Beruflich Dokumente

Kultur Dokumente

Us5377594 PDF

Hochgeladen von

checolonoskiOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Us5377594 PDF

Hochgeladen von

checolonoskiCopyright:

Verfügbare Formate

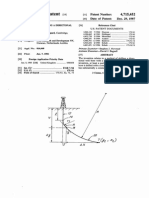

US005377594A

United States Patent [191

[11]

Patent Number:

5,377,594

Alford

[45]

Date of Patent:

Jan. 3, 1995

[54] FLEXIBLE LINEAR EXPLOSIVE CUTTING

4,815,384

[76] Inventor:

Sidney C. Alford, 41a Pickwick,

Corsham, Wiltshire, England, SN13

834,535

Aug. 14, 1990

[86] PCT No.:

371 Date:

102(e) Date:

PCI/GB90/01277

Apr. 14, 1992

Apr. 14, 1992

[87] PCT Pub. No.: W091/02939

PCT Pub. Date: Mar. 7, 1991

[30]

..... ..1o2/3o7

Gibb et a1. ............ .. 102/307

Lane .

FOREIGN PATENT DOCUMENTS

OHX

[21] Appl. No.:

[22] PCT Filed:

3/1989 Ringeletal.

4,856,430 8/1989

5,075,112 12/1991

OR FRACIURING CHARGE

2515413 10/1976 Germany .

8804573 8/1979 Germany .

OTHER PUBLICATIONS

Rama, S. et al., Connective Tissue Research 12:111-118,

1984.

Lane, I. William et al., Sharks Dont Get Cancer, Avery

Publishing Group Inc., 1992, updated edition 1993.

Primary Examiner-Peter A. Nelson

Attorney, Agent, or Firm-Finnegan, Henderson,

Farabow, Garrett & Dunner

Foreign Application Priority Data

Aug. 15, 1989 [GB]

United Kingdom ............... .. 8918552

[51]

[52]

1111. C16 ............................................ .. F42B 1/032

US. 01. ................................ .. 102/308; 102/310

[58]

Field of Search ...................... .. 102/307, 308, 310

[56]

References Cited

U.S. PATENT DOCUMENTS

2,981,185

3,177,808

4/1957

4/1965

Caldwell ............................. .. 102/20

Owen ............. ..

.. 102/308 X

3,185,089

5/1965

Parkhurst et a1. ................ .. 102/307

[57]

ABSTRACT

The invention provides a linear explosive cutting or

fracturing charge comprising a plurality of elements

connected together for articulation. Each element com

prises a body portion (1) de?ning a recess (9) for con

taining explosive material and connecting means (2)

whereby a plurality of elements can be connected to- .

gether for articulation.

16 Claims, 3 Drawing Sheets

US. Patent

Jan. 3, 1995

20

10

.

22

3/

Sheet 1 of 3

5,377,594

US. Patent

Jan. a, 1995

Sheet 2 of 3

5,377,594

III! 6

3/

22

Fig. 11

US. Patent

Jan. 3, 1995

Sheet 3 of 3

5,377,594

5,377,594

FLEXIBLE LINEAR EXPLOSIVE CUTTING OR

FRACI'URING CHARGE

The present invention relates to linear explosive cut

ting or fracturing charges.

A frequent requirement of demolition work, e.g.,

wave-shaping element, it again has the practical disad

when demolishing oil tankers or other large vessels for

scrap, is the severing of steel targets by means of explo

sives.

material is interposed between a strip of explosive and

the target. This has the effect of focusing the explo

sively generated shock wave along the intended frac

ture plane within the target. Although this linear cut

ting charge can be made inherently but weakly mag

netic by the use of magnetic rubber for forming the

vantage of only very limited ?exibility so that its stiff

ness coupled with a tendency to elastically recover its

10

Among the advantages of explosives over other

methods, such as mechanical cutting methods or burn

ing, are safety, since the operator does not need to be

close to the target structure at the moment of demoli

tion, speed, and the relative ease of transportation of the

means of demolition, since explosive charges are com

initial shape remain limiting factors when the cutting

charge is used in practice.

The present invention has as its object to provide a

linear explosive cutting or fracturing charge, and an

element for use in forming same, which overcomes or

mitigates the problem of in?exibility common to known

linear cutting charges and to enable a linear cutting or

fracturing charge of a required length to be produced

pact in comparison with the equipment required for

mechanical cutting or burning.

quickly and easily.

Explosives may be used for demolition by direct

The present invention provides an element for use in

application to the target surface, although attachment is 20 forming a linear explosive cutting or fracturing charge,

often dif?cult, the technique inefficient for a given

the element comprising a body portion for receiving an

quantity of explosive, and the result almost invariably

explosive material and connecting means comprising

disorderly and needlessly destructive for the task in

hand. Also projected fragments constitute a particular

hazard when this method is used.

Much greater explosive ef?ciency results from the

?rst and second connector parts at opposite sides of the

body portion whereby two or more said elements can

25 be connected together for articulation relative to one

another characterised in that a ?rst initiation channel

use of shaped charges, such as linear cutting charges

extends between the ?rst and second connector parts,

the frst initiation channel being adapted to receive an

wherein a high explosive is caused to act on an angle

section strip of metal in such a way that the two limbs

of the angle-section are driven towards each other,

explosive material to initiate, in use, detonation of ex

plosive material in said body portion, the element being

thereby generating an elongate jet of extremely fast

constructed and arranged such that when a plurality of

elements are connected together, the ?rst initiation

moving metal which has great penetrating power, even

on steel targets. However, such linear cutting charges

are rigid and cannot be conformed to targets which are

not ?at.

channels are connected end to end.

The present invention also provides a linear explosive

35

An alternative method of imparting directionality to

the energy released by an explosive depends upon the

nected together to form a chain and charged with ex

shaping of shock waves generated by the explosive

plosive material.

within the target. The shock waves may be caused to

fracture targets according to two principle mechanisms.

cutting or fracturing charge when formed from a plural

ity of elements according to the present invention con

The said connecting means may provide a hinge con

40 nection or, more preferably, a universal joint.

By initiating a mass of explosive in contact with, or

close to, the target surface at its two outer extremities

It will be appreciated that because the elements of a

linear cutting or fracturing charge according to the

with respect to the plane of intending fracture, the two

present invention can be articulated relative to one

separate detonation wave fronts converge along the

another, the linear cutting or fracturing charge can be

centre line, and collide. The ?rst mechanism results 45 conformed to surfaces which are not ?at. It will also be

from the extreme violence of such a collision which

appreciated that any required number of elements can

generates a narrow zone of extremely high pressure on

be connected together to provide a linear cutting

the target surface which fractures the target. If, on the

charge of a required length.

other hand, the width of the charge is approximately

Preferably, said connecting means comprises a ?rst

twice the thickness of the target, and the thickness of

connector part on one side of the body portion and a

explosive suf?cient only to give a pressure pulse of

second connector part on the opposite side of the body

sufficiently short duration, then the fracturing mecha

portion, the ?rst and-second connector parts being

nism consists of the coincidence of re?ected tension

adapted to connect with the second and ?rst connector

waves from the far side of the target surface. These

parts respectively of further similar elements. Said ?rst

re?ected tension waves cause a sudden application of 55 and second connector parts may be complementary

tensile forces across the plane of intended fracture, and

parts of snap-fit connectors whereby a plurality of said

the target splits from the distal surface towards the

elements can be quickly and easily snap-?t together.

surface on which explosive was placed. In practice,

Said ?rst connector part may be a ball member and said

both mechanisms usually occur at the same time, with

one of the two mechanisms clearly preponderant.

second connector part may be a complementary socket

One explosive cutting charge using such a mechanism

nected together by engaging the ball member of one

is disclosed in European Patent No. 0043215 wherein a

series of detonation wave collision charges are arranged

in cavities in a continuous rubber matrix. This charge

provide a universal ball-and-socket joint between the

has a small degree of ?exibility in the fracture plane but 65

member, whereby two or more elements can be con

element in the socket member of an adjacent element to

two elements.

Said body portion may comprise a recess for receiv

little or no lateral ?exibility. Another linear cutting

ing said explosive material. Thus, the body portion may

charge is disclosed in UK. patent application No.

comprise a bottom wall and at least one peripheral wall

8513325 wherein a prism or lens-section strip of inert

extending outwardly of said bottom wall to de?ne said

5,377,594

recess. According to one embodiment, said at least one

peripheral wall comprises opposed side walls and op

posed end walls and said connecting means is located

midway along said side walls.

ever increasing proportion of the explosive energy to be

directed tangentially away from the target and to be

wasted in the surrounding medium. Since, with the

preferred embodiment of the present invention, the

main charge of each element is initiated at the opposed

outer extremities and proceeds inwardly towards the

Said body portion may comprise initiation means on

that side thereof opposite said recess. The initiation

means may comprise a ?rst channel extending centrally

across said body portion, e.g., between said connecting

means, second and third channel extending outwardly

on either side of the ?rst channel and communicating

with the ?rst channel and apertures in the body portion

communicating the outer extremities of said second and

third channels with said recess, said channels and said

little of the explosive energy is dissipated in the sur

?rst channel and said apertures may comprise a slot in

said bottom wall at the outer extremity of each of the

second and third channels and adjacent a said end wall.

interposing an inert barrier element between the main

intended line of out there is no tendency for the detona

tion wave front to lean backwards and comparatively

rounding medium.

In order to ensure that detonation of the main charge

of each element proceeds from opposite outer extremi

ties thereof inwardly towards the intended line of cut, it

apertures being adapted to receive explosive material.

is necessary to prevent the direct or sympathetic initia

Said channels may be de?ned by walls upstanding from 15 tion of the main charge of one element by the detona

said bottom wall on that surface of the bottom wall

tion of the main explosive charge of a preceding ele

opposite said peripheral wall. The walls of said second

ment. This may be accomplished by spacing the adja

and third channels may diverge outwardly from said

cent elements suf?ciently far apart by said connecting

The body portion may further comprise at least one

means as to delay or prevent direct initiation or by

explosive charges of adjacent elements. Such an inert

barrier may conveniently be provided by a magnetic

recess for receiving a magnet which will enable the

element which will serve the dual functions of provid

element to be magnetically sectored to a ferrous target.

ing an inert barrier and enabling the elements to be

The element may further comprise a cover member 25 magnetically secured to a ferrous target.

for closing said channels. Said cover member may be a

The tendency towards sympathetic initiation be

snap, friction or force ?t with the upstanding walls

tween the main charges of adjacent elements may be

de?ning said channels and may comprise means for

further mitigated by the use of an explosive material of

supporting a detonator at one end of said ?rst channel.

relatively high detonation velocity for the initiation

Preferably, said connecting means are of hollow thin

train. This ensures that the desired initiation pattern of

walled construction. When a plurality of elements in

one element is further advanced before the shock wave

accordance with the invention are connected together

arrives from the initiation of the main explosive charge

so that the ?rst initiation channels thereof are connected

of the preceding element than would be the case if a

end to- end, the channels provide a continuous initiation

single explosive material were used both for the main

train extending over the length of the linear cutting or 35 charge and the initiation train.

fracturing charge. Thus, with the channels and the hol

As mentioned above, it is desirable that any particular

low connecting means filled with explosive material

element be in a suf?ciently advanced state of initiation

detonation can proceed in either direction from one

before the destructive effects of the preceding element

element to adjacent elements through the thin end walls

destroy it, or damage it to an extent that would impair

of the adjacent connector parts. As detonation of the 40 its correct functioning.

explosive material in the ?rst channel of each element

The potentially destructive mechanism of the preced

takes place, so detonation proceeds outwardly along the

ing element consists of the generation of a violent, for

second and third channels of the element and through

ward-travelling shock wave generated by the coinci

said apertures at the extremities of the second and third

dence of the two shock waves generated by the two

channels to initiate detonation of the main explosive 45 converging detonation waves of that charge. The for

charge contained in said recess from opposite outer

ward velocity of such a shock wave may, in some cases,

extremities thereof. In this way, detonation of the main

exceed the detonation velocity of explosive otherwise

explosive charge contained in said recess proceeds from

suitable for use in the present invention, and its effect

the opposite outer extremities thereof inwards towards

would be to induce initiation of the subsequent charge

the intended line of cut to provide the most ef?cient 50 prematurely at a point on its side; such premature initia

detonation con?guration and to maximise the propor

tion would generate a third detonation front which

tion of explosive energy imparted to the target. With

interferes detrimentally with those fronts intentionally

such an arrangement the proportion of explosive energy

generated at the outer edges of the element.

affecting the target greatly exceeds that of conventional

Greater separation of the elements mitigates this ten

linear explosive charges in which detonation proceeds 55 dency, but such separation is detrimental to the perfor

in a direction parallel with the intended line of cut.

mance of the charge array. Use of an explosive of lower

The linear explosive or fracturing charge of the pres

velocity than that in the initiation train would tend to

ent invention also has advantages over conventional

delay the generation of the destructive, forward

linear cutting charges when used for cutting cylindrical

directed shock wave, but such explosive would be less

targets such as large diameter steel pipes. When a con

effective at fracturing or cutting the target.

ventional linear cutting charge of the kind wherein

A preferred method of diminishing or eliminating this

detonation proceeds along the line of cut is applied to

undesirable effect utilises the so-called channel effect,

the outer circumference of a cylindrical target, the

wherein the explosive of the initiation means is pro~

inner surface of the explosive cutting charge provides a

vided with a hole or holes extending longitudinally

shorter path around the target than does the outer sur 65 along one or more of the ?rst, second and third chan

face so that as the detonation wave front progresses

around the target there is a tendency for the detonation

nels. The hole or holes may be lined with thin-walled

metal, plastic or ceramic, and is ?lled with air or other

wave front to lean back progressively. This causes an

gas. The detonation products of that part of the explo

5,377,594

sive ?rst detonated are driven along the hole at a veloc

ity exceeding the normal velocity of detonation of that

explosive, and initiate detonation in that part of the

explosive not yet reached by the normal detonation

14 which diverge outwardly from the walls 12 and

de?ne second and third initiation channels 15 and 16.

wave front. The detonation velocity is thus effectively

Slots 17 in the bottom wall 4 communicate the outer

extremities of the second and third initiation channels 15

and 16 with the recess 9 adjacent the end walls 7 and 8.

raised in that part of the explosive adjacent to the hole.

A rod or cylinder of explosive, provided with such a

The main initiation channel 13 extends centrally of the

body portion 1 between the ball member 10 and socket

channel, and initiated at one end, therefore attains a

member 11. Ball member 10 and socket member 11 are

detonation velocity substantially higher than that of an

of hollow thin-walled construction so that detonation of

otherwise similar body of explosive not thus provided.

an initiation train of explosive material contained in the

Although it is preferred that initiation of the main

channels 13 and members 10 and 11 of adjacent ele

charge of each element proceeds from opposite outer

ments can proceed through said thin walls to the main

extremities thereof inwardly towards the intended line

initiation channel 13 of an adjacent element.

of cut, the present invention can equally well be applied

Cover member 3 illustrated also in FIGS. 10 and 11

to simple concussion charges. In this case, initiation of 15 comprises a top wall 18 and depending side walls 19

the main explosive charge of each element may be along

which are a snap, force or friction ?t with the walls 12

the centre line thereof, e.g. through said connector

and 14 de?ning the channels 13, 15 and 16. A cylindrical

parts, in which case said second and third channels and

holder 20 for a detonator 21 (FIG. 3) is upstanding from

said apertures would be omitted.

the cover member 3 and has ?exible tangential ribs 22

The present invention will be more particularly de 20 extending inwardly thereof for accommodating detona

scribed with reference to the accompanying drawings,

tors of different diameters.

in which:

Delay elements 23 may be provided in the second and

FIG. 1 is a top plan view of an element for use in

third initiation channels 15 and 16 to ensure that the

forming a linear explosive cutting or fracturing charge

detonation fronts proceeding outwardly therealong

25

according to the present invention,

towards the slots 17 proceed parallel to the slots 17.

FIG. 2 is an end elevation of the element shown in

FIG. 1,

'

FIG. 3 is a sectional end elevation of the element

In use, the recess 9 is ?lled with a main charge 24

(FIG. 4) of explosive material and the initiation chan

nels 13, 15 and 16 are ?lled with an initiating charge 25

FIG. 4 is a top plan view of a body portion of the 30 of explosive material. Advantageously, the explosive

material 25 is of a higher detonation velocity than the

element shown in FIG. 1,

explosive material 24. The explosive material 25 com

FIG. 5 is an underneath plan view of the body por

municates with the explosive material 24 through the

tion of the element shown in FIG. 1,

slots 17 which are also ?lled with one or other of the

FIG. 6 is an end elevation of the body portion shown

shown in FIG. 1,

in FIG. 4,

35 explosive materials. With this arrangement initiation of

the main explosive charge 24 is from the outer extremi

FIG. 7 is a sectional end elevation of the body portion

ties thereof with detonation proceeding inwardly

shown in FIG. 4,

FIG. 8 is a side elevation of the body portion shown

in FIG. 4,

FIG. 9 is a side sectional elevation of the body por

tion shown in FIG. 4,

FIG. 10 is an underneath plan view of a cover mem

ber of the element shown in FIG. 1,

FIG. 11 is a top plan view of the cover member

towards the intended line of out, which is along the

centre line of the element extending through the ball

member 10 and socket member 11. As many elements

charged with explosive material as required can be

connected together as illustrated in FIG. 12 in the form

of a chain to provide a linear explosive cutting or frac

turing charge of any required length. Initiation of the

shown in FIG. 10, and

45 explosive charges can be from any one or more of the

elements and will then proceed outwardly in both direc

FIG. 12 is a plan view showing a plurality of elements

tions along the main initiation channels of the adjacent

according to FIG. 1 connected together into a chain to

elements.

form a linear explosive cutting or fracturing charge

The initiation channels may, if desired, be provided

according to the present invention.

with longitudinal holes which may be lined with thin

Referring to FIGS. 1 to 3 of the drawings, it will be

walled metal, plastic or ceramic and ?lled with air or

seen that the element illustrated therein comprises a

other gas. The holes suitably extend substantially cen

body portion 1, connecting means 2 and cover member

trally of the explosive in each channel.

3.

As outlined above, the provision of such holes elimi

Referring now also to FIGS. 4 to 9 it will be seen that

nates, or greatly mitigates, the problem of premature,

the body portion 1 comprises a bottom wall 4, opposed

mid-line initiation. By way of example, an 8 millimetre

side walls 5, 6 and opposed end walls 7, 8 depending

rod of the plastic explosive SX2, whose normal detona

from the bottom wall 4 to de?ne a recess 9 for receiving

tion velocity was found to be approximately 7,200 me

a main charge of explosive material.

nector part in the form of a complementary socket

tres a second in that form, detonated at a velocity of

approximately 9,100 metres a second when provided

with an air-?lled axial channel 3.2 millimetres in diame

member 11, the arrangement being such that the ball

ter.

The connecting means 2 comprises a ?rst connector

part in the form of a ball member 10 and a second con

member 10 of one element is a snap ?t with the socket

As can be seen from FIG. 12, due to the articulation

of the connected elements by means of the ball-and

member 11 of another similar element to provide an

articulated universal ball-and-socket joint between the 65 socket joints, the linear cutting charge of the present

adjacent elements as illustrated in FIG. 12.

invention can adapt a required radius of curvature to

Upstanding from the bottom wall 4 are parallel walls

provide arcuate cuts and/or to accommodate cylindri

12 de?ning a ?rst, main, initiation channel 13 and walls

cal or other non-planar targets.

5,377,594

If desired the recess 9 may be divided by a partition

wall 26 shown diagramatically in FIG. 5 to provide a

supplementary recess 9a. Supplementary recess 90 may

contain explosive material 24 or, more preferably, an

inert barrier element which may be in the form of a

sintered ferrite or other magnet 27 which will serve

both as a barrier to prevent sympathetic detonation of

2. An element according to claim 1, wherein said ?rst

and second connector parts are complementary parts of

snap-?t connectors.

3. An element according to claim 2, wherein said ?rst

connector part is a ball member and said second connec

tor part is a complementary socket member.

4. An element according to claim 1, wherein said

the main explosive charge 24 by the detonation of the

main explosive charge of a preceding element and also

body portion comprises a recess for receiving said addi

tional explosive material.

5. An element according to claim 4, wherein the ?rst

initiation channel is disposed on that side of the body

portion opposite said recess.

6. An element according to claim 4, wherein said

body portion comprises a bottom wall and at least one

to magnetically attach the element to a ferrous target.

The element of the present invention may be moulded

or formed from plastics material or rubber. A particu

larly suitable material is acrylonitrile butadiene styrene

(ABS) plastics material.

The following examples are given by way of illustra

peripheral wall extending outwardly of said bottom

tion.

wall to de?ne said recess.

7. An element according to claim 6, wherein said at

EXAMPLE 1

ments illustrated in FIGS. 1 to 3 of the drawings. The

least one peripheral wall comprises opposed side walls

and opposed end walls and said connecting means is

located, viewed in plan, midway along said side walls.

plastic explosive PE4 was used for both the main charge

8. An element according to any one of claims 5 to 7,

A linear cutting charge was assembled using the ele

wherein the ?rst initiation channel extends centrally

channels 13, 15 and 16 of each element. The main

across the body portion and second and third initiation

charge of each element measured 50 ><28><19 mm and

channels extend outwardly on either side of the ?rst

consisted of approximately 42 g of explosive. With a 25 initiation channel and communicate with the ?rst initia

spacing of 18.5 elements per metre this corresponded to

tion channel and apertures in the body portion commu

an explosive load of 777 g/m.

nicate with outer extremities of said second and third

The linear cutting charge was placed on the surface

initiation channels with said recess, said initiation chan

of a target consisting of a flat plate of 43A grade mild

nels and said apertures being adapted to receive explo

steel having a thickness of 50 mm. When the charge was

sive material.

detonated the target was cleanly fractured along the

9. An element according to claim 8, wherein said

intended line of cut.

initiation channels are de?ned by walls upstanding from

and initiation train and was inserted in the recess 9 and

said bottom wall on a surface thereof opposite said

EXAMPLE 2

peripheral walls.

A linear cutting charge was assembled as described in 35

10. An element according to claim 9, wherein the

Example 1 and was placed on the surface of a target

walls of said second and third initiation channels di

consisting of a ?at plate of 43A mild steel having a

verge outwardly from said ?rst channel and said aper

thickness of 40 mm. The cutting charge was arranged

tures comprise a slot in said bottom wall at an outer

with the centre-lines of the individual elements on an

extremity of each of the second and third channels and

arc of a circle of approximately 150 mm radius. When 40 adjacent a said end wall.

the charge was detonated the target was cleanly frac

11. An element according to claim 1, wherein said

tured along the intended arcuate line of cut.

body portion comprises at least one recess for receiving

I claim:

a magnet or inert barrier member.

1. An element for use in forming a linear explosive

12. An element according to claim 1, having its body

cutting or fracturing charge, the element comprising a 45 portion ?lled with said additional explosive material.

body portion for receiving an explosive material and

13. An element according to claim 8 having its body

connecting means comprising ?rst and second connec

portion ?lled with said additional explosive material,

tor parts at opposite sides of the body portion whereby

and the explosive material in one or more of the initia

two or more said elements can be connected together

tion channels being provided within a longitudinally

for articulation relative to one another characterized in

extending hole.

that the body portion de?nes a ?rst initiation channel

14. An element according to claim 9, comprising a

cover member for closing said initiation channels.

15. An element according to claim 14, wherein said

cover member comprises means for supporting a deto

which extends between the ?rst and second connector

parts with said ?rst initiation channel having a hollow

interior for receiving an explosive material and is

adapted to initiate, in use, detonation of additional ex 55 nator at one end of said ?rst initiation channel.

plosive material in said body portion, the ?rst and sec

16. An element according to claim 1 connected to at

ond connector parts of the element being constructed

least an additional one of said element to form a chain

and arranged such that when a plurality of the elements

with each said element of said chain charged with ex

are connected together, the ?rst initiation channels of

plosive material.

the connected elements are connected end to end.

60

65

>3

1k

>1

Das könnte Ihnen auch gefallen

- Connecting Rod Cracker: Rigid Support and Floating Die Crack Connecting RodsDokument12 SeitenConnecting Rod Cracker: Rigid Support and Floating Die Crack Connecting RodsOkta Pariantoro Budi SetiawanNoch keine Bewertungen

- Finite Element Simulation of Explosive WeldingDokument14 SeitenFinite Element Simulation of Explosive WeldingWahyu Lailil FaisNoch keine Bewertungen

- Pro Tech 1 CH 8Dokument31 SeitenPro Tech 1 CH 8weldsvNoch keine Bewertungen

- 2023-Research on the explosion release method and damage mechanism of titanium alloy fan bladeDokument13 Seiten2023-Research on the explosion release method and damage mechanism of titanium alloy fan bladelaokanNoch keine Bewertungen

- EP0928948B1Dokument5 SeitenEP0928948B1dfdfsdNoch keine Bewertungen

- Explosion Bonding: An SEO-Optimized TitleDokument6 SeitenExplosion Bonding: An SEO-Optimized TitleJason SmithNoch keine Bewertungen

- PerforatingDokument78 SeitenPerforatingامير العذاريNoch keine Bewertungen

- Fracture, Fatigue, Failure and Damage Evolution, Volume 3Dokument6 SeitenFracture, Fatigue, Failure and Damage Evolution, Volume 3Ali FahemNoch keine Bewertungen

- Hollow Charge - US Patent 4942819Dokument9 SeitenHollow Charge - US Patent 4942819warrior_2008Noch keine Bewertungen

- Us 5360355Dokument6 SeitenUs 5360355kimscribd66Noch keine Bewertungen

- Patent Search & Analysis Report (PSAR)Dokument4 SeitenPatent Search & Analysis Report (PSAR)Homik SoniNoch keine Bewertungen

- Us2475875 PDFDokument4 SeitenUs2475875 PDFchecolonoskiNoch keine Bewertungen

- United States Patent: Primary Examiner - (74) Attorney, Agent, or FirmDokument9 SeitenUnited States Patent: Primary Examiner - (74) Attorney, Agent, or FirmAdriana Daniela SanduNoch keine Bewertungen

- A Finite Element Parametric Study On Block Shear Failure of Steel Tension Members-2004 PDFDokument21 SeitenA Finite Element Parametric Study On Block Shear Failure of Steel Tension Members-2004 PDFMohammed Essam ShatnawiNoch keine Bewertungen

- Study On Strength and Sealing of A Bolted Flange JDokument7 SeitenStudy On Strength and Sealing of A Bolted Flange JŁukasz BolewskiNoch keine Bewertungen

- Engineering Fracture Mechanics: Z.X. Chen, L.H. Qian, S.J. ZhuDokument9 SeitenEngineering Fracture Mechanics: Z.X. Chen, L.H. Qian, S.J. ZhuMustafa MoussaouiNoch keine Bewertungen

- NASA 2001 Ices SCFDokument6 SeitenNASA 2001 Ices SCFRamprasad SrinivasanNoch keine Bewertungen

- A Review On Springback Effect in Sheet Metal Forming ProcessDokument7 SeitenA Review On Springback Effect in Sheet Metal Forming ProcessantonytechnoNoch keine Bewertungen

- Ion Cluster Acceleration for Subnuclear Particle ProductionDokument9 SeitenIon Cluster Acceleration for Subnuclear Particle ProductionVictor Von DoomNoch keine Bewertungen

- Explosion Bonding Process: Nobelclad Technical Bulletin NT 200Dokument9 SeitenExplosion Bonding Process: Nobelclad Technical Bulletin NT 200MilindMotghareNoch keine Bewertungen

- Criteria For Self Loosening of Fasteners Under VibrationDokument5 SeitenCriteria For Self Loosening of Fasteners Under VibrationMatheus Paes PeçanhaNoch keine Bewertungen

- Q23 Toolbox 2Dokument10 SeitenQ23 Toolbox 2Carlos ArenasNoch keine Bewertungen

- 5.well PerforationDokument13 Seiten5.well Perforationakshitppe11Noch keine Bewertungen

- HSFG Bolts PDFDokument12 SeitenHSFG Bolts PDFmcwong_98Noch keine Bewertungen

- EP0883790B1Dokument7 SeitenEP0883790B1dgfsduuwioNoch keine Bewertungen

- National Institute of Technology Raipur, (C.G.) : Term ProjectDokument11 SeitenNational Institute of Technology Raipur, (C.G.) : Term ProjectAman johnNoch keine Bewertungen

- Cotter JointDokument14 SeitenCotter JointAtharva SalunkheNoch keine Bewertungen

- United States: (12) Patent Application Publication (10) Pub. No.: US 2014/0332577 A1Dokument7 SeitenUnited States: (12) Patent Application Publication (10) Pub. No.: US 2014/0332577 A1amd mhmNoch keine Bewertungen

- NRC Publications Archive (Nparc) Archives Des Publications Du CNRC (Nparc)Dokument17 SeitenNRC Publications Archive (Nparc) Archives Des Publications Du CNRC (Nparc)Timmy VoNoch keine Bewertungen

- Drilling constant curvature well boresDokument7 SeitenDrilling constant curvature well boresandreNoch keine Bewertungen

- Effect of Weld Parameters On Mechanical Properties of The Friction Stir Welding Aa6063-T5Dokument9 SeitenEffect of Weld Parameters On Mechanical Properties of The Friction Stir Welding Aa6063-T5HUỲNH HOÀNG TÚNoch keine Bewertungen

- Excavator Structural Components & Welding FundamentalsDokument37 SeitenExcavator Structural Components & Welding Fundamentalssurianto100% (1)

- Analysis and Design For End Effects in Twisted Double TeesDokument20 SeitenAnalysis and Design For End Effects in Twisted Double TeesFabrizio BisernaNoch keine Bewertungen

- Traction device for motor vehiclesDokument5 SeitenTraction device for motor vehiclesxeron7126Noch keine Bewertungen

- MITIJME-August-2015, Full VolumeDokument60 SeitenMITIJME-August-2015, Full VolumeAbhishek SaxenaNoch keine Bewertungen

- Effect of Liner Geometry and Thickness in Shaped Charge WarheadsDokument7 SeitenEffect of Liner Geometry and Thickness in Shaped Charge WarheadsDani SaadNoch keine Bewertungen

- Eb 034949Dokument4 SeitenEb 034949gauravmeucerNoch keine Bewertungen

- Naik 2004 Compos Struct 66, 579. Composite Structures Under Ballistic ImpactDokument12 SeitenNaik 2004 Compos Struct 66, 579. Composite Structures Under Ballistic ImpactRicardo Gamboa CastellanosNoch keine Bewertungen

- Us 5531545Dokument10 SeitenUs 5531545Mark EdowaiNoch keine Bewertungen

- Cased Hole PerforatingDokument19 SeitenCased Hole PerforatingRolando Gabriel Segovia Perez100% (1)

- Us 4299169Dokument3 SeitenUs 4299169dfdfsdNoch keine Bewertungen

- 2021-Characteristics and mechanisms of turboshaft engine axial compressor casing containmentDokument10 Seiten2021-Characteristics and mechanisms of turboshaft engine axial compressor casing containmentlaokanNoch keine Bewertungen

- PENETRATION ANALYSlS OF CERAMIC ARMOR WITH COMPOSITE MATERIAL BACKING PDFDokument8 SeitenPENETRATION ANALYSlS OF CERAMIC ARMOR WITH COMPOSITE MATERIAL BACKING PDFagnysNoch keine Bewertungen

- United States Patent (19) : (45) Sept. 27, 1977Dokument4 SeitenUnited States Patent (19) : (45) Sept. 27, 1977aless2056Noch keine Bewertungen

- A Finite Element Parametric Study On Block Shear Failure of Steel Tension MembersDokument21 SeitenA Finite Element Parametric Study On Block Shear Failure of Steel Tension MembersNAUTILUS87Noch keine Bewertungen

- 2016 - The Failure Mechanisms of Hot Forging DiesDokument33 Seiten2016 - The Failure Mechanisms of Hot Forging DiesNguyen Hoang DungNoch keine Bewertungen

- ARMY - Chapter Eight Explosive BreachingDokument25 SeitenARMY - Chapter Eight Explosive Breachingrsreeth100% (1)

- Tensile Test On Brittle Material 2 DoneDokument12 SeitenTensile Test On Brittle Material 2 Done202302090036Noch keine Bewertungen

- 1-11 Other Welding Processes - Electro Slag, Rotary FrictionDokument24 Seiten1-11 Other Welding Processes - Electro Slag, Rotary FrictionSolomonNoch keine Bewertungen

- Strike Action Electromagnetic Machine For ImmersioDokument6 SeitenStrike Action Electromagnetic Machine For ImmersiomechsrinuNoch keine Bewertungen

- Member Stiffness and Contact Pressure Distribution of Bolted JointsDokument8 SeitenMember Stiffness and Contact Pressure Distribution of Bolted JointsreaderScribd9100% (1)

- Thrust SensorDokument6 SeitenThrust SensorArun Chand C VNoch keine Bewertungen

- Macro Element MethodDokument53 SeitenMacro Element MethodJony M. TemnikarNoch keine Bewertungen

- Great Information On Friction WeldDokument3 SeitenGreat Information On Friction WeldJason RichardsonNoch keine Bewertungen

- Forming metals using explosives and electromagnetic pulsesDokument6 SeitenForming metals using explosives and electromagnetic pulsesharicoolestNoch keine Bewertungen

- Explosive Forming or HERFDokument6 SeitenExplosive Forming or HERFharicoolestNoch keine Bewertungen

- Applsci 12 01273 v2Dokument16 SeitenApplsci 12 01273 v2Anandlal RNoch keine Bewertungen

- Reflow Soldering: Apparatus and Heat Transfer ProcessesVon EverandReflow Soldering: Apparatus and Heat Transfer ProcessesNoch keine Bewertungen

- Anti-Corrosion Methods and Materials: Article InformationDokument6 SeitenAnti-Corrosion Methods and Materials: Article InformationchecolonoskiNoch keine Bewertungen

- لماذا محمد صلى الله عليه و سلم هو الأعظم - أحمد ديداتDokument32 Seitenلماذا محمد صلى الله عليه و سلم هو الأعظم - أحمد ديداتahmed.ne7970100% (1)

- ماذا يثول الكتاب المقدس عن محمدDokument51 Seitenماذا يثول الكتاب المقدس عن محمدAbu Ahmed GhariebNoch keine Bewertungen

- SOAP AND DETERGENT MANUFACTURINGDokument13 SeitenSOAP AND DETERGENT MANUFACTURINGXsey Doh TukarnamoNoch keine Bewertungen

- Benzocaine (2 Steps)Dokument11 SeitenBenzocaine (2 Steps)checolonoski0% (1)

- Us 541899Dokument1 SeiteUs 541899checolonoskiNoch keine Bewertungen

- Patent - 一种用结晶控制技术制备球形化黑索今的方法 One Technique for Preparing ... - Google PatentsDokument9 SeitenPatent - 一种用结晶控制技术制备球形化黑索今的方法 One Technique for Preparing ... - Google PatentschecolonoskiNoch keine Bewertungen

- Us5032391 PDFDokument4 SeitenUs5032391 PDFchecolonoskiNoch keine Bewertungen

- بي PDFDokument2 Seitenبي PDFchecolonoskiNoch keine Bewertungen

- 1734 DDokument11 Seiten1734 DPasha TanNoch keine Bewertungen

- جورنال عراقى (جامعة تكريت) PDFDokument10 Seitenجورنال عراقى (جامعة تكريت) PDFchecolonoskiNoch keine Bewertungen

- 1734 DDokument11 Seiten1734 DPasha TanNoch keine Bewertungen

- 1734 DDokument11 Seiten1734 DPasha TanNoch keine Bewertungen

- Amphetamine Leucart ReactionDokument1 SeiteAmphetamine Leucart Reactionlukasz_wieczorek_praca100% (3)

- Us4278480 PDFDokument3 SeitenUs4278480 PDFchecolonoskiNoch keine Bewertungen

- Us4216720 PDFDokument7 SeitenUs4216720 PDFchecolonoskiNoch keine Bewertungen

- Urey1932 PDFDokument2 SeitenUrey1932 PDFchecolonoskiNoch keine Bewertungen

- Ravi2011 PDFDokument11 SeitenRavi2011 PDFchecolonoskiNoch keine Bewertungen

- Us2942965 PDFDokument2 SeitenUs2942965 PDFchecolonoskiNoch keine Bewertungen

- Us2787587 PDFDokument6 SeitenUs2787587 PDFchecolonoskiNoch keine Bewertungen

- fل PDFDokument2 Seitenfل PDFchecolonoskiNoch keine Bewertungen

- Us2741543 PDFDokument6 SeitenUs2741543 PDFchecolonoskiNoch keine Bewertungen

- Us2589532 PDFDokument7 SeitenUs2589532 PDFchecolonoskiNoch keine Bewertungen

- Us3457127 PDFDokument5 SeitenUs3457127 PDFchecolonoskiNoch keine Bewertungen

- Us2758006 PDFDokument16 SeitenUs2758006 PDFchecolonoskiNoch keine Bewertungen

- Us857580 PDFDokument2 SeitenUs857580 PDFchecolonoskiNoch keine Bewertungen

- PEPUNNUManuscript11jan2013 PDFDokument25 SeitenPEPUNNUManuscript11jan2013 PDFchecolonoskiNoch keine Bewertungen

- Gb191022030a PDFDokument2 SeitenGb191022030a PDFchecolonoskiNoch keine Bewertungen

- Us2344840 PDFDokument3 SeitenUs2344840 PDFchecolonoskiNoch keine Bewertungen

- Urey1931 PDFDokument9 SeitenUrey1931 PDFchecolonoskiNoch keine Bewertungen

- Effect of Preparation Method of Ni Catalyst Using Bentonite As The Support MaterialDokument8 SeitenEffect of Preparation Method of Ni Catalyst Using Bentonite As The Support MaterialNastitiNoch keine Bewertungen

- Chemistry Related Exam Questions and AnswersDokument11 SeitenChemistry Related Exam Questions and AnswersJoseph NyabugaNoch keine Bewertungen

- Test 1 Biology F4Dokument12 SeitenTest 1 Biology F4Nurfatin JamaludinNoch keine Bewertungen

- Predampening Benefits Shotcrete Quality and SafetyDokument3 SeitenPredampening Benefits Shotcrete Quality and SafetySantosh UpadhyayNoch keine Bewertungen

- Fisher Paykel Cosycot - Manual de Funcionamiento PDFDokument133 SeitenFisher Paykel Cosycot - Manual de Funcionamiento PDFpirihuey1234Noch keine Bewertungen

- Method Statement For Installation of Water Recticulation SystemDokument18 SeitenMethod Statement For Installation of Water Recticulation SystemRabi'atul Adawiyah Ismail100% (2)

- Bass String Diameters and TensionsDokument6 SeitenBass String Diameters and Tensionsbonruiz100% (1)

- Distillation Tower DesignDokument66 SeitenDistillation Tower DesignHavocFireNoch keine Bewertungen

- Polyclar For Wine - ASI v2Dokument47 SeitenPolyclar For Wine - ASI v2Giorgi GhambashidzeNoch keine Bewertungen

- CODEX STANDARD FOR FERMENTED MILKSDokument11 SeitenCODEX STANDARD FOR FERMENTED MILKSvabimhah100% (2)

- LCP SpanlockDokument8 SeitenLCP SpanlockGarfieldNoch keine Bewertungen

- Question Paper Synthesis and Analytical TechniquesDokument32 SeitenQuestion Paper Synthesis and Analytical TechniquesrajksdNoch keine Bewertungen

- Alkyl Halide and Aryl HalideDokument43 SeitenAlkyl Halide and Aryl HalideShivanshi0950% (2)

- Preliminary - Welding Procedure Specification (WPS)Dokument1 SeitePreliminary - Welding Procedure Specification (WPS)Rudi DaNoch keine Bewertungen

- 1984 WhiteheadDokument19 Seiten1984 WhiteheadAnita yuliyantiNoch keine Bewertungen

- Erosion Tecnalia 2016 06Dokument17 SeitenErosion Tecnalia 2016 06FernanNoch keine Bewertungen

- Lec 3.1 - Classification of Elements SK015 PDFDokument24 SeitenLec 3.1 - Classification of Elements SK015 PDFminaNoch keine Bewertungen

- Enzyme Assay Units: Amylase Units Lactase UnitsDokument4 SeitenEnzyme Assay Units: Amylase Units Lactase UnitsDaniel RincónNoch keine Bewertungen

- Hardness Desalination1Dokument18 SeitenHardness Desalination1Swati U NaikNoch keine Bewertungen

- Hardtop Ultra Comp ADokument13 SeitenHardtop Ultra Comp Anuryati jahariNoch keine Bewertungen

- Carbon Black ProcessDokument4 SeitenCarbon Black ProcessAnonymous azD9vQD100% (1)

- MSS SP-44-2016 Steel Pipeline FlangesDokument52 SeitenMSS SP-44-2016 Steel Pipeline Flangesarnoldbatista55100% (2)

- Unirub Techno India PVT 7Dokument7 SeitenUnirub Techno India PVT 7BalajiYachawadNoch keine Bewertungen

- Nu 5100 5100eg HalfDokument19 SeitenNu 5100 5100eg HalfCristian AedoNoch keine Bewertungen

- Acid BassDokument41 SeitenAcid BassRobert Edwards100% (1)

- PROCESS GAS SOLUTIONS: AERZEN'S RELIABLE COMPRESSORS AND BLOWERSDokument26 SeitenPROCESS GAS SOLUTIONS: AERZEN'S RELIABLE COMPRESSORS AND BLOWERSWesley andrade martins100% (1)

- 1000 Error Detection QuestionsDokument289 Seiten1000 Error Detection QuestionsSunil Kumar Jaiswal100% (2)

- 1584Dokument6 Seiten1584malsttarNoch keine Bewertungen

- Question Bank HTDokument12 SeitenQuestion Bank HTgreatrijuvanNoch keine Bewertungen

- MCQs From CBSE Class 10 Science Chapter 1Dokument59 SeitenMCQs From CBSE Class 10 Science Chapter 1kamal kumarNoch keine Bewertungen