Beruflich Dokumente

Kultur Dokumente

206 Full

Hochgeladen von

Rajdeep RajdipOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

206 Full

Hochgeladen von

Rajdeep RajdipCopyright:

Verfügbare Formate

A Capillary,

Noncirculating

Hydroponic

Method for Leaf

and Semi-head

Lettuce

Bernard A. Kratky1

Additional index words, Lactuca

sativa, transplanting, gardening,

growing systems

Summary. A simple, capillary, noncirculating hydroponic method is described. Lettuce seedlings are transplanted into 218-mm-long plastic

tubes containing 160 ml of growing

medium and the bottom 25 mm is

submerged into a tank of nutrient

solution. No additional fertilization,

watering, or monitoring is required

from transplanting until harvesting.

Although the nutrient solution level

may drop below the bottoms of the

tubes, the roots continue to take up

adequate water and nutrients to sustain growth. This method does not

require pumps or electrical power.

Green Ice leaf lettuce produced 24%

more salable yield growing with this

method than comparable plants growing in conventional soil culture.

orticulturists routinely have

recommended aeration or

circulation of nutrient solution in hydroponic systems since 1940,

when Arnon and Hoagland reported a

34% yield increase of tomatoes by aerating the nutrient solution (Arnon and

Hoagland, 1940). The additional production costs and complexities associated with aeration and circulation of

nutrient solution have retarded the

adoption of hydroponic practices to

their full potential in commercial agriculture. Thus, there is a need to develop simple, low-maintenance hydroponic systems that do not require power

or complex equipment and are relatively low in cost.

Noncirculating hydroponic sys1

Horticulturist, University of Hawaii, Beaumont Agricultural Research Center, 461 W. Lanikaula, Hilo, HI

96720.

206

terns have been described in which a

small pot or some other plant container rests on or above a layer of screen

(Imai, 1987; Kratky et al., 1988,1989).

The screen encourages root development and provides an anchor for plant

support. The lower part of the plant

container must be submerged in nutrient solution immediately after transplanting. As the plants grow, the nutrient solution level must be lowered gradually to a point just below the screen.

The correct management of the nutrient solution level is very important for

the proper establishment oftransplants,

and this process involves diligent attention of the grower. This report

describes a noncirculating capillary hydroponic method for growing leaf and

semi-head lettuce (Lactuca sativa L.)

in which no maintenance or monitoring is required from the time of transplanting until harvesting.

A shallow tank was built in a greenhouse located at 1300 m elevation by

placing two layers of 0.15-mm-thick

black polyethylene over a rectangular

frame, 9.7 1.2 m (Fig. 1). The frame

was constructed with 50 x 150-mm

lumber at ground level and 50 mm of

soil was excavated and removed from

within the frame to provide for a deeper

tank. Sheets of 13-mm-thick plywood

coated with white latex paint and reinforced with 19 x 64-mm lumber (to

prevent sagging) were placed over the

frame. Holes 38 mm in diameter were

drilled in the plywood at 200 230mm spacings.

Nutrient solution with a pH of

6.5 and an electrical conductivity of

1.0 mS was added to the polyethylene

tank. It consisted of a 75-mm depth of

water containing the following (in

mgliter -1): N, 93; P, 33; K, 108; Ca,

110; Mg, 18; S, 23; Fe, 2; Mn, 1; Zn,

0.3; Cu, 0.3; B, l; an Mo, 0.05. Fer-

tilizer salts included calcium nitrate,

potassium nitrate, potassium phosphate, and sulfates of potassium, magnesium, manganese, zinc, and copper.

Green Ice leaf lettuce and Green

Mignonette semi-head lettuce were

seeded in tapered plastic containers

(Stuewe and Sons, Corvallis, Ore.), 40

mm in diameter and 218 mm deep,

filled to the top with 160 ml of a 1 sand

: 1.2 peat : 0.8 vermiculite medium

and watered by overhead mist in a

seedling greenhouse. Care was taken

to pack the media uniformly, thus eliminating voids in the containers. The

containers with 18 -day-old seedlings

were transplanted into the top cover of

the tank such that 47 mm of the seedling container extended above the surface and 158 mm remained below the

plywoodcover. Therewere ten 4-mmdiameter holes in the portion of the

tapered plastic containers located below the cover, four oval holes (12 4

mm) in the lower 20 mm of the container, and a 7-mm-diameter hole in

the bottom of the container.

The bottom 25 mm of each container was immersed in nutrient solution and the resulting capillary action

was sufficient to wet the medium

throughout the containers, thus automatically watering the plants. No additional maintenance was required from

this time until harvesting. Daily minimum temperatures ranged from 7 to

17C, and daily maximum temperatures ranged from 19 to 31C. No

supplemental lighting was supplied.

After a 35-day growing period,

89% of the Green Ice and 81% of the

Green Mignonette heads were of

marketable quality, and the average

weights were 198 and 176 g/head,

respectively. In a succeeding trial with

19-day-old transplants and a 32-day

growing period, all of the Green Ice

Fig. 1. A capillary, noncirculating hydroponic method for leaf and semi-head lettuce.

HortTechnology - Apr./June 1993

and 97% of the Green Mignonette

were of marketable quality, and the

average weights were 157 and 134 g/

head, respectively.

The water consumption rates for

Green Ice and Green Mignonette

were 14.4 and 12.6 literkg-1, respectively, of harvest fresh weight of lettuce. Although the final nutrient solution levels were 6 to 20 mm below the

bottom of the containers, the growing

medium in the containers remained

moist. However, when the nutrient

solution level was 40 mm or more

below the bottom of the containers,

the medium in the containers was often dry, but the plant continued to

growwell. No determination was made

on the maximum distance between the

container and the nutrient solution

that would permit satisfactory growth

of the plants.

Lettuce growth from the capillary, noncirculating hydroponic method was compared to lettuce growth

from the noncirculating screen method

and from conventional greenhouse soil

(Manu silt loam) in an open-sided,

plastic-covered greenhouse located at

a 1300-m elevation. The noncirculating hydroponic methods used polyethylene-lined tanks (2.4 0.3 0.3

m) containing the same nutrient solution described earlier. Rockwool cubes

(25 x 25 x 40 mm) served as the plant

containers for the screen method, and

the screen was located 75 mm below

the top cover. The soil bed received a

preplant, broadcast, and incorporated

200-gm-2 rate of 16N-6P-13K. Plants

were arranged in double rows spaced

150 x 240 mm apart. There were four

replicates of each treatment, and the

experiment was arranged as a randomized complete block. There were six

trials with Green Ice leaf lettuce,

which were harvested in January, February, April, May, July, and August,

with an average transplant age of 20

days and a transplant-to-harvest time

of 41 days. Throughout this period,

daily minimum temperatures ranged

between 7 and 17C and daily maximum temperatures ranged between

19 and 31C. No supplemental lighting was supplied.

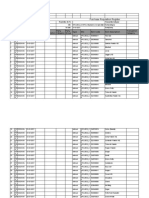

Salable yield of Green Ice lettuce was 24% greater from the capillary, noncirculating hydroponic method than from the conventional soil

method (Table 1). However, yields

from both noncirculating methods

were statistically similar. Therefore,

HortTechnology - Apr./June 1993

Table 1. Salable yields of Green Ice lettuce

grown by two noncirculating hydroponic

methods and conventional soil culture.

Leaf lettuce. Mean yields of six trials with 15

heads per treatment and four replications. The

average transplant age was 20 days and the

average transplant-to-harvest time was 41 days.

because the screen noncirculating

method required diligent attention

during the transplant establishment

period, the capillary noncirculating

hydroponic methods enjoys the advantage of high yield potential with no

maintenance from transplanting until

harvesting. The nutrient solution pH

values at the end of these trials ranged

from 6.1 to 7.0.

Minimal root growth was observed from the 4-mm holes in the

containers located between the original nutrient solution surface and the

plywood cover. However, there was

substantial root growth from the bottom hole and the oval holes of the containers that were immersed in nutrient

solution at the start of the growing

period. A significant portion of this

root mass emerged in a conical form

and was suspended in the air above the

nutrient solution. Remaining roots

floated both on and below the nutrient solution. Roots from adjacent

plants intermingled with each other.

When the plywood top cover was lifted

during the growing period, roots tore

and many roots in the conical suspension sank below the nutrient solution

level, causing the foliage to wilt or lose

vigor. Thus, it is important not to disturb the plants while they are growing.

After lettuce was transplanted in

the capillary, noncirculating hydroponic method, no additional watering, fertilization, or monitoring of pH

or electrical conductivity was required.

Thus, the only cultural operations required for this system are: preparation

of the nutrient solution, transplanting,

harvest, cleanup, and, perhaps, disease

or insect control.

In the capillary, noncirculating

hydroponic method, plant growth is

not affected adversely when the nutri-

ent solution level drops or remains

constant. However, severe wilting or

even death often occurs after a significant rise in the nutrient solution level.

Once roots have become acclimated to

a microclimate of moist air, they can

no longer tolerate submerged conditions. Therefore, this method is not

suitable for outdoor production because rainfall would cause the nutrient

solution level to rise.

Longer-term crops such as tomatoes would present a challenge to this

method because it would be necessary

to add nutrient solution during the

growing season. Application increments should be small to prevent root

injury.

Other types of tanks have been

used successfully with this growing

method. These includes plastic buckets with lids, large planting containers

lined with plastic trash bags, insulated

coolers, and old refrigerators lined with

polyethylene.

Additional studies are needed to

adapt this method to crops with longer

growing seasons. The capillary, noncirculating hydroponic method offers

promising potential for production of

intensive crops, for home gardens protected from rain, for educational purposes, and for growing plants used in

research.

Acknowledgement

The technical assistance of R.

Cupples, R. Kaneko, G. Maehira, Y.

Takushi, and G. Terasawa is greatly

appreciated.

Literature Cited

Arnon, D.I. and D.R. Hoagland. 1940.

Crop production in artificial culture solutions and in soils with specific reference to

factors influencing yields and absorption

of inorganic nutrients. Soil Sci. 50:463484.

Imai, H. 1987. AVRDC non-circulating

hydroponic system, p. 109-122. In: C.C.

Tu and T.F. Sheen (eds.). Proc. Symp on

Horticultural Production under Structure.

Taiwan Agr. Res. Inst., Taichung.

Kratky, B.A., J.E. Bowen, and H. Imai.

1988. Observations on a noncirculating

hydroponic system for tomato production.

HortScience 23:906-907.

Kratky, B.A., H. Imai, and J.S. Tsay. 1989.

Non-circulating hydroponic systems for

vegetable production. Proc. Natl.Agr. Plastics Congr. 21:22-27.

207

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Proposal Fish PlanDokument17 SeitenProposal Fish Planakyadav123100% (1)

- NCDCDokument14 SeitenNCDCsudadhich100% (1)

- The Indolence of The FilipinosDokument5 SeitenThe Indolence of The FilipinosPaulo Benedicto VillarNoch keine Bewertungen

- LicuadoraDokument28 SeitenLicuadoraPedro OcHo'aNoch keine Bewertungen

- Persepsi Masyarakat Terhadap Gangguan Gajah SUMATERA (Elephas Maximus Sumatranus) DI KABUPATEN OGAN Komering IlirDokument17 SeitenPersepsi Masyarakat Terhadap Gangguan Gajah SUMATERA (Elephas Maximus Sumatranus) DI KABUPATEN OGAN Komering IlirZulfi RimaNoch keine Bewertungen

- Changing Structure of Appropriations in Vedda Agriculture - James BrowDokument20 SeitenChanging Structure of Appropriations in Vedda Agriculture - James BrowGirawa KandaNoch keine Bewertungen

- Purchase Requisition RegisterDokument156 SeitenPurchase Requisition RegisterarnrockzzNoch keine Bewertungen

- Paper III - Objective III - ALexis Kabayiza - PHD AGBMDokument9 SeitenPaper III - Objective III - ALexis Kabayiza - PHD AGBMAlexis kabayizaNoch keine Bewertungen

- Poultry History and IndustryDokument39 SeitenPoultry History and IndustryGenNoch keine Bewertungen

- Adp 2014 15 PDFDokument251 SeitenAdp 2014 15 PDFHayat Ali ShawNoch keine Bewertungen

- Questionnaire SME Instr Phase 1 H2020 - RevDokument5 SeitenQuestionnaire SME Instr Phase 1 H2020 - RevkjmendozagNoch keine Bewertungen

- Boja 3Dokument18 SeitenBoja 3bojaNoch keine Bewertungen

- Dr. Jose Rizal's ProfessionsDokument2 SeitenDr. Jose Rizal's ProfessionsJames Michael33% (3)

- Trial Kedah 2014 SPM Biologi K3 SkemaDokument11 SeitenTrial Kedah 2014 SPM Biologi K3 SkemaCikgu Faizal0% (1)

- Ambo University, Woliso Campus School of Business and Economics Department of Agricultural EconomicsDokument2 SeitenAmbo University, Woliso Campus School of Business and Economics Department of Agricultural Economicsjima degagaNoch keine Bewertungen

- "THE MALLARD" February 2020Dokument16 Seiten"THE MALLARD" February 2020Anonymous SKP0jiK9Noch keine Bewertungen

- Grape vs. GrainDokument224 SeitenGrape vs. GrainmileveljovicNoch keine Bewertungen

- Factors Affecting Postharvest Quality of Fresh FruitsDokument27 SeitenFactors Affecting Postharvest Quality of Fresh FruitsGaganpreet KaurNoch keine Bewertungen

- Storage Behaviour of Different Potato Varieties Under Ambient ConditionsDokument4 SeitenStorage Behaviour of Different Potato Varieties Under Ambient Conditionsbasiru abubakarNoch keine Bewertungen

- Group 5 - PteridophytaDokument30 SeitenGroup 5 - PteridophytaLidya VelesiaNoch keine Bewertungen

- Auroville Work Exp.Dokument7 SeitenAuroville Work Exp.Sachit ShahNoch keine Bewertungen

- Chapter II: Review of Related Literature Foreign LiteratureDokument4 SeitenChapter II: Review of Related Literature Foreign Literaturecookie yoosungNoch keine Bewertungen

- Manual ESP 212Dokument49 SeitenManual ESP 212ManuelHerreraMontoyaNoch keine Bewertungen

- Form Pemutakhiran Data UKM TA 21-22 - Tingkat 3 Jurusan deDokument6 SeitenForm Pemutakhiran Data UKM TA 21-22 - Tingkat 3 Jurusan deNahdamar EnterpriseNoch keine Bewertungen

- B.Sc. Hons. AgricultureDokument4 SeitenB.Sc. Hons. AgricultureAli RazaNoch keine Bewertungen

- Wgs Classifieds 080414Dokument5 SeitenWgs Classifieds 080414Digital MediaNoch keine Bewertungen

- 40 Years of Chez Panisse: The Power of GatheringDokument6 Seiten40 Years of Chez Panisse: The Power of GatheringThe Recipe Club0% (6)

- Adepoju 2015 PublicationDokument5 SeitenAdepoju 2015 PublicationDelyana Fitria DewiNoch keine Bewertungen

- MUNGBEANDokument9 SeitenMUNGBEANFrancis Jay HalligNoch keine Bewertungen