Beruflich Dokumente

Kultur Dokumente

Metraflex Flanged Hose&Braid

Hochgeladen von

Julio Rosas Pezo0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

74 Ansichten1 SeiteMetraflex

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenMetraflex

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

74 Ansichten1 SeiteMetraflex Flanged Hose&Braid

Hochgeladen von

Julio Rosas PezoMetraflex

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

Metraflex Flanged Hose and Braid Pump Connector

OPERATION, INSTALLATION AND MAINTENANCE INSTRUCTIONS

General: Metraflex flanged pump connectors are flexible metal hose pump connectors designed to minimize vibration

and make up for pipe misalignment. They are available in three standard sizes and custom lengths. Please consult the

factory submittals for specific performance specifications.

Application:

1. Pump connectors are designed to absorb vibration and lateral movement only. They are NOT designed for axial

movement.

2. Pump connectors are available in a wide range of lengths and diameters. Each has its own performance

characteristics. Confirm that the braided connector ratings for temperature, pressure, vacuum, and movements

match the system requirements and that the material selected is chemically compatible with the process fluid or

gas.

3. Pump connectors are not flow directional, unless optional flow conditioning vanes are included.

Installation:

1. Inspect pump connector for shipping damage, insure that the shipping bar is intact. Damaged joints should not be

used.

2. Piping should be aligned as closely as possible, and within the allowed connector limit.

3. Unit lengths must not be altered during installation. Install at dimensions indicated on submittal drawings.

4. Piping must be properly supported so pump connectors do not carry any pipe loads.

5. Flange holes of the connector and adjacent pipe flange should be aligned properly. Do not try to compensate for

flange or pipe misalignment by putting any torsional, compressive, extension, or offset loads on pump connector.

Testing:

1. Joint may be one-time pressure tested to 1-1/2 times the products maximum operating pressure. Do not

exceed maximum pressure or temperature during operation.

2. Metraflex recommends hydrostatic test with all air in the system removed. If an air test is performed,

appropriate safety precautions must be made.

Precautions:

1. Connectors should not be installed in inaccessible areas where inspection is impossible.

2. Make sure proper drainage is available in the event of leakage when operating personnel are not available.

3. If welding near a braided connector, cover the unit with a weld blanket to keep weld splatter from damaging the

braid cover.

Maintenance:

Pump Connectors have no serviceable parts and do not require maintenance. Metraflex recommends periodic

inspection for leakage or damage such as dents or broken braid. If damaged, replace and do not use.

CUSTOMER

PROJECT

ENGINEER

DESCRIPTION:

Flanged Hose & Braid

Pump Connector

ARCHITECT

PRO. OR P.O. NO.

Operation, Installation and Maintenance Instructions

DRAWING BY:

JC

DATE:

DRAWING NO.

12/18/12

Flanged H&B-OIM

Das könnte Ihnen auch gefallen

- Saudi Aramco Piping QC Inspector Sample Interview QuestionsDokument6 SeitenSaudi Aramco Piping QC Inspector Sample Interview QuestionsRichard Periyanayagam100% (3)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsVon Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsBewertung: 4 von 5 Sternen4/5 (1)

- 2017 Alcon Catalogue NewDokument131 Seiten2017 Alcon Catalogue NewJai BhandariNoch keine Bewertungen

- HVAC Handbook Part 3 Piping DesignDokument122 SeitenHVAC Handbook Part 3 Piping DesignTanveer100% (7)

- Dr. Rife and Philip Hoyland's 3.3 MHZ SweepDokument2 SeitenDr. Rife and Philip Hoyland's 3.3 MHZ SweepKhalid Ibrahim100% (1)

- CA-Clipper For DOS Version 5.3 Programming and Utilities GuideDokument718 SeitenCA-Clipper For DOS Version 5.3 Programming and Utilities GuideChris Harker91% (11)

- Slide 1: No-Churn TelecomDokument11 SeitenSlide 1: No-Churn Telecomleongladxton100% (1)

- Composite Hose InformationDokument3 SeitenComposite Hose InformationXain ChaudharyNoch keine Bewertungen

- Hose Usage Guide PDFDokument10 SeitenHose Usage Guide PDFKaustav SahaNoch keine Bewertungen

- 3 Operating Instructions High Pressure Hoses-0513-ENDokument4 Seiten3 Operating Instructions High Pressure Hoses-0513-ENwarehousekiyanly.giNoch keine Bewertungen

- Merkblatt Schlaeuche - eDokument2 SeitenMerkblatt Schlaeuche - eacNoch keine Bewertungen

- Rubber Expansion Joints Installation GuideDokument3 SeitenRubber Expansion Joints Installation GuideLudi D. LunarNoch keine Bewertungen

- Gulper Toilet DatasheetDokument4 SeitenGulper Toilet DatasheetchilliandchocNoch keine Bewertungen

- Mechanical PlugsDokument6 SeitenMechanical Plugskategord0% (1)

- PTFE Expansion Joint Instructions 1Dokument1 SeitePTFE Expansion Joint Instructions 1DDNoch keine Bewertungen

- 2 Installation Guidelines NHP5Dokument7 Seiten2 Installation Guidelines NHP5Andrei ZahaNoch keine Bewertungen

- Checks To Be Carried Out On Receipt of The Actuator: ! - #$ Flow ControlDokument4 SeitenChecks To Be Carried Out On Receipt of The Actuator: ! - #$ Flow ControlSyko GuyNoch keine Bewertungen

- PIPA TM001 PE Pipe System Maintenance Guide June 2008Dokument11 SeitenPIPA TM001 PE Pipe System Maintenance Guide June 2008RicNoch keine Bewertungen

- JFEBEAR TP M 001 - Rev2 - Running ManualDokument13 SeitenJFEBEAR TP M 001 - Rev2 - Running ManualJoseph BenettonNoch keine Bewertungen

- Inspection of The SystemsDokument12 SeitenInspection of The SystemsTulen CabuldinNoch keine Bewertungen

- Orifice Flange Union Assembly and Orifice Run Installation and Operation ManualDokument8 SeitenOrifice Flange Union Assembly and Orifice Run Installation and Operation ManualNithin CpNoch keine Bewertungen

- Hose Selection: Selection, Installation and Maintenance of Hose and Hose AssembliesDokument2 SeitenHose Selection: Selection, Installation and Maintenance of Hose and Hose AssembliesAbdul JunaediNoch keine Bewertungen

- Flexrite Pipe Installation ManualDokument44 SeitenFlexrite Pipe Installation ManualHugo Andrés MejíaNoch keine Bewertungen

- 卧式离心泵说明书英文(大连双龙)Dokument16 Seiten卧式离心泵说明书英文(大连双龙)kamal arabNoch keine Bewertungen

- Interplant Standard - Steel IndustryDokument10 SeitenInterplant Standard - Steel IndustryVishal Singh PatelNoch keine Bewertungen

- Hco Parte ViiiDokument33 SeitenHco Parte ViiiWilliam Manuel Forero IbañezNoch keine Bewertungen

- Tube Fitting Technical SpecificationDokument4 SeitenTube Fitting Technical Specificationksivakumar09100% (2)

- Installation Instructions Model NLC, N, C, & Ep Metal Bellows Expansion JointsDokument1 SeiteInstallation Instructions Model NLC, N, C, & Ep Metal Bellows Expansion JointsAnonymous euEXCKlNoch keine Bewertungen

- Installation Instructions Spool Type Elastomer Expansion JointsDokument2 SeitenInstallation Instructions Spool Type Elastomer Expansion JointsAmina TaissaNoch keine Bewertungen

- Power Piping LinesDokument9 SeitenPower Piping LinesArar gargeNoch keine Bewertungen

- Installation and Care of Hose and Hose Assemblies: EroquipDokument12 SeitenInstallation and Care of Hose and Hose Assemblies: EroquipJa Dari EropahNoch keine Bewertungen

- HFCC D Iom 03Dokument16 SeitenHFCC D Iom 03geovany_villagraNoch keine Bewertungen

- Saudi Aramco Piping QC Inspector Sample Interview Questions & Answers..Dokument5 SeitenSaudi Aramco Piping QC Inspector Sample Interview Questions & Answers..Ch SIB100% (1)

- Design Practice General PipeDokument8 SeitenDesign Practice General PipedevNoch keine Bewertungen

- Flex InstallDokument5 SeitenFlex Installlinga007Noch keine Bewertungen

- 4 WNS Series Horizontal Gas Fired Oil BoilerDokument25 Seiten4 WNS Series Horizontal Gas Fired Oil Boilerfauzi endra100% (1)

- Bomba de Doble DiafragmaDokument3 SeitenBomba de Doble DiafragmaOmar Horna PinedoNoch keine Bewertungen

- Section - 15140 Supports&AnchorsDokument11 SeitenSection - 15140 Supports&AnchorsNana DelgadoNoch keine Bewertungen

- Dynaflo Deep Well Pumps 51813 EnglishDokument12 SeitenDynaflo Deep Well Pumps 51813 EnglishomarantonioNoch keine Bewertungen

- Piping FabricationDokument3 SeitenPiping FabricationNa100% (2)

- Installation Operation Maintenance: HFO Fan CoilsDokument12 SeitenInstallation Operation Maintenance: HFO Fan CoilsRd GzNoch keine Bewertungen

- GT-Turbine Flowmeter ManualDokument16 SeitenGT-Turbine Flowmeter Manualedgarcoo100% (1)

- Installation, Commissioning and Servicing of Hydraulic Pumps and MotorsDokument2 SeitenInstallation, Commissioning and Servicing of Hydraulic Pumps and Motorsbhaswath2000Noch keine Bewertungen

- SECTION 15125 Pipe Expansion Joints 00000000 PART 1 - GENERAL 1.1 DescriptionDokument3 SeitenSECTION 15125 Pipe Expansion Joints 00000000 PART 1 - GENERAL 1.1 DescriptionAnonymous yniiLtiNoch keine Bewertungen

- LANL EngDokument3 SeitenLANL EngNaNoch keine Bewertungen

- Plentyc6000 ManualDokument22 SeitenPlentyc6000 Manualsumu123Noch keine Bewertungen

- Boiler Installation and SetupDokument30 SeitenBoiler Installation and Setupcakhokhe100% (1)

- Hot Tap Form Proposed SignatoriesDokument43 SeitenHot Tap Form Proposed SignatoriesSongAn BuiNoch keine Bewertungen

- Electric Head Transfer Chromalox Service ManualDokument6 SeitenElectric Head Transfer Chromalox Service ManualJorge ReyesNoch keine Bewertungen

- Torquing ManualDokument17 SeitenTorquing ManualZool HilmiNoch keine Bewertungen

- User Guide Orifice Plates, Orifice Flanges, Metering Runs and Venturi TubesDokument12 SeitenUser Guide Orifice Plates, Orifice Flanges, Metering Runs and Venturi Tubesxaaabbb_550464353100% (1)

- EQUIPMENT - Testing ProceduresDokument7 SeitenEQUIPMENT - Testing ProceduresGon FloNoch keine Bewertungen

- Check+Valves Crane+FS IOM 0221Dokument6 SeitenCheck+Valves Crane+FS IOM 0221Himanshu PatilNoch keine Bewertungen

- 600ws Plunger OmegaDokument37 Seiten600ws Plunger Omegaariel feNoch keine Bewertungen

- XB 13 InstallDokument8 SeitenXB 13 InstalljbozakNoch keine Bewertungen

- Iron Balancing Valves IOM For Hattersley ColourDokument8 SeitenIron Balancing Valves IOM For Hattersley ColourMuhammad ElbarbaryNoch keine Bewertungen

- Instructions On Installation Operation and Maintenance For Kirloskar Multistage PumpDokument39 SeitenInstructions On Installation Operation and Maintenance For Kirloskar Multistage PumpManoj KumarNoch keine Bewertungen

- Multistage Pump - Kirloskar PDFDokument63 SeitenMultistage Pump - Kirloskar PDFpsuvarnasNoch keine Bewertungen

- Operating Instructions For Metal and Rubber Hose Lines: 1. Packaging / Storage / TransportationDokument4 SeitenOperating Instructions For Metal and Rubber Hose Lines: 1. Packaging / Storage / TransportationFabio TemporiniNoch keine Bewertungen

- Kpds AllmodelsDokument39 SeitenKpds AllmodelsSumit ChaurasiaNoch keine Bewertungen

- Damages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsVon EverandDamages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- Icp Schedules: Exam Window Program Schedule Application DeadlineDokument1 SeiteIcp Schedules: Exam Window Program Schedule Application DeadlineJulio Rosas PezoNoch keine Bewertungen

- Xplore Orld Iping: Thredolets®Dokument4 SeitenXplore Orld Iping: Thredolets®Julio Rosas PezoNoch keine Bewertungen

- Ul - Viza - Ex15229 - Fittings GroovedDokument2 SeitenUl - Viza - Ex15229 - Fittings GroovedJulio Rosas PezoNoch keine Bewertungen

- Ul - Viza - Ex15228 - Fittings Grooved PDFDokument3 SeitenUl - Viza - Ex15228 - Fittings Grooved PDFJulio Rosas PezoNoch keine Bewertungen

- Manual AvicadDokument676 SeitenManual AvicadOlivia BlanaruNoch keine Bewertungen

- Long Quiz Direct VariationDokument2 SeitenLong Quiz Direct VariationHermann Dejero LozanoNoch keine Bewertungen

- Project Robot ArmDokument62 SeitenProject Robot ArmTechs Solutions RobotsNoch keine Bewertungen

- Rationalizing The Seismic Coefficient Method PDFDokument41 SeitenRationalizing The Seismic Coefficient Method PDFandremr15100% (1)

- FluidsDokument10 SeitenFluidslara alghamdiNoch keine Bewertungen

- NPTEL CC Assignment4Dokument4 SeitenNPTEL CC Assignment4Paul Stark100% (1)

- Binomial Poisson Normal DistributionDokument9 SeitenBinomial Poisson Normal DistributionFahim MahmudNoch keine Bewertungen

- 10 - Chapter 4 PDFDokument143 Seiten10 - Chapter 4 PDFKalyan ChakravarthyNoch keine Bewertungen

- Research Proposal TransformerDokument3 SeitenResearch Proposal Transformersohalder1026Noch keine Bewertungen

- Corrosion Properties of Copper Nickel Alloys in Chlorinated Sea WaterDokument14 SeitenCorrosion Properties of Copper Nickel Alloys in Chlorinated Sea WaterArunNoch keine Bewertungen

- Relayoperationprinciples 141126065914 Conversion Gate01Dokument43 SeitenRelayoperationprinciples 141126065914 Conversion Gate01kenlavie2Noch keine Bewertungen

- Module 1 SIMPLE INTERESTDokument15 SeitenModule 1 SIMPLE INTERESTElle Villanueva VlogNoch keine Bewertungen

- Staircase Preliminary Design Based On NBC and IS CodeDokument10 SeitenStaircase Preliminary Design Based On NBC and IS CodeEducation. HubNoch keine Bewertungen

- Modal LogicDokument14 SeitenModal LogicL'Homme RévoltéNoch keine Bewertungen

- 0625 w16 Ms 33Dokument10 Seiten0625 w16 Ms 33yuke kristinaNoch keine Bewertungen

- Cell Biology: Science Explorer - Cells and HeredityDokument242 SeitenCell Biology: Science Explorer - Cells and HeredityZeinab ElkholyNoch keine Bewertungen

- Pump Station System Curves Session 1Dokument29 SeitenPump Station System Curves Session 1Toan LeNoch keine Bewertungen

- JP MS Ramaiah Edhitha 2015Dokument21 SeitenJP MS Ramaiah Edhitha 2015UtkarshNoch keine Bewertungen

- Completation Inteligent RevistaDokument9 SeitenCompletation Inteligent RevistaGabriel Castellon HinojosaNoch keine Bewertungen

- J Lithos 2018 02 011Dokument52 SeitenJ Lithos 2018 02 011Warwick HastieNoch keine Bewertungen

- Nilfisk 2016Dokument12 SeitenNilfisk 2016Ilham HamidNoch keine Bewertungen

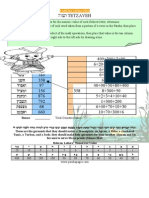

- Tetzaveh Parsha GematriaDokument1 SeiteTetzaveh Parsha GematriaRabbi Benyomin HoffmanNoch keine Bewertungen

- Aloe (Aloe Barbadensis Miller) Gel As An Agent in Delaying The Physical DETERIORATION OF EGGPLANT (Solanum Melongena), TOMATO (LycopersicumDokument20 SeitenAloe (Aloe Barbadensis Miller) Gel As An Agent in Delaying The Physical DETERIORATION OF EGGPLANT (Solanum Melongena), TOMATO (LycopersicumCyrus BautistaNoch keine Bewertungen

- Class Problems Sentences 13 The DDokument20 SeitenClass Problems Sentences 13 The DKnowledgeIsTruePowerNoch keine Bewertungen

- Recent Developments On The Interpretation of Dissolved Gas Analysis in TransformersDokument33 SeitenRecent Developments On The Interpretation of Dissolved Gas Analysis in TransformersputrasejahtraNoch keine Bewertungen

- PowerPoint Practice Exercise 1 InstructionsDokument3 SeitenPowerPoint Practice Exercise 1 InstructionsErick OumaNoch keine Bewertungen