Beruflich Dokumente

Kultur Dokumente

Basic Welding Theory

Hochgeladen von

AdangCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Basic Welding Theory

Hochgeladen von

AdangCopyright:

Verfügbare Formate

Welder Handbook PT McDermott Indonesia

TEORI DASAR

PENGELASAN

Welder Handbook PT McDermott Indonesia

1. POLARITY

A welder should understand the meaning of polarity, and recognize what effect it has

on the welding process. For proper penetration, uniform bead appearance and good

welding result, the correct polarity must be used when welding with any wire or

electrode.

Incorrect polarity will cause: poor penetration, Irregular bead shape, excessive spatter,

difficult to control the arc, overheating, and rapid burning of wire or electrode.

ARC BLOW

Occurs when the arc refuses to go where it is supposed to, blows wildly forward or

back, and produces spatters badly.

Most frequently encountered at the start and finish of joints, and in corners and

deep grooves, particularly when high amperages are being used in welding thick.

Makes welding very difficult, reduce speed and lowers weld quality

When the arc blow opposite to the direction of travel it is called back blow.

When the arc blows with the direction of travel, it is called forward blow.

Is caused by magnetic force acting on the arc, making the arc blow from its normal

path.

TO REDUCE ARC BLOW:

Reduce current

Weld toward a heavy tack or toward a weld already made

Use back stepping on long welds

Place ground connection as for from joint to be welded as is possible

If back blow is in the problem, place ground connection at start of weld and weld

towards a heavy tack

If forward blow causes trouble, place ground connection at the end of weld

Welder Handbook PT McDermott Indonesia

Wrap ground cable around the work piece and pass ground current through it in

such a direction that magnetic field will be set-up to neutralize the magnetic field

causing the blow

Hold as short and arc possible to help the arc force counteract the arc blow

If the machine bring used is of type producing both AC&DC, switch to AC.

Welder Handbook PT McDermott Indonesia

2. THE EFFECT OF THE WELDING HEAT ON METAL

Metals become larger when heated and become smaller upon cooling. During welding

the arc heats the metal being welded, causing it to become larger or expand. As the

heat is removed, the surrounding metal and air cause a cooling effect upon the heated

area, which results in the metal becoming smaller, or contracting. When this

expansion and contraction is not controlled, distortion (warping) is likely to result. On

the other extreme, if expansion and contraction is restrained, or controlled too rigidly,

severe stress and strain may result and impair the weld.

Three rules can be followed to aid in the prevention and control of distortion:

Reduce the forces that cause shrinkage.

Make shrinkage forces work to reduce distortion

Balance shrinkage force with other forces.

Reduce the force that cause shrinkage:

Avoid over welding

Over welding causes distortion, it is a waste of time and money. In certain cases it

may even weaken the joint.

Use proper joint preparation and fit-up

Use intermittent welds

Use back step welding method

Make shrinkage force work to minimize distortion

Pre-set parts out of position

Space parts to allow for shrinkage

Pre-bend (pre-camber)

Balance shrinkage forces with other forces

Balance one shrinkage force with another, i.e. by welding alternatively on both

sides.

Peering (but no advisable)

Welder Handbook PT McDermott Indonesia

Use of jigs and fixtures such as clamps, jigs, strong backs to hold the work in a

rigid position during welding.

Welder Handbook PT McDermott Indonesia

Legends:

Contraction in the weld & HAZ along

the length.

Bowing due to the greater volume

of metal at the top of the weld

Peaking due to the V angle

Ripple (in sheet) away from the weld

Contraction in the weld metal and

HAZ transverse to the weld

BACK STEP METHOD

Welder Handbook PT McDermott Indonesia

Welder Handbook PT McDermott Indonesia

3. TO STRIKE AND ESTABLISH AN ARC

The basis of arc welding is the continuous electric arc. The arc is maintained when the

welding current is force across gab between the electrode tip and bar metal. A welder

must be able to strike and establish the correct arc easily and quickly.

a.

Too long arc length

Increase of spatter

Poor penetration

Sound of arc will be more

of a hiss than a crackle

Metal will melt off the electrode

in large drops

Slag removal will be difficult

Welder Handbook PT McDermott Indonesia

b. Travel speed too fast

Bead will be thin & stringy

Poor penetration

c. Travel speed too slow

Weld metal will pile up and roll over

Excessive overlap

d.

Amperage too high

Bead will be flat

Excessive spatter

Excessive porosity

Electrode becomes overheated

e. Amperage too low

Difficult in striking the arc

Difficult in maintaining

correct arc length

Weld metal pile up

Excessive overlap

Poor penetration

LEGENDS:

Made by a correct procedure

To restart a continuous bead:

Amperage too low

Strike the arc

Spatter and undercut caused by excessively high amperage

Move the electrode to the crown of the crater

Voltage too low

Resume forward travel

Excessively high voltage or long arc

Travel speed too slow

Travel speed too fast

Welder Handbook PT McDermott Indonesia

10

4. RUNNING BEAD WITH WEAVING MOTION

Weaving is an oscillating motion, back and forth, crosswise to the direction of travel.

These motions are used to:

Flat out slag,

Deposit a wider bead,

Secure good penetration at the edge of the weld,

Allow gas to escape,

Avoid porosity.

Types of weaving motion:

The weave should not be wider than three times the diameter of electrode. And the

purpose accomplished by both these motions is substantially the same and their

usage is largely a matter of preference.

Welder Handbook PT McDermott Indonesia

Lap weld in the horizontal and flat position

11

Welder Handbook PT McDermott Indonesia

5. WELDING TECHNIQUES IN ALL POSITIONS

Fillet weld in the horizontal or flat position

Butt Weld in the horizontal position

12

Welder Handbook PT McDermott Indonesia

Running a bead in the vertical position welding down

Running a bead in the vertical position uphill progression.

13

Welder Handbook PT McDermott Indonesia

14

Running a bead in the overhead position

6. REHEAT AND INTERPASS CONTROL

The main reason for preheating and interpass control is to lower the cooling rate in the

Weld Metal (WM) and Heat Affected Zone (HAZ). The lower cooling rate, the lesser

the chance WM and Base Metal (BM) cracking. It lowers the chances of shrinkage

stresses. It will maintain the desired properties of the weld and the base material.

PREHEAT METHODS

Portable heating torches with rosebud tips

Ceramic heating elements

PREHEAT AREAS

At least 3 (75mm) away from the joint towards the center of the joint.

Preheat both external and internal (if accessible) areas of the joint.

MONITORING OF PREHEAT TEMPERATURES

Use temperature indicating crayon (ex: tempil stick) with the appropriate preheat

temperature requirements.

Apply to the joint at least one minute after preheated, 3 away from the joint.

MONITORING OF INTERPASS TEMPERATURE

Use temperature indicating crayons (tempil stick)

Apply to the joint at least one inch away from the welded joint.

Welder Handbook PT McDermott Indonesia

15

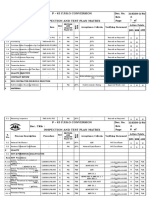

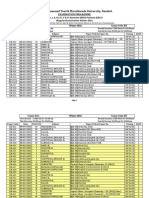

7. HOW TO READ AND USE THE WELDING PROCEDURE

SPECIFICATION (WPS)

Welding Procedure Specification is a specific guide for welders in execute their job.

Welder must understand the contents of a welding procedure and must be able to

identify the parameters stated in the WPS.

When there is doubt in executing a weld, always refer to the WPS for guidance.

Always follow the parameter in the welding procedure. DO NOT WELD WITHOUT A

WELDING PROCEDURE IN YOUR WORK AREAS.

HOW TO READ METHOD STATEMENT AND SPECIAL INSTRUCTION?

Certainly critical applications will require additional instructions to ensure that the work

will be done correctly. This instruction will supplement the welding procedure and

should also be followed strictly. The method statement will be displayed in the work

areas.

7. HOW TO READ AND USE THE WELDING PROCEDURE

SPECIFICATION (WPS)

Das könnte Ihnen auch gefallen

- Keylontic DictionaryDokument13 SeitenKeylontic Dictionaryvanesau2100% (8)

- NBR 6123 Building Construction - Bases For Design of Structures - Wind LoadsDokument102 SeitenNBR 6123 Building Construction - Bases For Design of Structures - Wind LoadsJosé de Paula MoreiraNoch keine Bewertungen

- Piping Isometric MaterrilalsDokument41 SeitenPiping Isometric MaterrilalsMonica HartNoch keine Bewertungen

- How TG-X Filler Rods Can Eliminate Back Shielding: Kobelco Welding TodayDokument2 SeitenHow TG-X Filler Rods Can Eliminate Back Shielding: Kobelco Welding TodaysatheeshNoch keine Bewertungen

- Basic Welding TheoryDokument12 SeitenBasic Welding TheoryBudimanNoch keine Bewertungen

- Arc Welding - Basic Steps ReadingDokument12 SeitenArc Welding - Basic Steps Readingaddayesudas100% (1)

- Final Practice Examination Answer Key: Rade HysicsDokument40 SeitenFinal Practice Examination Answer Key: Rade HysicsNenbon NatividadNoch keine Bewertungen

- Cigweld-Deposited Rates PDFDokument7 SeitenCigweld-Deposited Rates PDFNam_HitechNoch keine Bewertungen

- Piping Training - Section I - Piping ComponentsDokument24 SeitenPiping Training - Section I - Piping Componentsarshad1000100% (2)

- Mathematical Modelling of GTAW and GMAWDokument240 SeitenMathematical Modelling of GTAW and GMAWpatriciatavares2009100% (2)

- Visual Inspection Pr.Dokument7 SeitenVisual Inspection Pr.mtariqmasood100% (1)

- Piping CodesDokument3 SeitenPiping Codesmexx4u2nvNoch keine Bewertungen

- Welding Process and ConsumableDokument64 SeitenWelding Process and Consumablenizar_ikmps100% (1)

- Welding Procedures and Inspection Methodology For In-Service WeldingDokument14 SeitenWelding Procedures and Inspection Methodology For In-Service WeldingEl_memitoNoch keine Bewertungen

- Applying Shielded Metal Arc Welding TechniquesDokument134 SeitenApplying Shielded Metal Arc Welding Techniquesgaspardo123Noch keine Bewertungen

- PEGS-0710-COR-038 - External Cathodic Protection of Onshore Deep Well CasingDokument34 SeitenPEGS-0710-COR-038 - External Cathodic Protection of Onshore Deep Well CasingĐiệnBiênNhâm0% (1)

- 4.2 Design of Welded Joints v3Dokument50 Seiten4.2 Design of Welded Joints v3adrianhhhh1984Noch keine Bewertungen

- Welding Inspection HandbookDokument7 SeitenWelding Inspection HandbookDeepak Malhotra0% (1)

- Uphill Versus Downhill Welding PDFDokument4 SeitenUphill Versus Downhill Welding PDFPatrick DominguezNoch keine Bewertungen

- Types of Flanges-Definition of FlangesDokument4 SeitenTypes of Flanges-Definition of FlangesindikumaNoch keine Bewertungen

- Fillet WeldsDokument17 SeitenFillet Weldssoroush1111Noch keine Bewertungen

- CSWIP 3.2-2010 WIS10 Senior Welding InspectionDokument302 SeitenCSWIP 3.2-2010 WIS10 Senior Welding Inspectionapply19842371100% (9)

- كيفية حساب كمية سلك اللحام المطلوبةDokument6 Seitenكيفية حساب كمية سلك اللحام المطلوبةBoodyBedaiwe50% (2)

- Most Common Types of Welding Defects PDFDokument6 SeitenMost Common Types of Welding Defects PDFManila CastilloNoch keine Bewertungen

- NDT - Dye PenetrateDokument10 SeitenNDT - Dye PenetrateAbuja sygNoch keine Bewertungen

- Hydro Test ProcedureDokument17 SeitenHydro Test Procedureyaser elgoharyNoch keine Bewertungen

- WeldQ Test Centre Examiner Manual v1.3Dokument63 SeitenWeldQ Test Centre Examiner Manual v1.3mammad EhsaniNoch keine Bewertungen

- Bleed Ring - ANSI Class 150-2500 (In)Dokument2 SeitenBleed Ring - ANSI Class 150-2500 (In)ulfatNoch keine Bewertungen

- Ipc2012 90605Dokument8 SeitenIpc2012 90605Marcelo Varejão CasarinNoch keine Bewertungen

- Civil Question and AnswerDokument20 SeitenCivil Question and AnswerAnirudh AgarwallaNoch keine Bewertungen

- Pipelines Welding HandbookDokument64 SeitenPipelines Welding HandbookSixto GerardoNoch keine Bewertungen

- Comparision of NDT Methods: Technical & CostsDokument11 SeitenComparision of NDT Methods: Technical & Costskailash100% (1)

- BS 499 PT2-1980Dokument23 SeitenBS 499 PT2-1980Krishna KumarNoch keine Bewertungen

- WeldingDokument13 SeitenWeldingAna Hidayah SyuhadaNoch keine Bewertungen

- Creep and Creep Damage Assessment in P91 Weld JointsDokument12 SeitenCreep and Creep Damage Assessment in P91 Weld JointsDeepakNoch keine Bewertungen

- Fillet WeldingDokument36 SeitenFillet WeldingDaria D'souzaNoch keine Bewertungen

- Finite Element Analysis and Opmization of Weld Distortion ChassisDokument6 SeitenFinite Element Analysis and Opmization of Weld Distortion ChassisJuan Sebastian CameroNoch keine Bewertungen

- Pi̇pe WorksDokument185 SeitenPi̇pe Workscevhos100% (1)

- ITP For Piping WorksDokument44 SeitenITP For Piping WorksSyafril Akbar100% (3)

- Pressure Vessel Fabrication ManualDokument67 SeitenPressure Vessel Fabrication Manualabhi_mohit2005100% (2)

- WeldDecayTesting TechSheet Sfs PDFDokument0 SeitenWeldDecayTesting TechSheet Sfs PDFNooruddin SheikNoch keine Bewertungen

- Weld CalculationDokument7 SeitenWeld CalculationDenny Syamsuddin100% (1)

- A Comparison Study of Pressure Vessel Design Using Different Standards PDFDokument319 SeitenA Comparison Study of Pressure Vessel Design Using Different Standards PDFJM100% (1)

- ME 328.3 E5 - Welding MetallurgyDokument41 SeitenME 328.3 E5 - Welding Metallurgytbmari100% (1)

- A Study On Welding Defects of Pressure VesselDokument24 SeitenA Study On Welding Defects of Pressure Vesseladamahmad1992100% (1)

- What Is The Difference Between A Weldolet and A SockoletDokument3 SeitenWhat Is The Difference Between A Weldolet and A SockoletWaqas Waqas100% (3)

- Electrode Consumption On Pipe WeldingDokument2 SeitenElectrode Consumption On Pipe Weldinganjangandak2932100% (1)

- QC Inspector (Offshore Pipeline Installation) Jobs in Propel Consult in UAE - United Arab Emirates - NaukrigulfDokument7 SeitenQC Inspector (Offshore Pipeline Installation) Jobs in Propel Consult in UAE - United Arab Emirates - NaukrigulfAshif IqubalNoch keine Bewertungen

- Numerical Analysis On The Effect of Welding Parameters in TIG Welding For INCONEL 625 AlloyDokument7 SeitenNumerical Analysis On The Effect of Welding Parameters in TIG Welding For INCONEL 625 AlloyErin BarryNoch keine Bewertungen

- Fillet Welded Joints - A Review of The Practicalities - Job Knowledge 66Dokument4 SeitenFillet Welded Joints - A Review of The Practicalities - Job Knowledge 66Anuj ShahiNoch keine Bewertungen

- The Rotary Draw Tube Bending GuideDokument13 SeitenThe Rotary Draw Tube Bending GuideFernandoNass100% (3)

- Coating Work Inspection Report 1Dokument1 SeiteCoating Work Inspection Report 1Jagannath SahuNoch keine Bewertungen

- 1.1 Welding Procedure Specification (WPS)Dokument35 Seiten1.1 Welding Procedure Specification (WPS)Mohamed WahidNoch keine Bewertungen

- Fabrication Work Flow 2014Dokument49 SeitenFabrication Work Flow 2014Herman_ms2000Noch keine Bewertungen

- Welding & Cutting ProcessDokument16 SeitenWelding & Cutting ProcesscvNoch keine Bewertungen

- Gtaw WeldingDokument37 SeitenGtaw WeldingSadhasivam VeluNoch keine Bewertungen

- Elbow DegreesDokument5 SeitenElbow DegreesMehman NasibovNoch keine Bewertungen

- Welding AWSDokument90 SeitenWelding AWSKhairil AminNoch keine Bewertungen

- Basic Welding TheoryDokument15 SeitenBasic Welding TheoryCarina MostralesNoch keine Bewertungen

- Essential Variables of SmawDokument7 SeitenEssential Variables of SmawAbdallah Mansour100% (6)

- Smaw Module New-Slht 11Dokument7 SeitenSmaw Module New-Slht 11Felix MilanNoch keine Bewertungen

- Information Sheet 8.2.1 Striking An ArcDokument4 SeitenInformation Sheet 8.2.1 Striking An ArcJerryson CabriasNoch keine Bewertungen

- Sonar-Based Volumetric Flow Meter ForDokument8 SeitenSonar-Based Volumetric Flow Meter Foramir sadighiNoch keine Bewertungen

- Key Change For 2011EN12464-1 PDFDokument19 SeitenKey Change For 2011EN12464-1 PDFJibaNoch keine Bewertungen

- NPS - 003 - 015 Tech Specs For 33kV 66kV 132kV Post InsulatorsDokument13 SeitenNPS - 003 - 015 Tech Specs For 33kV 66kV 132kV Post InsulatorsandcrisdanmatNoch keine Bewertungen

- Assessment Task 1 - Analysis of Different Text TypesDokument5 SeitenAssessment Task 1 - Analysis of Different Text TypesMohd ShaeezwanNoch keine Bewertungen

- Chen IEEE ASME Trans Mechatronics 2006Dokument7 SeitenChen IEEE ASME Trans Mechatronics 2006Edmund Luke Benedict SimpsonNoch keine Bewertungen

- Swami Ramanand Teerth Marathwada University, NandedDokument19 SeitenSwami Ramanand Teerth Marathwada University, NandedsmpopadeNoch keine Bewertungen

- Oiml R 137-1 & - 2 2009Dokument55 SeitenOiml R 137-1 & - 2 2009Marco VeraNoch keine Bewertungen

- MIDAS ChecklistDokument27 SeitenMIDAS ChecklistBhagirath JoshiNoch keine Bewertungen

- W5 - Liberty Union HSD - R.SpecificHeatExtraPractice - ANSWERKEYDokument5 SeitenW5 - Liberty Union HSD - R.SpecificHeatExtraPractice - ANSWERKEYMirjeta ZymeriNoch keine Bewertungen

- Pages From BeerVectorISM - C16P001P164 Problem 16-135, 16-136 PDFDokument8 SeitenPages From BeerVectorISM - C16P001P164 Problem 16-135, 16-136 PDFSerafinNoch keine Bewertungen

- Distillation Separation of Ethyl Acetate and WaterDokument4 SeitenDistillation Separation of Ethyl Acetate and WaterAleja GarzoonNoch keine Bewertungen

- Module 3 I Mechanical Analysis of Soils, Grain Size Distribution Ti CurveDokument2 SeitenModule 3 I Mechanical Analysis of Soils, Grain Size Distribution Ti CurveJohn Paul LiwaliwNoch keine Bewertungen

- Methods of Interstellar TravelDokument4 SeitenMethods of Interstellar TravelTimurNoch keine Bewertungen

- Engineering Drawing Project ReportDokument16 SeitenEngineering Drawing Project Report29 - 023 - Abid HasanNoch keine Bewertungen

- P DeltaDokument15 SeitenP DeltaAnnamalai VaidyanathanNoch keine Bewertungen

- Xe Sierra SG Modbus PDFDokument4 SeitenXe Sierra SG Modbus PDFLi TANGNoch keine Bewertungen

- Oscillatory Motion Learning Objectives:: Teaching StrategiesDokument3 SeitenOscillatory Motion Learning Objectives:: Teaching Strategiesآية حافظNoch keine Bewertungen

- 10th Maths (EM)Dokument352 Seiten10th Maths (EM)Murali MohanNoch keine Bewertungen

- Lesson Plan: Institute of Space TechnologyDokument6 SeitenLesson Plan: Institute of Space TechnologyShahzaib Anwar OffNoch keine Bewertungen

- MATCON - Experiment 5 Group 1Dokument7 SeitenMATCON - Experiment 5 Group 1Yolanda SelgaNoch keine Bewertungen

- Third Periodical Test SCIENCEDokument2 SeitenThird Periodical Test SCIENCEJoan Claire RegisNoch keine Bewertungen

- Design of Reinforced Concrete BeamDokument2 SeitenDesign of Reinforced Concrete BeamAndro RebuyasNoch keine Bewertungen

- Phy2 11 - 12 Q3 0101 FD 1Dokument16 SeitenPhy2 11 - 12 Q3 0101 FD 1Earl Clyde BañezNoch keine Bewertungen

- Volume BolaDokument14 SeitenVolume BolaLyfia SilitongaNoch keine Bewertungen

- AE 424 PPT 2.2 Physical CharacteristicsDokument48 SeitenAE 424 PPT 2.2 Physical CharacteristicsJohn Client Aclan RanisNoch keine Bewertungen

- Á1229.1Ñ Steam Sterilization by Direct Contact: 7698 Á1229ñ / General Information USP 41Dokument4 SeitenÁ1229.1Ñ Steam Sterilization by Direct Contact: 7698 Á1229ñ / General Information USP 41Yuli BlandónNoch keine Bewertungen

- Simulado - 1 IPhoDokument9 SeitenSimulado - 1 IPholeonardo sathlerNoch keine Bewertungen