Beruflich Dokumente

Kultur Dokumente

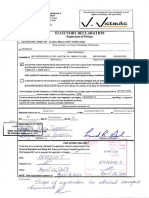

PSG Pipe Supports

Hochgeladen von

fileseekerOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PSG Pipe Supports

Hochgeladen von

fileseekerCopyright:

Verfügbare Formate

16415_PIPESUPPCOV:PipeSupports Cover

13:16

Page 1

Pipe Supports India Ltd

Door No. 6

Plot No. 29 Industrial Estate

Perungudi

Chennai 600096

India

Tel:

+91 44 2496 1003

Fax:

+91 44 2496 1395

E-mail: psi@pipesupports.com

Pipe Supports Asia Ltd

26/5 Moo 9, Soi Rattanaraj

Bangna-Trad Km 18.2

Bangchalong

Bangplee

Samut Prakarn

10540

Thailand

Tel:

+66 2 312 7685-7

Fax:

+66 2 312 7707-10

E-mail: psa@pipesupports.com

Japan office

E-mail: psj@pipesupports.com

Pipe Supports Group

S.E. Asia office

E-mail: pss@pipesupports.com

China office

E-mail: psc@pipesupports.com

Taiwan office

E-mail: pst@pipesupports.com

USA office

E-mail: psu@pipesupports.com

Website www.pipesupports.com

Pipe Supports Group

Pipe Supports Limited

Salwarpe Road

Droitwich

Worcestershire

WR9 9BH

United Kingdom

Tel:

+44 (0)1905 795 500

Fax:

+44 (0)1905 794 126

E-mail: psl@pipesupports.com

29/4/09

Pipe Supports Ltd (UK)

Pipe Supports USA Inc

Pipe Supports Asia Ltd

Pipe Supports India Ltd

Pipe Supports Ltd was formed in 1968 to design and

manufacture the Comet range of pipe hangers. Now, part of

the Hill & Smith Holdings PLC group of companies, Pipe

Supports Ltd has an enviable reputation for quality,

reliability, competitiveness, engineering excellence and

financial strength. Our products have been supplied to every

continent of the world through an international sales

network dedicated to meeting its customers stringent

quality and delivery requirements.

Pipe Supports Group has a continual development

programme, resulting in the most comprehensive range of

products available from one source. To ensure the products

are of the highest standard, they are produced in a

manufacturing plant equipped with the latest technology.

Pipe

Support Systems

Through our global manufacturing presence we are able to

offer competitive prices for projects around the world.

Hill & Smith

Holdings PLC

CAT. REF. 01/08

16415

29/04/09

Proof 3

16415

29/04/09

Proof 3

2005

16415_PIPESUPPCOV:PipeSupports Cover

29/4/09

13:16

Page 2

OVER 30 YEARS EXPERIENCE, SUPPLYING POWER GENERATION,

OIL, GAS, OFFSHORE, PETROCHEMICAL, PHARMACEUTICAL,

CHEMICAL AND WATER INDUSTRIES WORLDWIDE

Mission Statement. We are committed to being the

premier choice pipe support company for our customers,

suppliers and employees.

Global Service. Pipe Supports Limited was formed in

1968 to design and manufacture the Comet range of pipe

hangers. Now part of the Hill and Smith Holdings PLC group

of companies, Pipe Supports Ltd has an enviable reputation

for quality, reliability, competitiveness, engineering

excellence and financial strength. Our products have been

supplied to every continent of the world through an

international sales network dedicated to meeting its

customers stringent quality and delivery requirements.

16415

29/04/09

Proof 3

From its origins in the heart of the United Kingdom, Pipe

Supports Limited has grown into a worldwide organisation

with manufacturing plants in the UK, USA, India and

Thailand.

The Pipe Supports Group has a continual development

programme, resulting in the most comprehensive range of

products available from one source. To ensure the products

are of the highest standard, they are produced in

manufacturing plants equipped with the latest technology.

Through this global manufacturing presence, we are able to

offer competitive prices for projects around the world.

16415

29/04/09

Proof 3

H''''' PC''''' A'''''

CONTENTS

16415 P'''' 1 -110:14745 '1'2'3

29/4/09

12:38

P''' 1

Hanger Design

Pipe Clamps and Ancillaries

Load Group Basis

Additional Ancillary Items

Spenco Beam Attachments

Comlin Isolation Products

Easislide Low Friction Bearings

Constant Effort Supports

Variable Effort Supports

Dynamic Restraints

Turnbuckle Load Cell

10

Cryogenic Supports

11

16415

29/04/09

Proof 3

16415 P'''' 1 -110:14745 '1'2'3

H''''' PC''''' A'''''

29/4/09

12:38

P''' 2

PIPEWORK, STRESS ANALYSIS AND HANGER DESIGN

Over 30 Years worldwide experience.

Pipe Supports Limited has over 30 years experience of

designing and supplying hanger systems for power

stations, petrochemical complexes, pulp and paper mills

and other industrial installations. ISO 9001 approved,

PSL is establishing a reputation throughout the world

for its ability to accurately analyse piping stress, then

engineer, design and manufacture a cost-effective

support system.

Global design and supply solutions.

With design offices in the USA, Thailand, India, Japan

and the UK utilising the most up-to-date engineering

and design software we offer a fully co-ordinated

service: stress analysis of pipework, hanger selection,

design and detailing, manufacturing and contract

management. This service will ensure cost-effective

hanger systems, delivered in accordance with design

requirements.

Stress analysis.

We use PC-based piping stress analysis programs. These

software packages are engineering tools used in the

mechanical design and analysis of piping systems. A

model of the piping system is created using simple beam

elements and the loading conditions imposed on the

system are defined. From this input the software

produces results in terms of deflections, loads and

stresses throughout the system. In addition, they

compare these results with the allowable limits. PSL

spring hangers are automatically selected and sized

within such programs. They can analyse any piping

system for all normal and transient conditions, plus all

possible modes of operation.

Typical pipe

hanger

assembly.

Design of pipe hanger systems

To optimise this service, we have developed PSLCAD, a

bespoke package that functions within the Autocad

environment. It is designed to facilitate the selection,

drawing and listing of all standard components, spring

units and steelwork. This programme is also available

for customers to use in-house, enabling them to

maintain design responsibility, and at the same time

achieve dramatic savings in man hours.

We also offer FastDraw, a selection and detailing

program operating in MS Excel. Fast Draw provides the

facility to select and detail over 400 hanger

configurations including constant, variable and rigid

assemblies. The output includes a consolidated hanger

listing and individual support drawings, providing all

relevant dimensions and system data. The program is

available to customers and we are confident that

dramatic time savings can be realised using this

program.

For users of InterGraph, PDS and Bentley Plant Space

Design three dimensional modelling of Pipe Supports

products is available using SupportModeler by Pelican

Forge Software Corporation. www.pelicanforge.com

Production of detailed hanger drawings at Pipe

Supports Limited.

16415

29/04/09

Proof 3

Surveys of existing pipe hanger systems

Our engineers are experienced in surveying existing

systems reporting on their condition and making

recommendations on their correct installation and

future safe operation. Such surveys are increasingly

being demanded by utilities and safety authorities.

16415 P'''' 1 -110:14745 '1'2'3

H''''' PC''''' A'''''

29/4/09

12:38

P''' 3

PIPE CLAMPS AND ANCILLARIES LOAD GROUP BASIS

Index

114

LUG ATTACHMENT

234

ROD COUPLING

12

PC2

TWO BOLT PIPE

CLAMP

19

PC3

THREE BOLT PIPE

CLAMP

236

SPHERICAL

WASHER

41

RC4 & RC6

RISER CLAMPS

280

CUP FOR SPHERICAL

WASHER

59

FPR

FLAT PLATE TYPE

RISER CLAMP

281

DUAL FACED

ROCKER WASHER

75

PB

PIPE CLAMP BASES

230

EYE ROD

282

PLATE FOR DUAL

FACED ROCKER

WASHER

82

486

SPREADER BEAM

I BEAM TYPE

226 & 227

HANGER ROD &

ALL THREAD ROD

238

CLEVIS

83

487

SPREADER BEAM

TWIN CHANNEL

TYPE

122

BEAM WELDING

ATTACHMENT

235

TURNBUCKLE

122A

BEAM WELDING

ATTACHMENT FOR USE

WITH DUAL FACED

ROCKER WASHER

10

125

INVERTED BEAM

WELDING

ATTACHMENT

130

CEILING PLATE

7

8

11

277

LOCKNUT

274

CLEVIS PIN

278

FULL NUT

239

WELDLESS EYE NUT

9

279

FLAT WASHER

10

11

16415

29/04/09

Proof 3

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Nov 94Dokument16 SeitenNov 94Yllen de AgrelaNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Tablas de EsparragosDokument1 SeiteTablas de Esparragossgm6911Noch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Nov 94Dokument16 SeitenNov 94Yllen de AgrelaNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Jul03 PDFDokument24 SeitenJul03 PDFmailtosamrajNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Gylon ProductsDokument12 SeitenGylon ProductsfileseekerNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Men 0100Dokument20 SeitenMen 0100fileseekerNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Dec 93Dokument20 SeitenDec 93thlim19078656Noch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Trunnion Calculation SheetDokument3 SeitenTrunnion Calculation Sheetsudhisnair67% (3)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- 870 On CRN PDFDokument3 Seiten870 On CRN PDFfileseekerNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- 905 On CRNDokument6 Seiten905 On CRNfileseekerNoch keine Bewertungen

- HotTap Tie-In Analysis Caesar IIDokument24 SeitenHotTap Tie-In Analysis Caesar IIvarshneydushyantNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- HotTap Tie-In Analysis Caesar IIDokument24 SeitenHotTap Tie-In Analysis Caesar IIvarshneydushyantNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Pressure Vessel Newsletter Pressure Vessel Newsletter Pressure Vessel Newsletter Pressure Vessel NewsletterDokument22 SeitenPressure Vessel Newsletter Pressure Vessel Newsletter Pressure Vessel Newsletter Pressure Vessel NewsletterfileseekerNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- 870 On CRN PDFDokument3 Seiten870 On CRN PDFfileseekerNoch keine Bewertungen

- MEN0701Dokument24 SeitenMEN0701fileseekerNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Men 1297 PDFDokument24 SeitenMen 1297 PDFfileseekerNoch keine Bewertungen

- Rigid StiffnessDokument28 SeitenRigid StiffnessvsvineeshNoch keine Bewertungen

- Aug 92Dokument16 SeitenAug 92sabi_shiNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Rigid StiffnessDokument28 SeitenRigid StiffnessvsvineeshNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Mechanical Engineering: Merger Turns To Collaboration - COADE Remains IndependentDokument24 SeitenMechanical Engineering: Merger Turns To Collaboration - COADE Remains IndependentfileseekerNoch keine Bewertungen

- Mechanical Engineering: COADE, CAESAR II Celebrates 20 YearsDokument28 SeitenMechanical Engineering: COADE, CAESAR II Celebrates 20 YearsjanacadNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Men 0202Dokument28 SeitenMen 0202fileseekerNoch keine Bewertungen

- MEN0296Dokument28 SeitenMEN0296fileseekerNoch keine Bewertungen

- Mechanical Engineering: CAESAR II Receives TD12 Approval by TranscoDokument20 SeitenMechanical Engineering: CAESAR II Receives TD12 Approval by TranscofileseekerNoch keine Bewertungen

- Jul03 PDFDokument24 SeitenJul03 PDFmailtosamrajNoch keine Bewertungen

- Mechanical Engineering: COADE, CAESAR II Celebrates 20 YearsDokument28 SeitenMechanical Engineering: COADE, CAESAR II Celebrates 20 YearsfileseekerNoch keine Bewertungen

- Men 0703Dokument24 SeitenMen 0703fileseekerNoch keine Bewertungen

- Malleable Iron Swing Check Valve: 700 SWP/1000 CWP - Y-Pattern - Threaded EndsDokument1 SeiteMalleable Iron Swing Check Valve: 700 SWP/1000 CWP - Y-Pattern - Threaded EndsfileseekerNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Mechanical Engineering: CAESAR II Receives TD12 Approval by TranscoDokument20 SeitenMechanical Engineering: CAESAR II Receives TD12 Approval by TranscofileseekerNoch keine Bewertungen

- Jan 00Dokument20 SeitenJan 00Sachin ChavanNoch keine Bewertungen

- National Plumbing CodeDokument20 SeitenNational Plumbing CodeDonixNoch keine Bewertungen

- Manual VN93 - Ver.2.0Dokument62 SeitenManual VN93 - Ver.2.0Ranko AmortizerNoch keine Bewertungen

- Heat Trans Final ExamDokument1 SeiteHeat Trans Final ExamAaron GamezNoch keine Bewertungen

- 3.5 Nu TBG Rev1Dokument1 Seite3.5 Nu TBG Rev1haryantoNoch keine Bewertungen

- Installation Operation Maintenance: Chilled Water Fan Coil Unit Model HFCA Size 03 14Dokument16 SeitenInstallation Operation Maintenance: Chilled Water Fan Coil Unit Model HFCA Size 03 14mgs nurmansyahNoch keine Bewertungen

- API 5l Spec OngcDokument27 SeitenAPI 5l Spec OngcjamilvoraNoch keine Bewertungen

- Manjung Power Station - MalaysiaDokument96 SeitenManjung Power Station - MalaysiaMakoya_malume100% (1)

- Horizontal Split Case Fire Pumps Installation and Operating ManualDokument12 SeitenHorizontal Split Case Fire Pumps Installation and Operating ManualPuntanata SiagianNoch keine Bewertungen

- Tianjin Jieda Temperature Instruments Factory Bimetallic ThermometerDokument18 SeitenTianjin Jieda Temperature Instruments Factory Bimetallic ThermometerbunkeringNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Nipple Outlet: Welding Onto Header PipeDokument1 SeiteNipple Outlet: Welding Onto Header PipeSumner TingNoch keine Bewertungen

- GS Saf 321aDokument20 SeitenGS Saf 321aAhmad SaeedNoch keine Bewertungen

- WI-INSP-02 R1 Work Instruction - Heat Exchanger InspectionDokument5 SeitenWI-INSP-02 R1 Work Instruction - Heat Exchanger InspectionRakesh MishraNoch keine Bewertungen

- Katalog 1Dokument103 SeitenKatalog 1INoch keine Bewertungen

- Aquion Prosystems POU ManualDokument12 SeitenAquion Prosystems POU ManualGreg ReynekeNoch keine Bewertungen

- Light Pole On MSE Walls DetailsDokument3 SeitenLight Pole On MSE Walls DetailswalidNoch keine Bewertungen

- Approved Hemp For Installation of New Crude Oil Heater Package at Dps Dal-13-110Dokument12 SeitenApproved Hemp For Installation of New Crude Oil Heater Package at Dps Dal-13-110Roshin99Noch keine Bewertungen

- PVR6 Service Manual 265664 REV 04 19Dokument8 SeitenPVR6 Service Manual 265664 REV 04 19Partagon PowNoch keine Bewertungen

- Valve Standards ANSI BS APIDokument6 SeitenValve Standards ANSI BS APInaveenbaskaran1989Noch keine Bewertungen

- Blind FlangesDokument5 SeitenBlind FlangeszohaNoch keine Bewertungen

- QIP-PDI-G.3 - Design Instruction For Standard Pipe Support SelectionDokument1 SeiteQIP-PDI-G.3 - Design Instruction For Standard Pipe Support Selectiondimas prasetyoNoch keine Bewertungen

- 80 Series Mda Installation ManualDokument31 Seiten80 Series Mda Installation ManualAnonymous qNM765ILNoch keine Bewertungen

- Varian GC 450 Pre Installation Requirements English PDFDokument14 SeitenVarian GC 450 Pre Installation Requirements English PDFmardonioandrade0% (1)

- Liquefied Gas Pump Installation GuideDokument6 SeitenLiquefied Gas Pump Installation GuideLuis Meza ArevaloNoch keine Bewertungen

- Storage Tank Construction-ProcedureDokument37 SeitenStorage Tank Construction-ProcedureKarthikeyan Ganesan100% (1)

- Firefighting Design ChecklistDokument5 SeitenFirefighting Design ChecklistAli OsmanNoch keine Bewertungen

- 2015 StoneAge - LowresDokument51 Seiten2015 StoneAge - LowresAZLAN ABDULLAINoch keine Bewertungen

- P0050S MGPSDokument21 SeitenP0050S MGPSDmytro 1Noch keine Bewertungen

- Hibon Tri Lobe Blower ManualDokument55 SeitenHibon Tri Lobe Blower Manualmsaqibraza9350% (2)

- Master Fire Fighting BoqDokument10 SeitenMaster Fire Fighting Boqكرم عمروNoch keine Bewertungen

- Asme B31.3 Wall THK Equation - y ValuesDokument1 SeiteAsme B31.3 Wall THK Equation - y Valuesjoaquin torrano veraNoch keine Bewertungen