Beruflich Dokumente

Kultur Dokumente

A0436 Thermal Behavior

Hochgeladen von

tahera aqeelOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

A0436 Thermal Behavior

Hochgeladen von

tahera aqeelCopyright:

Verfügbare Formate

Journal of Thermal Analysis and Calorimetry, Vol.

72 (2003) 607617

THERMAL BEHAVIOUR OF UREA-FORMALDEHYDE

RESINS DURING CURING

K. Siimer*, T. Kaljuvee and P. Christjanson

Tallinn Technical University, Ehitajate tee 5, 19086 Tallinn, Estonia

Abstract

Urea-formaldehyde (UF) resins are the most widely used polycondensation resins today in manufacturing particleboards. The performance of UF resins in their processing is greatly influenced by curing characteristics. The cure process has been monitored by TG-DTA technique on a Setaram

labsysTM instrument in dynamic heating conditions at different heating rates. Commercial UF resins

from different suppliers used in Estonian particleboard factories were selected for TG-DTA measurements. Experiments were carried out without and with catalysts. Ammonium chloride and ammonium sulphate were used. Curing characteristics were evaluated both for fresh and aged resins.

Keywords: curing, polycondensation, storage, TG-DTA technique, urea-formaldehyde resins

Introduction

Urea-formaldehyde resins are the most widely used adhesives for bonding wood products today, in particular, for manufacturing particleboards. Their processing is greatly influenced by curing conditions, especially by the degree of cure, therefore it is very important to study the curing characteristics of the resins. Various methods for evaluating

curing characteristics of UF resins have been proposed and used in practice. The thermal

behaviour of the resins during curing has been followed by thermogravimetric analysis [1], differential thermal analysis [2], differential scanning calorimetry [36], supported by data from IR spectroscopy [2] and 13NMR spectroscopy [5]. The generation of

bonding strength during curing was directly monitored by dynamic mechanical analysis [78], more modern thermomechanical analysis [9], and automatic bonding evaluation system [10]. Direct investigation of formaldehyde emission during curing has given

valuable information concerning the crosslinking and decomposition processes [4, 11].

In the present work, the curing process of UF resins was followed by the TG-DTA

method which makes it possible to simultaneously characterise the heat of curing process

and the thermal stability of cured resin. Commercial UF resins from different suppliers,

and presumably of different synthesis procedures in Estonian particleboard factories have

been used. Consequently, it is interesting to compare their curing behaviour and thermal

stability both from theoretical and practical point of view. In this study, four commercial

resins were selected for TG-DTA measurements.

*

Author for correspondence: ksiimer@staff.ttu.ee

13886150/2003/ $ 20.00

2003 Akadmiai Kiad, Budapest

Akadmiai Kiad, Budapest

Kluwer Academic Publishers, Dordrecht

608

SIIMER et al.: UREA-FORMALDEHYDE RESINS

Experimental

TG-DTA measurements were carried out by a labsysTM instrument (Setaram) with the

heating rates of 3, 5 and 10 K min1, measuring sensitivity 50 V. Temperature of

samples ranged from 20 to 450C and the measurements were recorded in dynamic

helium atmosphere (40 mL min1), the mass of the samples being 10 to 20 mg. The

TG-DTA test was carried out with an open standard platinum crucible (100 L). As a

reference, an identical empty crucible was used. DTA, TG and DTG curves were registered considering reference runs at the same experimental conditions. The heat flow

on DTA curves was expressed in V s mg1. Enthalphy of the curing reaction is not

exactly determined, as the characteristic exoeffect in DTA curve is overlapped by

water evaporation endotherm. In this study, the peak temperatures are the main apparent indices to characterise the curing system.

Commercial UF resins from different suppliers, and presumably of different

synthesis procedures have been used, which are labelled as UF1, UF2, UF3 and UF4.

In Table 1, the standard analysis of these resins is presented.

Table 1 Standard analysis of commercial UF resins

Characteristics

UF1

UF2

UF3

UF4

Dry solids (treated at 105C, 3 h)/%

68.7

69.0

67.8

68.2

8.2

8.1

8.5

8.4

pH

Viscosity 25C/ cP

Density 20C/ g cm3

Gel time at 100C/ s

Free formaldehyde/ %

307

1.275

56

0.13

380

1.295

51

0.1

490

1.273

66

0.15

480

1.286

81

0.1

From the table it appears that standard properties of all resins studied are quite similar regardless of different sources of resins. It is explained by the fact that modern UF resins are synthesised by a typical three-step procedure with close formaldehyde to urea ratio (1.031.08/1). This final ratio may be achieved by gradual addition of urea in small

portions during synthesis. Due to the nearly equal molar ratio of components, UF resins

contain only small amounts of free formaldehyde (0.10.15%). In the synthesis of resins,

formaldehyde aqueous solution with 58% of methanol content was used, only in case of

UF2 the methanol-free formaldehyde solution of higher concentration was applied. It is

seen from the table that dynamic viscosity of resins is different at a close solid content,

and it does not correlate with the gelation time of catalysed (1% NH4Cl) resin at 100C,

thus indicating a complicated relation between resin structure and curing behaviour. Otherwise, the initial viscosity of resins determines the rate of slow structuration at room

temperature. The final gelation of UF1, UF2, UF3 and UF4 occurred during 53, 39, 27

and 31 days according to their initial viscosities. Curing characteristics were evaluated

both for fresh resins and aged up to gelation resins.

J. Therm. Anal. Cal., 72, 2003

SIIMER et al.: UREA-FORMALDEHYDE RESINS

609

Curing experiments were carried out without and with ammonium chloride and

ammonium sulphate as catalysts. 20% solutions of catalysts were used.

Results and discussion

The curing mechanism of UF resins depends on curing conditions, whether reactions

are carried out with or without catalyst, hence, in acid or alkaline media. To make

more obvious the differences between the various resins, curves of UF resins with

different reactivity are compared as an example. UF1 is the resin of high content of

hydroxymethyl groups (over 50% of bound formaldehyde), therefore, with high reactivity [12]. On the contrary, the resin UF4 has the highest condensation degree as

compared to other resins studied, and contains only 37% of hydroxymethyl groups.

UF4 was well-proved in industrial PB manufacturing and therefore, greater attention

was paid to this resin in this work.

Fig. 1 TG-DTA curves of UF1 curing with 1% ammonium chloride (5 K min1)

In Fig. 1, curing curve of UF1 with 1% of ammonium chloride is shown.

It is generally believed that in presence of acid catalyst, the first exotherm arises

from polycondensation reaction of primary amino groups of unreacted urea with

hydroxymethyl groups of resin. Exothermic reaction of UF1 cure with mass loss takes

place with a peak maximum at 84C. The large endothermic peak of water evaporation

with a minimum at 103C is derived from the initial resin water and that from condensation reaction. In temperature region up to 200C no obvious thermic effects take place,

the slight mass loss in this region is contributed to slow formaldehyde emission [6].

In Fig. 2, curing curve of UF1 obtained without ammonium chloride is presented. In curing without catalyst, in mildly alkaline medium (resin pH 8.2), polycondensation takes place preferably over formation of methylene linkages between

linear resin fragments [12]. The resin curing process proceeds in extended temperature region and the exothermic effects are overlapped by endothermic effects of water

evaporation. A slight exotherm can be observed in the range of 95100C, and the

J. Therm. Anal. Cal., 72, 2003

610

SIIMER et al.: UREA-FORMALDEHYDE RESINS

endoeffect with a minimum at 114C in DTA curve refers to water evaporation. The

other slight exotherms are visible at 130 and 162C. Characteristic temperatures of

resin decomposition begin in the same temperature region as in the case of UF1 catalytic curing. Resin destruction endotherm with a minimum at 233236C has been attributed to degradation of methylene ether linkages by many authors. The proved

endotherm with a minimum at 314C belongs to decomposition of the most stable

unit in the UF resin methylenediurea [1].

Fig. 2 TG-DTA curves of UF1 curing without catalyst (5 K min1)

For comparison, curves for UF4 curing with and without ammonium chloride are

presented. This resin, as compared to UF1, contains smaller amount of reactive hydroxymethyl groups. Lower reactivity of resin also reveals in considerably higher gel time (Table 1). In Fig. 3, curve of UF4 curing with 1% ammonium chloride is shown.

Fig. 3 TG-DTA curves of UF4 curing with 1% ammonium chloride (5 K min1)

J. Therm. Anal. Cal., 72, 2003

SIIMER et al.: UREA-FORMALDEHYDE RESINS

611

From the figure it can be seen that curing exotherm is shifted to higher temperature than in case of UF1. The exothermic peak maximum reveals at 87C and the water evaporation endotherm at 109C.

In Fig. 4, curing UF4 without catalyst is illustrated. The same observations as in

case of UF1 can be brought out: water evaporation from initial resin begins earlier as

polycondensation reaction, and curing takes place in extended temperature region. As

compared to curing UF1 without catalyst (Fig. 2), the characteristic temperatures are

shifted to higher values.

Fig. 4 TG-DTA curves of UF4 curing without catalyst (5 K min1)

In Fig. 5, the mass loss of all studied resins cured without and with 1% ammonium

chloride is shown. As can be seen from Fig. 5a, in case of curing without catalyst, the

structural differences appear more clearly because of slower polycondensation processes.

The degradation is higher in case of methanol-free UF2 which does not contain the more

stable methyl ether groups. In curing with catalyst (Fig. 5b), because of a more profound

structuration of resins, the mass loss in all cases is quite similar.

The temperatures of exotherms and endotherms depend strongly on heating rate

with which the curing experiments are recorded. In Fig. 6, crosslinking exotherms

and water evaporation endotherms for resin UF2 at various heating rates are compared. The peak maximum of exotherm shifts from 80 to 91C with raising heating

rate. The use of higher heating rate (10 K min1) generally reduces the resolution between different events. The lower heating rate (3 K min1) is much more sensitive to

variations. From Fig. 6 it appears that in this case, two endothermic peaks of water

evaporation with minimums at 107 and 115C, derived from two different sources,

are revealed. In the present work, mainly the rate of 5 K min1 was used.

For commercial applications, the combination of high reaction heat and fast curing rate is desirable. Observed effects differ with resin type. In Fig. 7, the curing

curves of more reactive resin UF1 with 1 and 1.5% ammonium chloride (the amounts

commonly used in practice) are compared. Increasing the catalyst content only in this

narrow range produces a more reactive system which reveals in somewhat lower tem-

J. Therm. Anal. Cal., 72, 2003

612

SIIMER et al.: UREA-FORMALDEHYDE RESINS

peratures of exotherm and endotherm. Also, the exothermic reaction heat has risen a

little. Curing the resin with higher content of catalyst, total mass loss is more extensive due to resin hydrolysis.

Fig. 5 Mass loss of four UF resins during curing (5 K min1), a without catalyst,

b with 1% ammonium chloride

Fig. 6 DTA curves of UF2 curing: 1 3 K min1; 2 5 K min1; 3 10 K min1

J. Therm. Anal. Cal., 72, 2003

SIIMER et al.: UREA-FORMALDEHYDE RESINS

613

Fig. 7 DTA curves of UF1 curing: 1 1.0% and 2 1.5% ammonium chloride

When comparing the less reactive resin UF4 with UF1, the changes in peak temperature values depending on catalyst content are less noticeable. Only minor

changes occur, increasing the catalyst content in relatively large limits. In Fig. 8, curing exotherms for UF4 depending on catalyst content in the range of 1 to 4% are presented. For more detailed examination of the formation of curing exotherm, in Fig. 8b

the peak maximums are shown in expanded scale. It can be seen from the figure that

the twofold increase in catalyst content from 1 to 2% diminishes the exothermic peak

maximum temperature only 0.4C. The total shift of exothermic peak maximum in

this range is 1.4C.

Fig. 8 Dependence of UF4 curing on ammonium chloride content

In the presence of acid catalyst and excess of amino functionalities, resin curing

occurs mainly by the formation of methylene groups [12]. From Fig. 8 it is seen that

the exothermic behaviour during curing depends on the amount of catalyst. Increase

in catalyst content only promotes one part of curing reactions, shifting the exothermic

J. Therm. Anal. Cal., 72, 2003

614

SIIMER et al.: UREA-FORMALDEHYDE RESINS

peak to lower temperature. At the same time, higher amount of catalyst approximates

the rate of different reactions, giving the other exothermic peak with a maximum in

the region of 9394C. The possibilities for such kind of behaviour are evident, considering the presence of amino groups and hydroxymethyl groups of different functionality and reactivity in polymeric and monomeric parts of resin, and of very different chain length and branching rate [13]. Also, higher amount of catalyst promotes

deeper curing of resin, which results in crosslinking of the most complicated structures giving exothermic effect at higher temperature.

Degradation of cured resins begins with the liberation of formaldehyde from

dimethylene ether groups [11]. Clear dependence of peak temperature of endothermic

decomposition on acid catalyst content (Fig. 9) is caused by poor resistance of ether

structures to acid.

Fig. 9 UF4 decomposition endotherms in the region of 230240C depending on ammonium chloride content

In fact, this kind of destruction can be regarded as postcuring of resin, as released formaldehyde participates in further reactions, finally giving more stable

methylene groups. Otherwise, dimethylene ether groups in cured resin can be the

source of free formaldehyde due to preferred hydrolysis in presence of moisture. At

the same time, the conditions favour formaldehyde release from particleboards as

compared to further curing reactions.

In several particleboard factories, ammonium chloride is not used as catalyst because of the generation of hydrochloric acid causing corrosion problems. The other

commonly used curing catalyst is ammonium sulphate. A set of experiments was performed with UF4 using ammonium sulphate as catalyst. In Fig. 10a, DTA curves up

to 350C depending on catalyst content are presented. In Fig. 10b, the precise structure of curing exotherm is illustrated. Comparing the exothermic peak temperatures

with those in Fig. 8, it can be concluded that the same amount of ammonium sulphate

promotes the curing process more than ammonium chloride, shifting curing reactions

to lower temperature (e.g., in case of 2% catalyst the first exothermic peak maximums are 84.5 and 86.1C, respectively).

J. Therm. Anal. Cal., 72, 2003

SIIMER et al.: UREA-FORMALDEHYDE RESINS

615

Fig. 10 Dependence of UF4 curing on ammonium sulphate content

From the technological standpoint, it is important to know the behaviour of

long-time stored resins in curing process. During resin storage, the structural changes

in resin take place. The main reaction during storage is the formation of methylene

linkages adjacent to secondary amino groups [12]. This reaction occurs not only between hydroxymethylureas and urea in monomeric part but also between free terminal hydroxymethyl and amino groups in polymeric part of resins. Storage period also

involves the migration of hydroxymethyl groups from the polymeric to monomeric

resin components [12, 14]. In connection with the decrease of the content of hydroxymethyl groups during storage, the higher temperature values in exothermic curing reaction are revealed. In Fig. 11, curing curves of fresh and aged resins for UF1, UF2

and UF3 are presented.

Fig. 11 DTA curves of 1 fresh and 2 aged resins curing with 1% ammonium chloride:

a UF1, b UF2 and c UF3

J. Therm. Anal. Cal., 72, 2003

616

SIIMER et al.: UREA-FORMALDEHYDE RESINS

From Fig. 11 it appears that the shift of the exothermic peak maximum of aged resin

is greater in case of more reactive UF1 reaching to 4C. In case of UF2 this shift is 2C

and in case of UF3 only 1C. The last resin is of higher conversion degree as compared

with the others [12]. In Fig. 12, DTA curves of cure process for aged (30 days at 25C)

UF4 with ammonium chloride and in alkaline medium without adding catalyst are compared with those of fresh resin.

Fig. 12 DTA curves of 1 fresh and 2 aged UF4 curing: a with ammonium chloride;

b without catalyst

In case of aged UF4, no differences in curing exotherm temperatures compared

to fresh resin are revealed (Fig. 12a) but as a result of structuration processes during

resin storage, exothermic heat of crosslinking is decreased about four times. The shift

of the minimum of water evaporation endotherm is 5C. DTA curve of aged resin in

decomposition region (over 200C) shows only somewhat higher temperature of

endotherm (1C). In curing without catalyst, aged resin reveals very slight peaks in

extended temperature region (Fig. 12b).

Conclusions

Curves for commercial UF resins from different suppliers cured with 1 to 4% ammonium chloride show that exothermic reaction of crosslinking with mass loss takes

place in all cases at 8386C, and the reaction heat evolved is close. Water evaporation from curing system exhibits by large endothermic peak in DTA curve with a

minimum at 103109C. Common to all resins is that in further heating up to 200C,

no changes in the reaction heat values with simultaneous slight mass loss are observed, explained by the formation of extended polymer chains. At temperatures over

200C the resins begin to decompose showing series of endothermic and exothermic

effects in similar temperature regions. The curing mechanism depends strongly on

pH value of the system. Increasing the catalyst content, a more acidic system is pro-

J. Therm. Anal. Cal., 72, 2003

SIIMER et al.: UREA-FORMALDEHYDE RESINS

617

duced and the resin crosslinking takes place at lower temperature with somewhat

higher reaction heat evolved. The same content of ammonium sulphate, as compared

to ammonium chloride, promotes the curing process noticeably more.

UF resins without catalyst, hence in alkaline medium, cure in extended temperature region, and DTA curves have no sharp exothermic peaks. Total resin mass loss

during curing is lower in this case.

Aged nearly up to gelation, UF resins reveal higher crosslinking temperatures,

and essentially lower reaction heat is evolved. The shift of the exothermic peak temperature as a result of resin storage is higher in case of UF1, which has a lower initial

degree of conversion.

References

1

2

3

4

5

6

7

8

9

10

11

S. Zeman and L. A. Tokrov, Thermochim. Acta, 202 (1992) 181.

S. Chow and P. R. Steiner, Holzforschung, 29 (1975) 4.

G. E. Myers and J. A. Koutsky, Holzforschung, 44 (1990) 117.

M. Szesztay, Z. Lszl-Hedvig, E. Kovacsovics and F. Tds, Holz Roh Werkst., 51 (1993) 297.

A. Pizzi and L. A. Panamgama, J. Appl. Polym. Sci., 58 (1995) 109.

R. O. Ebewele, J. Appl. Polym. Sci., 58 (1995) 1689.

K. Umemura, S. Kawai, R. Ueno, Y. Mizuno and H. Sasaki, Mokuzai Gakkaishi, 42 (1996) 489.

K. Umemura, S. Kawai, H. Sasaki, R. Hamada and Y. Mizuno, J. Adhesion, 59 (1996) 87.

A. Pizzi, J. Appl. Polym. Sci., 63 (1997) 603.

M. Dunky, Intern. J. Adhes. & Adhes., 18 (1995) 95.

S.-I. Tohmura, C.-Y. Hse and M. Higuchi, Int. Contrib. Wood Adhes. Res., Meeting Date

1998, (1999) 93.

12 P. Christjanson, K. Siimer, T. Pehk and I. Lasn, Holz Roh Werkst., accepted.

13 K. Siimer, T. Pehk and P. Christjanson, Macromol. Symp., 148 (1999) 149.

14 M. G. Kim, H. Wan, B. Y. No and W. L. Nieh, J. Appl. Polym. Sci., 82 (2001) 1155.

J. Therm. Anal. Cal., 72, 2003

Das könnte Ihnen auch gefallen

- Pen Rchive Oulouse Rchive Uverte : O A T A O OataoDokument32 SeitenPen Rchive Oulouse Rchive Uverte : O A T A O Oataotahera aqeelNoch keine Bewertungen

- 7-Blade Element TheoryDokument33 Seiten7-Blade Element TheoryAnonymous Da8GxwVNoch keine Bewertungen

- PDFDokument30 SeitenPDFtahera aqeelNoch keine Bewertungen

- 8.31 Mercury in Water: S. Nishi B. G. LiptákDokument7 Seiten8.31 Mercury in Water: S. Nishi B. G. Liptáktahera aqeelNoch keine Bewertungen

- 5 1033 PDFDokument12 Seiten5 1033 PDFtahera aqeelNoch keine Bewertungen

- User Manual: FDTD & Code BasicsDokument37 SeitenUser Manual: FDTD & Code Basicstahera aqeelNoch keine Bewertungen

- n9415 PDFDokument9 Seitenn9415 PDFtahera aqeelNoch keine Bewertungen

- GG 150Dokument52 SeitenGG 150tahera aqeelNoch keine Bewertungen

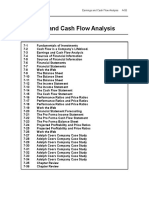

- Earnings and Cash Flow Analysis: SlidesDokument6 SeitenEarnings and Cash Flow Analysis: Slidestahera aqeelNoch keine Bewertungen

- National Income, Saving and Investment: Handbook of Statistics On Pakistan EconomyDokument10 SeitenNational Income, Saving and Investment: Handbook of Statistics On Pakistan Economytahera aqeelNoch keine Bewertungen

- United States Patent (191 ': HoracekDokument5 SeitenUnited States Patent (191 ': Horacektahera aqeelNoch keine Bewertungen

- Research Article: Synthesis and Thermal Degradation Studies of Melamine Formaldehyde ResinsDokument7 SeitenResearch Article: Synthesis and Thermal Degradation Studies of Melamine Formaldehyde Resinstahera aqeelNoch keine Bewertungen

- Melamine Formaldehyde Curing Studies andDokument7 SeitenMelamine Formaldehyde Curing Studies andtahera aqeelNoch keine Bewertungen

- Delta-Size FR PDSDokument1 SeiteDelta-Size FR PDStahera aqeelNoch keine Bewertungen

- Processing Polyester Resins For Coatings Applications: Manually Controlled Laboratory EquipmentDokument11 SeitenProcessing Polyester Resins For Coatings Applications: Manually Controlled Laboratory Equipmenttahera aqeelNoch keine Bewertungen

- United States Patent (,9) : Miyake Et A1Dokument10 SeitenUnited States Patent (,9) : Miyake Et A1tahera aqeelNoch keine Bewertungen

- 22 0204 DeuroWet MA11 TDS EnglischDokument2 Seiten22 0204 DeuroWet MA11 TDS Englischtahera aqeelNoch keine Bewertungen

- 22 0802 DeuroSlide FA TDS EnglischDokument2 Seiten22 0802 DeuroSlide FA TDS Englischtahera aqeelNoch keine Bewertungen

- Small and Portable UnitDokument2 SeitenSmall and Portable Unittahera aqeelNoch keine Bewertungen

- Deurolease Phe (GB) MsdsDokument7 SeitenDeurolease Phe (GB) Msdstahera aqeel100% (1)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Fsw530 SeriesDokument1 SeiteFsw530 SeriesjufrejjNoch keine Bewertungen

- Defects - Solidification Cracking - TWIDokument8 SeitenDefects - Solidification Cracking - TWIJlkKumarNoch keine Bewertungen

- JeniDokument40 SeitenJenijenifer darisNoch keine Bewertungen

- Daso Cooling LoadDokument31 SeitenDaso Cooling LoadObakoma JosiahNoch keine Bewertungen

- MP112 Mechanics and Modern Physics Problem Set 6 / 2015Dokument2 SeitenMP112 Mechanics and Modern Physics Problem Set 6 / 2015CristianNoch keine Bewertungen

- Law of The Wall - ARPDokument6 SeitenLaw of The Wall - ARPAshok BishtNoch keine Bewertungen

- c791 pH-USP PDFDokument4 Seitenc791 pH-USP PDFNdra PompomorinNoch keine Bewertungen

- Design of Mems Based Microcantilever Using Comsol MultiphysicsDokument3 SeitenDesign of Mems Based Microcantilever Using Comsol Multiphysicsbasavaraj hagaratagiNoch keine Bewertungen

- Design of A Three-Storey Commercial Building: I. Description of The StructureDokument8 SeitenDesign of A Three-Storey Commercial Building: I. Description of The StructureShōya Ishida100% (1)

- Parameters For Foundation DesignDokument8 SeitenParameters For Foundation DesignMehedi Hasan100% (2)

- Exp7 Calcite CrystalDokument9 SeitenExp7 Calcite Crystalctremblaylcsd150Noch keine Bewertungen

- 18ME43 FM Module 5Dokument37 Seiten18ME43 FM Module 5Adarsha DNoch keine Bewertungen

- 13 30 Minhaal Kalyan Chevron.8569Dokument19 Seiten13 30 Minhaal Kalyan Chevron.8569Rohan DangareNoch keine Bewertungen

- 2 Bas365Dokument2 Seiten2 Bas365Pavan Kumar SinghNoch keine Bewertungen

- Mathematical Model For Blood Flow in An ArteryDokument11 SeitenMathematical Model For Blood Flow in An ArteryChoy Yaan YeeNoch keine Bewertungen

- Seminar ReportDokument19 SeitenSeminar ReportAjit8675100% (7)

- Daouadji 2016Dokument29 SeitenDaouadji 2016Zahra ZahraNoch keine Bewertungen

- Determination of Hydrocarbon Dew Point Using A Gas ChromatographDokument11 SeitenDetermination of Hydrocarbon Dew Point Using A Gas Chromatographmajid maheriNoch keine Bewertungen

- THE BOUNDARY CONDITIONS IN DIRECT SIMPLE SHEAR TESTS Developments For Peat Testing at Low Normal StressDokument92 SeitenTHE BOUNDARY CONDITIONS IN DIRECT SIMPLE SHEAR TESTS Developments For Peat Testing at Low Normal StressTiago SchuckNoch keine Bewertungen

- Interatomic DistanceDokument3 SeitenInteratomic DistanceisaacNoch keine Bewertungen

- Design Calculation Alternate Staging (Using Mmrda Materials) of Vup at Ch. 16+415Dokument5 SeitenDesign Calculation Alternate Staging (Using Mmrda Materials) of Vup at Ch. 16+415swapan.boseNoch keine Bewertungen

- Construction of Optical FiltersDokument34 SeitenConstruction of Optical FiltersAvnish KumarNoch keine Bewertungen

- Example 4.1: School of Engineering - EN334Dokument7 SeitenExample 4.1: School of Engineering - EN334Ismail DoğanNoch keine Bewertungen

- Flow Through NozzlesDokument13 SeitenFlow Through NozzlesBharat SharmaNoch keine Bewertungen

- Ultrasonic Testing - Wikipedia PDFDokument26 SeitenUltrasonic Testing - Wikipedia PDFKarthicWaitingNoch keine Bewertungen

- Solar Assisted Air Conditioning of Buildings - An OverviewDokument16 SeitenSolar Assisted Air Conditioning of Buildings - An OverviewoilladdaNoch keine Bewertungen

- Cargas de DiseñoDokument3 SeitenCargas de DiseñoYURITZI MARTINEZ CUELLARNoch keine Bewertungen

- Astm E273Dokument4 SeitenAstm E273Jimmy MárquezNoch keine Bewertungen

- Tag 0240-BH-0103-0104Dokument1 SeiteTag 0240-BH-0103-0104Alexander AcuñaNoch keine Bewertungen

- Lecture 11 - Introduction To Distributed Normal LoadsDokument30 SeitenLecture 11 - Introduction To Distributed Normal LoadsLantretz LaoNoch keine Bewertungen