Beruflich Dokumente

Kultur Dokumente

Analysis of Fiber-Reinforcement Po - Ymer Composite Grid Reinforced Concrete Beams

Hochgeladen von

hastoutomoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Analysis of Fiber-Reinforcement Po - Ymer Composite Grid Reinforced Concrete Beams

Hochgeladen von

hastoutomoCopyright:

Verfügbare Formate

ACI STRUCTURAL JOURNAL

TECHNICAL PAPER

Title no. 100-S27

Analysis of Fiber-Reinforced Polymer Composite Grid

Reinforced Concrete Beams

by Federico A. Tavarez, Lawrence C. Bank, and Michael E. Plesha

This study focuses on the use of explicit finite element analysis

tools to predict the behavior of fiber-reinforced polymer (FRP)

composite grid reinforced concrete beams subjected to four-point

bending. Predictions were obtained using LS-DYNA, an explicit

finite element program widely used for the nonlinear transient

analysis of structures. The composite grid was modeled in a discrete

manner using beam and shell elements, connected to a concrete

solid mesh. The load-deflection characteristics obtained from the

simulations show good correlation with the experimental data.

Also, a detailed finite element substructure model was developed to

further analyze the stress state of the main longitudinal reinforcement at ultimate conditions. Based on this analysis, a procedure

was proposed for the analysis of composite grid reinforced concrete

beams that accounts for different failure modes. A comparison of

the proposed approach with the experimental data indicated that

the procedure provides a good lower bound for conservative

predictions of load-carrying capacity.

Keywords: beam; composite; concrete; fiber-reinforced polymer; reinforcement; shear; stress.

INTRODUCTION

In recent years, research on fiber-reinforced polymer (FRP)

composite grids has demonstrated that these products may be as

practical and cost-effective as reinforcements for concrete

structures.1-5 FRP grid reinforcement offers several advantages

in comparison with conventional steel reinforcement and FRP

reinforcing bars. FRP grids are prefabricated, noncorrosive, and

lightweight systems suitable for assembly automation and ideal

for reducing field installation and maintenance costs. Research

on constructability issues and economics of FRP reinforcement

cages for concrete members has shown the potential of

these reinforcements to reduce life-cycle costs and significantly

increase construction site productivity.6

Three-dimensional FRP composite grids provide a mechanical

anchorage within the concrete due to intersecting elements, and

thus no bond is necessary for proper load transfer. This type of

reinforcement provides integrated axial, flexural, and shear

reinforcement, and can also provide a concrete member with

the ability to fail in a pseudoductile manner. Continuing

research is being conducted to fully understand the behavior of

composite grid reinforced concrete to commercialize its use

and gain confidence in its design for widespread structural

applications. For instance, there is a need to predict the correct

failure mode of composite grid reinforced concrete beams

where there is significant flexural-shear cracking.7 This type

of information is critical for the development of design

guidelines for FRP grid reinforced concrete members.

Current flexural design methods for FRP reinforced concrete

beams are analogous to the design of concrete beams using

conventional reinforcement.8 The geometrical shape, ductility,

modulus of elasticity, and force transfer characteristics of FRP

composite grids, however, are likely to be different than

250

conventional steel or FRP bars. Therefore, the behavior of

concrete beams with this type of reinforcement needs to be

thoroughly investigated.

OBJECTIVES

The objectives of the present study were: 1) to investigate

the ability of explicit finite element analysis tools to predict

the behavior of composite grid reinforced concrete beams,

including load-deflection characteristics and failure modes;

2) to evaluate the effect of the shear span-depth ratio in the

failure mode of the beams and the stress state of the main

flexural reinforcement at ultimate conditions; and 3) to

develop an alternate procedure for the analysis of composite grid

reinforced concrete beams considering multiple failure modes.

RESEARCH SIGNIFICANCE

The research work presented describes the use of advanced

numerical simulation for the analysis of FRP reinforced

concrete. These numerical simulations can be used effectively

to understand the complex behavior and phenomena observed

in the response of composite grid reinforced concrete beams. In

particular, this effort provides a basis for the understanding of

the interaction between the composite grid and the concrete

when large flexural-shear cracks are present. As such, alternate

analysis and design techniques can be developed based on the

understanding obtained from numerical simulations to ensure

the required capacity in FRP reinforced concrete structures.

Background

Several researchers have studied the viability of threedimensional FRP grids to reinforce concrete members.3,5,9,10

One specific type of three-dimensional FRP reinforcement is

constructed from commercially manufactured pultruded FRP

profiles (also referred to as FRP grating cages). Figure 1 shows

a schematic of the structural members present in a concrete

beam reinforced with the three-dimensional FRP reinforcement

investigated in this study.

A pilot experimental and analytical study was conducted

by Bank, Frostig, and Shapira3 to investigate the feasibility

of developing three-dimensional pultruded FRP grating cages

to reinforce concrete beams. Failure of all beams tested occurred

due to rupture of the FRP main longitudinal reinforcement in

the shear span of the beam. Experimental results also revealed

that most of the deflection at high loads appeared to occur

due to localized rotations at large flexural crack widths

ACI Structural Journal, V. 100, No. 2, March-April 2003.

MS No. 02-100 received March 27, 2002, and reviewed under Institute publication

policies. Copyright 2003, American Concrete Institute. All rights reserved, including the making of copies unless permission is obtained from the copyright proprietors.

Pertinent discussion will be published in the January-February 2004 ACI Structural

Journal if received by September 1, 2003.

ACI Structural Journal/March-April 2003

Federico A. Tavarez is a graduate student in the Department of Engineering Physics

at the University of Wisconsin-Madison. He received his BS in civil engineering from

the University of Puerto Rico-Mayagez and his MSCE from the University of

Wisconsin. His research interests include finite element analysis, the use of composite

materials for structural applications, and the use of discrete element methods for

modeling concrete damage and fragmentation under impact.

ACI member Lawrence C. Bank is a professor in the Department of Civil and

Environmental Engineering at the University of Wisconsin-Madison. He received his

PhD in civil engineering and engineering mechanics from Columbia University in

1985. He is a member of ACI Committee 440, Fiber Reinforced Polymer Reinforcement.

His research interests include FRP reinforcement systems for structures, progressive

failure of materials and structural systems, and durability of FRP materials.

Michael E. Plesha is a professor in the Engineering Mechanics and Astronautics

Program in the Department of Engineering Physics at the University of WisconsinMadison. He received his PhD from Northwestern University in 1983. His research

interests include finite element analysis, discrete element analysis, dynamics of

geologic media, constitutive modeling of geologic discontinuity behavior, soil structure

interaction modeling, and continuum modeling of jointed saturated rock masses.

developed in the shear span near the load points. The study

concluded that further research was needed to obtain a better

understanding of the stress state in the longitudinal reinforcement at failure to predict the correct capacity and failure

modes of the beams.

Further experimental tests on concrete beams reinforced

with three-dimensional FRP composite grids were conducted to

investigate the behavior and performance of the grids when

used to reinforce beams that develop significant flexural-shear

cracking.7 Different composite grid configurations were

designed to study the influence of the FRP grid components

(longitudinal bars, vertical bars, and transverse bars) on the

load-deflection behavior and failure modes. Even though failure

modes of the beams were different depending upon the

characteristics of the composite grid, all beams failed in their

shear spans. Failure modes included splitting and rupture of

the main longitudinal bars and shear-out failure of the

vertical bars. Research results concluded that the design

of concrete beams with composite grid reinforcements must

account for failure of the main bars in the shear span.

A second phase of this experimental research was performed

by Ozel and Bank5 to investigate the capacity and failure modes

of composite grid reinforced concrete beams with different shear

span-to-effective depth ratios. Three different shear spandepth ratios (a/d) were investigated, with values of 3, 4.5, and 6,

respectively.11 The data obtained from this recently completed

experimental study was compared with the finite element results

obtained in the present study.

Experimental studies have shown that due to the development of large cracks in the FRP-reinforced concrete beams,

most of the deformation takes place at a relatively small

number of cracks between rigid bodies.12 A schematic of this

behavior is shown in Fig. 2. As a result, beams with relatively

small shear span-depth ratios typically fail due to rupture of the

main FRP longitudinal reinforcement at large flexural-shear

cracks, even though they are over-reinforced according to

conventional flexural design procedures.5,7,13,14 Due to the

aforementioned behavior for beams reinforced with composite

grids, especially those that exhibit significant flexural-shear

cracking, it is postulated that the longitudinal bars in the

member are subjected to a uniform tensile stress distribution,

plus a nonuniform stress distribution due to localized rotations at large cracks, which can be of great importance in

determining the ultimate flexural strength of the beam. The

present study investigates the stress-state at the flexuralshear cracks in the main longitudinal bars, using explicit

finite element tools to simulate this behavior and determine

the conditions that will cause failure in the beam.

ACI Structural Journal/March-April 2003

Fig. 1Structural members in composite grid reinforced

concrete beam.

Fig. 2Deformation due to rotation of rigid bodies.

Numerical analysis of FRP composite grid

reinforced beams

Implicit finite element methods are usually desirable for

the analysis of quasistatic problems. Their efficiency and

accuracy, however, depend on mesh topology and severity

of nonlinearities. In the problem at hand, it would be very

difficult to model the nonlinearities and progressive damage/

failure using an implicit method, and thus an explicit method

was chosen to perform the analysis.15

Using an explicit finite element method, especially to

model a quasistatic experiment as the one presented herein,

can result in long run times due to the large number of time

steps that are required. Because the time step depends on the

smallest element size, efficiency is compromised by mesh

refinement. The three-dimensional finite element mesh for

this study was developed in HyperMesh16 and consisted of

brick elements to represent the concrete, shell elements to

represent the bottom longitudinal reinforcement, and beam

elements to represent the top reinforcement, stirrups, and

cross rods. Figure 3 shows a schematic of the mesh used for

the models developed. Beams with span lengths of 2300,

3050, and 3800 mm were modeled corresponding to shear

span-depth ratios of 3, 4.5, and 6, respectively. These models

are referred to herein as short beam, medium beam, and long

beam, respectively. The cross-sectional properties were

identical for the three models. As will be seen later, the longitudinal bars play an important role in the overall behavior of the

system, and therefore they were modeled with greater detail

than the rest of the reinforcement. The concrete representation

consisted of 8-node solid elements with dimensions 25 x 25 x

12.5 mm (shortest dimension parallel to the width of the beam),

with one-point integration. The mesh discretization was established so that the reinforcement nodes coincided with the

concrete nodes. The reinforcement mesh was connected to the

concrete mesh by shared nodes between the concrete and the

251

Fig. 3Finite element model for composite grid reinforced concrete beam.

Fig. 4Short beam model at several stages in simulation.

reinforcement. As such, a perfect bond is assumed between the

concrete and the composite grid.

The two-node Hughes-Liu beam element formulation with

2 x 2 Gauss integration was used for modeling the top longitudinal bars, stirrups, and cross rods in the finite element

models. In this study, each model contains two top longitudinal

bars with heights of 25 mm and thicknesses of 4 mm. The

models also have four cross rods and three vertical members

at each stirrup location, as shown in Fig. 3. The vertical

members have a width of 38 mm and a thickness of 6.4 mm.

The cross rod elements have a circular cross-sectional

area with a diameter of 12.7 mm. To model the bottom

longitudinal reinforcement, the four-node BelytschkoLin-Tsay shell element formulation was used, as shown

in Fig. 3, with two through-the-thickness integration points.

252

Boundary conditions and event simulation time

To simulate simply supported conditions, the beam was

supported on two rigid plates made of solid elements. The

finite element simulations were displacement controlled,

which is usually the control method for plastic and nonlinear

behavior. That is, a displacement was prescribed on the rigid

loading plates located on top of the beam. The prescribed

displacement was linear, going from zero displacement at t =

0.0 s to 60, 75, and 90 mm at t = 1.0 s for the short, medium,

and long beams, respectively. The corresponding applied

load due to the prescribed displacement was then determined

by monitoring the vertical reaction forces at the concrete

nodes in contact with the support elements.

The algorithm CONTACT_AUTOMATIC_SINGLE_

SURFACE in LS-DYNA was used to model the contact

ACI Structural Journal/March-April 2003

between the supports, load bars, and the concrete beam.

This algorithm automatically generates slave and master

surfaces and uses a penalty method where normal interface

springs are used to resist interpenetration between element

surfaces. The interface stiffness is computed as a function

of the bulk modulus, volume, and face area of the elements

on the contact surface.

The finite element analysis was performed to represent

quasistatic experimental testing. As the time over which the

load is applied approaches the period of the lowest natural

frequency of vibration of the structural system, inertial forces

become more important in the response. Therefore, the load

application time was chosen to be long enough so that inertial

effects would be negligible. The flexural frequency of vibration

was computed analytically for the three beams using conventional formulas for vibration theory. 17 Accordingly, it was

determined that having a load application time of 1.0 s

was sufficiently long so that inertial effects are negligible

and the analysis can be used to represent a quasistatic experiment. For the finite element simulations presented in this

study, the CPU run time varied approximately from 22 to

65 h (depending on the length of the beam) for 1.0 s of load

application time on a 600 MHz PC with 512 MB RAM.

Material models

Material Type 72 (MAT_CONCRETE_DAMAGE) in

LS-DYNA was chosen for the concrete representation in the

present study. This material model has been used successfully

for predicting the response of standard uniaxial, biaxial, and

triaxial concrete tests in both tension and compression. The

formulation has also been used successfully to model the

behavior of standard reinforced concrete dividing walls

subjected to blast loads.18 This concrete model is a plasticitybased formulation with three independent failure surfaces

(yield, maximum, and residual) that change shape depending

on the hydrostatic pressure of the element. Tensile and

compressive meridians are defined for each surface, describing

the deviatoric part of the stress state, which governs failure in

the element. Detailed information about this concrete material

model can be found in Malvar et al.18 The values used in

the input file corresponded to a 34.5 MPa concrete compressive

strength with a 0.19 Poissons ratio and a tensile strength of

3.4 MPa. The softening parameters in the model were chosen to

be 15, 50, and 0.01 for uniaxial tension, triaxial tension, and

compression, respectively.19

The longitudinal bars were modeled using an orthotropic

material model (MAT_ENHANCED_COMPOSITE_DAMAGE),

which is material Type 54 in LS-DYNA. Properties used for

this model are shown in Table 1. Because the longitudinal

bars were drilled with holes for cross rod connections, the

tensile strength in the longitudinal direction of the FRP bars

was taken from experimental tensile tests conducted on

notched bar specimens with a 12.7 mm hole to account

for stress concentration effects at the cross rod locations.

The tensile properties in the transverse direction were

taken from tests on unnotched specimens. 11 Values for

shear and compressive properties were chosen based on

data in the literature. The composite material model uses

the Chang/Chang failure criteria. 20

The remaining reinforcement (top longitudinal bars, stirrups,

and cross rods) was modeled using two-noded beam elements

using a linear elastic material model (MAT_ELASTIC) with

the same properties used for the longitudinal direction in the

bottom FRP longitudinal bars. A rigid material model

ACI Structural Journal/March-April 2003

Fig. 5Experimental and finite element load-deflection

results for short, medium, and long beams.

Fig. 6Typical failure of composite grid reinforced concrete

beam (Ozel and Bank5).

Table 1Material properties of FRP bottom bars

Ex

26.7 GPa

Xt

266.8 MPa

151.0 MPa

Ey

14.6 GPa

Yt

Gxy

3.6 GPa

Sc

6.9 MPa

xy

0.26

Xc

177.9 MPa

0.5

Yc

302.0 MPa

(MAT_RIGID) was used to model the supports and the

loading plates.

FINITE ELEMENT RESULTS AND DISCUSSION

Graphical representations of the finite element model for

the short beam at several stages in the simulation are shown

in Fig. 4. The lighter areas in the model represent damage

(high effective plastic strain) in the concrete material model.

As expected, there is considerable damage in the shear span

of the concrete beam. Figure 4 also shows the behavior of the

composite grid inside the concrete beam. All displacements

in the simulation graphics were amplified using a factor of 5

to enable viewing. Actual deflection values are given in

Fig. 5, which shows the applied load versus midspan deflection behavior for the short, medium, and long beams for the

experimental and LS-DYNA results, respectively. The

jumps in the LS-DYNA curves in the figure represent the

progressive tensile and shear failure in the concrete elements. As

shown in this figure, the ultimate load value from the finite

element model agrees well with the experimental result. The

model slightly over-predicts the stiffness of the beam, however,

and under-predicts the ultimate deflection.

The significant drop in load seen in the load-deflection

curves produced in LS-DYNA is caused by failure in the

253

Fig. 7Medium beam model at several stages in simulation.

Fig. 8Long beam model at several stages in simulation.

longitudinal bars, as seen in Fig. 4. The deformed shape

seen in this figure indicates a peculiar behavior throughout the length of the beam. It appears to indicate that after

a certain level of damage in the shear span of the model,

localized rotations occur in the beam near the load points.

These rotations create a stress concentration that causes

the longitudinal bars to fail at those locations. This deflection

behavior was also observed in the experimental tests.

Figure 6 shows a typical failure in the longitudinal bars

from the experiments conducted on these beams. 11 As

shown in this figure, there is considerable damage in the

shear span of the member. Large shear cracks develop in

the beam, causing the member to deform in the same

fashion as the one seen in the finite element model.

Figure 7 shows the medium beam model at several stages

in the simulation. The figure also shows the behavior of the

main longitudinal bars. Comparing this simulation with the

one obtained for the short beam, it can be seen that the shear

damage is not as significant as in the previous simulation.

The deflected shape seen in the longitudinal bars shows that

this model does not have the abrupt changes in rotation that

254

were observed in the short beam, which would imply that this

model does not exhibit significant flexural-shear damage. For

this model, the finite element analysis slightly over-predicted

both the stiffness and the ultimate load value obtained from

the experiment. On the other hand, the ultimate deflection

was under-predicted. Failure in this model was also caused

by rupture of the longitudinal bars at a location near the load

points. In the experimental test, failure was caused by a

combination of rupture in the longitudinal bars as well as

concrete crushing in the compression zone. This compressive

failure was located near the load points, however, and

could have been initiated by cracks formed due to stress

concentrations produced by the rigid loading plates. 11

Figure 8 shows the results for the long beam model.

Comparing this simulation with the two previous ones, it

can be seen that this model exhibits the least shear damage,

as expected. As a result, the longitudinal bars exhibit a

parabolic shape, which would be the behavior predicted

using conventional moment-curvature methods based on the

curvature of the member. Once again, the stiffness of the

beam was slightly over-predicted. However, the ultimate load

ACI Structural Journal/March-April 2003

Table 2Summary of experimental and finite

element results

Total load capacity, kN

Fig. 9(a) Tensile force in longitudinal bars; and (b) internal

moment in longitudinal bars.

value compares well with the experimental result. Failure in

the model was caused by rupture of the longitudinal bars.

Failure in the experimental test was caused by a compression

failure at a location near one of the load application bars,

followed by rupture of the main longitudinal bars. Figure 5

also shows the time at total failure for each beam, which can

be related to the simulation stages given in Fig. 4, 7, and 8

for the short, medium, and long beam, respectively.

To investigate the stress state of a single longitudinal bar

at ultimate conditions, the tensile force and the internal

moment of the longitudinal bars at the failed location for the

three finite element models was determined, as shown in

Fig. 9(a) and (b). It is interesting to note that for the short

beam model, the tensile force at failure was approximately

51.6 kN, while for the medium beam model and the long

beam model the tensile force at failure was approximately

76.5 kN. On the other hand, the internal moment in the short

beam model was approximately 734 N-m, while the internal

moment was approximately 339 N-m for both the short beam

model and the long beam model. It is clear that the shear

damage in the short beam model causes a considerable

localized effect in the stress state of the longitudinal bars,

which is important to consider for design purposes.

According to Fig. 9(a), the total axial load in the longitudinal

bars for the short beam model produces a uniform stress of

130 MPa, which is not enough to fail the element in tension

at this location. However, the ultimate internal moment

produces a tensile stress at the bottom of the longitudinal

bars of 141 MPa. The sum of these two components produces

a tensile stress of 271 MPa. When this value is entered in the

Chang/Chang failure criterion for the tensile longitudinal

direction, the strength is exceeded and the elements fail.

Using conventional over-reinforced beam analysis formulas,

the tensile force in the longitudinal bars at midspan would

be obtained by dividing the ultimate moment obtained from

the experimental test by the internal moment arm. This

would imply that there is a uniform tensile force in each

longitudinal bar of 88.1 kN. This tensile force is never

achieved in the finite element simulation due to considerable

shear damage in the concrete elements. As a result of this

shear damage in the concrete, the curvature at the center of

the beam is not large enough to produce a tensile force in the

bars of this magnitude (88.1 kN). The internal moment in the

longitudinal bars shown in Fig. 9(b), however, continues

to develop, resulting in a total failure load comparable to

the experimental result. As mentioned before, the force in

the bars according to the simulation was approximately

51.6 kN, which is approximately half the load predicted

using conventional methods. Therefore, the use of conventional

beam analysis formulas to analyze this composite grid reinforced

beam would not only erroneously predict the force in the

longitudinal bars, but it would also predict a concrete

ACI Structural Journal/March-April 2003

Tensile force in each

main bar, kN

Finite

element

analysis

Flexural

analysis

Finite

element

analysis

Beam

Experimental

Flexural

analysis

Short

215.7

196.2

215.3

90.7

51.6

Medium

143.2

130.8

161.9

90.7

76.5

Long

108.1

97.9

113.0

90.7

76.5

compression failure mode, which was not the failure

mode observed from the experimental tests.

The curves for the medium beam model and the long beam

model, shown in Fig. 9, show that for both cases, the beam

shear span-depth ratio was sufficiently large so that the stress

state in the longitudinal bars would not be greatly affected by the

shear damage produced in the beam. As such, the ultimate axial

force obtained in the longitudinal bars for both models was

close to the ultimate axial load that would be predicted by using

conventional methods.

In summary, Table 2 presents the ultimate load capacity

for the three models, including experimental results, conventional flexural analysis results, and finite element results. As

shown in this table, conventional flexural analysis under-predicts

the actual ultimate load carried by the beams and a better

ultimate load prediction was obtained using finite element

analysis. The tensile load in the bars was computed (analytically)

by dividing the experimental moment capacity by the internal

moment arm computed by using strain compatibility. Although

the finite element results over-predicted the ultimate load for the

medium and long beams, the simulations provided a better

understanding of the complex phenomena involved in the

behavior of the beams, depending on their shear span-depth

ratio. The results for tensile load in the bars reported in this table

suggest that composite grid reinforced concrete beams

with values of shear span-depth ratio greater than 4.5 can be

analyzed by using the current flexural theory.

It is important to mention that the concrete material model

parameters that govern the post-failure behavior of the material

played a key role in the finite element results for the three finite

element models. In the concrete material formulation, the

elements fail in an isotropic fashion and, therefore, once an

element fails in tension, it cannot transfer further shear.

Because the concrete elements are connected to the reinforcement mesh, this behavior causes the beam to fail prematurely

as a result of tensile failure in the concrete. Therefore, the

parameters that govern the post-failure behavior in the

concrete material model were chosen so that when an element

fails in tension, the element still has the capability to transfer

shear forces and the stresses will gradually decrease to zero.

Because the failed elements can still transfer tensile stresses,

however, the modifications caused an increase in the stiffness

of the beam. In real concrete behavior, when a crack opens,

there is no tension transfer between the concrete at that

location, causing the member to lose stiffness as cracking

progresses. Regarding shear transfer, factors such as aggregate interlock and dowel action would contribute to transfer

shear forces in a concrete beam, and tensile failure in the

concrete would not affect the response as directly as in the

finite element model.

255

Stress analysis of FRP bars

As discussed previously, failure modes observed in experimental tests performed on composite grid reinforced concrete

beams suggest that the longitudinal bars are subjected to a

uniform tensile stress plus a nonuniform bending stress due

to localized rotations at locations of large cracks. This section

presents a simple analysis procedure to determine the stress

conditions at which the longitudinal bars fail. As a result of this

analysis, a procedure is presented to analyze/design a composite

grid reinforced concrete beam, considering a nonuniform stress

state in the longitudinal bars.

A more detailed finite element model of a section of the

longitudinal bars was developed in HyperMesh16 using shell

elements, as shown in Fig. 10. A height of 50.8 mm was

specified for the bar model, with a thickness of 4.1 mm. The

length of the bar and the diameter of the hole were 152 and

12.7 mm, respectively. The material formulation and properties

were the same as the ones used for the longitudinal bars in the

concrete beam models, with the exception that now the

unnotched tensile strength of the material (Xt = 521 MPa) was

used as an input parameter because the hole was incorporated in

the model.

The finite element model was first loaded in tension to

establish the tensile strength of the notched bar. The load

was applied by prescribing a displacement at the end of the

bar. Figure 10 shows the simulation results for the model at

three stages, including elastic deformation and ultimate

failure. As expected, a stress concentration developed on the

boundary of the hole causing failure in the web of the model,

followed by ultimate failure of the cross section. A tensile

strength of 274 MPa was obtained for the model. A value

of 267 MPa was obtained from experimental tests conducted on notched bars (tensile strength used in Table 2),

demonstrating good agreement between experimental

and finite element results.

A similar procedure was performed to establish the

strength of the bar in pure bending. That is, displacements

were prescribed at the end nodes to induce bending in the

model. Figure 11 shows the simulation results for the model

at three stages, showing elastic bending and ultimate failure

caused by flexural failure at the tension flange. As shown in

this figure, the width of the top flange was modified to

prevent buckling in the flange (which was present in the

original model). Because buckling would not be present in a

longitudinal bar due to concrete confinement, it was decided

to modify the finite element model to avoid this behavior. To

maintain an equivalent cross-sectional area, the thickness of

the flange was increased. A maximum pure bending moment

of 2.92 kN-m was obtained for the model.

Knowing the maximum force that the bar can withstand in

pure tension and pure bending, the model was then loaded at

different values of tension and moment to cause failure. This

procedure was performed several times to develop a tensionmoment interaction diagram for the bar, as shown in Fig. 12.

The discrete points shown in the figure are combinations of

tensile force and moment values that caused failure in the

finite element model. This interaction diagram can be used

to predict what combination of tensile force and moment

would cause failure in the FRP longitudinal bar.

Considerations for design

The strength design philosophy states that the flexural

capacity of a reinforced concrete member must exceed the

flexural demand. The design capacity of a member refers

256

Fig. 10Failure on FRP bar subjected to pure tension.

Fig. 11Failure on FRP bar subjected to pure bending.

to the nominal strength of the member multiplied by a strengthreduction factor , as shown in the following equation

Mn Mu

(1)

For FRP reinforced concrete beams, a compression failure

is the preferred mode of failure, and, therefore, the beam

should be over-reinforced. As such, conventional formulas

are used to ensure that the selected cross-sectional area of the

longitudinal bars is sufficiently large to have concrete

compression failure before FRP rupture. Considering a concrete

compression failure, the capacity of the beam is computed using

the following8

a

M n = A f f f d ---

(2)

Af ff

a = ------------- 1 f c b

(3)

1 d a

f f = E f cu ----------------a

(4)

Experimental tests have shown, however, that there is

a critical value of shear Vscrit in a beam where localized rotations

due to large flexural-shear cracks begin to occur. The

ultimate moment in the beam is assumed to be related to

this shear-critical value and it is determined according to

the following equation

Mn = n ( t i e + m )

(5)

where n is the number of longitudinal bars. Once the beam has

reached the shear-critical value, it is assumed (conservatively)

that the tensile force t, which is the force in each bar at the

shear-critical stage, remains constant and any additional load is

carried by localized internal moment m in the longitudinal

bars. Furthermore, it is assumed that at this stage the concrete

is still in its elastic range, and, therefore, the internal moment

arm ie can be determined by equilibrium and elastic strain

compatibility. The tensile force t in Eq. (5) is computed

ACI Structural Journal/March-April 2003

Table 3Summary of results for three beams using proposed approach

Beam

Experimental

ultimate

Theoretical shear

shear, kN

critical, kN

Total load capacity, kN

Equation for

moment capacity

Experimental

Analytical Tension in each

Pn = Mn /as main bar, kN

Short

108.1

88.1

Mn = t ie + m

216

199

70.7

Medium

71.6

88.1

Mn = Af f f (d a/ 2)

143

131

90.7

88.1

Mn = Af f f (d a/2)

109

99

90.7

Long

54.7

according to the following equation for a simply supported

beam in four-point bending

crit

Vs a

t = ---------------------s

ni e

(6)

where as is the shear span of the member. The obtained value

for the tension t in each bar is then entered in Eq. (7), which

is the equation for the interaction diagram, to determine the

ultimate internal moment m in Eq. (5) that causes the bar to

fail. In this equation, tmax and mmax are known properties of

the notched composite bar.

t 2

m = m max 1 --------- for t > 0 ; m > 0

t max

(7)

The aforementioned procedure is a very simplified analysis to

determine the capacity of a composite grid reinforced concrete

beam, and, as can be seen, it depends considerably on the shearcritical value Vscrit established for the beam. This value is

somewhat difficult to determine. Based on experimental data, a

value given by Eq. (8) (analogous to Eq. (9-1) of ACI

440.1R-01) can be considered to be a lower bound for

FRP reinforced beams with shear reinforcement.

crit

Vs

7 f Ef 1

--- f bd

= ----------------90 1 f c 6 c

(8)

where fc is the specified compressive strength of the concrete

in MPa. In summary, the ultimate moment capacity in the beam

is determined according to one of the following equations

crit

M n = A f f f d a--- for V ult < V s

crit

M n = n ( t i e + m ) for V ult > V s

(9)

(10)

According to Eq. (9), if the ultimate shear force computed

analytically based on conventional theory does not exceed

the shear-critical value Vscrit, the moment capacity can be

computed from flexural analysis. On the other hand, if the

computed ultimate shear force is greater than Vscrit, Eq. (10)

is used. Table 3 presents a summary showing the load capacity

for the three beams obtained experimentally and analytically

using the present approach. As shown in this table, the equation

used to determine the flexural capacity depends on the ultimate

shear obtained for each beam.

As seen in this procedure, the only difficulty in applying

these formulas is the fact that an equation needs to be determined

ACI Structural Journal/March-April 2003

Fig. 12Tension-moment interaction diagram for longitudinal bar.

to compute the maximum moment that the bar can carry as a

function of the tensile force acting in the bar. If a specific bar

is always used, however, this difficulty is eliminated, and if

the flexural demand is not exceeded, a higher capacity can be

obtained by increasing the number of longitudinal bars in the

section. According to the results obtained for the three beams

analyzed herein, the proposed procedure will under-predict

the capacity of the composite grid reinforced concrete beam,

but it will provide a good lower bound for a conservative

design. Furthermore, it will ensure that the longitudinal bars

will not fail prematurely as a result of the development of

large flexural-shear cracks in the member, and thus the

member will be able to meet and exceed the flexural demand

for which it was designed.

CONCLUSIONS

Based on the explicit finite element results and comparison

with experimental data, the following conclusions can be made:

1. Failure in the FRP longitudinal bars occurs due to a

combination of a uniform tensile stress plus a nonuniform

stress caused by localized rotations at large flexural-shear

cracks. Therefore, this failure mode has to be accounted for

in the analysis and design of composite grid reinforced concrete

beams, especially those that exhibit significant flexuralshear cracking;

2. The shear span for the medium beam and the long beam

studied was sufficiently large so that the stress state in the

longitudinal bars was not considerably affected by shear

damage in the beam. Therefore, the particular failure mode

observed by the short beam model is only characteristic of

257

beams with a low shear span-depth ratio. Moreover, according

to the proposed analysis for such systems, both the medium

beam and the long beam could be designed using conventional

flexural theory because the shear-critical value was never

reached for these beam lengths;

3. Numerical simulations can be used effectively to understand the complex behavior and phenomena observed in the

response of composite grid reinforced concrete beams and,

therefore, can be used as a complement to experimental

testing to account for multiple failure modes in the design

of composite grid reinforced concrete beams; and

4. The proposed method of analysis for composite grid

reinforced concrete beams considering multiple failure

modes will under-predict the capacity of the reinforced

concrete beam, but it will provide a good lower bound for

a conservative design. These design considerations will

ensure that the longitudinal bars will not fail prematurely

(or catastrophically) as a result of the development of large

flexural-shear cracks in the member, and thus the member

can develop a pseudoductile failure by concrete crushing,

which is more desirable than a sudden FRP rupture.

ACKNOWLEDGMENTS

This work was supported by the National Science Foundation under

Grant. No. CMS 9896074. Javier Malvar and Karagozian & Case are

thanked for providing information regarding the concrete material formulation

used in LS-DYNA. Jim Day, Todd Slavik, and Khanh Bui of Livermore

Software Technology Corporation (LSTC) are also acknowledged for their

assistance in using the finite element software, as well as Strongwell

Chatfield, MN, for producing the custom composite grids.

NOTATION

a

as

b

d

=

=

=

=

Ef

Ex

Ey

Gxy

f c

ff

ie

Mn

m

n

Sc

t

Vscrit

=

=

=

=

=

=

=

=

=

=

=

=

=

Vult

Xc

Xt

Yc

Yt

=

=

=

=

=

=

=

cu

f

xy

=

=

=

258

depth of equivalent rectangular stress block

length of shear span in reinforced concrete beam

width of rectangular cross section

distance from extreme compression fiber to centroid of tension

reinforcement

modulus of elasticity for FRP bar

modulus of elasticity in longitudinal direction of FRP grid material

modulus of elasticity in transverse direction of FRP grid material

shear modulus of FRP grid members

specified compressive strength of concrete

stress in FRP reinforcement in tension

internal moment arm in the elastic range

nominal moment capacity

internal moment in longitudinal FRP grid bars

number of longitudinal FRP grid bars

shear strength of FRP grid material

tensile force in a longitudinal bar at the shear critical stage

critical shear resistance provided by concrete in FRP grid reinforced concrete

ultimate shear force in reinforced concrete beam

longitudinal compressive strength of FRP grid material

longitudinal tensile strength of FRP grid material

transverse compressive strength of FRP grid material

transverse tensile strength of FRP grid material

weighting factor for shear term in Chang/Chang failure criterion

ratio of the depth of Whitneys stress block to depth to neutral axis

concrete ultimate strain

FRP reinforcement ratio

Poissons ratio of FRP grid material

REFERENCES

1. Sugita, M., NEFMACGrid Type Reinforcement, Fiber-ReinforcedPlastic (FRP) Reinforcement for Concrete Structures: Properties and

Applications, Developments in Civil Engineering, A. Nanni, ed., Elsevier,

Amsterdam, V. 42, 1993, pp. 355-385.

2. Schmeckpeper, E. R., and Goodspeed, C. H., Fiber-Reinforced

Plastic Grid for Reinforced Concrete Construction, Journal of Composite

Materials, V. 28, No. 14, 1994, pp. 1288-1304.

3. Bank, L. C.; Frostig, Y.; and Shapira, A., Three-Dimensional FiberReinforced Plastic Grating Cages for Concrete Beams: A Pilot Study, ACI

Structural Journal, V. 94, No. 6, Nov.-Dec. 1997, pp. 643-652.

4. Smart, C. W., and Jensen, D. W., Flexure of Concrete Beams

Reinforced with Advanced Composite Orthogrids, Journal of Aerospace

Engineering, V. 10, No. 1, Jan. 1997, pp. 7-15.

5. Ozel, M., and Bank, L. C., Behavior of Concrete Beams Reinforced

with 3-D Composite Grids, CD-ROM Paper No. 069. Proceedings of the

16th Annual Technical Conference, American Society for Composites,

Virginia Tech, Va., Sept. 9-12, 2001.

6. Shapira, A., and Bank, L. C., Constructability and Economics of FRP

Reinforcement Cages for Concrete Beams, Journal of Composites for

Construction, V. 1, No. 3, Aug. 1997, pp. 82-89.

7. Bank, L. C., and Ozel, M., Shear Failure of Concrete Beams Reinforced

with 3-D Fiber Reinforced Plastic Grids, Fourth International Symposium on

Fiber Reinforced Polymer Reinforcement for Reinforced Concrete Structures,

SP-188, C. Dolan, S. Rizkalla, and A. Nanni, eds., American Concrete

Institute, Farmington Hills, Mich., 1999, pp. 145-156.

8. ACI Committee 440, Guide for the Design and Construction of

Concrete Reinforced with FRP Bars (ACI 440.1R-01), American Concrete

Institute, Farmington Hills, Mich., 2001, 41 pp.

9. Nakagawa, H.; Kobayashi. M.; Suenaga, T.; Ouchi, T.; Watanabe, S.;

and Satoyama, K., Three-Dimensional Fabric Reinforcement, FiberReinforced-Plastic (FRP) Reinforcement for Concrete Structures: Properties

and Applications, Developments in Civil Engineering, V. 42, A. Nanni, ed.,

Elsevier, Amsterdam, 1993, pp. 387-404.

10. Yonezawa, T.; Ohno, S.; Kakizawa, T.; Inoue, K.; Fukata, T.; and

Okamoto, R., A New Three-Dimensional FRP Reinforcement, FiberReinforced-Plastic (FRP) Reinforcement for Concrete Structures: Properties

and Applications, Developments in Civil Engineering, V. 42, A. Nanni, ed.,

Elsevier, Amsterdam, 1993, pp. 405-419.

11. Ozel, M., Behavior of Concrete Beams Reinforced with 3-D

Fiber Reinforced Plastic Grids, PhD thesis, University of WisconsinMadison, 2002.

12. Lees, J. M., and Burgoyne, C. J., Analysis of Concrete Beams with

Partially Bonded Composite Reinforcement, ACI Structural Journal,

V. 97, No. 2, Mar.-Apr. 2000, pp. 252-258.

13. Shehata, E.; Murphy, R.; and Rizkalla, S., Fiber Reinforced

Polymer Reinforcement for Concrete Structures, Fourth International

Symposium on Fiber Reinforced Polymer Reinforcement for Reinforced

Concrete Structures, SP-188, C. Dolan, S. Rizkalla, and A. Nanni, eds.,

American Concrete Institute, Farmington Hills, Mich., 1999, pp. 157-167.

14. Guadagnini, M.; Pilakoutas, K.; and Waldron, P., Investigation on

Shear Carrying Mechanisms in FRP RC Beams, FRPRCS-5, FibreReinforced Plastics for Reinforced Concrete Structures, Proceedings of the

Fifth International Conference, C. J. Burgoyne, ed., V. 2, Cambridge, July

16-18, 2001, pp. 949-958.

15. Cook, R. D.; Malkus, D. S.; and Plesha, M. E., Concepts and

Applications of Finite Element Analysis, 3rd Edition, John Wiley &

Sons, N.Y., 1989, 832 pp.

16. Altair Computing, HyperMesh Version 2.0 Users Manual, Altair

Computing Inc., Troy, Mich., 1995.

17. Thompson, W. T., and Dahleh, M. D., Theory of Vibration with

Applications, 5th Edition, Prentice Hall, N.J., 1998, 524 pp.

18. Malvar, L. J.; Crawford, J. E.; Wesevich, J. W.; and Simons, D., A

Plasticity Concrete Material Model for DYNA3D, International Journal

of Impact Engineering, V. 19, No. 9/10, 1997, pp. 847-873.

19. Tavarez, F. A., Simulation of Behavior of Composite Grid Reinforced

Concrete Beams Using Explicit Finite Element Methods, MS thesis, University

of Wisconsin-Madison, 2001.

20. Hallquist, J. O., LS-DYNA Keyword Users Manual, Livermore

Software Technology Corporation, Livermore, Calif., Apr. 2000.

ACI Structural Journal/March-April 2003

Das könnte Ihnen auch gefallen

- Composite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)Von EverandComposite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)Bewertung: 4 von 5 Sternen4/5 (10)

- 612 - Aci Structural Journal by Wiryanto DewobrotoDokument168 Seiten612 - Aci Structural Journal by Wiryanto Dewobrotomavane25Noch keine Bewertungen

- 612 - ACI STRUCTURAL JOURNAL by Wiryanto Dewobroto PDFDokument168 Seiten612 - ACI STRUCTURAL JOURNAL by Wiryanto Dewobroto PDFchaval01Noch keine Bewertungen

- Marc Mentat RCDokument11 SeitenMarc Mentat RCMahmud Kori EffendiNoch keine Bewertungen

- Finite Element Modeling of Concrete Structures Reinforced With Internal and External Fibre-Reinforced PolymersDokument15 SeitenFinite Element Modeling of Concrete Structures Reinforced With Internal and External Fibre-Reinforced PolymersAli OmarNoch keine Bewertungen

- A Literature Review On Beam Column Joints With Different Loading Condition and Methods of StrengtheningDokument8 SeitenA Literature Review On Beam Column Joints With Different Loading Condition and Methods of StrengtheningIJRASETPublicationsNoch keine Bewertungen

- A. Dalalbashi 2'12Dokument7 SeitenA. Dalalbashi 2'12Qurrain MirNoch keine Bewertungen

- FEModels of GFRP and CFRP StrengtheningDokument14 SeitenFEModels of GFRP and CFRP StrengtheningCrystal SuriyaNoch keine Bewertungen

- A Review Paper On Analysis For FRP Composite Beams Using Finite Element MethodDokument4 SeitenA Review Paper On Analysis For FRP Composite Beams Using Finite Element MethodVikramNoch keine Bewertungen

- 4APM Islam Et Al 2011 CFRPDokument5 Seiten4APM Islam Et Al 2011 CFRPMashfiqul IslamNoch keine Bewertungen

- Finite Element Modelling of Strengthened Simple Beams Using FRP Techniques: A Parametric StudyDokument13 SeitenFinite Element Modelling of Strengthened Simple Beams Using FRP Techniques: A Parametric StudyRizki Nuursirullah MahibNoch keine Bewertungen

- A Parametric Study On The Flexural Strengthening of Reinforced Concrete Beams With Near Surface Mounted FRP BarsDokument13 SeitenA Parametric Study On The Flexural Strengthening of Reinforced Concrete Beams With Near Surface Mounted FRP BarskhaNoch keine Bewertungen

- Basappa - 2013 PDFDokument16 SeitenBasappa - 2013 PDFJackeline SantosNoch keine Bewertungen

- Non-Linear 3D Finite Element Analysis of Precast Reinforced Concrete Beam-Column Joint Under Monotonic Static Load - 2022Dokument12 SeitenNon-Linear 3D Finite Element Analysis of Precast Reinforced Concrete Beam-Column Joint Under Monotonic Static Load - 2022JuanNoch keine Bewertungen

- TCAN1 de 1Dokument282 SeitenTCAN1 de 1ronald torresNoch keine Bewertungen

- Project Phase ReportDokument6 SeitenProject Phase ReportYaswanth ReddyNoch keine Bewertungen

- Shear Behaviour For Deep BeamsDokument17 SeitenShear Behaviour For Deep BeamsMuhammad Hamza QadriNoch keine Bewertungen

- Pstruct 2020 112609Dokument27 SeitenPstruct 2020 112609hudasaadNoch keine Bewertungen

- E Ects of Superstructure Exibility On Strength of Reinforced Concrete Bridge DecksDokument11 SeitenE Ects of Superstructure Exibility On Strength of Reinforced Concrete Bridge DecksIsrael TenorioNoch keine Bewertungen

- Charoenphan Bank Plesha Composite Struct 2004Dokument8 SeitenCharoenphan Bank Plesha Composite Struct 2004api-3805818Noch keine Bewertungen

- Applied Sciences: Damage Analyses of Replaceable Links in Eccentrically Braced Frame (EBF) Subject To Cyclic LoadingDokument20 SeitenApplied Sciences: Damage Analyses of Replaceable Links in Eccentrically Braced Frame (EBF) Subject To Cyclic LoadingAndres Riffo VillagranNoch keine Bewertungen

- Krishna Et Al 2021 FRP BeamsDokument7 SeitenKrishna Et Al 2021 FRP BeamsHaytham BouzidNoch keine Bewertungen

- 5236-Article Text-11399-1-10-20180831 - نسخDokument9 Seiten5236-Article Text-11399-1-10-20180831 - نسخThanoon AlmarwasyNoch keine Bewertungen

- Bond Mechanism of NSM FRP Bars For Flexural Strengthening of Concrete StructuresDokument39 SeitenBond Mechanism of NSM FRP Bars For Flexural Strengthening of Concrete StructuresDoua AbdouNoch keine Bewertungen

- Abaqus Bond Pull Out SimulationDokument23 SeitenAbaqus Bond Pull Out Simulation429e10d421Noch keine Bewertungen

- Report On Concrete Structures Reinforced With FRP Bar PDFDokument8 SeitenReport On Concrete Structures Reinforced With FRP Bar PDFsrinivas thademNoch keine Bewertungen

- Engineering Structures: Ehsan Nasiri, Yi LiuDokument14 SeitenEngineering Structures: Ehsan Nasiri, Yi LiuMaruthish KvNoch keine Bewertungen

- Seismic Behaviour of Reinforced Concrete Beam-Column Joints With Vertical Distributed ReinforcementDokument11 SeitenSeismic Behaviour of Reinforced Concrete Beam-Column Joints With Vertical Distributed ReinforcementMarimuthu KaliyamoorthyNoch keine Bewertungen

- Finite Element Modeling of Reinforced Concrete Beams Strengthened With FRP LaminatesDokument16 SeitenFinite Element Modeling of Reinforced Concrete Beams Strengthened With FRP Laminatessvchaudhari100% (1)

- Finite Element Modeling of Reinforced Concrete Beam Patch Repaired and Strengthened With Fiber-Reinforced PolymersDokument9 SeitenFinite Element Modeling of Reinforced Concrete Beam Patch Repaired and Strengthened With Fiber-Reinforced PolymersbroodyNoch keine Bewertungen

- In Uence of Edge Sharpness On The Strength of Square Concrete Columns Confined With FRP Composite LaminatesDokument11 SeitenIn Uence of Edge Sharpness On The Strength of Square Concrete Columns Confined With FRP Composite LaminatesAboalmaaliNoch keine Bewertungen

- Mechanical Behaviour and Durability of FRP To Steel Adhesively Bonded JointsDokument205 SeitenMechanical Behaviour and Durability of FRP To Steel Adhesively Bonded JointsVietnhut PhanNoch keine Bewertungen

- Bond Experimental ACIDokument10 SeitenBond Experimental ACIMatias GaitanNoch keine Bewertungen

- Study of Damaged RC Beams Repaired by Bonding of CFRP LaminatesDokument17 SeitenStudy of Damaged RC Beams Repaired by Bonding of CFRP LaminatesIAEME PublicationNoch keine Bewertungen

- 10 1 1 859 2580 PDFDokument13 Seiten10 1 1 859 2580 PDFEl Youbi MohammedNoch keine Bewertungen

- Finite Element Analysis of Concrete Bridge Decks Reinforced With Fiber Reinforced Polymer BarsDokument15 SeitenFinite Element Analysis of Concrete Bridge Decks Reinforced With Fiber Reinforced Polymer BarsHuda AlrikabiNoch keine Bewertungen

- 1 s2.0 S0950061816317093 Main PDFDokument11 Seiten1 s2.0 S0950061816317093 Main PDFDaniela Gonzalez BetancurNoch keine Bewertungen

- LTRC Technical Summary 443 Elimination of Deck Joints Using A Corrosion Resistant FRP ApproachDokument2 SeitenLTRC Technical Summary 443 Elimination of Deck Joints Using A Corrosion Resistant FRP ApproachwalaywanNoch keine Bewertungen

- Bond Mechanism of Near-Surface-Mounted Fiber-Reinforced Polymer Bars For Flexural Strengthening of Concrete StructuresDokument10 SeitenBond Mechanism of Near-Surface-Mounted Fiber-Reinforced Polymer Bars For Flexural Strengthening of Concrete StructuresMishraq ul quraishNoch keine Bewertungen

- IJETR041352Dokument8 SeitenIJETR041352erpublicationNoch keine Bewertungen

- Engineering Structures: Paul M. Hopkins, An Chen, Mostafa YossefDokument12 SeitenEngineering Structures: Paul M. Hopkins, An Chen, Mostafa YossefpranavNoch keine Bewertungen

- Flexural Performance & Bond Charact of FRP Strengthening Techniques For Concrete Structures (2002) - Thesis PDFDokument325 SeitenFlexural Performance & Bond Charact of FRP Strengthening Techniques For Concrete Structures (2002) - Thesis PDFJulio Humberto Díaz RondánNoch keine Bewertungen

- PC Research PaperDokument5 SeitenPC Research PaperghNoch keine Bewertungen

- Vasant Matsagar (Eds.) - Advances in Structural Engineering - Materials, Volume Three 3 (2015, Springer India) PDFDokument1.033 SeitenVasant Matsagar (Eds.) - Advances in Structural Engineering - Materials, Volume Three 3 (2015, Springer India) PDFKarnalPreeth100% (2)

- Simulation of The Behavior of Corrosion Damaged Reinforced Concrete Beams With/without CFRP RetrofitDokument14 SeitenSimulation of The Behavior of Corrosion Damaged Reinforced Concrete Beams With/without CFRP RetrofitkarthikNoch keine Bewertungen

- Literature ReviewDokument4 SeitenLiterature ReviewjemuelNoch keine Bewertungen

- Analysis of The Seismic Performance ofDokument19 SeitenAnalysis of The Seismic Performance ofzhang zhaoboNoch keine Bewertungen

- Shear Strength of Dry and Epoxy Joints For Ultra-High-Performance Fiber-Reinforced ConcreteDokument11 SeitenShear Strength of Dry and Epoxy Joints For Ultra-High-Performance Fiber-Reinforced ConcreteSudeep JoshiNoch keine Bewertungen

- Repair of Earthquake-Damaged RC Columns With FRP Wraps: Aci Structural Journal Technical PaperDokument9 SeitenRepair of Earthquake-Damaged RC Columns With FRP Wraps: Aci Structural Journal Technical PaperD Raul CfNoch keine Bewertungen

- A State of The Art Review On Reinforced Concrete Beams With Openings Retrofitted With FRPDokument15 SeitenA State of The Art Review On Reinforced Concrete Beams With Openings Retrofitted With FRPenghrc.2208Noch keine Bewertungen

- Reinforced Concrete Slabs With Cut-Out OpeningsDokument6 SeitenReinforced Concrete Slabs With Cut-Out OpeningsAlexandru Stefan BothNoch keine Bewertungen

- Results in Engineering: Ahmed Godat, Omar Chaallal, Yasmeen ObaidatDokument14 SeitenResults in Engineering: Ahmed Godat, Omar Chaallal, Yasmeen ObaidatMohsen SadeghiNoch keine Bewertungen

- Development and Experimental Study of Bond Between FRP Rebar and ConcreteDokument6 SeitenDevelopment and Experimental Study of Bond Between FRP Rebar and ConcreteApplied Science and Engineering Journal for Advanced ResearchNoch keine Bewertungen

- Nonlinear Analysis of Beams Reinforced IDokument12 SeitenNonlinear Analysis of Beams Reinforced IMike MatshonaNoch keine Bewertungen

- FlexuralDokument9 SeitenFlexuralezekielNoch keine Bewertungen

- Amoushahi, Azhari - 2009 - Buckling of Composite FRP Structural Plates Using The Complex Finite Strip MethodDokument8 SeitenAmoushahi, Azhari - 2009 - Buckling of Composite FRP Structural Plates Using The Complex Finite Strip MethodAnne MonteiroNoch keine Bewertungen

- An Experimental Study On Kevlar Strengthening of Beam Column ConnectionsDokument9 SeitenAn Experimental Study On Kevlar Strengthening of Beam Column ConnectionsMarimuthu KaliyamoorthyNoch keine Bewertungen

- Nonlinear Finite Element Modeling of FRP-wrapped UHPC ColumnsDokument18 SeitenNonlinear Finite Element Modeling of FRP-wrapped UHPC ColumnsJamal Eddine HamiltonNoch keine Bewertungen

- Rehabilitation of Concrete Structures with Fiber-Reinforced PolymerVon EverandRehabilitation of Concrete Structures with Fiber-Reinforced PolymerNoch keine Bewertungen

- ECClinkslab Kim Ficsher LiDokument10 SeitenECClinkslab Kim Ficsher LihastoutomoNoch keine Bewertungen

- RILEM Schindler Concrete Setting Dec 03Dokument14 SeitenRILEM Schindler Concrete Setting Dec 03Mohd Raziff RazlanNoch keine Bewertungen

- Schindler Folliard ACC-IXDokument10 SeitenSchindler Folliard ACC-IXhastoutomoNoch keine Bewertungen

- Best Practices of Concrete Pavement TransitionDokument91 SeitenBest Practices of Concrete Pavement Transitionhastoutomo100% (1)

- BQ (Bill of Quantity)Dokument35 SeitenBQ (Bill of Quantity)hastoutomoNoch keine Bewertungen

- Naskah Publikasi LengkapDokument20 SeitenNaskah Publikasi LengkaphastoutomoNoch keine Bewertungen

- Aplicacion de Sowtfare para I.Q.Dokument34 SeitenAplicacion de Sowtfare para I.Q.Gabriel MenchuNoch keine Bewertungen

- Chromium Added Zinc BathDokument9 SeitenChromium Added Zinc BathHerdisNoch keine Bewertungen

- Project Report On Visualization of Flow Over Cylinder Using Dye Injection 1Dokument23 SeitenProject Report On Visualization of Flow Over Cylinder Using Dye Injection 1RAKESH SAHNoch keine Bewertungen

- Report On Dehumidification: Haldia Institute of TechnologyDokument18 SeitenReport On Dehumidification: Haldia Institute of Technologyindrajit majumderNoch keine Bewertungen

- Arch Action in BeamsDokument2 SeitenArch Action in Beamsshy10002022100% (1)

- Brinkman EquationDokument5 SeitenBrinkman EquationAdegbite Jamiu OyekanNoch keine Bewertungen

- CVE 202 Lecture Notes - 30062021Dokument6 SeitenCVE 202 Lecture Notes - 30062021odubade opeyemiNoch keine Bewertungen

- Space Frame 2019-Torque-Force 25.4X1.6Dokument24 SeitenSpace Frame 2019-Torque-Force 25.4X1.6luis nunezNoch keine Bewertungen

- ASTM D 6128 Jenike Shear Tester Standard PDFDokument20 SeitenASTM D 6128 Jenike Shear Tester Standard PDFdaniel123trigoNoch keine Bewertungen

- Homework #2 Due Feb 6, 2008 Spring Semester 2008: ME 363 - Fluid MechanicsDokument6 SeitenHomework #2 Due Feb 6, 2008 Spring Semester 2008: ME 363 - Fluid MechanicsMohannad NassarNoch keine Bewertungen

- 06-Combined FootingDokument12 Seiten06-Combined FootingHusein El MazloumNoch keine Bewertungen

- PTAP El Portico Proyecto III HVAC Load Analysis: Prepared byDokument8 SeitenPTAP El Portico Proyecto III HVAC Load Analysis: Prepared bykatherine palominoNoch keine Bewertungen

- Pitzer Model 1987Dokument84 SeitenPitzer Model 1987Ram KumarNoch keine Bewertungen

- C Knock-Out Isolation ValveDokument1 SeiteC Knock-Out Isolation ValveCarlos Alberto Aguilera MendezNoch keine Bewertungen

- ME 201 Mechanics of SolidsDokument2 SeitenME 201 Mechanics of SolidsUnnikrishnan TGNoch keine Bewertungen

- 1 s2.0 S0267726123000192 MainDokument14 Seiten1 s2.0 S0267726123000192 Mainlx nieNoch keine Bewertungen

- Simple DistillationDokument6 SeitenSimple DistillationA Arun100% (1)

- Solved Problems in Kinematics and DynamicsDokument7 SeitenSolved Problems in Kinematics and DynamicsJayson Acosta100% (1)

- CrashUp Surface TensionDokument33 SeitenCrashUp Surface TensionSameer ChakrawartiNoch keine Bewertungen

- HW-7. Transient Heat Conduction PDFDokument1 SeiteHW-7. Transient Heat Conduction PDFSafaa Hameed Al NaseryNoch keine Bewertungen

- Hydraulic NotesDokument73 SeitenHydraulic NotesE-klil Wawa100% (2)

- Unit 2 Energy MethodDokument10 SeitenUnit 2 Energy MethodYokesvaran KNoch keine Bewertungen

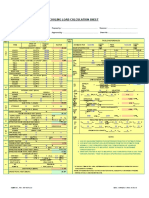

- Cooling Load Calculation Sheet: X X X X X X X X X X X X X X X X Cfm/Person Cfm/DoorDokument6 SeitenCooling Load Calculation Sheet: X X X X X X X X X X X X X X X X Cfm/Person Cfm/Doorashfaq-matte-799375% (4)

- Ls Dyna ThLs Dyna TheoryeoryDokument498 SeitenLs Dyna ThLs Dyna TheoryeoryxxleonardNoch keine Bewertungen

- Computers and Geotechnics: G.S.P. Singh, U.K. SinghDokument15 SeitenComputers and Geotechnics: G.S.P. Singh, U.K. Singhkatta_sridharNoch keine Bewertungen

- Non Linear Pushover AnalysisDokument10 SeitenNon Linear Pushover AnalysisyibungoNoch keine Bewertungen

- Oil Pipeline Engineering CourseDokument3 SeitenOil Pipeline Engineering CourseKarthik Sundararajan0% (1)

- Chapter 1. Introduction On Fluid Mechanics BookDokument70 SeitenChapter 1. Introduction On Fluid Mechanics BookMubarekNoch keine Bewertungen

- Reinforced Concrete I - 2013-2014Dokument188 SeitenReinforced Concrete I - 2013-2014alaa4altaie75% (4)

- Solucionario - Termodinamica - Cengel - 7ed (1) - 519-528Dokument10 SeitenSolucionario - Termodinamica - Cengel - 7ed (1) - 519-528Lizeth Maria lizarazoNoch keine Bewertungen