Beruflich Dokumente

Kultur Dokumente

Thermal Analysis PDF

Hochgeladen von

Sachin KumbharOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Thermal Analysis PDF

Hochgeladen von

Sachin KumbharCopyright:

Verfügbare Formate

Thermal

Analysis

&

Cooling

Curves

Rio Tinto

Iron & Titanium

Every body know this

system, frequently found

near the furnaces or the

cupolas

Its a Thermal Analysis System

to check especially:

Ceq, C, TL, Si or Undercooling

SORELMETAL

PMC Dec 2008

How does it work ?

It records the different steps of the cooling for the liquid and

solid alloy, by measuring of different electrical values. A

specific electrical value corresponds to each step of the

physical aspect of the alloy . These values are translated to

a graph.

SORELMETAL

PMC Dec 2008

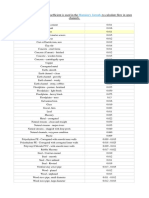

Some definitions:

TL: Liquidus temperature

1250

TE low: Low eutectic

temperature

TE upper: High eutectic

TE Gray: Gray eutectic

temperature

TE White: White eutectic

Tem perature: C

temperature

T Liq

1200

Te Gray

T

Te Low

1150

temperature

Te Upper

T Sol

Te White

TS: Solidus temperature

1100

T: Undercooling

R: Recalescence

SORELMETAL

50

100

150

200

250

300

Time: s

PMC Dec 2008

For Iron:

Each iron grade has a specific curve:

1: Lamellar graphite iron

2: DI

3: DI with low nodules count

4: White iron

5: pseudo lamellar graphite + lamellar graphite

SORELMETAL

PMC Dec 2008

For Example:

SORELMETAL

PMC Dec 2008

For DI, there are different typical curves:

Base Iron

SORELMETAL

PMC Dec 2008

For DI, there are different typical curves:

Treated iron

SORELMETAL

PMC Dec 2008

For DI, there are different typical curves:

Treated iron

+

Inoculation

SORELMETAL

PMC Dec 2008

10

Why using Thermal Analysis?:

A last Definition.

Undercooling = TE gray TE low

SORELMETAL

PMC Dec 2008

11

Why using Thermal Analysis?:

What happens if undercooling ( T ) becomes too high ?

Fe3C

SORELMETAL

PMC Dec 2008

12

Why using Thermal Analysis?:

What happens if TS becomes too low ?

Inverse

Inverse Chill

Chill

SORELMETAL

PMC Dec 2008

13

Why using Thermal Analysis?:

Inverse Chill

SORELMETAL

PMC Dec 2008

14

Why using Thermal

Analysis?:

The A, B, C curves

That gives

different

Cooling curves

SORELMETAL

PMC Dec 2008

15

Why using Thermal Analysis?:

=

TE

Gray

Small Delta T =

High Nucleation

SORELMETAL

PMC Dec 2008

16

Why using Thermal Analysis?:

High Nucleation =

less shrinkage

SORELMETAL

Thermal Analysis

can prevent

shrinkage

PMC Dec 2008

17

Why using

Thermal

Analysis?:

Thermal Analysis

can check the

iron quality

during

elaboration:

Especially after a

long maintain in

the furnace

SORELMETAL

PMC Dec 2008

18

Present Possibility:

Thermal Analysis with using the first and second derivations

This value could qualify the good nucleation

SORELMETAL

PMC Dec 2008

19

Present Possibility:

Thermal Analysis with 3 cups: presently for gray iron

This gray value is the right estimation of what we will probably obtain

in the casting regarding the white and the graphitic iron

SORELMETAL

PMC Dec 2008

Caldobase = Fonte de Base

C=3.64

Si=1.72

S=0.011

Cu=0.05

Mn=0.15

Concrete

Examples:

1 = Fonte de Base avec ajout de graphite

C=3.66

Si=1.72

SORELMETAL

20

Temprature four=1494

Temprature four=1512

PMC Dec 2008

1inoculada = Fonte traite _ en poche

C=3.62

Si=2.4

S=0.003

Mg=0.044

0.4% inoc.

Concrete

Examples:

2inoculada = Fonte traite _ en poche

C=3.69

Si=2.34

S=0.002

SORELMETAL

Mg=0.041

0.4% inoc.

21

Temprature poche=1405

Temprature poche=1395

PMC Dec 2008

22

1200

1180

1160

Liquidus

Time

Eutectique bas

13:55

Eutectique haut

1140

14:30

1120

14:40

1100

13:40

13:55

14:35 with Te

T solidus = 1119C

Gray Iron

SORELMETAL

14:09

14:24

35

30

25

20

15

10

5

0

-5

14:38

14:50

14:52

without Te

without Te + 1 Kg/T of good

graphite, Tfurnace = 1394C

without Te + strong

inoculation in the cup

graphite + 1.5Kg FeSi

correction, T furnace = 1470C

Surfusion

3.95

Recalescence

Ceq

3.9

3.85

Super

3.8

13:55

14:30

14:40

14:50

3.75

PMC Dec 2008

23

1160

Time

1155

1150

15:45

1145

15:50

1140

15:55

1135

Liquidus

1130

Eut ect ique bas

1125

15:36

16:10

16:20

Eut ect ique haut

15:50

16:04

16:19

16:33

16:25

without Te, T furnace =

1413C

without Te + 1 Kg/T of good

graphite

without Te + inoculation

without Te, T furnace =

1529C

without Te after Mg treatment

without Te with ladle

inoculation

25

4.4

4.35

4.3

4.25

4.2

4.15

4.1

4.05

Surfusion

16:00 with Te

T solidus = 1128C

20

15

Recalescence

Ceq

10

5

Ductile Iron

SORELMETAL

0

15:45 15:50 15:55 16:10 16:20 16:25

PMC Dec 2008

24

Conclusions:

Thermal Analysis can check:

the risk to obtain Fe3C and inverse chill

the risk to obtain shrinkage or porosities

Thermal Analysis gives a very good quality index by

the undercooling value

Thermal Analysis is cheap, has a good reproducibility,

human influence is low, traceability is easy

SORELMETAL

PMC Dec 2008

25

SORELMETAL

PMC Dec 2008

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Gratuity Application Sachin KumbharDokument1 SeiteGratuity Application Sachin KumbharSachin KumbharNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- SheetDokument24 SeitenSheetSachin KumbharNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- APR-22 CLD 4th WeekDokument10 SeitenAPR-22 CLD 4th WeekSachin KumbharNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- SheetDokument24 SeitenSheetSachin KumbharNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- ALL INDIA SAINIK SCHOOLS ENTRANCE EXAM AISSEE - AISSEE - 2024 - India Vidhi KumbharDokument1 SeiteALL INDIA SAINIK SCHOOLS ENTRANCE EXAM AISSEE - AISSEE - 2024 - India Vidhi KumbharSachin KumbharNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- MAPL Day Wise Plan Vs Actual May Week1-4Dokument36 SeitenMAPL Day Wise Plan Vs Actual May Week1-4Sachin KumbharNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Observations 05.11.2022Dokument7 SeitenObservations 05.11.2022Sachin KumbharNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Environmental Requirements STDDokument13 SeitenEnvironmental Requirements STDSachin KumbharNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Aspect ImpactsDokument36 SeitenAspect ImpactsSachin KumbharNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Side HSG LH & RH Cold Patch 14.2.23 DetailsDokument2 SeitenSide HSG LH & RH Cold Patch 14.2.23 DetailsSachin KumbharNoch keine Bewertungen

- Packing Standard For BPW HubDokument4 SeitenPacking Standard For BPW HubSachin KumbharNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- MAPL Plan 23 Jan To 31 JanDokument28 SeitenMAPL Plan 23 Jan To 31 JanSachin KumbharNoch keine Bewertungen

- 07.data For PPT OCT-21Dokument94 Seiten07.data For PPT OCT-21Sachin KumbharNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- SapreDokument20 SeitenSapreSachin KumbharNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Final ProgrammeDokument4 SeitenFinal ProgrammeSachin KumbharNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- PFMEA RankingDokument1 SeitePFMEA RankingSachin KumbharNoch keine Bewertungen

- Workplace Inspection Checklist: General Yes No NotesDokument4 SeitenWorkplace Inspection Checklist: General Yes No NotesSachin KumbharNoch keine Bewertungen

- kalpur-FE KSP SleevesDokument6 Seitenkalpur-FE KSP SleevesSachin KumbharNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- 8 D For ShrinkageDokument6 Seiten8 D For ShrinkageSachin KumbharNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Workplace Inspection Checklist: General Yes No NotesDokument4 SeitenWorkplace Inspection Checklist: General Yes No NotesSachin KumbharNoch keine Bewertungen

- Graphite NodulesDokument10 SeitenGraphite NodulesSachin KumbharNoch keine Bewertungen

- Vastu Colors For HomeDokument2 SeitenVastu Colors For HomeSachin KumbharNoch keine Bewertungen

- Roles of Health and Safety Committees: Hazard Identification, Evaluation, and ControlDokument12 SeitenRoles of Health and Safety Committees: Hazard Identification, Evaluation, and ControlSachin KumbharNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Oct-2020 Salvage ReportDokument6 SeitenOct-2020 Salvage ReportSachin KumbharNoch keine Bewertungen

- Control of Non-Conforming ProductsDokument10 SeitenControl of Non-Conforming ProductsSachin KumbharNoch keine Bewertungen

- PM/IS 5522/1 May 2019Dokument11 SeitenPM/IS 5522/1 May 2019Sachin KumbharNoch keine Bewertungen

- Mahalaxmi Calendar 2020 PDFDokument12 SeitenMahalaxmi Calendar 2020 PDFSachin KumbharNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Additives - Overview - EN ASK ChemicalDokument12 SeitenAdditives - Overview - EN ASK ChemicalSachin KumbharNoch keine Bewertungen

- Product - Overview - EN Antiveining CoatingDokument12 SeitenProduct - Overview - EN Antiveining CoatingSachin KumbharNoch keine Bewertungen

- Carborundum Industrial Catalog-CA1000Dokument172 SeitenCarborundum Industrial Catalog-CA1000John Pham NgocNoch keine Bewertungen

- MWF BrochureDokument6 SeitenMWF BrochurejohnsopranaNoch keine Bewertungen

- Effects of MN, P, S, Si, VDokument2 SeitenEffects of MN, P, S, Si, Vfaizalzol0% (1)

- Material Guide 2.0Dokument10 SeitenMaterial Guide 2.0Randy RappNoch keine Bewertungen

- Extractive Metallurgy of Gold. 2-: Fathi HabashiDokument20 SeitenExtractive Metallurgy of Gold. 2-: Fathi HabashieverolguinNoch keine Bewertungen

- Use Appropriate Strategies in Unlocking The: Meaning of Unfamiliar Words. (EN8V-Ie-4)Dokument17 SeitenUse Appropriate Strategies in Unlocking The: Meaning of Unfamiliar Words. (EN8V-Ie-4)anneNoch keine Bewertungen

- Hemsaw Practical Cutting GuideDokument38 SeitenHemsaw Practical Cutting GuideAntonius PrakosaNoch keine Bewertungen

- Electrician Job Interview Questions and AnswersDokument8 SeitenElectrician Job Interview Questions and AnswersAjay Chowdary Ajay ChowdaryNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Reclamation of Moisturized Flux in Submerged Arc WeldingDokument3 SeitenReclamation of Moisturized Flux in Submerged Arc WeldingIslam SahafayatNoch keine Bewertungen

- Comparison Between B31.3 & en 13480Dokument84 SeitenComparison Between B31.3 & en 13480sj2283% (6)

- Technical Bc-Bl-Bd-Be Sheet: Sheaves For Wire RopeDokument4 SeitenTechnical Bc-Bl-Bd-Be Sheet: Sheaves For Wire RopesandiluluNoch keine Bewertungen

- Tent StructuresDokument8 SeitenTent StructuresGUNJANNoch keine Bewertungen

- Self Priming Centrifugal Pump: Model T8A3S BDokument8 SeitenSelf Priming Centrifugal Pump: Model T8A3S BBeto LoayzaNoch keine Bewertungen

- MV Distribution TransformersDokument11 SeitenMV Distribution TransformerswaseemsamsodienNoch keine Bewertungen

- Material Data Sheet Mds D55 Rev. 5: TYPE OF MATERIAL: Ferritic/Austenitic Stainless Steel, Type 25Cr DuplexDokument1 SeiteMaterial Data Sheet Mds D55 Rev. 5: TYPE OF MATERIAL: Ferritic/Austenitic Stainless Steel, Type 25Cr Duplex1380miniNoch keine Bewertungen

- Angle Grinder StandDokument24 SeitenAngle Grinder StandVargNoch keine Bewertungen

- Transformers & Ring Main UnitsDokument57 SeitenTransformers & Ring Main Unitsoadipphone7031100% (1)

- Brochure EU PDFDokument12 SeitenBrochure EU PDFNewaz KabirNoch keine Bewertungen

- The Effect of Heat Treatment On Interface Properties of S45CDokument8 SeitenThe Effect of Heat Treatment On Interface Properties of S45CRamon BrownNoch keine Bewertungen

- Hot Cracking Susceptibility of Austenitic Stainless Steels: by T. Ogawa and E. TsunetomiDokument12 SeitenHot Cracking Susceptibility of Austenitic Stainless Steels: by T. Ogawa and E. Tsunetomipradip meneNoch keine Bewertungen

- Vertic Altifix Anchor PostDokument7 SeitenVertic Altifix Anchor PostSIZ Contract0% (1)

- A488 13208-2Dokument18 SeitenA488 13208-2DeepakRajurkarNoch keine Bewertungen

- BS3100 A2Dokument11 SeitenBS3100 A2AlexNoch keine Bewertungen

- BS IndexDokument11 SeitenBS IndexShirleyLiuNoch keine Bewertungen

- Metal Injection Moulding - EPMADokument36 SeitenMetal Injection Moulding - EPMAmomiercolesNoch keine Bewertungen

- Manning's Roughness CoefficientDokument2 SeitenManning's Roughness Coefficientdjuka15Noch keine Bewertungen

- Reverse Tehnique LS 7551 TECHDokument1 SeiteReverse Tehnique LS 7551 TECHAna_DragoiNoch keine Bewertungen

- Phase Diagrams - 040823Dokument23 SeitenPhase Diagrams - 040823Anthony MubangaNoch keine Bewertungen

- Metal and ExtractionDokument57 SeitenMetal and ExtractionMirawati EfendiNoch keine Bewertungen

- Steel Design CE 408Dokument23 SeitenSteel Design CE 408gundulpNoch keine Bewertungen