Beruflich Dokumente

Kultur Dokumente

Spectre M 1 Ds English

Hochgeladen von

Ogbedande Awo OrunmilaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Spectre M 1 Ds English

Hochgeladen von

Ogbedande Awo OrunmilaCopyright:

Verfügbare Formate

Spectrem 1

Ultra Low-Modulus Silicone Joint Sealant

Issued to: Tremco Incorporated

Product:

Product Description

Spectrem 1 is an ultra low-modulus, high-performance, onepart, moisture-curing silicone joint sealant.

Spectrem 1

C719: Pass ____ Ext:+100%

Comp:-50%

Substrate: Mortar, Concrete, Aluminum, and Glass [mortar and

concrete tested unprimed and primed with Tremprime Silicone Porous Primer]

Basic Uses

Spectrem 1 has exceptional physical properties, making it an

ideal sealant for sealing the most demanding dynamically

moving joints. This includes material having a high coefficient

of linear expansion such as aluminum curtainwalls, precast

concrete panels, metal panels and window perimeters.

Spectrem 1 is formulated for expansion, control, lap joints,

and EIFS applications. It also acts as an adhesive used in

conjunction with Spectrem Simple Seal. Simple Seal is used

as a bridge seal in both new construction and restoration work.

(Please refer to the Simple Seal data sheet for more on this

product.)

Compatibility and Continuity

Spectrem 1 Silicone Sealant is the recommended sealant for use

when detailing over the ExoAir Air Barrier system to ensure

an airtight seal throughout the building envelope. Spectrem

1 has excellent adhesion to most polyethylene backed self-

Property

As Supplied:

Validation Date: 12/19/14 - 12/18/19

No. 1014-S119

2015

SEALANT VALIDATION

adhering air barrier membranes. The performance of Spectrem

1 is exceptional when used on the polyethylene face of ExoAir

110/110LT, ExoAir TWF, and the cured surface of ExoAir 120,

ExoAir 220, and ExoAir 230. Spectrem 1 is recommended for

use with Tremcos Silicone Rubber Extrusions and Tremcos

patented solution, Proglaze ETA (Engineered Transition

Assembly), for sealing between challenging conditions such as

the opaque wall air barrier and window/curtain wall assemblies.

For more information on Proglaze ETA, ExoAir or Tremcos

Silicone Rubber Extrusions please visit the Tremco website at

www.tremcosealants.com.

TYPICAL PHYSICAL PROPERTIES

Test Method

Typical Value

Tack-free time

ASTM C679

Curing time

Full Adhesion

30-60 min.

7-14 days

14-21 days

Flow, sag or slump inches

Nil

ASTM C639

Tooling time

10-20 min.

As Cured: After 14 days at 77 F (25 C) and 50% R.H.

Hardness (Shore A)

ASTM C661

15

Tensile strength at maximum elongation

ASTM D412

1.38 MPa (200 psi)

Tensile strength at 100% elongation

ASTM D412

.24 MPa (35 psi)

Tear Strength, die ("C")

ASTM D624

.7 kN/m (40 pli)

Peel Strength

ASTM C794

5.2 kN/m (30 pli)

ASTM C1248

No Stain

Stain and Color change

ASTM C510 TT-S-001543A

None

Cyclic movement

ASTM C719

Aluminum, Glass, Concrete

Staining of Porous Substrates

White Marble Primed & Unprimed

Extension +100

Compression -50

www.tremcosealants.com

spectrem 1_sd.indd 1

Page 1 of 2

5/28/2015 3:37:13 PM

Tremco recommends that air temperatures be 40 F (5 C)

or above before applying any sealant. If colder weather is

imminent, please refer to the Tremco Guide for Cold Weather

Applications at www.tremcosealants.com.

Applicable Standards

Spectrem 1 meets or exceeds the requirements of the following

specifications:

ASTM C920 Type S, Grade NS, Class 100/50, Use NT, M, G, A

and O

ASTM C1248

ASTM C1382

ASTM E84

U.S. Federal Specification TT-S-001543A (COM-NBS) Class A

U.S. Federal Specification TT-S-00230C (COM-NBS) Class A,

Type II

CAN/CGSB 19.13-M87, MCG-2-40-B-N

EIMA Test Method 300.01

Spectrem 1 has been tested as a component of several

wall assemblies meeting ASTM E2357, the Standard

Test Method for Determining Air Leakage of Air Barrier

Assemblies, and NFPA 285, the Standard Fire Test Method

for Evaluation of Fire Propagation Characteristics of Exterior

Non-Load-Bearing Wall Assemblies Containing Combustible

Components.

Tooling & Cleaning

Tooling is recommended immediately after application to

ensure firm, intimate contact with the joint interface. Dry

tooling is preferred. Cleaning can be accomplished with

solvents such as IPA or MEK while sealant is in an uncured

state.

Joint Backing

Bond Breaking Tape

Closed cell polyethylene backer rods or Tremco sealant tape

illmod 600 is preferred as joint backing to control depth of

sealant bead. Where depth of joint will prevent use of joint

backing, an adhesive backed polyethylene tape should be

installed to prevent three-sided adhesion. Joint backing must

be dry at time of the sealant application.

Application

Spectrem 1 is easy to apply with conventional caulking

equipment. Fill joint completely and tool. At 75 F (23.9 C),

50% R.H. a durable skin will form within 10 to 30 minutes.

Please visit www.tremcosealants.com for complete application

instructions.

Packaging

10.1 oz. (300mL) cartridges, 20 oz. (600mL) sausages, 2 gal.

(7.6L) and 4.5 gal. (17L) pails and 55 gal. (208L) drums. All

colors are not available in all package sizes. Contact Tremco

Customer Service for more information.

Standard Colors

Aluminum Stone, Anodized Aluminum, Gray, Limestone, White,

Off White, Precast White, Bronze, Buff, Dark Bronze, Ivory, Rustic

Brick, Sandstone, Black, Adobe Tan, Champagne, and Charcoal.

INSTALLATION

Joint Design

May be used in any joint designed in accordance with accepted

architectural/engineering practices. Joint width should be 4

times anticipated movement, but not less than 1/4 inch (6mm)

wide.

Joint Dimensions

For joints 1/4 inch (6mm) to 1/2 inch (13mm) wide, the width

to depth ratio should be equal. Joints 1/2 inch (13mm) wide

or greater should have a depth of 1/2 inch (13mm). Minimum

joint size is 1/4 inch by 1/4 inch (6mm by 6mm).

Surface Preparation

Surfaces must be sound, clean, and dry. Contact surfaces should

be free of loose dirt, dust, oils, and any other contaminants.

Maintenance

Damaged sealant can be repaired. Consult your Tremco

Distributor or Representative for repair procedures.

Availability

Immediately available from your local Tremco Sales

Representative, Tremco Distributor or Tremco Warehouse.

Limitations

Do not apply to damp or contaminated surfaces.

Use with adequate ventilation.

Not intended for continuous water immersion.

Warranty

Tremco warrants its Products to be free of defects in material,

but makes no warranty as to appearance or color. Since

methods of application and on-site conditions are beyond

our control and can affect performance, Tremco makes no

other warranty, expressed or implied, including warranties of

MERCHANTABILITY and FITNESS FOR A PARTICULAR PURPOSE,

with respect to Tremco Products. Tremcos sole obligation shall

be, at its option, to replace or refund the purchase price of the

quantity of Tremco Products proven to be defective and Tremco

shall not be liable for any loss or damage.

Please refer to our website at www.tremcosealants.com

for the most up-to-date Product Data Sheets.

Tremco Commercial Sealants & Waterproofing

3735 Green Road, Beachwood, OH 44122 // Phone: 216.292.5000 // 800.321.7906

220 Wicksteed Avenue, Toronto, ON M4H 1G7 // Phone: 416.421.3300 // 800.363.3213

1451 Jacobson Avenue, Ashland OH 44805 // Phone: 419.289.2050 // 800.321.6357

www.tremcosealants.com

spectrem 1_sd.indd 2

0515/SP1SD Page 2 of 2

5/28/2015 3:37:13 PM

Das könnte Ihnen auch gefallen

- 16 OduDokument53 Seiten16 OduRanson Oyadare Kennedy III93% (95)

- 16 OduDokument53 Seiten16 OduRanson Oyadare Kennedy III93% (95)

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Ogbe Ose Ayo SalamiDokument14 SeitenOgbe Ose Ayo SalamiOgbedande Awo Orunmila94% (18)

- RedGard Installation InstructionsDokument5 SeitenRedGard Installation InstructionsAlex LongNoch keine Bewertungen

- Build Your ASE Dennis AkomeahDokument3 SeitenBuild Your ASE Dennis AkomeahOgbedande Awo Orunmila89% (36)

- Imule - The Astral PactDokument5 SeitenImule - The Astral PactOgbedande Awo Orunmila100% (3)

- Build Your ASE Dennis AkomeahDokument3 SeitenBuild Your ASE Dennis AkomeahOgbedande Awo Orunmila89% (36)

- Esu OrikisDokument5 SeitenEsu OrikisOgbedande Awo Orunmila100% (6)

- Okanran Meji 8daycleansingDokument3 SeitenOkanran Meji 8daycleansingOgbedande Awo Orunmila100% (2)

- David Hudson Patent For The Preparation of GDokument13 SeitenDavid Hudson Patent For The Preparation of GStephen PattersonNoch keine Bewertungen

- D3618-05 Detection of Lead in Paint and Dried Paint Films1Dokument3 SeitenD3618-05 Detection of Lead in Paint and Dried Paint Films1Sara SánNoch keine Bewertungen

- Proglaze IIDokument3 SeitenProglaze IIMohammad ALTAKINoch keine Bewertungen

- Tremco® 830: Thermoplastic, Elastomeric Glass and Siding SealantDokument2 SeitenTremco® 830: Thermoplastic, Elastomeric Glass and Siding SealantDwinto RachmatNoch keine Bewertungen

- Nitoseal 125Dokument2 SeitenNitoseal 125Hantu TuahNoch keine Bewertungen

- Vulkem Athletic Play Surface Application SpecsDokument4 SeitenVulkem Athletic Play Surface Application SpecsOgbedande Awo OrunmilaNoch keine Bewertungen

- Spectrem 1Dokument2 SeitenSpectrem 1Joseph JayakanthanNoch keine Bewertungen

- Elastoroof PUDokument2 SeitenElastoroof PUpravi343450% (2)

- Product Data Sheet Asmacoat WP 810 Liquid Applied Polyurethane Waterproofing MembraneDokument3 SeitenProduct Data Sheet Asmacoat WP 810 Liquid Applied Polyurethane Waterproofing MembraneVaittianathan MahavapillaiNoch keine Bewertungen

- Proofex Torchseal (PE)Dokument2 SeitenProofex Torchseal (PE)kalidindivenkatarajuNoch keine Bewertungen

- Water Guard Epdm MembraneDokument4 SeitenWater Guard Epdm MembranefairmatechemicalNoch keine Bewertungen

- TDS - Mastertop 300Dokument3 SeitenTDS - Mastertop 300Venkata RaoNoch keine Bewertungen

- Sikaflex®-11 FCDokument4 SeitenSikaflex®-11 FCAbdulghani AsalaiNoch keine Bewertungen

- Waterproofing 5 PDFDokument7 SeitenWaterproofing 5 PDFSwapnil AlandNoch keine Bewertungen

- Eucolastic 1NS: S - C, P H SDokument2 SeitenEucolastic 1NS: S - C, P H Svasanth rNoch keine Bewertungen

- Durakol G HMDokument3 SeitenDurakol G HMpbodooNoch keine Bewertungen

- TREMproof250GC DS EnglishDokument2 SeitenTREMproof250GC DS EnglishOgbedande Awo OrunmilaNoch keine Bewertungen

- 3M 3015 VP Vapor Permeable Air Barrier TDS v8!18!17Dokument4 Seiten3M 3015 VP Vapor Permeable Air Barrier TDS v8!18!17Hari SantosoNoch keine Bewertungen

- SikaflexPRO TdsDokument6 SeitenSikaflexPRO TdsidontlikeebooksNoch keine Bewertungen

- iKOTE AC 40 (DEC-2023) V1.3Dokument2 SeiteniKOTE AC 40 (DEC-2023) V1.3nguyen hoang AnhNoch keine Bewertungen

- Aqua SealDokument2 SeitenAqua Sealpravi3434Noch keine Bewertungen

- TDS Pattex BondsealfillDokument5 SeitenTDS Pattex BondsealfilldknisNoch keine Bewertungen

- Super StopDokument1 SeiteSuper StopReyna Mari Espinoza AguilarNoch keine Bewertungen

- Preprufe 300R & 160RDokument6 SeitenPreprufe 300R & 160RvelarajanNoch keine Bewertungen

- Vulkem 350NF - Tremco Epoxy Primer - CVDokument5 SeitenVulkem 350NF - Tremco Epoxy Primer - CVAriel Sepúlveda CaroNoch keine Bewertungen

- Palmair Design ManualDokument37 SeitenPalmair Design ManualAlfred Harvey ElacionNoch keine Bewertungen

- Sikacrete - 114: Free Flowing Microconcrete For Grouting and RepairDokument3 SeitenSikacrete - 114: Free Flowing Microconcrete For Grouting and RepairQazinadeemNoch keine Bewertungen

- Elastuff 102Dokument3 SeitenElastuff 102pravi3434Noch keine Bewertungen

- Cmci Cmci: High Flow Epoxy Grout SystemDokument2 SeitenCmci Cmci: High Flow Epoxy Grout Systempravi3434Noch keine Bewertungen

- Sikaflex 11FCDokument3 SeitenSikaflex 11FCthe pilotNoch keine Bewertungen

- Cmci Cmci: High Performance Epoxy Grout SystemDokument2 SeitenCmci Cmci: High Performance Epoxy Grout Systempravi3434Noch keine Bewertungen

- Nitoproof 600Dokument4 SeitenNitoproof 600sandeepuaeNoch keine Bewertungen

- Bitustick XLSDokument2 SeitenBitustick XLSAbed DaherNoch keine Bewertungen

- 3m Window Film Prestige Nanotechnology D PrestigeDokument2 Seiten3m Window Film Prestige Nanotechnology D PrestigelarconeNoch keine Bewertungen

- Atlas E-Pro Patch PDSDokument2 SeitenAtlas E-Pro Patch PDSuks444Noch keine Bewertungen

- Conbextra EP75Dokument4 SeitenConbextra EP75Venkata Raju KalidindiNoch keine Bewertungen

- Thioflex 600 Pouring Grade TDSDokument3 SeitenThioflex 600 Pouring Grade TDSAhmed NacherNoch keine Bewertungen

- Roadsaver Silicone SLDokument2 SeitenRoadsaver Silicone SLTeddy TPNoch keine Bewertungen

- FLORPRUFE120Dokument2 SeitenFLORPRUFE120Walter PattiNoch keine Bewertungen

- RTV Is800 SeriesDokument4 SeitenRTV Is800 SeriesFaraan KhanNoch keine Bewertungen

- Acrabond KE45 Type RTV Silicone SealantDokument5 SeitenAcrabond KE45 Type RTV Silicone SealantdrvikaasNoch keine Bewertungen

- 05 - TDS - Mastertop 300Dokument4 Seiten05 - TDS - Mastertop 300Vimal KakNoch keine Bewertungen

- PDS Sikacrete 113 PPDokument4 SeitenPDS Sikacrete 113 PPKoh HanNoch keine Bewertungen

- Roof GuardDokument2 SeitenRoof Guardpravi3434Noch keine Bewertungen

- Cicol Et SlurryDokument3 SeitenCicol Et SlurryBalasubramanian Ananth100% (1)

- Product Data Sheet: G 2100 - Silicone SealantDokument2 SeitenProduct Data Sheet: G 2100 - Silicone SealantShahid BhattiNoch keine Bewertungen

- Nitomortar TSDokument2 SeitenNitomortar TSBalasubramanian AnanthNoch keine Bewertungen

- Specification GlassFiberDokument6 SeitenSpecification GlassFiberMukesh MaharjanNoch keine Bewertungen

- TDS-Foster 95-44 EN PDFDokument2 SeitenTDS-Foster 95-44 EN PDFEshaghNoch keine Bewertungen

- Pds-Cpd-Sikaflex Mortar Fix-UsDokument2 SeitenPds-Cpd-Sikaflex Mortar Fix-UsBudhi KurniawanNoch keine Bewertungen

- Cmci Cmci: Epoxy Grout System For Equipment BasesDokument2 SeitenCmci Cmci: Epoxy Grout System For Equipment Basespravi3434Noch keine Bewertungen

- Conbextra EP10Dokument2 SeitenConbextra EP10MuhammedHafis100% (1)

- Decofill: Fast Setting Flexible Acrylic SealantDokument2 SeitenDecofill: Fast Setting Flexible Acrylic SealantVenkata Raju KalidindiNoch keine Bewertungen

- MSDS - ASMACO RTV GasketDokument2 SeitenMSDS - ASMACO RTV GasketadminNoch keine Bewertungen

- 15 07 17 FT SiMP High TackDokument4 Seiten15 07 17 FT SiMP High TackAmon AlastorNoch keine Bewertungen

- Glazing Compatibility6 PDFDokument3 SeitenGlazing Compatibility6 PDFpandey008Noch keine Bewertungen

- Adhesive Trim Tape: High-Strength Double-Sided Adhesive Tape With Polyethylene Carrier and Acrylate AdhesiveDokument1 SeiteAdhesive Trim Tape: High-Strength Double-Sided Adhesive Tape With Polyethylene Carrier and Acrylate AdhesiveAnas EidNoch keine Bewertungen

- TDs - Emaco R101Dokument3 SeitenTDs - Emaco R101Venkata RaoNoch keine Bewertungen

- Jotafloor: Traffic Deck SystemDokument12 SeitenJotafloor: Traffic Deck SystemUnited Construction Est. TechnicalNoch keine Bewertungen

- Eucocrete Supreme Guide Specifications b653Dokument4 SeitenEucocrete Supreme Guide Specifications b653Ogbedande Awo OrunmilaNoch keine Bewertungen

- TREMproof250GC DS EnglishDokument2 SeitenTREMproof250GC DS EnglishOgbedande Awo OrunmilaNoch keine Bewertungen

- Henry Waterproofing BrochureDokument7 SeitenHenry Waterproofing BrochureOgbedande Awo OrunmilaNoch keine Bewertungen

- 3M Foam Tile NOADokument11 Seiten3M Foam Tile NOAOgbedande Awo OrunmilaNoch keine Bewertungen

- TBS109 RXT915 Flash Sealant Low Res UpdateDokument1 SeiteTBS109 RXT915 Flash Sealant Low Res UpdateOgbedande Awo OrunmilaNoch keine Bewertungen

- Acryl 60: Water-Based Acrylic Bonding and Modifying AdmixtureDokument4 SeitenAcryl 60: Water-Based Acrylic Bonding and Modifying AdmixtureOgbedande Awo OrunmilaNoch keine Bewertungen

- WPB - Painting BidDokument25 SeitenWPB - Painting BidOgbedande Awo OrunmilaNoch keine Bewertungen

- Alpha EngineeringDokument1 SeiteAlpha EngineeringOgbedande Awo OrunmilaNoch keine Bewertungen

- 33 - TDS - Thoro WaterplugDokument3 Seiten33 - TDS - Thoro WaterplugOgbedande Awo OrunmilaNoch keine Bewertungen

- Sharkskin Ultra NOADokument6 SeitenSharkskin Ultra NOAOgbedande Awo OrunmilaNoch keine Bewertungen

- OrikiEgunDokument13 SeitenOrikiEgunAbdel Antúnez98% (41)

- Ategbe (Iwure Ifa)Dokument3 SeitenAtegbe (Iwure Ifa)Ogbedande Awo OrunmilaNoch keine Bewertungen

- Chief Fama - Itadogun Ifa - Orun IfaDokument3 SeitenChief Fama - Itadogun Ifa - Orun IfaOgbedande Awo Orunmila82% (11)

- RGPV BE Syllabus BE-101 Engineering ChemistryDokument2 SeitenRGPV BE Syllabus BE-101 Engineering ChemistryDeepak prasadNoch keine Bewertungen

- Levis Green TechnologyDokument71 SeitenLevis Green TechnologyManish PareekNoch keine Bewertungen

- Ferulic Acid From Grains - BreweryDokument10 SeitenFerulic Acid From Grains - BreweryrinjaniNoch keine Bewertungen

- Soil Survey Module 3 Lesson 2Dokument8 SeitenSoil Survey Module 3 Lesson 2Mon AmiNoch keine Bewertungen

- 12th Science HSC Chemistry I PDFDokument14 Seiten12th Science HSC Chemistry I PDFSayyed SohelNoch keine Bewertungen

- Lab ManDokument59 SeitenLab Manajay sharmaNoch keine Bewertungen

- Organic Chemistry 9th Edition Wade Test BankDokument46 SeitenOrganic Chemistry 9th Edition Wade Test Bankjavierwarrenqswgiefjyn100% (26)

- Ceramics - Office of Environmental Health and SafetyDokument7 SeitenCeramics - Office of Environmental Health and SafetyKashaf ButtNoch keine Bewertungen

- Syllabus For Bachelor of Science (Biotechnology, Chemistry, Botany) Academic Year (2011)Dokument22 SeitenSyllabus For Bachelor of Science (Biotechnology, Chemistry, Botany) Academic Year (2011)rutwickNoch keine Bewertungen

- AlkaloidsDokument28 SeitenAlkaloidsKamala Badalova100% (2)

- Chemistry Final Study GuideDokument27 SeitenChemistry Final Study Guidesana lazfaNoch keine Bewertungen

- Mineral Wool Pipe Insulation: DescriptionDokument2 SeitenMineral Wool Pipe Insulation: DescriptionFaizal AchmadNoch keine Bewertungen

- Declaration of Compliance: Product Manufacturer - Plastchim-T ADDokument12 SeitenDeclaration of Compliance: Product Manufacturer - Plastchim-T ADDavid LauraNoch keine Bewertungen

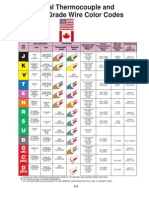

- International Thermocouple and Extension Grade Wire Color CodesDokument6 SeitenInternational Thermocouple and Extension Grade Wire Color CodesEdguitar TheLonelyNoch keine Bewertungen

- Cacl Ca: Seigfred John M. Miranda Che121.1 Laboratory 1Dokument5 SeitenCacl Ca: Seigfred John M. Miranda Che121.1 Laboratory 1Kathleen Caryl PiedadNoch keine Bewertungen

- Molecular Analysis of Er:YAG Laser Irradiation On DentinDokument5 SeitenMolecular Analysis of Er:YAG Laser Irradiation On DentinLeila MoghadasNoch keine Bewertungen

- 6 - Polymer ChemistryDokument34 Seiten6 - Polymer ChemistryClarkNoch keine Bewertungen

- 3503 - 3506, 1974. Pergamon Press.: Tetrahedron Letters No. 39, PP Printed in Great BritainDokument4 Seiten3503 - 3506, 1974. Pergamon Press.: Tetrahedron Letters No. 39, PP Printed in Great Britaintuyenvip441999Noch keine Bewertungen

- H S Removal TechnologyDokument31 SeitenH S Removal Technologytaufik budiarjoNoch keine Bewertungen

- June 2018 QP - Paper 1 OCR (A) Chemistry AS-LevelDokument24 SeitenJune 2018 QP - Paper 1 OCR (A) Chemistry AS-LevelRunNoch keine Bewertungen

- Point To Remember (12th)Dokument4 SeitenPoint To Remember (12th)Raju SinghNoch keine Bewertungen

- Chem Lab Unit 1Dokument6 SeitenChem Lab Unit 1Hudha ImthiharNoch keine Bewertungen

- Lab 03Dokument3 SeitenLab 03hightecrebelNoch keine Bewertungen

- PhosphatingDokument9 SeitenPhosphatingnirai101259Noch keine Bewertungen

- Ncert ch3 Chemistry Class 11Dokument26 SeitenNcert ch3 Chemistry Class 11Karan ManglaNoch keine Bewertungen

- Dr. - Jungho Cho. Introduction To Electrolyte Process Simulation Using PRO - II With PROVISIONDokument27 SeitenDr. - Jungho Cho. Introduction To Electrolyte Process Simulation Using PRO - II With PROVISIONamirNoch keine Bewertungen

- 06 07 08 Chemical EORDokument72 Seiten06 07 08 Chemical EORAndre WibawaNoch keine Bewertungen

- ĐỀ CƯƠNG ÔN TẬP KIỂM TRA GIỮA KÌ 10NCDokument4 SeitenĐỀ CƯƠNG ÔN TẬP KIỂM TRA GIỮA KÌ 10NCTrần Vũ HoàngNoch keine Bewertungen