Beruflich Dokumente

Kultur Dokumente

Reformer CH4 2

Hochgeladen von

Jose ValderramaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Reformer CH4 2

Hochgeladen von

Jose ValderramaCopyright:

Verfügbare Formate

Preprints of the 8th IFAC Symposium on Advanced Control of Chemical Processes

The International Federation of Automatic Control

Furama Riverfront, Singapore, July 10-13, 2012

Optimization of a methane autothermal reforming-based hydrogen

production system with low CO2 emissions

Wei Wu*,a and Chutima Tungpanututhb

a

Department of Chemical Engineering, National Cheng Kung University, Tainan 70101, Taiwan, R.O.C.

Department of Chemical and Materials Engineering, National Yunlin University of Science and Technology, Douliou, Yunlin

64002, Taiwan, R.O.C.

Abstract: The aim of this work is to develop a hydrogen production system with respect to saving energy

and reducing carbon dioxide. Methane and carbon dioxide are major feedstocks of an autothermal

reformer (ATR) and a CO2 reformer, respectively. The waste heat recovery technique is applied to build a

stand-alone ideal heat-integrated system. The proposed system configuration and optimal operating

conditions are verified with the Aspen HYSYS simulator.

Keywords: Autothermal reforming; CO2 reformer; Hydrogen production; Heat recovery; Optimization

Ersoz et al. [13] provided a simulation study for a fuel cell

system combined with a methane ATR-based hydrogen

production process. Furthermore, the optimization of the

methane ATR process with regard to the conflict between the

increase in hydrogen yield and the reduction in carbon

monoxide has also been investigated [14, 15]. Using a similar

approach, Silva et al. [16] undertook the simulation and

optimization of a glycerol ATR-based hydrogen production

process with the assistance of Aspen HYSYS.

1. Introduction

About 95% of the hydrogen that was produced in the U.S.

used a reforming process with natural gas as the feedstock.

The conventional process primarily consists of two steps.

First, the reformation of the feedstock with high temperature

steam to obtain a syngas and, second, a water gas shift (WGS)

reaction that produces hydrogen, carbon dioxide, and a few

residual materials [1]. As for fuel cell applications, the

pressure swing adsorption (PSA) process is connected to the

WGS reactor such that the purity of hydrogen can reach

almost 99.99+%, and the waste gas of PSA may flow into a

preferential oxidation (PROX) reactor to produce the high

temperature flue gas [2]. Moreover, the modeling, simulation

and optimization of a class of hydrogen production processes

using the Aspen HYSYS process simulator have been

studied [3, 4].

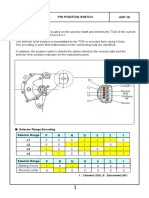

2. Description of Major Process Units

There are five major process units in our methane

autothermal reforming-based hydrogen production process.

Three two-phase streams of methane, water and air (oxygen)

are well mixed at room temperature with two molar ratios of

water-to-methane (H 2 O/CH 4 ) and oxygen-to-methane

(O 2 /CH 4 ) . The mixed stream is pre-heated by a heater

equipment and flows into the autothermal reforming (ATR)

reactor at the prescribed inlet temperature, TATR,in . Assuming

In general, methane reforming processes constantly generate

a large amount of carbon dioxide from the steam methane

reformer (SMR), WGS reactor and PROX reactor. The CO2

capture technologies including MEA absorption and

membrane processes can be devoted to reducing greenhouse

gas emissions [5, 6], but the capture and storage of CO2 need

additional electricity. Nord et al. [7] used the pre-combustion

CO2 capture technique to effectively reduce greenhouse gas

emissions. Recently, Fan et al. [8] utilized greenhouse gases

through the CO2 reforming process with specific catalysts to

improve hourly space velocity and hydrogen production, and

Fan et al. [9] studied the optimization of hydrogen

production from CO2 reforming of methane via experiments.

With regard to methane reforming-based hydrogen

production processes, a combination of partial oxidation and

steam reforming of methane in an autothermal reforming

(ATR) reactor has recently become more popular. The

modeling, kinetic analysis, and simulation of ATR of

methane for prescribed reactors have been studied [10-12].

IFAC, 2012. All rights reserved.

that the system is an adiabatic reactor with packed catalysts,

the major reactions are described as follows.

CH + 2O CO + 2H O ( ), H10 =-802.3kJ/mol (1)

CH + H O CO + 3H ( ), H 0 = 206.2 kJ/mol

2

(2)

CO + H O CO + H ( ),

(3)

H30= - 41.2 kJ/mol

CH + 2H O CO + 4H ( ), H 40 =165.0 kJ/mol (4)

and the kinetic rate equations for

661

are expressed as [10],

8th IFAC Symposium on Advanced Control of Chemical Processes

Furama Riverfront, Singapore, July 10-13, 2012

where

=

.

.

&

!"# !#

!"$ !#

&

'

*+

'&

*+

and

K e5 = exp(30782/ T + 42.97) . The CO2 reformer produces

syngas which is similar to the steam reforming of methane,

i.e. the large amount of CO in the outlet stream of the CO2

reformer is reproduced. Moreover, another high temperature

water gas shift (HTWGS) reactor with packed catalyst is

connected in order to convert components of CO and H2O in

the stream into CO2 and H2. The 600K operating temperature

of the HTWGS reactor is lower than that of the CO2 reformer,

so another heat exchanger for heat removal (i.e. a cooler) is

added to adjust the inlet temperature of HTWGS reactor,

(5)

k5 = 8.71 102 exp(23.7/ RT )

(6)

TWGS ,in . Moreover, the kinetic model of HTWGS is

(7)

expressed by,

PCO2 PH2

95 1.1 0.53

rWGS = 7.79 1014 exp

PCO PH2O 1

K e2 PCO PH2O

RT

=

where

/#

&.

!"# !#

'

*+

(8)

(11)

,- = 1 + /"$ !"$ + /# !# + /"# !"# +

Afterward the outlet stream of the HTWGS reactor flows into

the pressure swing adsorption (PSA) unit to produce high

purity hydrogen (99.95+%) by using a solid adsorbent, e.g.,

activated carbon can be separated. Assuming that the PSA

process is an isothermal one, the outlet composition of the

PSA is expressed as follows

. The reaction rate constant 01 = 021 exp(61 /89),

j=1, ,4, the adsorption constant for the combustion of

"

methane /:" = /2:

exp(<:" /89) , i=CH4, O2, and the

adsorption constant of species i /: = /2: exp(<: /89),

i=CO, H2, CH4, H2O. Notably, the rate equation is based on

the

temperature

dependence

of

the

Langmuir-Hinshelwood-Hougen-Watson (LHHW) model.

All kinetic data including kinetic parameters ( 021 , 61 ) ,

equilibrium constants ( /> , /> & , /> ) and adsorption

constants (/21 , <: ) are taken from the reference cited [10].

Since the outlet temperature of the ATR reactor could

be over 850K and the stream contains a high percentage of

carbon dioxide, a CO2 reformer aims to reduce the

greenhouse gas emission and increase hydrogen production

accordingly. In our approach, the outlet stream of the ATR

reactor needs to be mixed with the second feed flow of

methane ?CH |ABBC at room temperature, and the well-mixed

stream flows into the CO2 reformer at the prescribed inlet

temperature, TCO R,in . Assuming that the system is a

yH2 ,PSA ,out = S PSA

y i ,PSA ,out = (1 S PSA )

i = H2, CH4, CO, CO2, H2O

H G

(13)

(14)

where S PSA (= 99.95%) represents the hydrogen purity from

the PSA. Moreover, the mass flow rates of H2 and CO2 at two

exits of the PSA unit are,

(9)

with the corresponding kinetic model

= 0D F"# F"$

i ,PSA ,in

and the outlet composition of PSA waste gas is shown by

y i ,PSA ,in

y i ,PSA ,out =

yi ,PSA ,in + (1 S PSA ) y H2 ,PSA ,in

i = CH4, CO, CO2, H2O

nonisothermal tubular reactor with packed catalysts, the

reversible endothermic reaction proceeds in a CO2 reformer

[9],

CH + CO 2CO + 2H ( D ), HDE = 205 kJ/mol

y i ,PSA ,in

(12)

(10)

662

8th IFAC Symposium on Advanced Control of Chemical Processes

Furama Riverfront, Singapore, July 10-13, 2012

CH4 |LIJJK

298K, 1atm

CH4 |MIJJK

298K, 1atm

Figure 1 Methane autothermal reforming-based hydrogen production system

FH2 = y H2 ,PSA ,out FPSA ,in

methane ?CH |ABBC and inlet temperature of the CO2

(15)

reformer , TCO R ,in , are adjustable variables of the CO2

2

FCO2 = y CO2 ,PSA ,out FPSA ,in

(16)

reformer, and inlet temperature of the HTWGS reactor ,

TWGS ,in , is an adjustable variable of the HTWGS reactor.

When the waste gas of the PSA flows into a preferential

oxidation (PROX) reactor, the high temperature flue gas is

produced. The kinetics of the PROX reactor are simplified as

1

Cat

C

(17)

CO+ O2

CO2 , HCO

= 282.99 kJ/mol

2

Moreover, the operating conditions are set by the ATR with

H2O/CH4 =1.5 , O2 /CH 4 = 0.55 and TATR ,in = 773K , the CO2

reformer with ?CH |ABBC = 9.92 kg/h at 25C, and the

HTWGS reactor with TWGS ,in = 664K . Moreover, Fig. 2(a)

and the corresponding reaction rate is shown by

0.5 0.1

O2 CO

rCO = 3.528 10 exp( 33092 / RT )P P

2

(18)

demonstrates that the proposed hydrogen production system

with the aid of the CO2 reformer can ensure a higher

Notably, the built-in property database in the Aspen HYSYS

hydrogen flow rate and lower carbon dioxide flow rate than

provides accurate thermodynamic data, which are calculated

with the conventional design in Fig. 2(b). Obviously, the CO2

with the Peng-Robinson equation of state.

reformer can contribute to increased hydrogen production by

Demonstration: In Fig. 1, the water-to-methane molar ratio

consuming carbon dioxide. However, the CO2 reformer in

(H2O/CH4 ) , oxygen-to-methane molar ratio (O 2 /CH 4 ) , inlet

this process design needs an additional methane feed flow

due to a very low composition of methane in the outlet of

temperature of the ATR reactor, TATR ,in , are denoted as

ATR.

adjustable variables of the ATR unit, the second feed flow of

(a)

663

8th IFAC Symposium on Advanced Control of Chemical Processes

Furama Riverfront, Singapore, July 10-13, 2012

(b)

Figure 2 Methane ATR-based hydrogen production system: (a) CO2 reformer with the second feed of methane (b)

without CO2 reformer

To achieve reduce the energy needed and the carbon dioxide

produced, a heat recovery method, shown in Fig. 3, is

developed. The flue gas produced from the PROX reactor

goes through two heat exchangers to rapidly heat the inlet

flow of the ATR reactor, and the recirculating streams go

Figure 3

through another two heat exchangers to cool the outlet flow

of the CO2 reformer. Finally, the outlet stream of the fourth

heat exchanger (HX4) reaches a temperature of 774 K and

this can be treated as the heat source for the CO2 reformer.

Methane ATR-based hydrogen production system with waste heat recovery

I, the optimization algorithm for maximizing hydrogen

selectivity is described as follows.

(20)

max S H

Notably, the original devices of heater and cooler shown in

Fig. 2(a) are replaced by four heat exchangers. Using the

Aspen HYSYS simulator, although the waste heat recovery

design may reduce the hydrogen yield by about 2.5%, but the

total benefits with regard to saving energy make this process

worthwhile.

ui

subject to

573 K

3. Process Optimization

Maximizing the hydrogen yield and minimizing carbon

dioxide emissions are the optimization goals for the hydrogen

production system; presented in this work. Two optimization

strategies are introduced. First, the hydrogen selectivity in

terms of the flow rates leaving the reactor is defined as

T2UV- WU2X # 2YZ

RS = (T2UV- WU2X 2W 1)

\]^

, j = CH4, H2O, CO, CO2, O2 (19)

TATR ,in 823 K

0.3

O2 /CH4

H2O/CH4

0.7

2

803 K

TCO2R ,in 983 K

573 K

TWGS ,in 773 K

(21)

and the corresponding model equations have been built in the

Aspen HYSYS. Notably,

This shows that if the hydrogen product increases or the

carbon dioxide decreases in the outlet flow of the HTWGS

reactor, then the value of RS definitely increases. For Case

ui TATR ,in ,O2 /CH4 ,H2O/CH4 ,TCO2R ,in ,CH4 Feed ,TWGS ,in

664

8th IFAC Symposium on Advanced Control of Chemical Processes

Furama Riverfront, Singapore, July 10-13, 2012

represents one of decision variables. The upper and lower

limits of physical constraints are based on the previous study

of operating conditions for each reactor.

4. Conclusions

The configuration proposed in this work is an energy-saving

process, since the ATR reactor reduces energy consumption

by up to 57.4%, and the waste heat recovery design can

completely take over functions of heater and cooler. The

proposed system can also reduce carbon dioxide emissions,

because the CO2 reformer can reduce these by 42.54% and

increase hydrogen yield by over 13.60%. It has been verified

that the ATR reactor plus CO2 reformer can provide greater

hydrogen produce than the conventional SMR process.

However, both HTWGS and PROX reactors may generate a

large amount of CO2 if the waste heat is not enough and the

concentration of CO is too high.

Remark 2: The hydrogen selectivity is denoted as a sole

objective function, but the maximization of hydrogen

selectivity could identify the operating scenarios for

maximizing the hydrogen yield and minimizing carbon

dioxide emissions simultaneously. Seven decision variables

are determined by solving this constrained optimization

problem. The optimal operating conditions are verified with

the Aspen HYSYS simulator. Second, the carbon dioxide

selectivity for the evaluation of the effect of carbon dioxide

reduction is shown by

T2UV- WU2X "$ 2YZ

R_` = (T2UV- WU2X 2W

)\]^

, k = CH4, H2, H2O, CO, O2 (22)

Acknowledgment

Notably, the total carbon dioxide reduction is relevant to

decrease the value of R_` . Thereby, Case II for the

optimization algorithm in regard to the minimization of R_`

is described as

(23)

min S CO

ui

The authors would like to thank the National Science Council

of the Republic of China for financially supporting this

research under Contract No. NSC 100-2211-E-006-264.

[1]

subject to the same constraints in Eq. (21).

Table 1 Comparisons of process before and after

optimization

Component/

before

Case I for

Case II for

selectivity

optimization

maximizing

minimizing

H2

CH4

H 2O

CO

CO2

O2

(kg/h)

SH2 (kg/h)

SCO2 (kg/h)

23.53

0.09

46.58

65.86

87.46

12.81

22.71

0.99

18.46

82.70

58.49

10.92

21.12

5.44

21.87

79.45

51.40

9.15

[2]

[3]

[4]

[5]

Remark 3: Similarly, the carbon dioxide selectivity is

another objective function. The minimization of carbon

dioxide selectivity could identify the operating scenarios for

maximizing the hydrogen yield and minimizing carbon

dioxide emissions simultaneously. The optimal operating

conditions can be found by solving the minimization

algorithm according to seven decision variables. Similarly,

the systems performance with regard to the reduction in

carbon dioxide emissions can be evaluated by the Aspen

HYSYS simulator. Furthermore, a comparison of the system

before and after using optimization strategies is shown in

Table 1. Obviously, both optimization cases may induce a

lower hydrogen yield than the original design with the

emissions by 38.4%~45.9%. Moreover, if the waste heat

recovery design is employed, then the hydrogen yield for the

system using Cases I and II usually decrease by 2.5%.

However, it is truly compensated by saving energy and

reducing carbon dioxide emissions. he mass flow of CO2 falls

from 87.46 kg/h to 58.49 kg/h, and the optimization of Case

II can achieve up to a 41.23% reduction in carbon dioxide

emissions.

[6]

[7]

[8]

[9]

665

References

Xu J, Froment GF. Methane steam reforming,

methanation and water-gas shift: I. intrinsic

kinetics. AIChE J. 1989;35: pp.88-96.

Liu K, Song C, Subramani V. Hydrogen and

Syngas Production and Purification Technologies,

A John Wiley & Sons, Inc., 2010.

Posada A, Manousiouthakis V. Heat and power

integration of methane reforming based hydrogen

production. Industrial & Engineering Chemistry

Research 2005;44:9113-19.

Zamaniyan A, Behroozsarand A, Ebrahimi H.

Modeling and simulation of large scale hydrogen

production. Journal of Natural Gas Science and

Engineering 2010;2: 293-301.

Aresta M. Carbon Dioxide Recovery and

Utilization,

Kluwer

Academic

Publishers,

Netherlands, 2003.

Tarun CB, Croiset E, Douglas PL, Gupta M,

Chowdhury MHM. Techno-economic study of CO2

capture from natural gas based hydrogen plants.

Journal of Greenhouse Gas Control 2007;1:55-61.

Nord LO, Anantharaman R, Bolland O. Design and

off-design analyses of a pre-combustion CO2

capture process in a natural gas combined cycle

power plant. International Journal of Greenhouse

Gas Control 2009;3:385-92.

Fan MS, Abdullah AZ, Bhatia S. Utilization of

greenhouse gases through carbon dioxide reforming

of methane over NieCo/MgOeZrO2: preparation,

characterization and activity studies. Appl Catal B

2010;100:365-77.

Fan MS, Abdullah AZ, Bhatia S. Hydrogen

production from carbon dioxide reforming of

methane over NieCo/MgOeZrO2 catalyst: Process

optimization. International Journal of Hydrogen

Energy 2011;36: 4875-86.

8th IFAC Symposium on Advanced Control of Chemical Processes

Furama Riverfront, Singapore, July 10-13, 2012

[10]

[11]

[12]

[13]

[14]

[15]

[16]

Hoang DL, Chan SH. Modeling of a catalytic

autothermal methane reformer for cell applications.

Applied Catalysis A: General 2004; 268:207-16.

Zahedi nezhad M, Rowshanzamir S, Eikani MH.

Autothermal reforming of methane to synthesis gas:

Modeling and simulation. International Journal of

Hydrogen Energy 2009;34: 1292-1300.

Halabi MH, de Croon MHJM, van der Schaaf J,

Cobden PD, Schouten JC. Modeling and analysis of

autothermal reforming of methane to hydrogen in a

fixed bed reformer. Chemical Engineering Journal

2008; 137: 56878.

Ersoz A, Olgun H, Ozdogan S. Simulation study of

a proton exchange membrane (PEM) fuel cell

system with autothermal reforming. Energy

2006;36:1490-1500.

Behroozsarand A, Ebrahimi H, Zamaniyan A.

Multiobjective

optimization

of

industrial

autothermal reformer for syngas production using

nonsorting genetic algorithm II. Ind. Eng. Chem.

Res., 2009;48:7529-39.

Akbari MH, Sharafian Ardakani AH, Andisheh

Tadbir M. A microreactor modeling, analysis and

optimization for methane autothermal reforming in

fuel cell applications. Chemical Engineering

Journal 2011; 166:1116-25.

Silva GF, Fereira ALO, Cartaxo SJM, Fernandes

FAN. Simulation and optimization of H2

production by autothermal reforming of glycerol.

Computer

Aided

Chemical

Engineering

2009:27:987-92.

666

Das könnte Ihnen auch gefallen

- Optimisation of SRUDokument12 SeitenOptimisation of SRUHuzefaFDNoch keine Bewertungen

- Syngas Production in A Novel Methane Dry Reformer by Utilizing of Tri - Reforming Process For Energy Supplying Modeling and SimulationDokument15 SeitenSyngas Production in A Novel Methane Dry Reformer by Utilizing of Tri - Reforming Process For Energy Supplying Modeling and SimulationMinhaj GhouriNoch keine Bewertungen

- Modeling and Simulation of Methanation Catalytic Reactor in Ammonia UnitDokument8 SeitenModeling and Simulation of Methanation Catalytic Reactor in Ammonia UnitMartin NizNoch keine Bewertungen

- Circulating Fluidized Bed Technology: Proceedings of the First International Conference on Circulating Fluidized Beds, Halifax, Nova Scotia, Canada, November 18-20, 1985Von EverandCirculating Fluidized Bed Technology: Proceedings of the First International Conference on Circulating Fluidized Beds, Halifax, Nova Scotia, Canada, November 18-20, 1985P. BasuBewertung: 5 von 5 Sternen5/5 (1)

- Principles and Case Studies of Simultaneous DesignVon EverandPrinciples and Case Studies of Simultaneous DesignNoch keine Bewertungen

- Handbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4Von EverandHandbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4Bewertung: 5 von 5 Sternen5/5 (1)

- Handbook for Transversely Finned Tube Heat Exchanger DesignVon EverandHandbook for Transversely Finned Tube Heat Exchanger DesignNoch keine Bewertungen

- Circulating Fluidized Bed Technology: Proceedings of the Second International Conference on Circulating Fluidized Beds, Compiègne, France, 14-18 March 1988Von EverandCirculating Fluidized Bed Technology: Proceedings of the Second International Conference on Circulating Fluidized Beds, Compiègne, France, 14-18 March 1988Noch keine Bewertungen

- Fuel Property Estimation and Combustion Process Characterization: Conventional Fuels, Biomass, Biocarbon, Waste Fuels, Refuse Derived Fuel, and Other Alternative FuelsVon EverandFuel Property Estimation and Combustion Process Characterization: Conventional Fuels, Biomass, Biocarbon, Waste Fuels, Refuse Derived Fuel, and Other Alternative FuelsNoch keine Bewertungen

- Chemical Process Design: Computer-Aided Case StudiesVon EverandChemical Process Design: Computer-Aided Case StudiesNoch keine Bewertungen

- Advanced Gas-Heated Reformer: P. W. FarneilDokument9 SeitenAdvanced Gas-Heated Reformer: P. W. FarneilAlfonso BlancoNoch keine Bewertungen

- Simulation and Optimization of Hydrogen Production From Autothermal Reforming of Ethane For Fuel Cell ApplicationsDokument91 SeitenSimulation and Optimization of Hydrogen Production From Autothermal Reforming of Ethane For Fuel Cell ApplicationsainmnrhNoch keine Bewertungen

- Kinetics of Zinc Oxide Sulfidation For Packed-Bed Desulfurizer Modeling PDFDokument9 SeitenKinetics of Zinc Oxide Sulfidation For Packed-Bed Desulfurizer Modeling PDFSuprio KamalNoch keine Bewertungen

- Xu and FromentDokument9 SeitenXu and FromentJhimmy Terceros100% (1)

- Autothermal Reforming ProcessDokument9 SeitenAutothermal Reforming ProcessOliver Everett EspinoNoch keine Bewertungen

- Ammonia and Urea Production PDFDokument10 SeitenAmmonia and Urea Production PDFئارام ناصح محمد حسێنNoch keine Bewertungen

- Potassium Carbonate Using AspenplusDokument5 SeitenPotassium Carbonate Using AspenpluspancokomNoch keine Bewertungen

- Dme BDokument8 SeitenDme Bdewi xiaNoch keine Bewertungen

- #To Study On Boiler Selection For "Process Industry" (Minor Project 3rd Year)Dokument34 Seiten#To Study On Boiler Selection For "Process Industry" (Minor Project 3rd Year)BHUSHAN MESHRAMNoch keine Bewertungen

- Aspen Plus® Process Simulation of Calcium Looping With Different Indirect Calciner Heat Transfer Concepts - ScienceDirectDokument10 SeitenAspen Plus® Process Simulation of Calcium Looping With Different Indirect Calciner Heat Transfer Concepts - ScienceDirectZhofran BintangNoch keine Bewertungen

- Catalyst HandbookDokument290 SeitenCatalyst HandbookAriawan Darari100% (2)

- Steam Reforming Via Gas Shift, Pre Reformer and Reformer TechnologyDokument20 SeitenSteam Reforming Via Gas Shift, Pre Reformer and Reformer TechnologyShawn ChanNoch keine Bewertungen

- Chapter 15 Heat Exchanger NetworksDokument29 SeitenChapter 15 Heat Exchanger NetworksRina Hapsarininggar0% (1)

- P 3 2 e 12 150dpi19 5772 PDFDokument12 SeitenP 3 2 e 12 150dpi19 5772 PDFkeyur1109Noch keine Bewertungen

- HYSYS TutorialDokument30 SeitenHYSYS TutorialEhsan Ahz100% (2)

- Description of Ammonia Manufacturing ProcessesDokument4 SeitenDescription of Ammonia Manufacturing ProcessesSameer PandeyNoch keine Bewertungen

- Line Diagram-MasterDokument75 SeitenLine Diagram-MasterAloke BanerjeeNoch keine Bewertungen

- Wood BoilerDokument59 SeitenWood BoilerRoberto ScheferNoch keine Bewertungen

- Optimal Design of An Air-Cooled Condenser For Flue Gas From A PowDokument316 SeitenOptimal Design of An Air-Cooled Condenser For Flue Gas From A PowJimmy Nuñez VarasNoch keine Bewertungen

- Heat Integration AssignmentDokument8 SeitenHeat Integration AssignmentMian Kamran AliNoch keine Bewertungen

- Topsoe Sec Ref Cat RKS 2Dokument5 SeitenTopsoe Sec Ref Cat RKS 2Vo Duc Minh MinhNoch keine Bewertungen

- 2004 Rev Vacuum EjectorDokument5 Seiten2004 Rev Vacuum EjectorIndranil HatuaNoch keine Bewertungen

- Thermal Ox PDFDokument8 SeitenThermal Ox PDFHeri SetyantoNoch keine Bewertungen

- Hydrogen From Refinery Off GasDokument3 SeitenHydrogen From Refinery Off Gaskulaspiro100% (1)

- Process Burner SpacingDokument5 SeitenProcess Burner SpacingkanuparthyjNoch keine Bewertungen

- Aspen Workbook - 2013Dokument83 SeitenAspen Workbook - 2013tophat36Noch keine Bewertungen

- Investigation of Coil Outlet Temperature Effect On The Performance of Naphtha Cracking FurnaceDokument11 SeitenInvestigation of Coil Outlet Temperature Effect On The Performance of Naphtha Cracking FurnaceSantoso WijayaNoch keine Bewertungen

- Thermal Design of A Fluidized Bed Steam Boiler Using Refuse Derived Fuel (RDF) in Organic Rankine Cycle (#487643) - 612964 PDFDokument17 SeitenThermal Design of A Fluidized Bed Steam Boiler Using Refuse Derived Fuel (RDF) in Organic Rankine Cycle (#487643) - 612964 PDFnemochuNoch keine Bewertungen

- REFORMER Upgrades To Convection Section & Radiant Section at TRINGEN 1 Ammonia Plant, Trinidad X 0Dokument8 SeitenREFORMER Upgrades To Convection Section & Radiant Section at TRINGEN 1 Ammonia Plant, Trinidad X 0David PierreNoch keine Bewertungen

- Reactor Modeling and Simulations in Synthesis Gas ProductionDokument39 SeitenReactor Modeling and Simulations in Synthesis Gas ProductionSteven Sandoval100% (1)

- Hysys Modelling Reactions With HysysDokument8 SeitenHysys Modelling Reactions With HysysoptimisteveNoch keine Bewertungen

- Topsøe Hydrogen Technology - Energy Efficient and Flexible SolutionsDokument8 SeitenTopsøe Hydrogen Technology - Energy Efficient and Flexible Solutionsdavid alonzo100% (1)

- Auto Thermal Reactor:: Secondary ReformerDokument6 SeitenAuto Thermal Reactor:: Secondary ReformerAtif MehfoozNoch keine Bewertungen

- Boiler Furnace PDFDokument8 SeitenBoiler Furnace PDFசுந்தர மூர்த்தி சேப்பிளையார்Noch keine Bewertungen

- Dew Point Od Acid GasDokument4 SeitenDew Point Od Acid GassrshahNoch keine Bewertungen

- CRE Notes 13-A Methanol ReactorDokument11 SeitenCRE Notes 13-A Methanol ReactorjoeNoch keine Bewertungen

- Simulation of Ammonia Production From Synthesis GaDokument12 SeitenSimulation of Ammonia Production From Synthesis Gasagar dasguptaNoch keine Bewertungen

- Sulphuric Acid - Process EngineeringDokument12 SeitenSulphuric Acid - Process EngineeringChaitanya Potti100% (1)

- Deaerator Brochure 01Dokument6 SeitenDeaerator Brochure 01Rafael Cavalcanti50% (2)

- Failure of LP Flash Drum Packing Bed Support: Geoff BlewettDokument10 SeitenFailure of LP Flash Drum Packing Bed Support: Geoff BlewettDheeraj DheeruNoch keine Bewertungen

- 8.10 Sulfuric Acid 8.10.1 General1-2 Sulfuric Acid (H2SO4) Is ADokument9 Seiten8.10 Sulfuric Acid 8.10.1 General1-2 Sulfuric Acid (H2SO4) Is AgetaddNoch keine Bewertungen

- Bubbling Fluidized Bed (BFB)Dokument12 SeitenBubbling Fluidized Bed (BFB)Prasenjit AdakNoch keine Bewertungen

- 160722021623Dokument48 Seiten160722021623ELTIPAZONoch keine Bewertungen

- Recovering Heat When Generating PowerDokument8 SeitenRecovering Heat When Generating Poweraliscribd46Noch keine Bewertungen

- RINNER Motor 57 SeriesDokument2 SeitenRINNER Motor 57 Serieschar_lynNoch keine Bewertungen

- s46mcc8 PDFDokument385 Seitens46mcc8 PDFvivekt5100% (1)

- Petrol Retail Outlet & Operations: Submitted By: Vasu Gupta (09721101718) Bba-E2, Sem 5 Batch-2018/21Dokument9 SeitenPetrol Retail Outlet & Operations: Submitted By: Vasu Gupta (09721101718) Bba-E2, Sem 5 Batch-2018/21Vasu Gupta0% (1)

- Mitsubishi Marine Engine - S6R2-T2MPTK3LM (Package)Dokument2 SeitenMitsubishi Marine Engine - S6R2-T2MPTK3LM (Package)david alvianNoch keine Bewertungen

- Volvoconstruction Equivalencias Filtros PDFDokument21 SeitenVolvoconstruction Equivalencias Filtros PDFWladimir Amaguaña100% (1)

- Adn enDokument91 SeitenAdn enAnonymous cPzveVRHINoch keine Bewertungen

- Group 5 RCV Lever: 1. StructureDokument7 SeitenGroup 5 RCV Lever: 1. StructurethierrylindoNoch keine Bewertungen

- Brittle Fracture The Cold Hard Facts Vern Ragle FinalDokument42 SeitenBrittle Fracture The Cold Hard Facts Vern Ragle FinalCharle MathewNoch keine Bewertungen

- Engine Performance With Variable Valve TimingDokument4 SeitenEngine Performance With Variable Valve TimingWilliam KibbeNoch keine Bewertungen

- 4S Jetting TricksDokument3 Seiten4S Jetting TricksAz MørktVargNoch keine Bewertungen

- Be11 enDokument12 SeitenBe11 enSaqlain Mir100% (1)

- Trator Case 270 PDFDokument539 SeitenTrator Case 270 PDFMarcio Soraia Zopi100% (1)

- PP FWpumpDokument10 SeitenPP FWpumpMohammad MohseniNoch keine Bewertungen

- Inspection Check List BoilerDokument4 SeitenInspection Check List BoilerHADINoch keine Bewertungen

- Cessna P210N Notes - IflyPeteDokument11 SeitenCessna P210N Notes - IflyPetealbucurNoch keine Bewertungen

- RC Datasheet PDFDokument20 SeitenRC Datasheet PDFRicardo BarrosNoch keine Bewertungen

- Engine System FundamentalsDokument17 SeitenEngine System FundamentalsJha PuiNoch keine Bewertungen

- Ch15 - Mustard OilDokument5 SeitenCh15 - Mustard OilMohammad Afreen RahmanNoch keine Bewertungen

- Hazardous Area Classification PONSL RevisedDokument106 SeitenHazardous Area Classification PONSL RevisedMuhamad Firdaus Bin AzizanNoch keine Bewertungen

- BMW N47Dokument8 SeitenBMW N47masinac91100% (1)

- Emd F7 PDFDokument144 SeitenEmd F7 PDFAnup KumarNoch keine Bewertungen

- Himax CR2816-1100 Himax CR2816-1100 Himax CR2816-1100 Himax CR2816-1100 Himax CR2816-1100Dokument1 SeiteHimax CR2816-1100 Himax CR2816-1100 Himax CR2816-1100 Himax CR2816-1100 Himax CR2816-1100Nohelia Luz Jiménez ValenzuelaNoch keine Bewertungen

- Plan Maintenance Schedule Operations For Auxiliary EnginesDokument5 SeitenPlan Maintenance Schedule Operations For Auxiliary EnginesAayush Agrawal100% (1)

- Chieftain R Fly New LowresDokument2 SeitenChieftain R Fly New LowresValBMS100% (1)

- General Torque Specifications N52 PDFDokument3 SeitenGeneral Torque Specifications N52 PDFRoman NavaNoch keine Bewertungen

- 310EDokument5 Seiten310EGLCNoch keine Bewertungen

- BDS Diesel Engine Generator (Operation-Maintenance) ManualDokument73 SeitenBDS Diesel Engine Generator (Operation-Maintenance) Manualkhanh khanhNoch keine Bewertungen

- Transmisión Automática Parte 2Dokument39 SeitenTransmisión Automática Parte 2romeo_mec100% (1)

- Sugar Mill Short DescriptionDokument2 SeitenSugar Mill Short DescriptionAnindya Vikram SinghNoch keine Bewertungen

- SERIES 9100A Pumps and Dispensers Installation/Operation ManualDokument68 SeitenSERIES 9100A Pumps and Dispensers Installation/Operation ManualEstacion AvenidaNoch keine Bewertungen