Beruflich Dokumente

Kultur Dokumente

01 MS For Piling Testing (FINAL)

Hochgeladen von

Joe PSOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

01 MS For Piling Testing (FINAL)

Hochgeladen von

Joe PSCopyright:

Verfügbare Formate

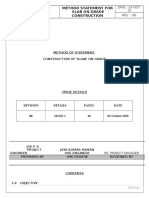

METHOD STATEMENT FOR

TESTS ON PILE

FOUNDATION

DATE : 24-OCT15

REV : 01

METHOD OF STATEMENT

TESTS ON PILE FOUNDATION

ISSUE DETAILS

REVISION

DETAILS

PAGES

DATE

00

FIRST ISSUE

13

04 July 2015

01

RE-ISSUE-1

12

24 Oct 2015

JOE P S

PROJECT ENGINEER

PREPARED BY

JAYA KUMAR RAMAN

HSE ENGINEER

HSE REVIEW

J.K. DEY

SR. PROJECT MANAGER

REVIEWED BY

TABLE OF CONTENTS

1|Page

METHOD STATEMENT FOR

TESTS ON PILE

FOUNDATION

1.

DATE : 24-OCT15

REV : 01

Objective

2.

Scope of Work

3.

Purpose

4.

Reference

5.

Responsibility

6.

Method of Test Procedures

6.1 Static Load Test

6.2 Pile Integrity Test

6.3 Ultrasonic Test

Safety

Related Forms

Attachments

7.

8.

9.

Risk Assessment

1.0

2.0

Objective

Pile tests are carried out for checking the homogeneity and integrity of concrete in deep

foundation, Load bearing capacity of bored piles, drilled shafts, concrete piles or auger cast

piles.

Purpose

To provide a detailed description for Various Pile test methods to ensure that the works

are performed in a safe, professional and controlled manner.

3.0

Scope of Works

This procedure covers Mobilization of materials and equipments, testing of piles in

Annode storage building.

4.0

References:

Relevant ASTM Codes

2|Page

METHOD STATEMENT FOR

TESTS ON PILE

FOUNDATION

5.0

Contract Drawings & Specification

EMAL Red book

ADEHMS code of practice

Responsibility

Project Manager

DATE : 24-OCT15

REV : 01

To bear overall responsibility for timely and quality execution of

works and ensures the effective use of resources and manpower

Project Engineers

To ensure all operations are in accordance with the relevant

Project contract specifications and this method statement and

check the accuracy of the works done by the site engineers

Site Engineers

To ensure that all earth works are carried out as per the approved

shop drawings. Coordinate with surveyors for accuracy of the work.

QA/QC Engineer

To ensure that the works are carried out as per the specifications.

Necessary tests are to be carried out for conformity and results are to

be provided to the Engineer.

HSE Officer

To ensure that the works are carried out in a safe manner. Give

necessary guidelines to the workforce and facilitate safe working

condition

Foreman

To ensure to carry out the work in the safe manner with proper

control over labors and equipments. Coordinate with surveyor for

accuracy of the work

6.0 METHOD OF TESTING

6.A.

Static Axial Compression Load Test on preliminary & Working Pile

1. Objective

Static loading test on a pile is the purpose of finding the settlement to be expected at the

estimated working load, or some multiple thereof, determining the ultimate bearing

capacity, or checking the structural soundness of the pile.

2. Work Sequence

A. Codal Standard & Project Specification

B. Preparation of Pile Head

C. Arrangement of Reaction System for the Load Test

D. Arrangement for Measurement of Load & Pile Head Settlement

E. Application of Load & Off Loadings

F. Recording of Loads & respective Pile Head Movements

G. Preparation of Load Test Report

3|Page

METHOD STATEMENT FOR

TESTS ON PILE

FOUNDATION

DATE : 24-OCT15

REV : 01

Standard

Pile testing of bored cast in situ vertical piles shall be carried out in accordance with this

method statement and as per the references as mentioned in clause no.4

Preparation of Pile Head

After the test pile is cast the top portion of pile (Pile head) will be chipped off to horizontal

to natural ground Level

Reaction System for the Load Test

Kentledge will be placed on platform using crane and at every layer of block, safety guide

ropes shall be provided for side barricade.

The reaction for the load test on 600 mm diameter pile will be obtained from the Kent

ledge placed on a platform supported on the ground as the test pile as shown in the

typical Drawing no. SCPL/DD/LT/001. The centre of gravity of the Kent ledge will be on the

axis of the pile and the load applied by the hydraulic jacks will be co-axial with the pile.

The Kent ledge for the load test shall be minimum 10% more than the test load.

The position of main girders shall be marked on ground and main girder shall then be

positioned for 600 mm dia. piles. The secondary girders will then be placed on the main

girders. The Kent ledge comprising of pre-cast concrete blocks will be placed over the

secondary girders as per the requirement of test loads.

The main girders will be supported on firm ground to bear the reaction load at the either

end, which will be weighing approximately 125 MT. If necessary, suitable grillage of

timber or steel shall be provided to bear such load.

Arrangement for Measurement of Load & Pile Head Settlement

The load from the reaction system will be applied on to the pile head by hydraulic jack of

suitable capacity. The load transmitted to the pile will be measured using pressure

Gauge. The hydraulic jack will be placed on the bearing plate co-axially with the pile.

The Pile Head movement/settlement shall be measured using 4 dial gauges of accuracy

not less than 0.01 mm and shall be recorded at every 10 min intervals for 1 hour; and 1

hour intervals during the test load.

The dial gauge shall be supported from the datum bar. Datum bar will be erected on

unmovable support placed at the distance of 0.50m to 1.0m from the surface of test pile.

Surface of the datum bar shall be checked by the sprit level or any other leveling

instrument.

Bearing plate of 30 to 50 mm thickness as per the requirement shall be placed in

between the Pile top & jack and Jack & main girders. Before the pile load test starts all

the arrangements shall be checked in conjunction with Consultant/Clients

representative.

Application of Load

Pile Test shall be carried out after 28 days of cast or achieving required compressive

strength.

The jack will be hydraulically operated and the applied load can be calculated by

multiplying the hydraulic pressure to the piston area of the jack.

4|Page

METHOD STATEMENT FOR

TESTS ON PILE

FOUNDATION

DATE : 24-OCT15

REV : 01

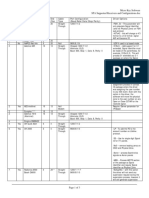

The load increments and decrements shall be carried out in stages as shown in Table 1

for preliminary test pile and in Table 2 for Working Pile. Each load shall be held for 1 hr. if

the movements of the pile head are less than 0.25mm per hour otherwise the load shall

be held for 2 hours.

Pile head movement shall be recorded as mentioned in the Table No.1 for Preliminary Pile

and Table No.2 for working Pile. Test pile shall be loaded until the test load is reached

which is 250% of the Working Load for Preliminary Piles and 150% of the Working Load

for Working Piles. The test load shall be held for 24 hours.

Thereafter the unloading is to be carried out at 1hr. interval until zero load is reached.

Decrement/Unloading shall be carried out as per the stages mentioned in Table 1 and

Table 2.

After removing all loads, the final Pile Head movement on recovery of load shall be

recorded after 1 hour.

Results:

The criteria for the elastic settlement of the proposed pile tip levels as per the vertical

pile load test in accordance with the requirement specified in Specification (CLP-1414Q6210-44EW-0001, Rev-0):

At 1.5 times the Working Load Maximum Settlement = 6 mm

At 2.5 times the Working Load Maximum Settlement = 6 mm

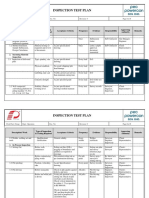

Table 1: Loading Stages for Load Test on Preliminary Pile

LOAD of (%)

TIME

SETTLEMENT CONDITION

Cycle - 1

0

25% WL

50% WL

75% WL

0

1 hr

1 hr

1 hr

100% WL

1 hrs.

75% WL

15 Min.

Off Loading

50% WL

15 Min.

Off Loading

25% WL

15 Min.

Off Loading

1 hr.

Off Loading

Till the rate of settlement is not more

than 0.25mm/hr otherwise for 2 hr.

Cycle 2

100%

125%

150%

175%

200%

WL

WL

WL

WL

WL

1

1

1

1

1

hr

hr

hr

hr

hr

Till the rate of settlement is not more

than 0.25mm/hr otherwise for 2 hr.

5|Page

METHOD STATEMENT FOR

TESTS ON PILE

FOUNDATION

225% WL

250% WL

225% WL

200% WL

175% WL

150% WL

125% WL

100% WL

75% WL

50% WL

25% WL

0

1 hr

24 hr

15 Min.

15 Min.

15 Min.

15 Min.

15 Min.

15 Min.

15 Min.

15 Min.

15 Min.

1 hr.

DATE : 24-OCT15

REV : 01

Test Load

Off Loading

Off Loading

Off Loading

Off Loading

Off Loading

Off Loading

Off Loading

Off Loading

Off Loading

Off Loading

Note: We shall submit details of static calculation for frame and kentledge including design

of main girder & secondary girder 7 days before tests.

6|Page

METHOD STATEMENT FOR

TESTS ON PILE

FOUNDATION

DATE : 24-OCT15

REV : 01

3. Equipment

Hydraulic Jack with electrical powered hydraulic pump motor set

Crawler crane or Mobile crane

Survey Equipments with necessary accessories

Welding Machine

Dial gauge, Pressure Gauge and other Hand Tools (If any)

6.B.Low strain Pile Integrity Test

1. Objective

7|Page

METHOD STATEMENT FOR

TESTS ON PILE

FOUNDATION

DATE : 24-OCT15

REV : 01

Low strain integrity testing provides velocity and force (optional) data on structural elements

(that is, structural columns, driven concrete piles, cast in place concrete piles, concrete filled

steel pipe piles, timber piles, etc.). This data assists evaluation of pile integrity and pile physical

dimensions (that is, cross-sectional area, length), continuity, and consistency of the pile

material.

The purpose of the testing is to detect any major discontinuities or defaults in foundation which

may lead of failure of the file shaft.

2. Work Sequence

Preparation

Field Notes

Taking Measurements

Data Quality Checks

Analysis of Measurements

Preparation

1. EMAL approved Third Party Laboratory shall carry out the following all steps in Low strain

integrity test

2. Pile shall be chipped off to the required cut-off level and shaft face shall be levelled with

approved Materials.

3. For cast-in-place piles, the Integrity test shall be carried out after 7 day of casting or concrete

strength achieves at least 75% of its design strength

4. Pile head surface should be accessible, clean of loose concrete or other foreign materials. If the

pile head is contaminated, remove a sufficient pile section to reach sound concrete.

4.

Prepare small area by

hand grinder to provide a smooth surface for motion sensor

attachment and impact

5. For piles with diameters larger then 500mm, attach the accelerometer at a minimum of three

locations so that an integrity evaluation near the pile head may be made for each localized

section of pile.

6. Position the apparatus for applying the impact force so that the impact is applied axially with

the pile and at a distance no larger than 300mm from the accelerometer.

7. Set up the apparatus for recording, reducing and displaying data so that it is operational and

the force and velocity signals are zeroed.

Field Notes

It includes the following information in detailed records, as available, for each pile tested

a) Pile identification, nominal and actual pile head diameter and length

b) Date and method of concrete placement, date of pile tested

c) As-built geometry that is, total concrete volume, nominal or actual diameter versus

length, permanent or temporary casing, steel reinforcement, etc.

d) Soil stratigraphy

e) Any specific observation related to each pile tested that affects the pile construction,

excavation, integrity, etc.

f) Location of transducers at pile head and corresponding measurements

Taking Measurements

1

Apply several impacts and record each individual impact or the average, if required, or

both.

8|Page

METHOD STATEMENT FOR

TESTS ON PILE

FOUNDATION

2.

3.

DATE : 24-OCT15

REV : 01

If only the individual impacts are recorded, ensure that the apparatus for recording,

reducing, and displaying data is capable of averaging up to 10 individual records.

Record the number of impacts for a specific averaged record. Take, record, and display a

series of velocity and force (optional) measurements.

Data Quality Checks

1. For confirmation of data quality, the operator shall monitor the velocity and force (optional)

from several impact events for consistency.

2. Ensure that the apparatus for recording, reducing, and displaying data is capable of

determining the measurement device overload threshold. Do not use the records of

impacts that cause the measurement device to overload.

3. Consistent records are the result of uniform impacts on sound concrete, transducer

systems that are properly functioning, motion sensors that are firmly attached, and the

apparatus for recording, reducing, and displaying data properly functioning.

4. If records are not repeatable, do not use the data. If the cause of poor data is not a motion

sensor attachment problem but rather is found to be a transducer malfunction, repair or

recalibrate it before further use.

5. All components of the apparatus for obtaining dynamic measurements and the apparatus

for recording, reducing, and displaying data be calibrated if any signs of system

malfunctions become apparent

Analysis of Measurements

1. The recorded data shall be subjected to further analysis in a computer to quantify better

the extent of an apparent anomaly.

2. The results of the analysis shall include a quantitative assessment of pile integrity. Such

further use and interpretation of the data is a matter of engineering judgment and

experience

3. Test result shall be submitted to EMAL for approval.

Equipment

1. Hand held hammer

2. Accelerometers/ Transducers

3. PDI tester collector

6.C.Ultrasonic Crosshole Testing for Pile Integrity

1. Objective

Ultrasonic crosshole test provides the details of homogeneity and integrity of concrete in

deep foundation such as bored piles, drilled shafts, concrete piles or auger cast piles.

The test measures the propagation time and relative energy of an ultrasonic pulse between

parallel access ducts (cross hole) or in a single tube (single hole) installed in the deep

foundation element. This method is most applicable when performed in tubes that are

installed during construction.

2. Work Sequence

1. Installation of Preformed Access Ducts

2. Preparing Access ducts for Testing

3. Probe Preparation

4. Obtaining Measurements with the Apparatus

5. Data Quality Checks

6. Analysis of Measurements

Test Arrangement

9|Page

METHOD STATEMENT FOR

TESTS ON PILE

FOUNDATION

DATE : 24-OCT15

REV : 01

Installation of Preformed Access Ducts

1. 50mm dia MS pipe shall be supplied at site and Jointed for required length using

welding.

2. Exterior face of tube shall be free from contamination (such as oil, dirt, loose rust, mill

scale etc.)

3. Access tubes shall be closed-ended at the bottom and fitted with removalble end caps

at the top to prevent entry of concrete or foreign objects which could block the tubes

prior to testing operations.

4. For pile dia >1000mm, three nos of MS pipes shall be installed as access tube at equal

distance.

5. The access tubes shall be installed such that their bottom is as close as possible to the

bottom of the pile concrete, so that the bottom condition can be tested.

6. The access tubes shall have a minimum concrete cover of 1 tube diameter

7. Access tubes shall be secured to the inside of the main axial reinforcement of the steel

cage at frequent and regular intervals along their length to maintain the tube alignment

during cage lifting, lowering and subsequent concreting of the deep foundation.

8. Care should be taken to ensure that all access tubes are as parallel to each other as

possible

Preparing Access ducts for Testing

1. Checks shall be carried out to ensure testing apparatus is functioning correctly prior to

mobilizing to site

2. Tests shall be performed no sooner than 3 to 7 days after casting depending on

concrete strength and shaft diameter

3. The access ducts shall be exposed and the protective top caps removed. And length of

each access duct will be recorded. If the access duct is blocked, record the depth of

blockage from the access duct top. Access ducts shall be filled to the top with clean

water

4. Center-to-center distance of exposed access duct also will be recorded.

Probe preparation

1. To obtain a good acoustic coupling between the probes and the water in the access

ducts, the probes shall be clean and free from all contaminants.

2. The functionality of the equipment should be checked according to the manufacturers

operation instructions. Check that test equipment and probes are functioning correctly

prior to actual testing by verifying that ultrasonic pulses are received in the recording

apparatus.

Obtaining Measurements with the apparatus

1. safety and any special instructions or manufacturers procedures pertaining to the

particular apparatus Employed shall be followed while testing in progress

2. The pair of access ducts being tested shall be recorded. The probe cable pulley guides

will be into the access ducts. Then the transmitter and receiver probes will be inserted

into these access ducts ensuring that the cables are engaged over the respective cable

pulley guides fixed at the access duct tops. If the access duct tops are not level, then

the probes will be places at the level of the lower access duct top.

10 | P a g e

METHOD STATEMENT FOR

TESTS ON PILE

FOUNDATION

DATE : 24-OCT15

REV : 01

3. Test Apparatus will be adjusted, if necessary, selecting the transmitter power setting

and receiver gain required for the access duct separation distance and concrete

characteristics encountered such that an ultrasonic pulse with good amplitude can be

consistently obtained in a portion of deep foundation good quality. Return the probes to

the access duct bottoms

4. The deep foundation element top and bottom are more likely to contain contaminated

concrete than at intermediate locations. Setting the signal conditioning gains should be

done at an intermediate location along the element length. The gain setting may be

manually or automatically adjusted to adapt to different spacing between tested access

duct pairs so that good signal strength is maintained

5. Recording the ultrasonic pulses shall be begin as the probes are raised. Both the probes

will lifted by steadily pulling the probe cables simultaneously at a speed of ascent slow

enough to capture one ultrasonic pulse for each depth interval specified.

6. If an ultrasonic pulse is not obtained for any depth and the test repeated until all depth

intervals have an associated ultrasonic pulse.

Data Quality Checks:

1. After completing data acquisition, checks shall be carried on the ultrasonic profile

obtained and the ultrasonic profile quality.

2. Comparison shall be made on the length of the measured ultrasonic profile with the

measured access duct length. In comparing these measurements a correction should

be made to account for the length between the bottom of the probe assembly to the

exact point of the transmitter and receiver on the probe. The difference between the

corrected measurements shall not exceed 1 % of the measured length or 0.25 m,

whichever is larger.

3. The captured data are will be labeled with the deep foundation element identification,

identification of the two access ducts for the data set, date of test, identification of the

test operator, and any further necessary project information such as site and location

details as required.

Analysis of Measurements

1. Pile ultrasonic test shall be carried out by authorized third party laboratory. Test results

will be submitted to EMAL

Equipment

1. Weighted Measuring Tape

2. Probes

2. Transmitter/receiver Probe

4. Probe centralizer

5. Signal Transmission Cables

6. Data recording device and other necessary tools

7. Safety Precautions:

All the precautions shall be taken to ensure that load test is conducted without violating

any safety precautions in general. Area around the pile test will be barricaded using

safety ribbons and unauthorized persons will not be allowed inside the barricaded area.

All the jacks, pumps and hose pipes shall be checked before starting the test. The area

shall be adequately illuminated to enable working during night.

11 | P a g e

METHOD STATEMENT FOR

TESTS ON PILE

FOUNDATION

DATE : 24-OCT15

REV : 01

8. Related Forms:

1. Approved shop drawings.

2. Inspection request.

9. Attachments:

Risk Assessment

APPENDIX-A

METHOD STATEMENT- BRIEFING REGISTER

Project: EMIRATES ALUMINIUM SMELTER PROJECT

Date:

Sheet No:

Time:

Delivery by:

Induction Type: Task Specific (Detail): Construction of Anode Storage Building

I have been briefed of the contents of the above method statement regarding pile testing

procedures, I fully understand all that has been said to me. I have also had the opportunity to raise any

queries relating to the work that is to be carried out.

NO.

NAME (PRINT)

EMPLOYER

(PRINT)

SIGNATURE #

PAYROLL NO

1

2

3

4

5

6

12 | P a g e

Das könnte Ihnen auch gefallen

- ServiceNow Admin Certification Book PDFDokument196 SeitenServiceNow Admin Certification Book PDFOmar Ait RahhoNoch keine Bewertungen

- Method Statement For GeotextileDokument17 SeitenMethod Statement For GeotextileGökhan Gökçe0% (1)

- Method Statement - Piling WorkDokument7 SeitenMethod Statement - Piling WorkLook100% (1)

- Method Statement of Sheet Piling WorksDokument59 SeitenMethod Statement of Sheet Piling WorksDevapradatta Nath100% (10)

- Method Statement For Trial Pit ExcavationDokument4 SeitenMethod Statement For Trial Pit ExcavationCwazy MarooyNoch keine Bewertungen

- Inspection Test Plan Piling WorkDokument4 SeitenInspection Test Plan Piling WorkAhmad AfeeqNoch keine Bewertungen

- Quality Control of PilingDokument2 SeitenQuality Control of PilingBudi Ariyadi100% (3)

- Pile Load Test ProcedureDokument24 SeitenPile Load Test ProcedureRamkumar K100% (4)

- Method Statement For Pile DrivingDokument2 SeitenMethod Statement For Pile DrivingLim Han Jian100% (5)

- Work Method Statement of Piling WorkDokument11 SeitenWork Method Statement of Piling Worksangamesh yadahalliNoch keine Bewertungen

- MS Remedial Spun Pile A2p6Dokument29 SeitenMS Remedial Spun Pile A2p6AlsonChinNoch keine Bewertungen

- ITP & Ceklis Bored PileDokument5 SeitenITP & Ceklis Bored Pilefari_civil06Noch keine Bewertungen

- Pile MethodologyDokument14 SeitenPile MethodologyVelmurugan BalasubramanianNoch keine Bewertungen

- BoredPile CHecklist UpdateDokument3 SeitenBoredPile CHecklist UpdateGnabBang75% (12)

- Procedure - For Pile Load TestDokument14 SeitenProcedure - For Pile Load TestimranNoch keine Bewertungen

- MS For Slab On GradeDokument9 SeitenMS For Slab On GradeJoe PSNoch keine Bewertungen

- Method Statement FOR PDA TestDokument3 SeitenMethod Statement FOR PDA TestMarivic D. SantosNoch keine Bewertungen

- Guideline Static Axial Compression Pile Load TestDokument15 SeitenGuideline Static Axial Compression Pile Load Testcecdesign09Noch keine Bewertungen

- 26.05.2021-METHOD STATEMENT - VERTICAL LOAD TEST by Anchor MethodDokument16 Seiten26.05.2021-METHOD STATEMENT - VERTICAL LOAD TEST by Anchor MethodpdksubudhiNoch keine Bewertungen

- STATIC LOAD TEST - การทดสอบการรับน้ำหนักของเสาเข็มDokument11 SeitenSTATIC LOAD TEST - การทดสอบการรับน้ำหนักของเสาเข็มWilrutstien WilrutstienNoch keine Bewertungen

- Method Statement For Piling Work (Edited)Dokument18 SeitenMethod Statement For Piling Work (Edited)Faeez Zain100% (6)

- A Lecture Notes 2012 Dda2132 CHP 3b Pile TestDokument13 SeitenA Lecture Notes 2012 Dda2132 CHP 3b Pile Testmkpasha55mpNoch keine Bewertungen

- SOP of Pull Out, Lateral & Compression - REV01Dokument8 SeitenSOP of Pull Out, Lateral & Compression - REV01Prince MittalNoch keine Bewertungen

- Method Statement For Compression Pile Load TestDokument5 SeitenMethod Statement For Compression Pile Load TestNguyễn Văn GiápNoch keine Bewertungen

- Yjack - Ms 20170211 - BD For Bp600mm Wl2827kn Tl5654knDokument56 SeitenYjack - Ms 20170211 - BD For Bp600mm Wl2827kn Tl5654knKS Lee100% (1)

- Plate Load TestDokument3 SeitenPlate Load TestniteshNoch keine Bewertungen

- Method Statement For PilingDokument13 SeitenMethod Statement For Pilingfree4bruce100% (1)

- Submission of Construction Methodology of Piling Works - Reg.Dokument5 SeitenSubmission of Construction Methodology of Piling Works - Reg.SHYAMA PRASAD SAMANTA100% (1)

- Method Statement For Bored Cast Insitu PileDokument10 SeitenMethod Statement For Bored Cast Insitu PileVijay JamadarNoch keine Bewertungen

- Method Statement For Pile Chipping and Capping Beam: Vascon Engineers LTDDokument12 SeitenMethod Statement For Pile Chipping and Capping Beam: Vascon Engineers LTDshahaji0% (1)

- Method Statement For Anti Termite TreatmentDokument7 SeitenMethod Statement For Anti Termite TreatmentSagar Aliasjackey100% (2)

- Method of Statement For Static Loading TestDokument27 SeitenMethod of Statement For Static Loading TestTengku Azaha Tengku IsmailNoch keine Bewertungen

- Method Statement For Aac BlockworkDokument10 SeitenMethod Statement For Aac BlockworkobieNoch keine Bewertungen

- Pull Out TestDokument4 SeitenPull Out TestjmiguelmenaNoch keine Bewertungen

- Method Statement FOR Launching of Prestressed I Beams AT RB 014, Jalan Tapah - Teluk Intan (Pier 2 To Abutment 2)Dokument14 SeitenMethod Statement FOR Launching of Prestressed I Beams AT RB 014, Jalan Tapah - Teluk Intan (Pier 2 To Abutment 2)MAYMODERN STEELNoch keine Bewertungen

- Method of Statement For R.C Piling WorkDokument10 SeitenMethod of Statement For R.C Piling WorkMacgjoyner SaLauNoch keine Bewertungen

- Tetrapod - PQPDokument70 SeitenTetrapod - PQPGunawan IwanNoch keine Bewertungen

- Vertical Pile Load Test (Sabarmati Station Building)Dokument9 SeitenVertical Pile Load Test (Sabarmati Station Building)Vipin Kumar ParasharNoch keine Bewertungen

- Method Statement For Earthwork Excavation & BackfillingDokument6 SeitenMethod Statement For Earthwork Excavation & Backfillingjing aytonaNoch keine Bewertungen

- Professor Dr. Md. Jahangir AlamDokument47 SeitenProfessor Dr. Md. Jahangir AlamShah Mohammad IqbalNoch keine Bewertungen

- Part417 Continuous Flight Auger PilesDokument5 SeitenPart417 Continuous Flight Auger PilesNaga RjkNoch keine Bewertungen

- Pile Instalation Methods 2Dokument9 SeitenPile Instalation Methods 2Bright MuzaNoch keine Bewertungen

- Pile Load Test Procedure-1Dokument5 SeitenPile Load Test Procedure-1S GoudaNoch keine Bewertungen

- PG Y4 Entrance Exam Syllabus 2021 2022Dokument11 SeitenPG Y4 Entrance Exam Syllabus 2021 2022Saquib.MahmoodNoch keine Bewertungen

- Method Stament PDA TestDokument14 SeitenMethod Stament PDA TestTonni KurniawanNoch keine Bewertungen

- Method Statement Static Pile Load TestDokument19 SeitenMethod Statement Static Pile Load TestRakesh Rana100% (4)

- 01 Method Statement For Pile Cap Foundations (Findal)Dokument8 Seiten01 Method Statement For Pile Cap Foundations (Findal)Joe PS83% (6)

- Cast-In-Situ Bored Piling Works by ConventionalMethod1Dokument11 SeitenCast-In-Situ Bored Piling Works by ConventionalMethod1jitendraNoch keine Bewertungen

- Method Statement - Test PilingDokument5 SeitenMethod Statement - Test PilingMcr Kumara0% (1)

- Activity A.3 - Pilling, Pile Cap & Pier WorksDokument3 SeitenActivity A.3 - Pilling, Pile Cap & Pier Worksbhaskar100% (2)

- WMS Excavation & BACKFILLINGDokument28 SeitenWMS Excavation & BACKFILLINGRepl microsoft, PuneNoch keine Bewertungen

- Method Statement Excavation BackfillingDokument16 SeitenMethod Statement Excavation BackfillingMohsen KeramatiNoch keine Bewertungen

- Static Pile Load Test ManualDokument57 SeitenStatic Pile Load Test Manualphamminhquang100% (1)

- Method Statement For Sheet PilingDokument8 SeitenMethod Statement For Sheet PilingAbdul Muneer PalapraNoch keine Bewertungen

- STANDARD TEST METHOD PIT (Pile Integrity Test)Dokument5 SeitenSTANDARD TEST METHOD PIT (Pile Integrity Test)senthilNoch keine Bewertungen

- Method Statement For Bored PilesDokument18 SeitenMethod Statement For Bored PilesKaushalye Mahanama Dissanayake100% (3)

- Static and PDA Load Test Method StatementDokument20 SeitenStatic and PDA Load Test Method StatementMikiRoniWijaya100% (1)

- Static Load Test Methodology: in Accordance With ASTM D1143Dokument8 SeitenStatic Load Test Methodology: in Accordance With ASTM D1143sumitNoch keine Bewertungen

- Pile Load Test Procedure-2Dokument9 SeitenPile Load Test Procedure-2S GoudaNoch keine Bewertungen

- Wireless Pile Load Test Kit PresentationDokument41 SeitenWireless Pile Load Test Kit PresentationKhang VũNoch keine Bewertungen

- Pile Test MetheodlogyDokument13 SeitenPile Test MetheodlogyArkhitekton engineeringNoch keine Bewertungen

- Static Pile Load Testing and Pile Dynamic Analysis: 8-1 IntroductionDokument8 SeitenStatic Pile Load Testing and Pile Dynamic Analysis: 8-1 IntroductionBassam ElsayedNoch keine Bewertungen

- Civil Sub-Contractor Organization Chart: ManagerDokument1 SeiteCivil Sub-Contractor Organization Chart: ManagerJoe PSNoch keine Bewertungen

- Method Statement For Curing & De-ShutteringDokument2 SeitenMethod Statement For Curing & De-ShutteringJoe PSNoch keine Bewertungen

- Technical Data Sheet Technical Data Sheet Technical Data Sheet Technical Data SheetDokument1 SeiteTechnical Data Sheet Technical Data Sheet Technical Data Sheet Technical Data SheetJoe PSNoch keine Bewertungen

- Attn: Mr. XXXXX Through: Mr. XXXXXXXXXXXXX Sub: Resignation From The ServiceDokument1 SeiteAttn: Mr. XXXXX Through: Mr. XXXXXXXXXXXXX Sub: Resignation From The ServiceJoe PSNoch keine Bewertungen

- Method Statement For Construction of Pile CAP: DATE: 24-OCT-15 REV: 01Dokument8 SeitenMethod Statement For Construction of Pile CAP: DATE: 24-OCT-15 REV: 01Joe PSNoch keine Bewertungen

- 01 Method Statement For Pile Cap Foundations (Findal)Dokument8 Seiten01 Method Statement For Pile Cap Foundations (Findal)Joe PS83% (6)

- Tunnel Construction ProgrammeDokument2 SeitenTunnel Construction ProgrammeJoe PSNoch keine Bewertungen

- Visio-Work Flow Chart - ExcavationDokument1 SeiteVisio-Work Flow Chart - ExcavationJoe PSNoch keine Bewertungen

- Psychology: Kubler-Ross ModelDokument8 SeitenPsychology: Kubler-Ross ModelJoe PSNoch keine Bewertungen

- Silent NightDokument2 SeitenSilent NightJoe PSNoch keine Bewertungen

- Monthly Expenditure ReportDokument10 SeitenMonthly Expenditure ReportJoe PSNoch keine Bewertungen

- Primavera SyllabusDokument1 SeitePrimavera SyllabusJoe PSNoch keine Bewertungen

- NCP 21 AssignmentDokument17 SeitenNCP 21 AssignmentSri Harsha100% (1)

- Quality Control in PlacementDokument8 SeitenQuality Control in PlacementsarvadhNoch keine Bewertungen

- Implementing A jPOS GatewayDokument19 SeitenImplementing A jPOS GatewaydenyuuuNoch keine Bewertungen

- Rural Bank: Case StudyDokument10 SeitenRural Bank: Case StudyChelsea DyanNoch keine Bewertungen

- Xilinx Answer 58495 PCIe Interrupt Debugging GuideDokument18 SeitenXilinx Answer 58495 PCIe Interrupt Debugging GuiderajaramghoshNoch keine Bewertungen

- Sand ColumnDokument16 SeitenSand ColumnZulfadli MunfazNoch keine Bewertungen

- MCC Instruction Manual Rev PDFDokument44 SeitenMCC Instruction Manual Rev PDFvidhyaNoch keine Bewertungen

- Receptoras, Cableado y ConfiguraciónDokument3 SeitenReceptoras, Cableado y ConfiguraciónAntonioNoch keine Bewertungen

- Slab CulvertDokument1 SeiteSlab CulvertSivaramakrishnaNalluri100% (1)

- PLC To Rio CommunicationDokument1 SeitePLC To Rio CommunicationSubrat DasNoch keine Bewertungen

- Unit 2Dokument48 SeitenUnit 2bharathimmkNoch keine Bewertungen

- Quiz in ArtsDokument2 SeitenQuiz in ArtsLeigh Paz Fabrero-UrbanoNoch keine Bewertungen

- HolidayDokument5 SeitenHolidayAnanthiNoch keine Bewertungen

- Case Study PresentationDokument12 SeitenCase Study PresentationParvathi MurukeshNoch keine Bewertungen

- HRD C Frame Anchor TDSDokument18 SeitenHRD C Frame Anchor TDSronyNoch keine Bewertungen

- Sowmya ResumeDokument4 SeitenSowmya ResumesowmyaNoch keine Bewertungen

- Dortek Hospital Doors BrochureDokument10 SeitenDortek Hospital Doors BrochureAbdul BaseerNoch keine Bewertungen

- Data Tiering in BW4HANA and SAP BW On HANA Roadmap UpdateDokument14 SeitenData Tiering in BW4HANA and SAP BW On HANA Roadmap UpdateNarendra PeddireddyNoch keine Bewertungen

- Android Application DevelopmentDokument1 SeiteAndroid Application DevelopmentK S SAI PRASADNoch keine Bewertungen

- Stratford 2004Dokument10 SeitenStratford 2004carlrequiolaNoch keine Bewertungen

- FM Local ChandpurDokument14 SeitenFM Local ChandpurShaiful IslamNoch keine Bewertungen

- Chapter 1 Final PaperDokument43 SeitenChapter 1 Final Paperjohanna faith israelNoch keine Bewertungen

- Barchart SteleronDokument4 SeitenBarchart Steleroncumpio425428Noch keine Bewertungen

- Bor11999 NSW Manual Bk1 Structural Fire AccusticDokument72 SeitenBor11999 NSW Manual Bk1 Structural Fire AccusticEmanuel Ifrim100% (1)

- Mobile Broadband Router: Installation, Operation, and Maintenance GuideDokument88 SeitenMobile Broadband Router: Installation, Operation, and Maintenance Guideaxj42128Noch keine Bewertungen

- Heating, Home Inspection Course and Exam - North America, CanadaDokument56 SeitenHeating, Home Inspection Course and Exam - North America, CanadaAli Noroozi100% (1)

- Study of Prefabrication in IndiaDokument6 SeitenStudy of Prefabrication in IndiaSayed WafiNoch keine Bewertungen

- Cardinia Creek Parklands: Manna Gum Picnic AreaDokument2 SeitenCardinia Creek Parklands: Manna Gum Picnic AreaSamuel RoseNoch keine Bewertungen

- The Chow CollectionDokument51 SeitenThe Chow CollectionStephen ChowNoch keine Bewertungen

- Think WoodDokument10 SeitenThink WoodkusumoajiNoch keine Bewertungen