 800

Depending on the measuring range and the accuracy required,

the thermometers are connected in two-wire, three-wire or fourwire systems to the output devices.

The measuring inserts are therefore available with two, three or

four internal conductors. If the resistance of the internal conductor is negligibly small, measuring inserts with only two internal

conductors can be used for the three-wire and four-wire systems.

Exact balancing of the internal conductor under operating conditions is only possible with three conductors. If the resistance of

the internal conductor is greater than 0.2 c, its magnitude is indicated on the mounting flange of the measuring insert.

2/60

Siemens FI 01 2003

The thermometer is heated up by the thermometer current compared to the material to be measured. The heating-up error thus

produced increases with the square of the thermometer current

and linearly with the resistance of the measuring resistor. Apart

from the magnitude of the thermometer current, the error depends on the design of the thermometer and on the heat transfer

between the protective tube and the medium. A high measuring

power is required for output instruments operating according to

the deflection method. To keep the heating-up error within permissible limits, the thermometer current should not be greater

than 10 mA in this case.

When measuring the temperature of gases with very small flow

velocities, a considerably greater heating-up error occurs than

in measurements with very fast gases or liquids. The heating-up

error is negligibly small with high flow velocities.

Suitable protective fittings are used for installation in pipelines,

tanks etc. depending on the mechanical or chemical requirements.

The materials for the protective tubes or combinations of different protective tube materials must be carefully selected in order

to meet the requirements due to static pressure, flow and temperature. Furthermore, the indication response should be as fast

as possible.

The type of installation of the protective tubes depends on the

application. The protective tubes are screwed into the pipelines

in the case of operating pressures up to approx. 90 bar. Tapered

protective tubes which can be welded in are available for higher

pressures. Thermometers for measuring furnace temperatures

are fixed using flanges.

Owing to the different operating conditions, no guarantee can be

given for protective fittings. The manufacturer is responsible for

damages and measuring errors caused by wrong installation in

compliance with the General Terms of Delivery if the instruments

have been installed by the manufacturer and if the specifications

for the operating conditions furnished by the customer were correct and sufficiently detailed.

Measuring instruments for temperature

Resistance thermometers

Technical description

Installation examples and materials of protective tubes

Measuring point and maximum

operating temperature

Protective tube

material

No.

A. Steam power plants

Water and steam lines

(screw-in and welding-type

thermometers)

Measuring point and maximum

operating temperature

No.

D. Dye works

300 C

(572 F)

400 C

(752 F)

540 C

(1004 F)

570 C

(1058 F)

Bronze Sn Bz 6

(only for water)

St 35.8

2.1020

13 CrMo 44

1.7335

1. Breweries

10 CrMo 9 10

1.7380

Brewing water

80 C

(176 F)

Bronze Sn Bz 6 or

X 6 CrNiTi 18 10

2.1020

1.0305

Mash,

hot wort

100 C

(212 F)

Bronze or

X 6 CrNiTi 18 10

1.4541

1.4541

Cold wort

4 C

X 6 CrNiTi 18 10

(39,2 F)

1.4541

100 C

(212 F)

X 6 CrNiTi 18 10

1.4541

20 C

(68 F)

X 6 CrNiTi 18 10

1.4541

100 C

(212 F)

Bronze Sn Bz 6

2.1020

1.0305

Flue gas

550 C

St 35.8, enamelled

(1022 F)

Pulverized coal/air mixture

line

Water treatment

100 C

(212 F)

30 C

(86 F)

St 35.8 (with baffle

1.0305

rod)

X 6 CrNiTi 18 10 or

1.4541

X 6 CrNiMoTi 17 122 1.4571

In paper pulp (cylindrical paper 60 C

mills, hand-made paper, refiner) (140 F)

X 6 CrNiMoTi 17 122 1.4571

B. Paper mills

Jigger, automatic yarn skein

dying machine

For all tanks with internal lining: only flangetype thermometers

4. Malt houses

X 6 CrNiMoTi 17 122 1.4571

5. Yeast production

Steeping water

X 6 CrNiMoTi 17 122 1.4571

Sulphate lye evaporation,

140 C

heat exchanger, preheater and (284 F)

lye collecting tank

Yeast cooling

Yeast fermentation

X 6 CrNiMoTi 17 122 1.4571

4 C

X 6 CrNiTi 18 10

1.4541

(39,2 F)

33 C

X 6 CrNiMoTi 17 122 1.4571

(91,4 F)

F. Chemical and petrochemical industries

2. Sulphate pulp

In vat

180 C

(356 F)

otherwise

80 C

(176 F)

Cellulose multiple-stage

40 C

bleaching (moist chloric gases (104 F)

present)

3. Cereals production

1. Sulphite pulp

Vat, lye heater

Waste lye tank, etc.

X 6 CrNiMoTi 17 122 1.4571

2. Sugar factories

Salt removal in whey

150 C

(302 F)

40 C

(104 F)

140 C

(284 F)

110 C

(230 F)

E. Food industry

Salt removal in sugar juice

C. Cellulose manufacture

Boiling acid in vat,

peetz tank and acid tower

Hypochlorite tower,

alkali tower

Sulphite lye evaporation, heat

exchanger, preheater and lye

collecting tank

Protective tube

material

X 6 CrNiTi 18 10

1.4541

or

Corrosion-resistant steel, material Nos. 1.4541 and 1.4571, can be used

for many applications. The numerous substances to be measured in

these industrial branches render it sometimes difficult to recommend suitable protective tube materials. If required, please contact our representatives in these cases.

X 6 CrNiMoTi 17 122 1.4571

1.4571

Hastelloy C (59 Ni;

16 Mo; 15,5 Cr;

5,5 Fe; 3,8 W) or

X 6 CrNiMoTi 17 122

with Ti protective

sleeve

X 6 CrNiMoTi 17 122 1.4571

Siemens FI 01 2003

2/61

Measuring instruments for temperature

Resistance thermometers

Protective tubes, installation

Fig. 2/46 Protective tubes in a pipeline

Fig. 2/49 Screw-in protective tubes, mounted;

at top for low-pressure, with screw socket G;

at bottom for high-pressure, with screw socket G1

It must be possible to weld the pipe coupling and pipeline. Material according to data provided by pipeline or vessel manufacturer.

Thread

Mounting length in mm 100

160

Nominal diameter

50

65

80

100

125

150

175

200

250

300

350

400

500

600

700

125

115

100

90

75

65

45

80

70

65

55

45

45

G

250

400

L in mm

205

190

180

165

155

130

105

80

55

205

45

155

105

55

160

G1

250

100

100

100

65

65

65

65

65

65

65

65

65

65

125

100

100

65

65

65

65

65

Fig. 2/47 Flue gas resistance thermometer, fitted in a sheet-metal duct

(top) and a flue gas duct (bottom)

Fig. 2/50 Welding-type protective tubes, mounted;

top: wall thickness 35 mm; mounting using welded coupling;

bottom: wall thickness > 35 mm

Fig. 2/48 Screw-in resistance thermometer in a pulverized coal line, with

baffle rod

2/62

Siemens FI 01 2003

Measuring instruments for temperature

Resistance thermometers

Protective tubes, loading capacity to DIN 43 763

Protective tubes form B for low-pressure screw-in resistance thermometers and thermocouples

Fig. 2/51 Loading capacity of the protective tubes, form B, for low-pressure screw-in resistance thermometers and thermocouples

Protective tubes form C for high-pressure screw-in resistance thermometers and thermocouples

Mount.

length

Temperature

Measured medium

Water

Air

Max. permissible flow velocity

5 m/s

40 m/s

mm

Permissible pressure in bar

160

20

150

200

300

0 to 38

3.9 to 36

14 to 31

38

36

31

22

250

20

150

200

300

0 to 21

3.9 to 21

14 to 21

21

21

21

21

Mount.

length

Temperature

Fig. 2/52 Loading capacity of the protective tubes, form C, bronze

Measured medium

Water

Superh. steam

Air

Max. permissible flow velocity

5 m/s

40 m/s

40 m/s

mm

Permissible pressure in bar

160

20

200

250

294

400

0 to 91

14 to 91

39 to 84

79

14

39

79

65

91

91

84

79

65

250

20

200

250

251

400

0 to 40

14 to 40

39 to 40

14

39

40

30

40

40

40

40

30

Fig. 2/53 Loading capacity of the protective tubes, form C, St 35.8, mat. No. 1.0305

Mount.

length

Temperature

Measured medium

Water

Superh. steam

Air

Max. permissible flow velocity

5 m/s

40 m/s

40 m/s

mm

Permissible pressure in bar

160

20

200

250

300

302

350

500

0 to 100

14 to 93

39 to 91

86 to 89

89

14

39

86

89

87

65

95

93

91

89

89

87

65

250

20

200

250

264

500

0 to 50

14 to 50

39 to 50

50

14

39

50

50

35

35

35

35

Fig. 2/54 Loading capacity of the protective tubes, form C, 13 CrMo 44, mat. No. 1.7335, or X 6 CrNiMoTi 17 122, mat. No. 1.4571

Siemens FI 01 2003

2/63

Measuring instruments for temperature

Resistance thermometers

Protective tubes, loading capacity to DIN 43 763

Protective tubes form D for high-pressure welding-type resistance thermometers and thermocouples

Temper- Protective tube material 13 CrMo 44, mat. No. 1.7335

ature

Form D1 and form D4,

Form D2 and form D5,

mounting length 65 mm

mounting length 125 mm

Permissible pressure in bar

Fig. 2/55 Loading capacity of protective tubes, form D, made of

13 CrMo 44, mat. No. 1.7335

Super. steam

Air

Super. steam

Air

20

200

250

300

350

375

375

435

443

490

500

510

516

520

530

540

14

39

86

167

225

475

448

439

386

343

270

240

210

170

136

663

619

575

539

486

475

475

448

439

386

343

270

240

210

170

136

14

39

86

167

225

225

225

225

225

225

225

225

210

170

136

440

440

440

440

440

440

440

440

440

386

343

270

225

210

170

136

Max. permissible flow velocity for air and superheated steam:

60 m/s

Permissible water pressure with flow velocities up to 5 m/s:

450 bar

Temper- Protective tube material 10 CrMo 9 10, mat. No. 1.7380

ature

Forms D1 and D4, Forms D2 and D5, Outer diam. 18 mm,

mounting length

mounting length

mounting length

65 mm

125 mm

35 mm

65 mm

Permissible pressure in bar

C

Superh.

steam

Air

Superh.

steam

Air

20

200

250

300

350

375

375

450

470

480

490

500

510

520

522

530

540

550

560

570

14

39

86

167

225

475

442

399

371

337

301

265

230

225

203

177

153

132

117

597

550

528

507

485

475

475

442

399

371

337

301

265

230

225

203

177

153

132

177

14

39

86

167

225

225

225

225

225

225

225

225

225

225

203

177

153

132

117

396

396

396

396

396

396

396

396

396

371

337

301

265

230

225

203

177

153

132

117

Superh.

steam

Superh.

steam

14

39

86

167

225

590

551

14

39

86

167

225

500

500

444

355

285

271

215

184

159

142

232

201

171

155

136

Max. permissible flow velocity for air and superheated steam: 60 m/s

Permissible water pressure with flow velocities up to 5 m/s:

450 bar

The outer diameter of the protective tubes to DIN 43 763,

forms D1, D2, D4 and D5 is 24 mm.

Fig. 2/56 Loading capacity of protective tubes, form D or similar (top), made of 10 CrMo 9 10, mat. No. 1.7380

Temper- Protect. tube material X 6 CrNiMoTi 17 122, mat. No. 1.4571;

ature

Form D1 and form D4,

Form D2 and form D5,

mounting length 65 mm

mounting length 125 mm

Max. permissible flow velocity of

Water, superheated steam or Water, superheated Air

air 60 m/s

steam 30 m/s

60 m/s

Permissible pressure in bar

C

Superheated steam Air

20

200

250

300

350

400

10

27

75

150

225

Fig. 2/57 Loading capacity of protective tubes, form D, made of X 6 CrNiMoTi 17 122, mat. No. 1.4571

2/64

Siemens FI 01 2003

450

275

266

266

266

266

Superheated steam Air

10

27

75

150

225

350

335

320

300

280

266

Measuring instruments for temperature

Resistance thermometers

Protective tubes, loading capacity to DIN 43 763

Protective tubes of form F

Mount.

length

Flange

nominal

pressure

Measured medium

Water

Sup. steam

Air

Max. permissible flow velocity in m/s

5

225

285

345

40

10

20

30

40

40

68

40

45

30

30

40

42

25

25

18

18

Permissible pressure in bar

mm

40

100

40

100

40

100

As shown

in the diagrams

As shown

in the diagrams

40

100

40

75

40

58

40

100

40

65

40

45

Fig. 2/58 Loading capacity of the protective tubes, form F, X 6 CrNiMoTi 17 122, mat. No. 1.4571, or X 6 CrNiTi 18 10, mat. No. 1.4541

Protective tubes of form G

Mounting

length

Measured medium

Water

Superh. steam

Air

Max. permissible flow velocity in m/s

5

mm

160

220

280

40

10

20

30

40

100

98

58

100

58

38

Permissible pressure in bar

As shown in the As shown in the

diagrams

diagrams

100

100

100

100

100

100

Fig. 2/59 Loading capacity of the protective tubes, form G, X6 CrNiMoTi 17 122, mat. No. 1.4571, or X 6 CrNiTi 18 10, mat. No. 1.4541

Siemens FI 01 2003

2/65

Measuring instruments for temperature

Flue gas resistance thermometers

With connection head

Application

The sensor is suitable for a temperature range from -50 to 600 C

(-58 to 1112 F).

The sensor is also available with a built-in temperature transmitter.

Design

Design

According to DIN 43 764: thermometer without mount

Protective tube

Form

A, DIN 43 763; cylindrical, 15 mm diameter

(0.59 inch), wall thickness 3 mm (0.12 inch),

seamless

St 35.8, mat. No. 1.0305, enamelled

1 bar above atmospheric, to DIN 43 763

Material

Loading

capacity

Measuring insert Replaceable, with measuring insert tube

(8 mm diameter (0.31 inch)) made of stainless steel; terminal block with clamping

springs

Please order mounting flange or threaded sleeve separately.

Fig. 2/60 Flue gas resistance thermometer with connection head, dimensions in mm (inches)

Ordering data

Accessories

kg (lb)

Flue gas resistance thermometer

Mounting length

kg (lb)

mm (inch)

Measuring resistor

(winding) embedded

in ceramic

1 Pt100 measuring

resistor, three-wire

system

Order No.

500 (19.7)

710 (28.0)

1000 (39.4)

1400 (55.1)

2000 (78.7)

0.9 (1.98)

1.1 (2.43)

1.5 (3.31)

1.9 (4.19)

2.7 (5.95

7MC1000-1BA2 7

7MC1000-2BA2 7

7MC1000-3BA2 7

7MC1000-4BA2 7

7MC1000-5BA2 7

1

4

6

Additional information

Please add "-Z" to Order No.,

and specify Order code(s) and

plain text.

Order code

Different design (mounting

length, protective tube material

etc.), specify in plain text.

Y01

Calibration carried out at one

point, specify desired temperature in plain text (order equivalent number of times for

several calibration points).

Y33

Siemens FI 01 2003

Gas-tight threaded sleeve

Material: 9 SMnPb 28,

mat. No. 1.0718, for 15 mm

(0.59 inch) protective tube

diameter,

G internal thread with

gasket

G internal thread with

gasket

0.3 (0.66)

7MC2998-5CA

0.4 (0.88)

7MC2998-5DA

0.4 (0.88)

7MC2998-5DC

See page 2/77 for ordering a temperature transmitter fitted in the

connection head

Connection head, form B,

made of cast light alloy,

with 1 cable bushing and

Screw cover

Standard hinged cover

High hinged cover

2/66

Mounting flange, adjustable,

to DIN 43 734; material: GTW

35, mat. No. 0.8035,

for 15 mm (0.59 inch) protective tube diameter

Individual parts:

measuring inserts on page 2/74.

Measuring instruments for temperature

Low-pressure screw-in resistance thermometers

With connection head, without neck tube

Application

The sensor is suitable for a temperature range from -50 to 400 C

(-58 to 752 F). The sensor is also available with a built-in temperature transmitter.

Design

Design

Protective tube

Form

Loading

capacity

Screw socket

According to DIN 43 765: screw-in

thermometer

B, DIN 43 763; cylindrical, 9 mm (0.35 inch)

diameter, wall thickness 1 mm (0.04 inch)

To DIN 43 763; cf. page 2/63

G; suitable is gasket 21 x 26,

similar to form C or D, DIN 7603

Measuring insert Replaceable, with measuring insert tube

(6 mm diameter (0.24 inch)) made of stainless steel; terminal block with clamping

springs

Technical data

Response times to VDI/VDE 3 522

In water with flow velocity

v = 0.4 m/s (1.31 ft/s)

In air with flow velocity

v = 1 m/s (3.28 ft/s)

Explosion protection

t0.5 = 25 s

t0.9 = 75 s

t0.5 = 2 min

t0.9 = 6.3 min

Fig. 2/61 Low-pressure screw-in resistance thermometer with connection

head, without neck tube, dimensions in mm (inches)

II 2G EEx ia IIC

T4/T6, zone 1

Ordering data

Low-pressure screw-in resistance thermometer

Measuring resistor

Protective

Mounting

tube to

length

DIN 43 763,

form

Measuring insert not

explosion protected

Measuring insert

explosion protected

Protective tube and

screw socket

X 6 CrNiMoTi 17 122,

mat. No. 1.4571

Protective tube and

screw socket

X 6 CrNiMoTi 17 122,

mat. No. 1.4571

mm (inch)

kg (lb)

Order No.

Order No.

1 Pt100 measuring

resistor, embedded in

ceramic, three-wire

system

B1

B2

B3

100 (3.9)

160 (6.3)

230 (9.1)

360 (14.2)

510 (20.1)

0.6 (1.32)

0.7 (1.54)

0.8 (1.76)

0.9 (1.98)

1.0 (2.20)

7MC1006-1DA1 7

7MC1006-2DA1 7

7MC1006-3DA1 7

7MC1006-4DA1 7

7MC1006-5DA1 7

7MC1006-1DE1 7

7MC1006-2DE1 7

7MC1006-3DE1 7

7MC1006-4DE1 7

7MC1006-5DE1 7

2 Pt100 measuring

resistors, embedded

in ceramic, two-wire

system

B1

B2

B3

100 (3.9)

160 (6.3)

230 (9.1)

360 (14.2)

510 (20.1)

0.6 (1.32)

0.71 (1.57)

0.81 (1.79)

0.91 (2.01)

1.01 (2.23)

7MC1006-1DB1 7

7MC1006-2DB1 7

7MC1006-3DB1 7

7MC1006-4DB1 7

7MC1006-5DB1 7

7MC1006-1DF1 7

7MC1006-2DF1 7

7MC1006-3DF1 7

7MC1006-4DF1 7

7MC1006-5DF1 7

1

4

6

1

4

6

Connection head form B

Made of cast light alloy, with 1 cable bushing and

-screw cover

-standard hinged cover

-high hinged cover

Made of stainless steel, with 1 cable bushing and

-screw cover

Additional information

Please add "-Z" to Order No., and specify Order code(s) and

plain text.

Order code

Different design (mounting length, protective tube material etc.), Y01

specify in plain text.

Calibration carried out at one point, specify desired temperature Y33

in plain text (order equivalent number of times for several calibration points).

See page 2/77 for ordering a temperature transmitter fitted in the connection head

Individual parts:

measuring inserts on page 2/74, connection heads on page 2/76.

1

) When using head transmitters, only use connection heads with high hinged cover.

Siemens FI 01 2003

2/67

Measuring instruments for temperature

Low-pressure screw-in resistance thermometers

With connection head and neck tube

Application

The sensor is suitable for a temperature range from -50 to 600 C

(-58 to 1112 F). The sensor is also available with a built-in temperature transmitter.

Design

Design

According to DIN 43 765: screw-in

thermometer

Protective tube

Form

Loading

capacity

Screw socket

B, DIN 43 763; cylindrical, 9 mm (0.35 inch)

diameter, wall thickness 1 mm (0.04 inch)

To DIN 43 763; cf. page 2/63

G; suitable is gasket 21 x 26,

similar to form C or D, DIN 7603

Measuring insert Replaceable, with measuring insert tube

(6 mm diameter (0.24 inch))

made of stainless steel;

terminal block with clamping springs

Technical data

Response times to VDI/VDE 3 522

In water with flow velocity

v = 0.4 m/s (1.31 ft/s)

In air with flow velocity

v = 1 m/s (3.28 ft/s)

Explosion protection

t0.5 = 25 s

t0.9 = 75 s

t0.5 = 2 min

t0.9 = 6.3 min

Fig. 2/62 Low-pressure screw-in resistance thermometer with neck tube,

dimensions in mm (inches)

II 2G EEx ia IIC

T4/T6, zone 1

Ordering data

Low-pressure screw-in resistance thermometer

Measuring resistor

Protective

Mounting

tube to

length

DIN 43 763,

form

Measuring insert not

explosion protected

Measuring insert

explosion protected 1)

Protective tube and

screw socket

X 6 CrNiMoTi 17 122,

mat. No. 1.4571

Protective tube and

screw socket

X 6 CrNiMoTi 17 122,

mat. No. 1.4571

mm (inch)

kg (lb)

Order No.

Order No.

1 Pt100 measuring

B1

resistor, embedded in B2

ceramic, three-wire

B3

system

160 (6.3)

250 (9.84)

400 (15.7)

0.8 (1.76)

0.9 (1.98)

1.0 (2.20)

7MC1007-5DA1 7

7MC1007-6DA1 7

7MC1007-7DA1 7

7MC1007-5DE1 7

7MC1007-6DE1 7

7MC1007-7DE1 7

2 Pt100 measuring

resistors, embedded

in ceramic, two-wire

system

160 (6.3)

250 (9.84)

400 (15.7)

0.9 (1.98)

1.0 (2.20)

1.1 (2.43)

7MC1007-5DB1 7

7MC1007-6DB1 7

7MC1007-7DB1 7

7MC1007-5DF1 7

7MC1007-6DF1 7

7MC1007-7DF1 7

1

4

6

1

4

6

B1

B2

B3

Connection head form B,

Made of cast light alloy, with 1 cable bushing and

-screw cover

-standard hinged cover

-high hinged cover

Made of stainless steel, with 1 cable bushing and

-screw cover

Additional information

Please add "-Z" to Order No., and specify Order code(s) and

plain text.

Order code

Different design (mounting length, protective tube material etc.), Y01

specify in plain text.

Calibration carried out at one point, specify desired temperature Y33

in plain text (order equivalent number of times for several calibration points).

See page 2/77 for ordering a temperature transmitter fitted in the connection head

Individual parts:

measuring inserts on page 2/74, connection heads on page 2/76.

1

) When using head transmitters, only use connection heads with high hinged cover.

2/68

Siemens FI 01 2003

Measuring instruments for temperature

High-pressure screw-in resistance thermometers

With connection head and neck tube

Application

The sensor is suitable for a temperature range from -50 to 600 C

(-58 to 1112 F).

The sensor is also available with a built-in temperature transmitter.

Design

Design

Protective tube

Form

Loading

capacity

Screw socket

Measuring insert

According to DIN 43 766: screw-in thermometer

C, DIN 43 763; cylindrical, 11 mm

(0.43 inch) diameter, wall thickness 2 mm

(0.08 inch)

To DIN 43 763; cf. page 2/63

G1; suitable is gasket 33 x 39,

similar to form C or D, DIN 7603

Replaceable, with measuring insert tube

(6 mm (0.24 inch) diameter) made of stainless steel;

terminal block with clamping springs

Technical data

Fig. 2/63 High-pressure screw-in resistance thermometer with neck tube

Response times to VDI/VDE 3 522

In water with flow velocity

v = 0.4 m/s (1.31 ft/s)

In air with flow velocity

t 0.5 = 32 s

t 0.9 = 96 s

t 0.5 = 2.2 min

t 0.9 = 6.8 min

v = 1 m/s (3.28 ft/s)

Ordering data

High-pressure screw-in resistance thermometer

Measuring resistor

Protective

Mounting

tube to

length

DIN 43 763,

form

Protective tube and

screw socket

X 6 CrNiMoTi

17 122, mat. No.

1.4571

mm (inch) kg (lb)

Order No.

1 Pt100 measuring

C1

resistor, embedded in

ceramic, three-wire sys- C2

tem

160 (6.3)

0.83 (1.83) 7MC1008-6DA17

250 (9.8)

0.93 (2.05) 7MC1008-7DA17

2 Pt100 measuring

C1

resistors, embedded in

ceramic, two-wire sys- C2

tem

160 (6.3)

0.86 (1.20) 7MC1008-6DB17

250 (9.8)

0.94 (2.07) 7MC1008-7DB17

Connection head form B,

Made of cast light alloy, with 1 cable bushing and

-screw cover

-standard hinged cover

-high hinged cover

Made of stainless steel, with 1 cable bushing and

-screw cover

1

4

6

7

Additional information

Please add "-Z" to Order No., and specify Order code(s) and

plain text.

Order Code

Different design (mounting length, protective tube material

etc.), specify in plain text.

Y01

Calibration carried out at one point, specify desired tempera- Y33

ture in plain text (order equivalent number of times for several calibration points).

See page 2/77 for ordering a temperature transmitter fitted in the

connection head

Individual parts:

measuring inserts on page 2/74, connection heads on page 2/76.

Siemens FI 01 2003

2/69

Measuring instruments for temperature

High-pressure welding-type resistance thermometers

With connection head and neck tube

Application

The sensor is suitable for a temperature range from 0 to 540, or

550 C (32 to 1004 or 1022 F). The sensor is also available with

a built-in temperature transmitter.

Design

Design

Protective tube

Form

Loading cap.

Neck tube

Measuring insert

Acc. to DIN 43 767: screw-in thermometer

D, DIN 43 763; tapered, for welding in; with

female thread M18 x 1.5 for neck tube

To DIN 43 763; cf. page 2/64

Stainless steel, unscrewable

Replaceable, with measuring insert tube

made of stainless steel;

terminal block with clamping springs

Technical data

Response times to VDI/VDE 3 522

In water with flow velocity v = 0.4 m/s (1.31 ft/s)

Explosion protection

t 0.5 = 25 s

t 0.9 = 80 s

II 2G EEx ia IIC T4/

T6, zone 1

Fig. 2/64 High-pressure welding-type resistance thermometer with connection head and neck tube, dimensions in mm (inches)

Ordering data

High-pressure screw-in resistance thermometer

Measuring

resistor

Protective

Mounting

tube to

length

DIN 43 763,

form

I1

Protective

tube length

Length

I3

I4

Total length kg (lb)

without

connection head

I5

mm (inch)

mm (inch)

mm (inch) mm (inch)

1 Pt100 measuring resistor,

embedded in

ceramic,

three-wire

system

D1

65 (2.6)

D4

140 (5.5)

200 (7.9)

D2

200 (7.9)

50 (2.0)

110 (4.3)

50 (2.0)

125 (4.9)

D5

260 (10.2)

D1

2 Pt100 measuring resisD4

tors,

embedded in

ceramic, twoD2

wire system

140 (5.5)

110 (4.3)

50 (2.0)

65 (2.6)

200 (7.9)

200 (7.9)

110 (4.3)

50 (2.0)

125 (4.9)

D5

Connection head form B

260 (10.2)

110 (4.3)

Meas. insert not explosion protected expl. protected 1)

Temperature

up to 540 C

up to 550 C

up to 550 C

(1004 F)

(1022 F)

(1022 F)

Prot. tube

13 CrMo 44,

mat. No. 1.7335

Prot. tube X 6

Prot. tube X 6

CrNiMoTi 17 122, CrNiMoTi 17 122,

mat. No. 1.4571 mat. No. 1.4571

Order No.

Order No.

Order No.

7MC1010-

7MC1010-

7MC1010-

305 (12.0)

0.78 (1.7)

1GA2 7

1FA2 7

1FE2 7

365 (14.4)

0.82 (1.8)

2GA2 7

2FA2 7

2FE2 7

395 (15.6)

0.85 (1.9)

3GA2 7

3FA2 7

3FE2 7

365 (14.4)

0.95 (2.1)

4GA2 7

4FA2 7

4FE2 7

395 (15.6)

0.98 (2.2)

5GA2 7

5FA2 7

5FE2 7

365 (14.4)

0.95 (2.1)

6GA2 7

6FA2 7

6FE2 7

395 (15.6)

0.98 (2.2)

7GA2 7

7FA2 7

7FE2 7

395 (15.6)

1.15 (2.5)

8GA2 7

8FA2 7

8FE2 7

305 (12.0)

0.79 (1.7)

1GB2 7

1FB2 7

1FF2 7

365 (14.4)

0.83 (1.8)

2GB2 7

2FB2 7

2FF2 7

395 (15.6)

0.86 (1.9)

3GB2 7

3FB2 7

3FF2 7

365 (14.4)

0.86 (1.9)

4GB2 7

4FB2 7

4FF2 7

395 (15.6)

1.00 (2.2)

5GB2 7

5FB2 7

5FF2 7

365 (14.4)

0.96 (2.1)

6GB2 7

6FB2 7

6FF2 7

395 (15.6)

1.00 (2.2)

7GB2 7

7FB2 7

7FF2 7

395 (15.6)

1.20 (2.7)

8GB2 7

8FB2 7

8FF2 7

1

4

6

1

4

6

1

4

6

made of cast light alloy, with 1 cable bushing and

- screw cover

- standard hinged cover

- high hinged cover

made of stainless steel, with 1 cable bushing and

- screw cover

Additional information

Please add "-Z" to Order No., and specify Order code(s) and plain text.

Order code

Different design (mounting length, protective tube material etc.), specify in plain text.

Y01

Calibration carried out at one point, specify desired temperature in plain text (order equiva- Y33

lent number of times for several calibration points).

See page 2/77 for ordering a temperature transmitter fitted in the connection head

Individual parts: measuring inserts on page 2/74, connection heads on page 2/76.

1

) When using head transmitters, only use connection heads with high hinged cover.

2/70

Siemens FI 01 2003

Measuring instruments for temperature

Flange-type resistance thermometers

With connection head

Application

The sensor can be installed in tanks and pipelines; it is suitable

for a temperature range from -50 to 600 C (-58 to 1112 F).

The sensor is also available with a built-in temperature transmitter.

Design

Protective tube

Form

Material

Flange

Measuring insert

2

Cylindrical, 11 mm (0.43 inch) diameter, wall

thickness 2 mm (0.08 inch)

X 6 CrNiMoTi 17 122, mat. No. 1.4571

Nominal diameter DN 25, nominal pressure

PN 40 (ANSI on request)

Replaceable, with measuring insert tube

(6 mm (0.24 inch) diameter) made of stainless steel; terminal block with clamping

springs

Technical data

Response times to VDI/VDE 3 522

In water with flow velocity

v = 0.4 m/s (1.31 ft/s) t 0.5 = 32 s

t 0.9 = 96 s

t 0.5 = 2.2 min

In air with flow velocity

v = 1 m/s (3.28 ft/s)

t 0.9 = 6.8 min

II 2G EEx ia IIC T4/

Explosion protection

T6, zone 1

Fig. 2/65 Flange-type resistance thermometer with connection head, dimensions in mm (inches)

Ordering data

Flange-type resistance thermometer

Measuring resistor

Mounting

length

kg (lb)

mm (inch)

Measuring insert not

explosion protected

Measuring insert

explosion protected 1)

Order No.

Order No.

1 Pt100 measuring resistor, 160 (6.3)

embedded in ceramic,

250 (9.8)

three-wire system

1.5 (3.31)

7MC1017-1FA17

7MC1017-1FE17

1.5 (3.31)

7MC1017-2FA17

7MC1017-2FE17

2 Pt100 measuring resis160 (6.3)

tors, embedded in ceramic, 250 (9.8)

two-wire system

1.6 (3.53)

7MC1017-1FB17

7MC1017-1FF17

1.6 (3.53)

7MC1017-2FB17

7MC1017-2FF17

1

4

6

1

4

6

Connection head form B,

Made of cast light alloy, with 1 cable bushing and

-screw cover

-standard hinged cover

-high hinged cover

Made of stainless steel, with 1 cable bushing and

-screw cover

Additional information

Please add "-Z" to Order No., and specify Order code(s)

and plain text.

Order code

Different design (mounting length, protective tube material

etc.), specify in plain text.

Y01

Calibration carried out at one point, specify desired tem- Y33

perature in plain text (order equivalent number of times

for several calibration points).

See page 2/77 for ordering a temperature transmitter fitted in the connection head

Individual parts:

measuring inserts on page 2/74, connection heads on page 2/76.

1

) When using head transmitters, only use connection heads with high hinged cover.

Siemens FI 01 2003

2/71

Measuring instruments for temperature

Flange-type resistance thermometers

With reduced response time,

with connection head

Application

The sensor can be installed in tanks and pipelines; it is suitable

for a temperature range from -50 to 600 C (-58 to 1112 F).

The sensor is also available with a built-in temperature transmitter.

Design

Protective tube

Form

Material

Loading

capacity

Flange

Measuring insert

F, DIN 43 763; cylindrical, 12 mm (0.47 inch)

diameter, wall thickness 2.5 mm (0.1 inch),

tapered towards tip; tip cylindrical over

length of 47 mm (1.85 inch), 9 mm (0.35

inch) diameter, wall thickness 1.5 mm (0.06

inch)

X 6 CrNiMoTi 17 122, mat. No. 1.4571

To DIN 43 763; cf. page 2/65

Fig. 2/66 Flange-type resistance thermometer with reduced response

time; with connection head, dimensions in mm (inches)

Nominal diameter DN 25, nominal pressure

PN 40 (ANSI on request)

Replaceable, with measuring insert tube

(6 mm diameter) made of stainless steel;

terminal block with clamping springs

Technical data

Response times to VDI/VDE 3 522

In water with flow velocity

v = 0.4 m/s (1.31 ft/s) t 0.5 = 22 s

t 0.9 = 66 s

t 0.5 = 2.1 min

In air with flow velocity

v = 1 m/s (3.28 ft/s)

t 0.9 = 6.5 min

II 2G EEx ia IIC T4/

Explosion protection

T6, zone 1

Ordering data

Flange-type resistance thermometer

Measuring resistor

Mounting

length

kg (lb)

mm (inch)

1 Pt100 measuring resistor, 225 (8.9)

embedded in ceramic,

285 (11.2)

three-wire system

345 (13.6)

2 Pt100 measuring resis225 (8.9)

tors, embedded in ceramic, 285 (11.2)

two-wire system

345 (13.6)

Measuring insert not

explosion protected

Measuring insert

explosion protected 1)

Order No.

Order No.

1,5 (3.31)

7MC1041-1AA07

7MC1041-1EA07

1,5 (3.31)

7MC1041-2AA07

7MC1041-2EA07

1,5 (3.31)

7MC1041-3AA07

7MC1041-3EA07

1,6 (3.53)

7MC1041-1AB07

7MC1041-1EB07

1,6 (3.53)

7MC1041-2AB07

7MC1041-2EB07

1,6 (3.53)

7MC1041-3AB07

7MC1041-3EB07

1

4

6

1

4

6

Connection head form B,

Made of cast light alloy, with 1 cable bushing and

-screw cover

-standard hinged cover

-high hinged cover

Made of stainless steel, with 1 cable bushing and

-screw cover

Additional information

Please add "-Z" to Order No., and specify Order code(s)

and plain text.

Order code

Different design (mounting length, protective tube material

etc.), specify in plain text.

Y01

Calibration carried out at one point, specify desired tem- Y33

perature in plain text (order equivalent number of times

for several calibration points).

See page 2/77 for ordering a temperature transmitter fitted in the connection head

Individual parts:

measuring inserts on page 2/74, connection heads on page 2/76.

1

) When using head transmitters, only use connection heads with high hinged cover.

2/72

Siemens FI 01 2003

Measuring instruments for temperature

Resistance thermometers for damp rooms

Application

The sensor is suitable for a temperature range from -30 to

+60 C (-22 to +140 F).

Design

Protective tube

Connection head

Made of stainless steel

Made of cast light alloy, with cable bushing;

made of plastic on request

Measuring insert 1 or 2 Pt measuring resistors to DIN IEC 751,

connection in three-wire or four-wire system,

class B

Degree of protec- IP 65 to VDE 0470-1

tion

Fig. 2/67 Resistance thermometer for moist rooms, dimensions in mm

(inches)

Ordering data

Designation

kg (lb)

Order No.

With 1 Pt100 measuring resistor

0.1 (0.22)

7MC1027-1AA

With 2 Pt100 measuring resistors

0.1 (0.22)

7MC1027-1AB

Resistance thermometer for damp

rooms

Additional information

Please add "-Z" to Order No., and specify Order

code(s) and plain text.

Order code

Different design (mounting length, protective tube

material etc.), specify in plain text.

Y01

Calibration carried out at one point, specify desired Y33

temperature in plain text (order equivalent number

of times for several calibration points).

See page 2/77 for ordering a temperature transmitter fitted in the

connection head.

Siemens FI 01 2003

2/73

Measuring instruments for temperature

Resistance thermometers

Accessories

Measuring inserts

Design to DIN 43 762

Components

Measuring insert with resistor, insert tube with retaining plate,

terminal block with clamping springs and 2 or 3 internal conductors of Cu-Ni sheathed wire for each Pt100 measuring resistor.

The resistance of the internal conductors is stated on the measuring insert if it is greater than 0.2 c

The measuring inserts have a filling of Al2O3 powder which surrounds the measuring resistor and the internal conductors and

results in a high vibration resistance (for temperatures up to

600 C (1112 F)). The winding is embedded in a ceramic body.

Fig. 2/68 Measuring insert for flue gas resistance thermometers

If the vibrations at the measuring location are greater than normal, the special vibration-proof measuring inserts should be

used (for temperatures up to 450 C (842 F)). The measuring resistor is embedded in an homogeneous, fused glass body.

Fig. 2/69 Measuring insert for low-pressure, high-pressure and flangetype resistance thermometers, dimensions in mm (inches)

Ordering data

Measuring insert for flue gas resistance thermometer 7MC1000 (not explosion protected),

for temperatures up to 600 C, insert tube made of stainless steel

Measuring insert length

Mounting length of

resistance thermometer

kg (lb)

Measuring resistor; winding

embedded in ceramic

1 Pt100 measuring

resistor, three-wire

system

mm (inch)

mm (inch)

525 (20.7)

Order No.

500 (19.7)

0.22 (0.49) 7MC1900-1EA

735 (28.9)

710 (28.0)

0.27 (0.60) 7MC1900-2EA

1025 (40.4)

1000 (39.4)

0.32 (0.71) 7MC1900-3EA

1425 (56.1)

1400 (55.1)

0.42 (0.93) 7MC1900-4EA

2025 (79.7)

2000 (78.7)

0.62 (1.37) 7MC1900-5EA

Measuring insert for low-pressure, high-pressure and flange-type resistance thermometers (not explosion protected)

Insert tube made of stainless steel

Measuring Screw-in therinsert

mometer withlength

out neck tube,

7MC1006

mm (inch)

Screw-in thermometer with

neck tube,

7MC1007 and

7MC1008

Welding-type

thermometer

7MC1010

mm (inch)

mm (inch)

Flange-type

thermometer

7MC1017 7MC1041

kg (lb)

Measuring resistor; winding embedded

in ceramic (max. 600 C (1112 F))

Total length

without

Mounting length Mounting length connection head Mounting length

1 Pt100 measuring

resistor,

three-wire system

two-wire system

mm (inch)

Order No.

Order No.

mm (inch) mm (inch)

2 Pt100 measuring

resistors,

145 (5.7)

100 (3.9)

0.15 (0.33) 7MC1910-1JA

7MC1910-1JB

205 (8.1)

160 (6.3)

0.16 (0.35) 7MC1910-2JA

7MC1910-2JB

275 (10.8)

230 (9.1)

0.17 (0.37) 7MC1910-3JA

7MC1910-3JB

315 (12.4)

160 (6.3)

305 (12.0)

160 (6.3)

225 (8.9)

0.18 (0.40) 7MC1910-4JA

7MC1910-4JB

375 (14.8)

365 (14.4)

285 (11.2) 0.19 (0.42) 7MC1910-5JA

7MC1910-5JB

405 (15.9)

360 (14.2)

250 (9.8)

395 (15.6)

250 (9.8)

0.20 (0.44) 7MC1910-6JA

7MC1910-6JB

435 (17.1)

345 (13.6)

7MC1910-8JA

7MC1910-8JB

555 (21.1)

510 (20.1)

400 (15.8)

0.21 (0.46) 7MC1910-7JA

7MC1910-7JB

Further measuring inserts on request.

2/74

Siemens FI 01 2003

Measuring instruments for temperature

Resistance thermometers

Accessories

Explosion protected measuring insert

Application

An explosion protected measuring insert is suitable for installation in a protective fitting and for connection to a certified intrinsically-safe circuit of category "ia" or "ib".

The measuring insert may only be used if the protective fitting

has the degree of protection IP 20 according to DIN 40 050.

Design

The measuring resistor is fitted in a 60-mm (2.36-inch) long

stainless steel sleeve with an outer diameter of 6 mm (0.24 inch).

The sleeve and the sheath of the supply cable are welded. The

sheath of the supply cable is also made of stainless steel, and

its outer diameter is 5 mm (0.2 inch).

The conductors are made of special copper and are embedded

in highly compacted magnesium oxide powder. The connection

points between the measuring resistor and the conductors are

additionally isolated. The conductors are potted in the terminal

base.

Fig. 2/70 Explosion protected measuring insert for resistance thermometers, dimensions in mm (inches)

Resistance of internal

conductor

The rating plate is located underneath the retaining plate.

Technical data

Measuring temperature

-200 to +450 C (-328 to +842 F)

The temperature depends on the maximum measuring current which can flow in

the connected measuring circuit if an error

occurs.

Outer diameter

of sleeve 6 mm (0.24 inch)

Per measuring circuit, i.e. for both

conductors of the two-wire system:

0.17 /m (0.052 /ft) measuring insert

Insulation resistance

of measuring insert

> 1000 M at room temperature

Explosion protection

II 2G EEx ia IIC T4/T6, zone 1

Ordering data

Explosion protected measuring insert for low-pressure, high-pressure and flange-type resistance thermometers

Insert tube made of stainless steel

Measuring

Screw-in therinsert length mometer without neck tube,

7MC1006

Screw-in ther- Welding-type

mometer with thermometer

neck tube

7MC1010

7MC1007

Total length

without

Flange-type

thermometer

7MC1017

kg (lb)

Mounting

length

Mounting

length

connection

head

Mounting

length

Mounting

length

mm (inch)

mm (inch)

mm (inch)

mm (inch)

mm (inch)

mm (inch)

145 (5.7)

100 (3.9)

0.15 (0.33) 7MC1913-1AA22

7MC1913-1AB12

205 (8.1)

160 (6.3)

0.16 (0.35) 7MC1913-2AA22

7MC1913-2AB12

275 (10.8)

230 (9.1)

0.17 (0.37) 7MC1913-3AA22

7MC1913-3AB12

315 (12.4)

160 (6.3)

305 (12.0)

160 (6.3)

225 (8.9)

0.18 (0.40) 7MC1913-4AA22

7MC1913-4AB12

375 (14.8)

365 (14.4)

285 (11.2)

0.19 (0.42) 7MC1913-5AA22

7MC1913-5AB12

405 (15.9)

360 (14.2)

250 (9.8)

395 (15.6)

250 (9.8)

0.20 (0.44) 7MC1913-6AA22

7MC1913-6AB12

435 (17.1)

345 (13.6)

0.20 (0.44) 7MC1913-7AA22

7MC1913-7AB12

555 (21.1)

510 (20.1)

400 (15.8)

0.21 (0.46) 7MC1913-8AA22

7MC1913-8AB12

7MC1041

Measuring resistor; winding

embedded in ceramic (max. 450 C

(842 F))

1 Pt100 measuring 2 Pt100 measuring

resistor, three-wire resistors, two-wire

system

system

Outer diameter of sleeve

6 mm (0.24 inch)

6 mm (0.24 inch)

Order No.

Order No.

Further measuring inserts on request.

Siemens FI 01 2003

2/75

Measuring instruments for temperature

Resistance thermometers

Accessories - Welding-type protective tubes,

neck tubes and connection heads

Welding-type protective tubes

Ordering data

Welding-type protective tube for high-pressure resistance thermometers to DIN 43 767, without neck tube, without connection head;

tapered shank with cylindrical welding stub, for measuring insert tube with 6 mm OD;

female thread M18 x 1.5 (including steel screw plug); see page 2/64 for loading capacity

Protective tube Mounting

to DIN 43 763, length

form

Protective tube kg (lb)

length

Up to 540 C (1004 F)

Up to 550 C (1022 F)

(No loading diagram to DIN 43 763)

Protective tube made of

13 CrMo 44, mat. No. 1.7335

Protective tube made of

X 6 CrNiMoTi 17 122, mat. No. 1.4571

mm (inch)

mm (inch)

Order No.

Order No.

D1

65 (2.56)

140 (5.51)

0.3 (0.66)

7MC1905-1GA

7MC1905-1DA

D4

65 (2.56)

200 (7.87)

0.5 (1.1)

7MC1905-2GA

7MC1905-2DA

D2

125 (4.92)

200 (7.87)

0.5 (1.1)

7MC1905-3GA

7MC1905-3DA

D5

125 (4.92)

260 (10.24)

0.6 (1.32)

7MC1905-4GA

7MC1905-4DA

Neck tubes

Ordering data

Neck tube for high-pressure welding-type resistance thermometers

made of stainless steel, mat. No. 1.4571, with thread at both ends, for measuring insert tube with 6 mm (0.24 inch) OD

Neck tube length

Total length of resistance thermometer,

without connection head

Protective tube length

kg (lb)

Order No.

mm (inch)

mm (inch)

mm (inch)

135 (5.31)

395 (15.55)

260 (10.24)

0.14 (0.31)

7MC1906-1AA

165 (6.50)

305/365 (12.01/14.37)

140/200 (5.51/7.87)

0.15 (0.33)

7MC1906-2AA

195 (7.68)

395 (15.55)

200 (7.87)

0.18 (0.40)

7MC1906-3AA

225 (8.86)

365 (14.37)

140 (5.51)

0.20 (0.44)

7MC1906-4AA

255 (10.04)

395 (15.55)

140 (5.51)

0.22 (0.49)

7MC1906-5AA

Connection heads for low and high-pressure resistance thermometers, flue gas and flange-type resistance thermometers

Ordering data

dimensions in mm (inches)

Designation

kg

Order No.

Connection head, form B

Degree of protection IP 54, DIN 40 050

Made of cast light alloy, with screw cover and

with 1 cable bushing

0.14 (0.31) 7MC1907-1BA

Connection head, form B

Degree of protection IP 54, DIN VDE 0470-1

Made of plastic, with screw cover and

with 1 cable bushing

0.08 (0.18) 7MC1907-1BK

Connection head, form B

Degree of protection IP 65, DIN VDE 0470-1

Made of cast light alloy, with standard hinged cover and

0.3 (0.66) 7MC1907-1BF

with 1 cable bushing

Accessories:

Quick-release clamp

0.02 (0.04) 7MC1907-1BS

(degree of protection of connection head reduced to IP54)

Connection head, form B

Degree of protection IP 65, DIN VDE 0470-1

Made of cast light alloy, with high hinged cover and with

0.3 (0.66) 7MC1907-1BL

1 cable bushing

Accessories:

Quick-release clamp

0.02 (0.04) 7MC1907-1BS

(degree of protection of connection head reduced to IP54)

Connection head, form B-VA

Degree of protection IP 65

Made of stainless steel, with screw cover and

with 1 cable bushing

Connection heads with a drilled hole of 15.5 mm diameter instead of the female thread M24 x 1.5 on request.

2/76

Siemens FI 01 2003

0.65 (1.43) 7MC1907-1BV

Measuring instruments for temperature

Temperature transmitters

General information

Customer:

Address:

Contact partner:

Purchasing dept.: .................................................................................... Tel.:

Sales dept. .............................................................................................. Tel.:

Process dept.: ......................................................................................... Tel.:

Inquiry:

Quotation:

Place and date:

Summary

The following temperature transmitters are available for installation in the connection head:

SITRANS TK-L

Programmable two-wire temperature transmitter

(4 to 20 mA), without electrical isolation, only for Pt100 resistance thermometers.

SITRANS TK

Programmable two-wire temperature transmitter (4 to 20 mA),

electrical isolation for resistance thermometers and thermocouples.

SITRANS TK-H

Two-wire temperature transmitter with HART communication

(4 to 20 mA), electrical isolation for resistance thermometers

and thermocouples.

SITRANS T3K PA

Temperature transmitter with PROFIBUS-PA connection, electrical isolation for resistance thermometers and thermocouples.

Fig. 2/71 Temperature transmitters: SITRANS T3K PA (left),

SITRANS TK-L (right) and SITRANS TK/TK-H (top)

Ordering data

To order the sensor with a built-in temperature transmitter, add

"-Z" to the Order No. of the sensor, and supplement by the following Order code:

Transmitter to be fitted

Order code

SITRANS TK-L, without Ex

K00

SITRANS TK-L, EEx ia IIC and EEx n for zone 2

K02

SITRANS TK, without Ex

K10

SITRANS TK, EEx n for zone 2

K11

Detailed information on the transmitters:

SITRANS TK, EEx ia IIC

K12

SITRANS TK-L

See page 2/50

SITRANS TK-H, without Ex

K20

SITRANS TK/TK-H

See page 2/52

SITRANS TK-H, EEx n for zone 2

K21

See page 2/45

SITRANS TK-H, EEx ia IIC

K22

SITRANS T3K PA, without Ex

K30

SITRANS T3K PA, EEx ia IIC (CENELEC)

K31

SITRANS T3K PA, intrinsic safety (FM)

K33

Customer-specific setting of the built-in transmitter

(specify settings in plain text)

Y11

SITRANS TK/TK-H can be fitted instead of the terminal block

(only versions without explosion protection) or in the high hinged

cover.

SITRANS T3K PA can only be fitted in the high hinged cover of

the connection head.

SITRANS T3K PA

Siemens FI 01 2003

2/77

Measuring instruments for temperature

Questionnaire for temperature sensors

(resistance thermometers or thermocouples)

Operating conditions

Sensor design

1. Application: ...........................................................................

(e.g. exhaust gas measurement)

1.

2. Location:................................................................................

(e.g. pipe bend, tank)

1.1. Tolerance: ............................................................................

3. Mounting position: .................................................................

(e.g. vertical, 45 against flow)

4. Temperature (measuring point):............................................

Operating temperature:.........................................................

Temperature range:...............................................................

5. Medium:.................................................................................

6. Pressure: ...............................................................................

Rated pressure......................................................................

Operating pressure ...............................................................

7. Flow: ......................................................................................

8. Vibrations:..............................................................................

9. Miscellaneous:.......................................................................

(e.g. vessel or pipe, PTFE lining)

Ambient conditions

Measuring element...............................................................

(type and standard) (e.g. Pt100 or TC type K)

1.2. Design: .................................................................................

(e.g. Pt100 or 2, 3 or 4-wire system)

1.3. Degree of protection/type of protection: ..............................

2.

Protective fitting:...................................................................

2.1. Protective tube: ....................................................................

(dimensions/material)

2.2. Mounting: .............................................................................

(dimensions/material)

2.3. Neck tube:............................................................................

(dimensions/material)

2.4. Mounting length/nominal length:..........................................

3.

Material certificates: .............................................................

4.

Connection: ..........................................................................

4.1. Connection head/box:..........................................................

(e.g. seawater atmosphere, chemical plant)

4.2. Cable:...................................................................................

(dimensions/insulation/standard)

Definition:.....................................................................................

.....................................................................................................

.....................................................................................................

4.3. Other: ...................................................................................

.............................................................................................

Special information

1. Mounting of temperature transmitter in connection head: ....

...............................................................................................

...............................................................................................

2. Packaging regulations:..........................................................

...............................................................................................

...............................................................................................

Miscellaneous

Please additionally provide the following: rough sketch, installation diagram, section of drawing, photo

2/78

Siemens FI 01 2003

5.

Tests:....................................................................................

.............................................................................................

6.

Accessories:.........................................................................

.............................................................................................

7.

Supplementary requirements:..............................................

.............................................................................................

Das könnte Ihnen auch gefallen

- DFM54 EngDokument2 SeitenDFM54 EngAnonymous KWO434Noch keine Bewertungen

- Filharmony Shipmanagement, Inc QuotationDokument3 SeitenFilharmony Shipmanagement, Inc QuotationJoel Albert FantoneNoch keine Bewertungen

- MacGregor HH Crane PDFDokument1 SeiteMacGregor HH Crane PDFrinaldy fernandaNoch keine Bewertungen

- Instruction Manual: Board CraneDokument10 SeitenInstruction Manual: Board CraneKL PetrachkovNoch keine Bewertungen

- DW E DiagramWF - 20210704105408.440 - XDokument98 SeitenDW E DiagramWF - 20210704105408.440 - XiinsukniaNoch keine Bewertungen

- Single Rope Timber Grab - OPERATION MANUALDokument12 SeitenSingle Rope Timber Grab - OPERATION MANUALSlamet SusantoNoch keine Bewertungen

- Viking: Product ManualDokument26 SeitenViking: Product ManualCristian RobiconNoch keine Bewertungen

- UR A Pdf148 Mooring AnchoringDokument21 SeitenUR A Pdf148 Mooring AnchoringMeleti Meleti MeletiouNoch keine Bewertungen

- Q22-Fat Procedure SN 1676 Mt1-Cr-7350 - BDokument29 SeitenQ22-Fat Procedure SN 1676 Mt1-Cr-7350 - BAnonymous 1ykzuaxWgYNoch keine Bewertungen

- LH 185 DS 0062 6Dokument6 SeitenLH 185 DS 0062 6Primelift Safety Resources LimitedNoch keine Bewertungen

- Quality Control Measurement Report Subject: Propeller Push Up. Rudder & Propeller Section Nord HoustonDokument2 SeitenQuality Control Measurement Report Subject: Propeller Push Up. Rudder & Propeller Section Nord HoustonAhmed Magdy100% (1)

- Cranes & Davits Heavy Duty Winches & Capstan Pilot Ladder & Fire Wire Reels Air Motors Air /electric Winches A Driven & Hand PumpDokument14 SeitenCranes & Davits Heavy Duty Winches & Capstan Pilot Ladder & Fire Wire Reels Air Motors Air /electric Winches A Driven & Hand PumpChieuNoch keine Bewertungen

- 01 - System Description - Twin Stern RollerDokument16 Seiten01 - System Description - Twin Stern Rollermiguel100% (1)

- Parts Manual: Date Group Fig. 4Dokument20 SeitenParts Manual: Date Group Fig. 4ruslanNoch keine Bewertungen

- Khan Cranes PresentationDokument28 SeitenKhan Cranes PresentationMili Marius100% (1)

- FRC Davit 3 Tech DescriptionDokument5 SeitenFRC Davit 3 Tech DescriptionSamo SpontanostNoch keine Bewertungen

- Chintana Naree BriefDokument11 SeitenChintana Naree BriefWinston Rodrigues100% (1)

- Paper Design and Manufacturing of Fixture For Leveling of End Carriage in The Assembly of End CarriageDokument11 SeitenPaper Design and Manufacturing of Fixture For Leveling of End Carriage in The Assembly of End CarriageSumit TatedNoch keine Bewertungen

- Active Heave Compensation Winch System - ACE Winches PDFDokument24 SeitenActive Heave Compensation Winch System - ACE Winches PDFxxshNoch keine Bewertungen

- ENSCO 8501: General InformationDokument1 SeiteENSCO 8501: General InformationtphsbNoch keine Bewertungen

- Cranes Cargo PDFDokument4 SeitenCranes Cargo PDFpangestu100% (1)

- P103102 - 11.00 - Doc - Freedom Manual-Old Chain Selection Guide PDFDokument45 SeitenP103102 - 11.00 - Doc - Freedom Manual-Old Chain Selection Guide PDFAnonymous M0OEZEKoGiNoch keine Bewertungen

- Muir 500 ManualDokument28 SeitenMuir 500 ManualLight HouseNoch keine Bewertungen

- SP2552-2-15-1 UM (From Inspector 2023)Dokument667 SeitenSP2552-2-15-1 UM (From Inspector 2023)kodrys100% (1)

- Crane Electrical Part 5Dokument117 SeitenCrane Electrical Part 5ruslan100% (1)

- Hydraulically Driven Deck MachineryDokument2 SeitenHydraulically Driven Deck MachineryMohamed FouadNoch keine Bewertungen

- CR-Catalog2 FEB08 PDFDokument23 SeitenCR-Catalog2 FEB08 PDFanjangandak2932Noch keine Bewertungen

- Kumera Gear 4s PDFDokument4 SeitenKumera Gear 4s PDFloloNoch keine Bewertungen

- Watertight Sliding DoorDokument21 SeitenWatertight Sliding DoorarnoldbusaNoch keine Bewertungen

- HS - Marine KatalogDokument20 SeitenHS - Marine KatalogGogyNoch keine Bewertungen

- TTS Hose Handl Cranes PDFDokument4 SeitenTTS Hose Handl Cranes PDFSyaiful Anam0% (1)

- Crane Load Chart-D-008 R2 (2) 52Dokument1 SeiteCrane Load Chart-D-008 R2 (2) 52sdNoch keine Bewertungen

- Towing Winch Emergency Release Systems-Cu Aplicare Din 2020Dokument4 SeitenTowing Winch Emergency Release Systems-Cu Aplicare Din 2020tonyNoch keine Bewertungen

- SC 360apr-Th-M 04 28-40Dokument13 SeitenSC 360apr-Th-M 04 28-40Ivaylo IvanovNoch keine Bewertungen

- Rescue Boat DavitDokument7 SeitenRescue Boat DavitOliver DsouzaNoch keine Bewertungen

- Approval Drawing Anti Heeling Sys BloomfossDokument33 SeitenApproval Drawing Anti Heeling Sys BloomfossBudi HartonoNoch keine Bewertungen

- Spare Parts 3.100 KCDokument28 SeitenSpare Parts 3.100 KCGogaNoch keine Bewertungen

- Gunclean-Toftejorg SSt40TDokument2 SeitenGunclean-Toftejorg SSt40Tmoe_htwe_1Noch keine Bewertungen

- M85817010 - Manuale NH 25 UK-1 PDFDokument32 SeitenM85817010 - Manuale NH 25 UK-1 PDFvinetamarinovicNoch keine Bewertungen

- PM-0002-0011 Manual de Chancado - 419 - 501Dokument83 SeitenPM-0002-0011 Manual de Chancado - 419 - 501Christian SantillanNoch keine Bewertungen

- Zanussi Hod TypeDokument126 SeitenZanussi Hod Typesohorye santoshNoch keine Bewertungen

- To Meet Your Challenges: Foldable Knuckle Boom Telescopic Boom Jib Knuckle Boom Heavy Duty Foldable Knuckle BoomDokument24 SeitenTo Meet Your Challenges: Foldable Knuckle Boom Telescopic Boom Jib Knuckle Boom Heavy Duty Foldable Knuckle BoompradewoNoch keine Bewertungen

- Spare Parts Manual: 6.2.2 Crane House AssemblyDokument2 SeitenSpare Parts Manual: 6.2.2 Crane House AssemblyZdravko LovićNoch keine Bewertungen

- TS - Cranes CISDI - Rev3 - 26112008 PDFDokument30 SeitenTS - Cranes CISDI - Rev3 - 26112008 PDFppankajrNoch keine Bewertungen

- Computational Fluid Dynamic Analysis of PropulsorDokument92 SeitenComputational Fluid Dynamic Analysis of PropulsorTi AnnelNoch keine Bewertungen

- 60t Crane SP2552-1-15-1 UMDokument400 Seiten60t Crane SP2552-1-15-1 UMkodrysNoch keine Bewertungen

- 02 - Operation Instructions - Stern RollerDokument15 Seiten02 - Operation Instructions - Stern Rollermiguel100% (1)

- Polylux WebkatalogDokument96 SeitenPolylux WebkatalogNesil Abiera50% (2)

- MM-2-5 Seal & Stern T BRG PDFDokument76 SeitenMM-2-5 Seal & Stern T BRG PDFndlong60Noch keine Bewertungen

- 01.00 - Liebherr WinchDokument5 Seiten01.00 - Liebherr WinchJonesNoch keine Bewertungen

- TTS-LMG Cargo CranesDokument6 SeitenTTS-LMG Cargo CranesAttar AkbarNoch keine Bewertungen

- Leistritz L3MA Schroefpomp Medium PressureDokument8 SeitenLeistritz L3MA Schroefpomp Medium Pressureashfaq shaikhNoch keine Bewertungen

- HX1 Horizontal Windlass Iss 2Dokument24 SeitenHX1 Horizontal Windlass Iss 2edgar luisNoch keine Bewertungen

- Teras Pegasus 3 Specs & GA - Updated 26.11.13 PDFDokument3 SeitenTeras Pegasus 3 Specs & GA - Updated 26.11.13 PDFSanieBurhanNoch keine Bewertungen

- Flupec Overview Hawe v30dDokument4 SeitenFlupec Overview Hawe v30dArdeleana TisaNoch keine Bewertungen

- MK 02 PDFDokument239 SeitenMK 02 PDFndlong60Noch keine Bewertungen

- SW 52 DS 0069 2Dokument6 SeitenSW 52 DS 0069 2sssssNoch keine Bewertungen

- TI266ten 0409Dokument12 SeitenTI266ten 0409Keren ArteagaNoch keine Bewertungen

- TR88 Ac1e3x2c2000Dokument24 SeitenTR88 Ac1e3x2c2000Xavier MonroyNoch keine Bewertungen

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsVon EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNoch keine Bewertungen

- Fieldbus GuideDokument33 SeitenFieldbus GuideAmin Hasan AminNoch keine Bewertungen

- PI Buffering User GuideDokument33 SeitenPI Buffering User GuidePaul Ramos CarcaustoNoch keine Bewertungen

- OPC Security White Paper #1: Understanding OPC and How It Is DeployedDokument39 SeitenOPC Security White Paper #1: Understanding OPC and How It Is DeployedAmin Hasan AminNoch keine Bewertungen

- AnalyzingPISystemDataWorkbook StudentDokument188 SeitenAnalyzingPISystemDataWorkbook StudentAmin Hasan AminNoch keine Bewertungen

- 0x80070005 DCOM Error: OPC Training InstituteDokument9 Seiten0x80070005 DCOM Error: OPC Training InstituteRonald FloresNoch keine Bewertungen

- DCOM Configuration Guide - OPCHDAIntDokument53 SeitenDCOM Configuration Guide - OPCHDAIntAmin Hasan AminNoch keine Bewertungen

- Cable Schedule SampleDokument9 SeitenCable Schedule SampleAmin Hasan AminNoch keine Bewertungen

- nema-IP Rating Chart PDFDokument3 Seitennema-IP Rating Chart PDFAlexander OngNoch keine Bewertungen

- Hart ProtocolDokument80 SeitenHart ProtocolPatil Mohan100% (1)

- VD CalculatorDokument4 SeitenVD CalculatorArnabNoch keine Bewertungen

- Craig Hickman: - Curriculum VitaeDokument2 SeitenCraig Hickman: - Curriculum Vitaecraigh92Noch keine Bewertungen

- Bimetallic CorrosionDokument20 SeitenBimetallic CorrosionchristophedepaepeNoch keine Bewertungen

- Fundamental PI Instruction ManualDokument18 SeitenFundamental PI Instruction ManualAmin Hasan AminNoch keine Bewertungen

- Chemical Feed Cooling System TreatmentDokument4 SeitenChemical Feed Cooling System TreatmentAmin Hasan AminNoch keine Bewertungen

- 2005 16 Autumn Wiring Matters Earthing Your Questions AnsweredDokument7 Seiten2005 16 Autumn Wiring Matters Earthing Your Questions AnsweredAbhijeet KulkarniNoch keine Bewertungen

- Thermo Well CalculationDokument7 SeitenThermo Well Calculationade_sofyanNoch keine Bewertungen

- Fluid Power System DynamicsDokument52 SeitenFluid Power System Dynamicsjtee84Noch keine Bewertungen

- nema-IP Rating Chart PDFDokument3 Seitennema-IP Rating Chart PDFAlexander OngNoch keine Bewertungen

- Power Separation Guidelines II PDFDokument9 SeitenPower Separation Guidelines II PDFmabdullaNoch keine Bewertungen

- Transformer Losses CalculationDokument6 SeitenTransformer Losses CalculationSaranya Jayakumar0% (1)

- Chiller PlantDokument5 SeitenChiller PlantAmin Hasan AminNoch keine Bewertungen

- Chemical Feed Cooling System TreatmentDokument4 SeitenChemical Feed Cooling System TreatmentAmin Hasan AminNoch keine Bewertungen

- Flowmeter Piping RequirementsDokument3 SeitenFlowmeter Piping RequirementsfarargNoch keine Bewertungen

- Chiller PlantDokument5 SeitenChiller PlantAmin Hasan AminNoch keine Bewertungen

- EarthingDokument13 SeitenEarthingAmin Hasan AminNoch keine Bewertungen

- System Pressure: Table 1 3: Fractional 316 or 304 STAINLESS STEEL (Seamless)Dokument5 SeitenSystem Pressure: Table 1 3: Fractional 316 or 304 STAINLESS STEEL (Seamless)Amin Hasan AminNoch keine Bewertungen

- Stakeholder Management Plan TemplateDokument11 SeitenStakeholder Management Plan TemplateVlad ScortanuNoch keine Bewertungen

- 2005 16 Autumn Wiring Matters Earthing Your Questions AnsweredDokument7 Seiten2005 16 Autumn Wiring Matters Earthing Your Questions AnsweredAbhijeet KulkarniNoch keine Bewertungen