Beruflich Dokumente

Kultur Dokumente

Statistical Process Control

Hochgeladen von

skkuumarCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Statistical Process Control

Hochgeladen von

skkuumarCopyright:

Verfügbare Formate

Statistical Process Control

(SPC based on2nd Edition by AIAG)

Insights and practical implementation workshop

Faculty

Mr V V Iyer

Overview

Data based management is insisted upon a lot by many customers, since intuitive

way of working and taking decisions is quite detrimental to one and all.

Statistical Process Control ( SPC ) is the technique, which has to be well

understood and implemented with right spirit. Surprisingly, many experienced

personnel does not show much of interest on SPC, due to the fear factor and lack of

understanding.

ISO/TS 16949 mandates SPC as one of its requirements and today, not only the

automobiles, but also many non-automotives started embracing this technique,

since it is proved to be a wonderful tool to reduce variations.

This two day workshop will deal a lot on SPC techniques, with reference to the

latest edition ( 2nd edition ) of SPC manual by AIAG.

Key Take away

To familiarize the participants to understand the basic Statistical approach and also

to make them to practically work with data with lot more confidence.

Also to provide enough insights on SPC, which will help the participants to

practically implement the learning and to avoid the possible errors while adopting

SPC in their respective work area.

Methodology

Class room lecture, very interesting visuals, case studies for each technique

collected from different industries.

Participants are requested to bring their scientific calculators to perform all the

exercises. There will be about 20 exercises throughout the 2 days.

Course contents

Origin of SPC

Basic Statistical approach

Average and Range

Causes of variation

The Sigma factor

Initial Process Study (Ppk Study )

Process & machine capability studies

How to interpret 1.67 and 1.33 the magic figures

Stability Vs Capability : A practical approach

Dealing with Non-normal distribution patterns for Cpk studies

Histogram and how to use them for improving the process

Process Control charts ( both Variable & Attribute )

Z-scale methodology

How to deal with non-random patterns (Actions to be taken )

Participants:

Supervisors, Engineers and Managers from all technical functions such as

Manufacturing, QA, Engineering ( R&D ), Purchase and tool room

About Facilitator

Prof. V.V.Iyer is a Post graduate in statistics and PG.Diploma in Statistical

Quality control from The Indiian Statistical Institute,Kolkatta which is an

institution of National importance, started way back in 1931 by Prof. P C.

Mahalanobis as Non Profit distribution learning Society.He has also done SDP

Fellowship from the same institute in Quality Management.He served the Indian

statistical Institute as a professor for more than 25 years.

He is having more than 2.5 decades of experience in teaching ,training and

consultancy in the areas of Quality Management,Quality and Productivity

Improvement. Etc.Prof. Iyer also worked in Tata Consultancy Services as

Associate Vice President in Learning for four years and developed and

delivered several training modules in the areas of application of statistics in

industries. Conducted more than 600 inplant training programmes and trained more

than 9000 personnel at various level.Presently Prof V.V.Iyer is a practicing

consultant in Quality Management and operates from Chennai.

Rs 12,000/- per day + 10.3 Service tax

Arrangements to be made by you

1.

2.

3.

4.

5.

6.

Hall arrangements

LCD Projector/OHP

White board marker pen

The course materials to be Xeroxed depending upon no. of participants.

Writing pad and pen to the participants

Pick-up and drop to the Resource Person

Das könnte Ihnen auch gefallen

- Six Sigma Black Belt: (BB-17 Batch)Dokument4 SeitenSix Sigma Black Belt: (BB-17 Batch)sathya_145Noch keine Bewertungen

- Six Sigma Black Belt: Certification ProgramDokument4 SeitenSix Sigma Black Belt: Certification ProgrambreezeeeNoch keine Bewertungen

- Test Automation Fundamentals: A Study Guide for the Certified Test Automation Engineer Exam * Advanced Level Specialist * ISTQB® CompliantVon EverandTest Automation Fundamentals: A Study Guide for the Certified Test Automation Engineer Exam * Advanced Level Specialist * ISTQB® CompliantNoch keine Bewertungen

- Test Automation Fundamentals: A Study Guide for the Certified Test Automation Engineer Exam – Advanced Level Specialist – ISTQB® CompliantVon EverandTest Automation Fundamentals: A Study Guide for the Certified Test Automation Engineer Exam – Advanced Level Specialist – ISTQB® CompliantNoch keine Bewertungen

- Weser Services BrochureDokument13 SeitenWeser Services BrochureSenthil_KNoch keine Bewertungen

- Certified Six Sigma Black Belt PDFDokument2 SeitenCertified Six Sigma Black Belt PDFthindmanmohanNoch keine Bewertungen

- Six Sigma Black Belt: (BB-20 Batch)Dokument4 SeitenSix Sigma Black Belt: (BB-20 Batch)mahesh_mirleNoch keine Bewertungen

- Technology Adoption Life Cycle A Complete Guide - 2020 EditionVon EverandTechnology Adoption Life Cycle A Complete Guide - 2020 EditionNoch keine Bewertungen

- Strategic Technology Plan A Complete Guide - 2020 EditionVon EverandStrategic Technology Plan A Complete Guide - 2020 EditionNoch keine Bewertungen

- Quality Management Iso9001:2015 Changes: A Guide to ImplementationVon EverandQuality Management Iso9001:2015 Changes: A Guide to ImplementationBewertung: 5 von 5 Sternen5/5 (1)

- Technology In Education A Complete Guide - 2020 EditionVon EverandTechnology In Education A Complete Guide - 2020 EditionNoch keine Bewertungen

- Six Sigma BroucherDokument6 SeitenSix Sigma BroucherGuna GayathriNoch keine Bewertungen

- Technology Life Cycle A Complete Guide - 2020 EditionVon EverandTechnology Life Cycle A Complete Guide - 2020 EditionNoch keine Bewertungen

- Analytics For Management Brochure 2017Dokument3 SeitenAnalytics For Management Brochure 2017Rohan NaiduNoch keine Bewertungen

- Thesis Business Process ManagementDokument4 SeitenThesis Business Process ManagementCustomThesisPapersUK100% (2)

- Product Life Cycle Engineering A Complete Guide - 2020 EditionVon EverandProduct Life Cycle Engineering A Complete Guide - 2020 EditionNoch keine Bewertungen

- Market Process Economics A Complete Guide - 2020 EditionVon EverandMarket Process Economics A Complete Guide - 2020 EditionNoch keine Bewertungen

- GUI Test Automation Strategy A Complete Guide - 2020 EditionVon EverandGUI Test Automation Strategy A Complete Guide - 2020 EditionNoch keine Bewertungen

- Management Of Technology A Complete Guide - 2020 EditionVon EverandManagement Of Technology A Complete Guide - 2020 EditionNoch keine Bewertungen

- Lean Kaizen: A Simplified Approach to Process ImprovementsVon EverandLean Kaizen: A Simplified Approach to Process ImprovementsNoch keine Bewertungen

- Technology Ado Ption Lifecycle A Complete Guide - 2020 EditionVon EverandTechnology Ado Ption Lifecycle A Complete Guide - 2020 EditionNoch keine Bewertungen

- Small Business Technology A Complete Guide - 2020 EditionVon EverandSmall Business Technology A Complete Guide - 2020 EditionNoch keine Bewertungen

- Technical Education And Training A Complete Guide - 2020 EditionVon EverandTechnical Education And Training A Complete Guide - 2020 EditionNoch keine Bewertungen

- New Technology Management A Complete Guide - 2020 EditionVon EverandNew Technology Management A Complete Guide - 2020 EditionNoch keine Bewertungen

- Project Report PDFDokument47 SeitenProject Report PDFAnand Shrêe Kumar75% (4)

- Process Manufacturing And PLM A Complete Guide - 2019 EditionVon EverandProcess Manufacturing And PLM A Complete Guide - 2019 EditionNoch keine Bewertungen

- Continuous Improvement- 30 Proven tools to drive Profitability, Quality and Operational Effectiveness in Manufacturing & Service Industry: Business Process Management and Continuous Improvement Executive Guide series, #4Von EverandContinuous Improvement- 30 Proven tools to drive Profitability, Quality and Operational Effectiveness in Manufacturing & Service Industry: Business Process Management and Continuous Improvement Executive Guide series, #4Bewertung: 3 von 5 Sternen3/5 (5)

- Technology Roadmap Strategy A Complete Guide - 2020 EditionVon EverandTechnology Roadmap Strategy A Complete Guide - 2020 EditionNoch keine Bewertungen

- Consumer Technology A Complete Guide - 2019 EditionVon EverandConsumer Technology A Complete Guide - 2019 EditionNoch keine Bewertungen

- Manufacturing And PLM A Complete Guide - 2019 EditionVon EverandManufacturing And PLM A Complete Guide - 2019 EditionNoch keine Bewertungen

- Acidic AcidDokument67 SeitenAcidic AcidManharsinh DodiyaNoch keine Bewertungen

- Dual Use Technology A Complete Guide - 2020 EditionVon EverandDual Use Technology A Complete Guide - 2020 EditionNoch keine Bewertungen

- Hiring Tech Talent Strategy A Complete Guide - 2020 EditionVon EverandHiring Tech Talent Strategy A Complete Guide - 2020 EditionNoch keine Bewertungen

- Mobility As A Service Strategy A Complete Guide - 2020 EditionVon EverandMobility As A Service Strategy A Complete Guide - 2020 EditionNoch keine Bewertungen

- Cost Estimation in Agile Software Development: Utilizing Functional Size Measurement MethodsVon EverandCost Estimation in Agile Software Development: Utilizing Functional Size Measurement MethodsNoch keine Bewertungen

- Economics Of Strategy A Complete Guide - 2020 EditionVon EverandEconomics Of Strategy A Complete Guide - 2020 EditionNoch keine Bewertungen

- Innovation Process Strategy A Complete Guide - 2020 EditionVon EverandInnovation Process Strategy A Complete Guide - 2020 EditionNoch keine Bewertungen

- Model Driven Engineering A Complete Guide - 2020 EditionVon EverandModel Driven Engineering A Complete Guide - 2020 EditionNoch keine Bewertungen

- Technical Reference Model A Complete Guide - 2020 EditionVon EverandTechnical Reference Model A Complete Guide - 2020 EditionNoch keine Bewertungen

- Iimk BaDokument10 SeitenIimk Baathulyasathyan16Noch keine Bewertungen

- Ptdoem Flyer Oct2012Dokument3 SeitenPtdoem Flyer Oct2012simonyeo888Noch keine Bewertungen

- Technology Adoption Strategy A Complete Guide - 2020 EditionVon EverandTechnology Adoption Strategy A Complete Guide - 2020 EditionNoch keine Bewertungen

- Technology Acceptance Model A Complete Guide - 2020 EditionVon EverandTechnology Acceptance Model A Complete Guide - 2020 EditionNoch keine Bewertungen

- CSP Technology Product A Complete Guide - 2019 EditionVon EverandCSP Technology Product A Complete Guide - 2019 EditionNoch keine Bewertungen

- Strategy Management For IT Services A Complete Guide - 2020 EditionVon EverandStrategy Management For IT Services A Complete Guide - 2020 EditionNoch keine Bewertungen

- Economics Of Information A Complete Guide - 2020 EditionVon EverandEconomics Of Information A Complete Guide - 2020 EditionNoch keine Bewertungen

- IIMB CourseSyllabus QM101.1xDokument8 SeitenIIMB CourseSyllabus QM101.1xkPrasad8Noch keine Bewertungen

- HCM Technology Strategy A Complete Guide - 2019 EditionVon EverandHCM Technology Strategy A Complete Guide - 2019 EditionNoch keine Bewertungen

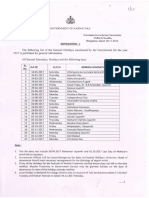

- Tamil Nadu - Holidays List 2017Dokument4 SeitenTamil Nadu - Holidays List 2017skkuumarNoch keine Bewertungen

- Fme Developing CompetenciesDokument29 SeitenFme Developing CompetenciesdmaloofNoch keine Bewertungen

- Andhra - Holidays List 2017Dokument2 SeitenAndhra - Holidays List 2017skkuumarNoch keine Bewertungen

- Karnataka - Holidays List 2017Dokument10 SeitenKarnataka - Holidays List 2017skkuumarNoch keine Bewertungen

- Training Effectiveness Evaluation FormDokument1 SeiteTraining Effectiveness Evaluation FormskkuumarNoch keine Bewertungen

- Training Effectiveness Evaluation FormDokument1 SeiteTraining Effectiveness Evaluation FormskkuumarNoch keine Bewertungen

- ESI Wage Ceiling IncreaseDokument1 SeiteESI Wage Ceiling IncreaseskkuumarNoch keine Bewertungen

- Mind Map Tutor HandbookDokument24 SeitenMind Map Tutor HandbookWalter100% (1)

- HR ExecutiveDokument2 SeitenHR ExecutiveGuru Pratap GiriNoch keine Bewertungen

- 007 Organizational Coaching Best PracticesDokument4 Seiten007 Organizational Coaching Best PracticesMichelle ChaudhuriNoch keine Bewertungen

- Listening SkillsDokument62 SeitenListening SkillsskkuumarNoch keine Bewertungen

- A Mind Map Laws PadDokument2 SeitenA Mind Map Laws PadzskebapciNoch keine Bewertungen

- UntitledDokument8 SeitenUntitledapi-224840214Noch keine Bewertungen

- Appraisal LetterDokument2 SeitenAppraisal LetterAparna KaleNoch keine Bewertungen

- New Travel Policy L1 & L2Dokument8 SeitenNew Travel Policy L1 & L2skkuumarNoch keine Bewertungen

- HR Budget Six SigmaDokument29 SeitenHR Budget Six SigmaskkuumarNoch keine Bewertungen

- Travel Policy IIDokument3 SeitenTravel Policy IIlegendleo_siva4133Noch keine Bewertungen

- UntitledDokument8 SeitenUntitledapi-224840214Noch keine Bewertungen

- Travel Policy - UsableDokument5 SeitenTravel Policy - UsableSwati KumariNoch keine Bewertungen

- Employee Engagement Study: Mafoi Consulting Solutions LTDDokument14 SeitenEmployee Engagement Study: Mafoi Consulting Solutions LTDsanthi62Noch keine Bewertungen

- Appointment Letter1Dokument2 SeitenAppointment Letter1skkuumarNoch keine Bewertungen

- HR Budget Six SigmaDokument29 SeitenHR Budget Six SigmaskkuumarNoch keine Bewertungen

- Budget Planner - Overview / Help: InstructionsDokument7 SeitenBudget Planner - Overview / Help: InstructionsRakesh Ranjan KumarNoch keine Bewertungen

- Evaluation of Kirk Patrick's ModelDokument7 SeitenEvaluation of Kirk Patrick's ModelRishi BhandariNoch keine Bewertungen

- 09 KHGhardaDokument4 Seiten09 KHGhardafatimanehaNoch keine Bewertungen

- Time SheetDokument1 SeiteTime SheetskkuumarNoch keine Bewertungen

- Balance Scorecard 1Dokument38 SeitenBalance Scorecard 1tlq1mpoNoch keine Bewertungen

- 09 KHGhardaDokument4 Seiten09 KHGhardafatimanehaNoch keine Bewertungen

- 5s ChecklistDokument3 Seiten5s Checklistvickram_chandu9526Noch keine Bewertungen

- Spacehandbook 20180418 Web PDFDokument24 SeitenSpacehandbook 20180418 Web PDFMizta HariNoch keine Bewertungen

- School To Club Sport Transition: Strategy and Product Design EssentialsDokument8 SeitenSchool To Club Sport Transition: Strategy and Product Design EssentialsSamuel AyelignNoch keine Bewertungen

- COMPREHENSIVE WRITTEN REPORT BeltranbernasDokument8 SeitenCOMPREHENSIVE WRITTEN REPORT BeltranbernasDianne Beltran100% (1)

- Soi For Nor Fo1 BugagonDokument4 SeitenSoi For Nor Fo1 BugagonCsjdm Bfp BulacanNoch keine Bewertungen

- Sap Is Retail Sample Resume UsefulDokument4 SeitenSap Is Retail Sample Resume UsefulVinay Kumar0% (1)

- SC - 10th CBSE - Term Test 2 - 17.11.2021 - MathsDokument12 SeitenSC - 10th CBSE - Term Test 2 - 17.11.2021 - MathsBhanu PurushothamaNoch keine Bewertungen

- DLL Sept. 11-15, 2023Dokument5 SeitenDLL Sept. 11-15, 2023Arcee Joy RadovanNoch keine Bewertungen

- Math 9 LM Draft 3.24.2014Dokument241 SeitenMath 9 LM Draft 3.24.2014merryjoey heranaNoch keine Bewertungen

- Cognitive Diagnostic AssessmentDokument43 SeitenCognitive Diagnostic AssessmentReza MobashsherniaNoch keine Bewertungen

- 09 Bloom Gardner Matrix Example 2009Dokument2 Seiten09 Bloom Gardner Matrix Example 2009Ellen Jaye BensonNoch keine Bewertungen

- Structural Functionalism of MediaDokument3 SeitenStructural Functionalism of Mediasudeshna860% (1)

- CJR Group FDokument9 SeitenCJR Group FNadya TanjungNoch keine Bewertungen

- ACADEMIC MANUAL - National Institute of Fashion TechnologyDokument455 SeitenACADEMIC MANUAL - National Institute of Fashion TechnologyRalucaFlorentinaNoch keine Bewertungen

- AWS Certified Developer Associate Updated June 2018 Exam GuideDokument3 SeitenAWS Certified Developer Associate Updated June 2018 Exam GuideDivyaNoch keine Bewertungen

- Lessonn 1.2 ActivityDokument2 SeitenLessonn 1.2 ActivityDanica AguilarNoch keine Bewertungen

- World Class 1 Student Book 181108183750 PDFDokument5 SeitenWorld Class 1 Student Book 181108183750 PDFRonald MaderaNoch keine Bewertungen

- Essay Writing Digital NotebookDokument10 SeitenEssay Writing Digital Notebookapi-534520744Noch keine Bewertungen

- Gabriel FormosoDokument3 SeitenGabriel FormosoMargaret Sarte de Guzman100% (1)

- HUU001-لغة انجليزية فنيةDokument102 SeitenHUU001-لغة انجليزية فنيةAlaa SaedNoch keine Bewertungen

- Life Cycle Costing PDFDokument25 SeitenLife Cycle Costing PDFItayi NjaziNoch keine Bewertungen

- The Digital Cities Challenge: Designing Digital Transformation Strategies For EU Cities in The 21st Century Final ReportDokument119 SeitenThe Digital Cities Challenge: Designing Digital Transformation Strategies For EU Cities in The 21st Century Final ReportDaniela StaciNoch keine Bewertungen

- Math g4 m3 Full ModuleDokument590 SeitenMath g4 m3 Full ModuleNorma AguileraNoch keine Bewertungen

- Rancangan Pengajaran Harian Strategi Mampatan, Pecutan Dan Pengayaan (M2P) Dalam Pelaksanaan KurikulumDokument17 SeitenRancangan Pengajaran Harian Strategi Mampatan, Pecutan Dan Pengayaan (M2P) Dalam Pelaksanaan KurikulumHeera ShiniNoch keine Bewertungen

- FINC304 Managerial Economics: Session 11 - Game TheoryDokument22 SeitenFINC304 Managerial Economics: Session 11 - Game TheoryJephthah BansahNoch keine Bewertungen

- DLL - English 5 - Q3 - W6Dokument14 SeitenDLL - English 5 - Q3 - W6Veronica EscabillasNoch keine Bewertungen

- Final Exam b2 Answer SheetDokument2 SeitenFinal Exam b2 Answer SheetTolga ÖzcanNoch keine Bewertungen

- Customer Buying Behaviour Towards Ayurvedic ProductDokument11 SeitenCustomer Buying Behaviour Towards Ayurvedic ProductLOVE CHAWLANoch keine Bewertungen

- Year 5daily Lesson Plans Success Criteria Pupils Can 1. Listen and Underline 4 Correct Words. 2. Read and Fill in at Least 6 Blanks CorrectlyDokument8 SeitenYear 5daily Lesson Plans Success Criteria Pupils Can 1. Listen and Underline 4 Correct Words. 2. Read and Fill in at Least 6 Blanks Correctlyjulie ayobNoch keine Bewertungen

- Herbart SpencerDokument32 SeitenHerbart SpencerMohit PuriNoch keine Bewertungen