Beruflich Dokumente

Kultur Dokumente

STR8 Guia Rapido

Hochgeladen von

David Saymon0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

213 Ansichten2 Seitenstr8 driver

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenstr8 driver

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

213 Ansichten2 SeitenSTR8 Guia Rapido

Hochgeladen von

David Saymonstr8 driver

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

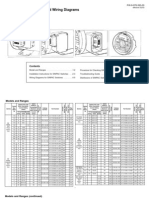

STR4/8 Quick Setup Guide

Requirements

To begin, make sure you have the following equipment:

A compatible stepper motor.

A small flat blade screwdriver for tightening the connectors (included).

A suitable DC power supply. AMP recommends the PS150A24 or PS320A48 available from Applied Motion.

Motor & Power Supply

Connector

Input & Output

Signals

Run Current, Idle Current

Steps/rev, Inertia, Self Test

Status LEDs

Motor Selector

Layout of the front panel of the STR drive.

Wiring the Drive

Step 1 - wiring the DC supply

a. Wire the drive to the DC power source.

(do not apply power until all connections to the drive have been made)

Note, the STR4 accepts DC voltages from 24-48V, while the STR8 accepts

DC voltages from 24-75V.

b. Ensure a proper earth ground connection by using the screw on the

left side of the chassis.

If using an external fuse, we recommend the following in-line with the V+ connection :

STR4: 3AG, 4 amp (Littlefuse 313004P)

STR8: 3AG, 6.25 amp (Littlefuse 3136.25P)

*See the STR Hardware Manual for more information about

power supply and fuse selection.

Step 2 - wiring the motor

Connect the drive to the motor. Four lead motors can be connected in only one way, as shown in Figure 1.

We recommend that eight lead motors be connected in parallel, as shown in Figure 2.

If using a non-Applied Motion Products motor, please refer to your motor specs for wiring information.

A+

A- B+

red lue low

b el ite

y h

w

Figure 1

A+ A- B+ B-

B-

t

wh

k/ wht

t

g/ ht

e

r

wh

g

o

an k+ l/w d/

or lac ye +re

b ed+ ow

r ell

y

l

+b

Figure 2

920-0031 A

Setting up the Drive

Step 4 - selecting current

Step 3 - selecting the motor

Selecting the motor

Motor selection is done with the 16 position

rotary switch on the front of the drive; refer to

the label on the drive to see the motor choices

available to you. Turn the rotary switch to the

number that represents the motor you have.

This selects important information stored on

the drive, such as current and anti-resonance

settings, to get the best performance from

your motor.

Step 5 - load inertia

1 2

1 2

1 2

1 2

100%

90%

80%

70%

50%

90%

Step 6 - step resolution

SW3 chooses between two load

inertia ratio ranges.

There are 4 microstep resolutions to

choose from as well as full and half step.

This information is used in the anti-

resonance configuration.

200

200 with microstep emulation (smooth)

400

400 with microstep emulation (smooth)

2000

5-10X

0-4X

SW4 sets the idle

current to either

50% or 90% of the

selected

running

current.

Sets the running current to

70%, 80%, 90% or 100% of the

motors rated maximum current.

5000

5 6 7

5 6 7

5 6 7

5 6 7

20000

12800

5000

2000

5 6 7

5 6 7

5 6 7

5 6 7

400

SMOOTH

400

200

SMOOTH

200

12800

20000

Step 7 - self test

Step 8 - user manual

The STR has a built in Self Test function. If switch 8 is

moved to the ON position the drive will automatically rotate

the motor back and forth, two turns in each direction. This

feature can be used to confirm that the motor is correctly

wired, selected and otherwise operational.

A full user manual for the STR is available for download

from our web site. This contains full details on setup,

wiring and installation.

www.applied-motion.com/support

ON OFF

SELF TEST

If you have any questions or comments, please call Applied Motion Products

Customer Support: (800) 525-1609, or visit us online at

www.applied-motion.com.

404 Westridge Dr.

Watsonville, CA 95076

Tel: 800-525-1609 Fax: 831-761 -6544

www.applied-motion.com

920-0031 A

Das könnte Ihnen auch gefallen

- Gecko Drive g340 - 815e28e418 PDFDokument7 SeitenGecko Drive g340 - 815e28e418 PDFRemus PopescuNoch keine Bewertungen

- Probo Step VXDokument3 SeitenProbo Step VXIvan VillanevaNoch keine Bewertungen

- Warning: OS77 Series Single Set Point SwitchDokument2 SeitenWarning: OS77 Series Single Set Point SwitchJohn GarnetNoch keine Bewertungen

- TB6560 3axis DriverDokument11 SeitenTB6560 3axis DriverPHQ1910Noch keine Bewertungen

- Owner'S Manual: Powertap SLDokument39 SeitenOwner'S Manual: Powertap SLsinkdeepNoch keine Bewertungen

- Atv71 Installation Manual EngDokument43 SeitenAtv71 Installation Manual EngArun SudarsanNoch keine Bewertungen

- Variable Speed Drives for Asynchronous Motors Installation ManualDokument43 SeitenVariable Speed Drives for Asynchronous Motors Installation ManualsilvaroneNoch keine Bewertungen

- Applied Motion 3540moDokument10 SeitenApplied Motion 3540moPham TruongNoch keine Bewertungen

- User's Manual: Step Motor DriverDokument20 SeitenUser's Manual: Step Motor DriverAdalmi Santos SilvaNoch keine Bewertungen

- 3540i Hardware ManualDokument14 Seiten3540i Hardware ManualRicardo PossebonNoch keine Bewertungen

- Hardware Manual ACS800-07 Drives (500 To 2800 KW)Dokument193 SeitenHardware Manual ACS800-07 Drives (500 To 2800 KW)Bhanu Prakash100% (1)

- Parker SSD 650 Easy Start GuideDokument17 SeitenParker SSD 650 Easy Start Guideeng_karamazabNoch keine Bewertungen

- Pololu - A4988 Stepper Motor Driver CarrierDokument7 SeitenPololu - A4988 Stepper Motor Driver CarrierJuan Alberto Casares ZaragozaNoch keine Bewertungen

- GSC300Dokument21 SeitenGSC300saneesh81Noch keine Bewertungen

- Warning: Canstart™ 9641/9642Dokument4 SeitenWarning: Canstart™ 9641/9642montoya2333Noch keine Bewertungen

- Ajustes Trans 140GDokument13 SeitenAjustes Trans 140GDomingo Cruz Garcia100% (3)

- Testing Methods For Rebuild UnitsDokument8 SeitenTesting Methods For Rebuild UnitsBhone ThantNoch keine Bewertungen

- User Manual v2 9-AMC-AASD15A 4DOF+TL+Surge-SRS-SimtoolsDokument29 SeitenUser Manual v2 9-AMC-AASD15A 4DOF+TL+Surge-SRS-Simtoolsnelu petNoch keine Bewertungen

- BPM24RT100BL Specspecifications UpdateDokument8 SeitenBPM24RT100BL Specspecifications UpdatemalleNoch keine Bewertungen

- Rotork Control Pub005-002!00!1008Dokument16 SeitenRotork Control Pub005-002!00!1008kamal_khan85Noch keine Bewertungen

- Manual Mystery ESCDokument8 SeitenManual Mystery ESCdruidhanetNoch keine Bewertungen

- ST400 Series Tachometers: User ManualDokument22 SeitenST400 Series Tachometers: User ManualEdison100Noch keine Bewertungen

- Must Be Set.: Set As Required.: Parameter NumberDokument9 SeitenMust Be Set.: Set As Required.: Parameter NumberMetodi NacevNoch keine Bewertungen

- Torque Follower Setup Rev 1Dokument7 SeitenTorque Follower Setup Rev 1NelsonNoch keine Bewertungen

- Variador Carlo GavazziDokument107 SeitenVariador Carlo GavazziPepe ChampiiNoch keine Bewertungen

- Manual Sigma VDokument420 SeitenManual Sigma VJocemar MartinsNoch keine Bewertungen

- Catalog MPDokument28 SeitenCatalog MPCARLOSWAR101Noch keine Bewertungen

- Σ-V Series USER'S MANUALDokument409 SeitenΣ-V Series USER'S MANUALmssurajNoch keine Bewertungen

- Datasheet 1182 PDFDokument6 SeitenDatasheet 1182 PDFabs0001Noch keine Bewertungen

- LS SV IG5A Easy Start GuideDokument16 SeitenLS SV IG5A Easy Start GuidePhong Nguyen100% (2)

- Changzhou Wantai Electrical Appliance Co., LTD: User Guide For 4 Axis TB6560 Driver BoardDokument11 SeitenChangzhou Wantai Electrical Appliance Co., LTD: User Guide For 4 Axis TB6560 Driver BoardP BNoch keine Bewertungen

- Yaskawa Pulse TrainDokument409 SeitenYaskawa Pulse Traincorrecaminos69Noch keine Bewertungen

- Installation Instructions and Wiring Diagrams For All Models and RangesDokument8 SeitenInstallation Instructions and Wiring Diagrams For All Models and RangesMaria MusyNoch keine Bewertungen

- CNC4x35a User ManualDokument6 SeitenCNC4x35a User ManualAdrian SBNoch keine Bewertungen

- Altivar Atv66 User ManualDokument52 SeitenAltivar Atv66 User ManualNitin SutarNoch keine Bewertungen

- Em-176 Dc-Motor Controller 12/24Vdc 10ADokument2 SeitenEm-176 Dc-Motor Controller 12/24Vdc 10AMarco Taype FelixNoch keine Bewertungen

- Volvo Diesel Generator p150v Tad720geDokument4 SeitenVolvo Diesel Generator p150v Tad720geEvany Ziñho QNoch keine Bewertungen

- Engine Brake Tests (Mack E-Tech™ Engine With J-Tech™ Engine Brake) Operational TestsDokument10 SeitenEngine Brake Tests (Mack E-Tech™ Engine With J-Tech™ Engine Brake) Operational TestsVictor ValenciaNoch keine Bewertungen

- CV7300 Instruction Manual 11-05Dokument132 SeitenCV7300 Instruction Manual 11-05boomdenNoch keine Bewertungen

- Product - Support-Precor-Service Manuals-Commercial Treadmill-C956i (240 VAC) (Serial Code Z5)Dokument69 SeitenProduct - Support-Precor-Service Manuals-Commercial Treadmill-C956i (240 VAC) (Serial Code Z5)Gabino Ubilio MurilloNoch keine Bewertungen

- Parker SSD Drives 650 Series Quick Start GuideDokument2 SeitenParker SSD Drives 650 Series Quick Start Guideeng_karamazabNoch keine Bewertungen

- Yea-kaeps800000042j-Sgmjv - Chon Hang Motor Servo Sigma VDokument14 SeitenYea-kaeps800000042j-Sgmjv - Chon Hang Motor Servo Sigma VtrandanhhaiNoch keine Bewertungen

- Torsepc 5001TCP Manual 09'29'2003Dokument18 SeitenTorsepc 5001TCP Manual 09'29'2003mahh1234100% (2)

- Ec5111 6-09 PDFDokument5 SeitenEc5111 6-09 PDFAnonymous M0OEZEKoGiNoch keine Bewertungen

- 82-E2MAN-IN Optidrive ODE-2 IP20 IP66 User Guide v3.20 PDFDokument28 Seiten82-E2MAN-IN Optidrive ODE-2 IP20 IP66 User Guide v3.20 PDFDANE80Noch keine Bewertungen

- DYNA Power Control Manual For Plus 1, Plus 2, Plus 4 and Plus 6 Ft. Lb. SystemsDokument18 SeitenDYNA Power Control Manual For Plus 1, Plus 2, Plus 4 and Plus 6 Ft. Lb. SystemsDavid Coronado100% (1)

- EF03063 ElecFreaksDokument7 SeitenEF03063 ElecFreaksElectronicos CaldasNoch keine Bewertungen

- AUMA Valve ActuatorDokument14 SeitenAUMA Valve ActuatorSellappan MuthusamyNoch keine Bewertungen

- Ec5000 6-09 PDFDokument5 SeitenEc5000 6-09 PDFAnonymous M0OEZEKoGiNoch keine Bewertungen

- Abb Acs800 07 500 2800 PDFDokument193 SeitenAbb Acs800 07 500 2800 PDFJesus OliverosNoch keine Bewertungen

- V1000 Drive ManualDokument26 SeitenV1000 Drive ManualjitendrakumarmishraNoch keine Bewertungen

- ZTW Seal Series Boat ESC User ManualDokument7 SeitenZTW Seal Series Boat ESC User ManualBenoit THIRIONNoch keine Bewertungen

- ATV21 HVAC ShortformV2.1Dokument4 SeitenATV21 HVAC ShortformV2.1Syed Noman AhmedNoch keine Bewertungen

- Owner'S Guide: Microarc 4 - 100 MM 4Th AxisDokument15 SeitenOwner'S Guide: Microarc 4 - 100 MM 4Th AxisBen LernerNoch keine Bewertungen

- MC 10165615 0001Dokument7 SeitenMC 10165615 0001Roy Fernando Melchor sanchezNoch keine Bewertungen

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideVon EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideBewertung: 4.5 von 5 Sternen4.5/5 (8)

- Diesel Engine Care and Repair: A Captain's Quick GuideVon EverandDiesel Engine Care and Repair: A Captain's Quick GuideBewertung: 5 von 5 Sternen5/5 (1)

- Motorcycle, Solo (Harley-Davidson Model WLA)Von EverandMotorcycle, Solo (Harley-Davidson Model WLA)Noch keine Bewertungen

- PIC 16f877a Data SheetDokument234 SeitenPIC 16f877a Data Sheetanon-26401438% (8)

- Max 6675Dokument8 SeitenMax 6675david2014oooNoch keine Bewertungen

- TM-T20 Eng QR PDFDokument4 SeitenTM-T20 Eng QR PDFmauripeNoch keine Bewertungen

- User Manual Ex Es SsDokument150 SeitenUser Manual Ex Es Ssmoh300Noch keine Bewertungen

- Training Kit OP Manual en 112013Dokument175 SeitenTraining Kit OP Manual en 112013Diego A. MaldonadoNoch keine Bewertungen

- Delta Rpi m15 30a Inverter Data SheetDokument4 SeitenDelta Rpi m15 30a Inverter Data SheetDavid SaymonNoch keine Bewertungen

- PIC 16f877a Data SheetDokument234 SeitenPIC 16f877a Data Sheetanon-26401438% (8)

- Omron E5CK+UsersManual PDFDokument186 SeitenOmron E5CK+UsersManual PDFmaryNoch keine Bewertungen

- Delta Ia-Plc DVP TP C en 20190517 WebDokument52 SeitenDelta Ia-Plc DVP TP C en 20190517 WebKashif ZakaNoch keine Bewertungen

- 1200W With 5V/2A Standby / MEB-1K2A Series: Medical / Industrial AC-DC Power SupplyDokument13 Seiten1200W With 5V/2A Standby / MEB-1K2A Series: Medical / Industrial AC-DC Power SupplyDavid SaymonNoch keine Bewertungen

- DVP-PLC Application Manual Programming GuideDokument749 SeitenDVP-PLC Application Manual Programming GuideAli PadaryamNoch keine Bewertungen

- Delta Microphone: High Quality Pickup With 360 CoverageDokument2 SeitenDelta Microphone: High Quality Pickup With 360 CoverageDavid SaymonNoch keine Bewertungen

- Information: Step Motor Driver (Pulse Input Type)Dokument4 SeitenInformation: Step Motor Driver (Pulse Input Type)David SaymonNoch keine Bewertungen

- Delta RPI-Commercial Series: RPI - M12 / M15A / M20A / M30Dokument2 SeitenDelta RPI-Commercial Series: RPI - M12 / M15A / M20A / M30David SaymonNoch keine Bewertungen

- Delta RPI-Commercial Series: RPI - M12 / M15A / M20A / M30Dokument2 SeitenDelta RPI-Commercial Series: RPI - M12 / M15A / M20A / M30David SaymonNoch keine Bewertungen

- S10 PCB BoardDokument1 SeiteS10 PCB BoardDavid SaymonNoch keine Bewertungen

- Delta Rpi m15 30a Inverter Data SheetDokument4 SeitenDelta Rpi m15 30a Inverter Data SheetDavid SaymonNoch keine Bewertungen

- BC548 Hoja de Datos PDFDokument5 SeitenBC548 Hoja de Datos PDFJuan FiNoch keine Bewertungen

- Delta RPI-Commercial Series: RPI - M12 / M15A / M20A / M30Dokument2 SeitenDelta RPI-Commercial Series: RPI - M12 / M15A / M20A / M30David SaymonNoch keine Bewertungen

- Delta M30A / M50ADokument4 SeitenDelta M30A / M50ASunil SinghNoch keine Bewertungen

- Electric Actuator: SeriesDokument115 SeitenElectric Actuator: SeriesDavid SaymonNoch keine Bewertungen

- Macros For HMiDokument40 SeitenMacros For HMinascostaNoch keine Bewertungen

- Wireless Penetration TestingDokument11 SeitenWireless Penetration Testingdevil00xNoch keine Bewertungen

- Dvp02lc-Sl Loadcell o en 20101018Dokument38 SeitenDvp02lc-Sl Loadcell o en 20101018Pst Pst PstNoch keine Bewertungen

- DVP04PT-S Platinum Temperature ModuleDokument2 SeitenDVP04PT-S Platinum Temperature ModuleshaniimranNoch keine Bewertungen

- Wireless Penetration TestingDokument11 SeitenWireless Penetration Testingdevil00xNoch keine Bewertungen

- EvilDokument1 SeiteEvilDavid SaymonNoch keine Bewertungen

- TM-T20 Eng TRG Revc 03Dokument133 SeitenTM-T20 Eng TRG Revc 03Jorge Armando RodriguezNoch keine Bewertungen

- STR8 ApresentacaoDokument5 SeitenSTR8 ApresentacaoDavid SaymonNoch keine Bewertungen

- DVP - Communication ProtocolDokument15 SeitenDVP - Communication ProtocolKashif KhanNoch keine Bewertungen

- House and Furniture There Isare - 42265Dokument3 SeitenHouse and Furniture There Isare - 42265lavica13Noch keine Bewertungen

- PGCPS Department of Special Education Parent Virtual Workshop SeriesDokument2 SeitenPGCPS Department of Special Education Parent Virtual Workshop SeriesABC7 WJLANoch keine Bewertungen

- Product Stability RatioDokument5 SeitenProduct Stability Ratiowithravi100% (1)

- Artificial Intelligence: IV B.Tech - II Semester - Regular Examinations - March 2018Dokument3 SeitenArtificial Intelligence: IV B.Tech - II Semester - Regular Examinations - March 2018Vyshnavi ThottempudiNoch keine Bewertungen

- Lesson Plan: R.V. College of Engineering, BangaloreDokument14 SeitenLesson Plan: R.V. College of Engineering, BangaloreVeena Divya KrishnappaNoch keine Bewertungen

- What Is An Integrated CircuitDokument9 SeitenWhat Is An Integrated Circuitsurafel TarikuNoch keine Bewertungen

- ITB-017 DocumentDokument108 SeitenITB-017 DocumentRana Ahmad AamirNoch keine Bewertungen

- Recruitment Process Outsourcing Using Careerharmony System Improves Retention and Productivity For Global Printing Company'S European OperationsDokument4 SeitenRecruitment Process Outsourcing Using Careerharmony System Improves Retention and Productivity For Global Printing Company'S European Operations7aadkhanNoch keine Bewertungen

- Human Body Maths ModelDokument5 SeitenHuman Body Maths ModelARUN VNoch keine Bewertungen

- QAS05 146stabilitywithcommentsDokument10 SeitenQAS05 146stabilitywithcommentsDianne LimosNoch keine Bewertungen

- Supernova Simulation LabDokument3 SeitenSupernova Simulation LabAlli ANoch keine Bewertungen

- 16 - Impurities Removal From Liqued FuelsDokument21 Seiten16 - Impurities Removal From Liqued FuelsSHREENoch keine Bewertungen

- Supplemental Guidance For The Determination of Biochemical Oxygen Demand (BODs) and Carbonaceous BOD (CBODs) in Water and Wastewater (PDFDrive)Dokument62 SeitenSupplemental Guidance For The Determination of Biochemical Oxygen Demand (BODs) and Carbonaceous BOD (CBODs) in Water and Wastewater (PDFDrive)Thoriq RamadhanNoch keine Bewertungen

- 2022 1st QTR Narrative AccomplishmentDokument5 Seiten2022 1st QTR Narrative AccomplishmentErika Ahnne SantiagoNoch keine Bewertungen

- Os2 PDFDokument1 SeiteOs2 PDFBarry Ysrnr100% (1)

- Imperialism Digital Interactive NotebookDokument9 SeitenImperialism Digital Interactive NotebookMonica ChihuahuaNoch keine Bewertungen

- Datex Ohmeda S5 Aestiva - Technical ReferenceDokument368 SeitenDatex Ohmeda S5 Aestiva - Technical ReferenceAyaovi JorlauNoch keine Bewertungen

- 7th Grade Module 1 - Lesson 11Dokument16 Seiten7th Grade Module 1 - Lesson 11api-369302912Noch keine Bewertungen

- Spec ManualDokument797 SeitenSpec Manualhgogoriya100% (1)

- Workshops That Make Teaching More Effective & ExcitingDokument3 SeitenWorkshops That Make Teaching More Effective & ExcitingKat Romen100% (2)

- Emotional Intelligence PresentationDokument63 SeitenEmotional Intelligence PresentationPriyanka Khandelwal100% (1)

- Dubai Country ProfileDokument8 SeitenDubai Country ProfileVishal RajputNoch keine Bewertungen

- Economic Factors for Maximizing Condensate Recovery from Gas StreamsDokument8 SeitenEconomic Factors for Maximizing Condensate Recovery from Gas StreamsJosé Miguel Sagredo BonillaNoch keine Bewertungen

- Light Emitting Diodes: (LED'S)Dokument12 SeitenLight Emitting Diodes: (LED'S)fernanda barraganNoch keine Bewertungen

- ACTION SONG 27 FebDokument1 SeiteACTION SONG 27 FebAnonymous AGRLSm0h5Noch keine Bewertungen

- Introduction To Numerical Controlled Machines and AutomationDokument7 SeitenIntroduction To Numerical Controlled Machines and AutomationShanna0% (1)

- Imitating Interactive Intelligence Deep MindDokument96 SeitenImitating Interactive Intelligence Deep MindRubens ZimbresNoch keine Bewertungen

- Lesson Plan Grade 4 Math - Visualizing Numbers Up To 100 000 With Emphasis On Numbers 10 001 - 50 000Dokument12 SeitenLesson Plan Grade 4 Math - Visualizing Numbers Up To 100 000 With Emphasis On Numbers 10 001 - 50 000tinker05boushNoch keine Bewertungen

- Ather Mausi Ne Kali La ResumeDokument2 SeitenAther Mausi Ne Kali La ResumeRona NashNoch keine Bewertungen

- Городской этап Республиканской олимпиады по английскому языку 2021/2022Dokument4 SeitenГородской этап Республиканской олимпиады по английскому языку 2021/2022AdilNoch keine Bewertungen