Beruflich Dokumente

Kultur Dokumente

Weld

Hochgeladen von

ibnu.asad9840 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

56 Ansichten2 Seitencatalog welding

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldencatalog welding

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

56 Ansichten2 SeitenWeld

Hochgeladen von

ibnu.asad984catalog welding

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

University of Alaska Anchorage

Welding Technology

(WELD)

WELD A112 Shielded Metal Arc Welding (SMAW) 4 Credits

Introduces the welding of mild steels with covered electrodes. Includes

welding safety, electric arc welding equipment, electrode identification

and selection, basic joint design, and welding practice on carbon steel

plate.

Courses

WELD A114 Welding of High Strength Steels 4 Credits

Builds on knowledge and techniques covered in WELD A112.

Introduces the welding of high strength steels with covered electrodes.

Includes welding safety, low alloy electrode selection, welding joint

design, and alloy steel specifications.

Prerequisites: WELD A112.

WELD A101 Gas and Arc Welding 4 Credits

Introduces basic principles of welding. Covers oxyacetylene welding

(OAW), brazing, and silver. This course is equally divided between

OAW and shielded metal arc welding (SMAW) processes.

WELD A102 Gas Welding 2 Credits

Develops basic oxy-acetylene welding, brazing, and cast iron welding

skills, emphasizing hands-on class assignments.

May Be Stacked With: WELD A103 and WELD A104

WELD A103 Arc Welding 4 Credits

Provides training and hands-on experience required for structural steel

plate welding certification. Students certify on 0.375 inch plate, open

root or with backing, at ASME or AWS code standards.

May Be Stacked With: WELD A102 and WELD A104

WELD A117 Basic Pipefitting 4 Credits

Presents theory and practice for the layout and assembly of piping

offsets and pipe spool assemblies common to the oil and gas industry.

WELD A118 Welding Fabrication and Manufacturing 4 Credits

Provides relevant topics and skill enhancement in the field of welding

and fabrication for manufactured products.

Prerequisites: WELD A101.

WELD A104 Arc Welding: Low-Hydrogen Electrodes 4 Credits

Develops skills and techniques required for low-hydrogen electrode

welder certification, emphasizing hands-on experience. Students certify

on 0.375 inch plate with backing, to AWS code standards.

Registration Restrictions: Arc welding experience can substitute for

prerequisites.

May Be Stacked With: WELD A102 and WELD A103

Prerequisites: WELD A101 or WELD A103.

WELD A121 Pipe Welding Vertical-Down SMAW 4 Credits

Builds on knowledge and techniques covered in WELD A112.

Introduces vertical-down shielded metal arc welding (SMAW)

techniques on carbon steel pipe using EXX 10 electrodes. Includes

information on pipe material specifications, pipe fittings and assembly,

welder qualification and American Petroleum Institute (API) Standard

1104 requirements.

May Be Stacked With: WELD A122

Prerequisites: WELD A112.

WELD A105 Pipe Welding 4 Credits

Develops skills and techniques for pipe welding, all positions, open

root, uphill and downhill using ANSI Schedule 40 steel pipe sizes of

4-6 inch.

Registration Restrictions: Current certification of plate, open root,

vertically upward, or pre-test during registration.

May Be Stacked With: WELD A106

Prerequisites: WELD A103 and WELD A104.

WELD A122 Pipe Welding Vertical-Up SMAW 4 Credits

Builds on knowledge and techniques covered in WELD A121.

Introduces vertical-up shielded metal arc welding (SMAW) on carbon

and alloy steel pipe using EXX 10 and EXX18 electrodes. Includes

information on high-strength alloy pipe specifications and weld/welder

evaluation/qualifications defined in ASME IX and ANSI/ASME B31.3.

May Be Stacked With: WELD A121

Prerequisites: WELD A121.

WELD A106 Pipe Certification 4 Credits

Develops skills required for pipe welding, all positions, open root,

uphill and downhill using 6 inch Schedule 80 steel pipe, and certify on 6

inch Schedule 80 uphill procedure, ANSI B31 3 code standard.

May Be Stacked With: WELD A105

Prerequisites: WELD A105.

WELD A157 Technical Drawings for Welders 3 Credits

Provides instruction o interpreting various types of drawings that

are commonly used for construction projects that require welded

assemblies.

WELD A108 Wire Welding 4 Credits

Develops skills and techniques in wire-feed (MIG) welding on mild

steel, stainless steel and aluminum, with and without gas shielding.

Students gain hands-on experience with all wire types on the current

market.

WELD A109 TIG Welding 4 Credits

Develops skills and techniques for tungsten-inert gas (TIG) welding

on aluminum, zinc alloys, copper, magnesium, mild steel and stainless

steel. Emphasizes hands-on welding assignments.

Prerequisites: WELD A101 or WELD A102.

WELD A161 Gas Metal Arc Welding (GMAW) 4 Credits

Introduces gas metal arc welding (GMAW) techniques for joining

a number of metals. Includes information on power supplies, wire

feed equipment, shielding gases, filler metal selection, and electrical

characteristics of the arc.

WELD A162 Flux Cored Arc Welding (FCAW) 4 Credits

Builds on knowledge and techniques covered in WELD A112 or WELD

A161. Introduces theory and practice of FCAW using self-shielded

and dual-shielded wire processes. Covers physics of metal transfer,

electrical characteristics of power supplies, wire feeders, and filler

metal selection and storage.

Prerequisites: WELD A112 or WELD A161.

Welding Technology (WELD)

WELD A174 Gas Tungsten Arc Welding (GTAW) 4 Credits

Builds on knowledge and techniques covered in WELD A112.

Introduces gas tungsten arc welding (GTAW) techniques for joining

a number of metals. Includes information on power supplies, torches,

inert gases, filler metal selection and electrical characteristics of the arc.

Prerequisites: WELD A112.

WELD A190 Selected Topics in Welding Technology 1-4 Credits

Presents relevant topics and techniques in the field of welding and

fabrication.

Prerequisites: WELD A101.

WELD A207 Industrial Welding Qualification 2 Credits

Provides opportunity for experienced welding students to study,

practice and demonstrate mastery of one or more specific technical

welding methods leading to national industrial welding qualification.

Each student will be evaluated on an individual basis derived from the

student's professional objectives.

Registration Restrictions: Prequalification welding test.

WELD A261 Ultrasonic Testing 4 Credits

Covers the principles of ultrasonic testing methods with compression

and shear wave techniques. Examines inspection techniques in

accordance with AWS D1.1, API 1104 and ASME codes. Prepares

students for the level I, ASNT, SNT-TC-1A, recommended practice

examination.

Prerequisites: MATH A105.

WELD A262 General Nondestructive Testing 3 Credits

Presents nondestructive testing methods of dye penetrant, magnetic

particle, and visual testing. Includes the applications, advantages, and

limitations of these NDT methods. Prepares students for the Level I and

Level II American Society for Nondestructive Testing, SNT-TC-1A

recommended practice examination.

WELD A263 Radiographic Testing Safety 2 Credits

Presents the safety practices and USNRC regulations for industrial

radiography in nondestructive examination. Prepares for both

Radioactive Materials (RAM) and the X- ray category Industrial

Radiography Radiation Safety Personnel (IRRSP) examination

administered by the American Society for Nondestructive Testing

(ASNT).

Prerequisites: MATH A105.

WELD A264 Radiographic Testing 4 Credits

Presents theory and application of industrial radiography and meets

ASNT initial training hour requirements for Level I and Level II

radiographer. Includes operation of equipment, film exposures and

development, radiographic procedure specifications, interpretation of

radiographs, and a brief review of radiation safety.

Prerequisites: WELD A112 and WELD A263.

WELD A281 Welding Inspection and Code Review 4 Credits

Presents numerous welding inspection methods and a study of various

welding codes and standards in preparation for the American Welding

Society (AWS) Certified Welding Inspector (CWI) Examination.

Prerequisites: WELD A112 and WELD A157.

WELD A287 Welding Metallurgy Applications 5 Credits

Presents technical information in welding metallurgy. Includes

laboratory practice in metallography, heat-treating, and mechanical

properties testing.

Prerequisites: MATH A055 and WELD A112.

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Automotive Voltage DropDokument5 SeitenAutomotive Voltage Dropashraf.rahim139Noch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- How To Defend The Faith Without Raising Your VoiceDokument139 SeitenHow To Defend The Faith Without Raising Your VoiceCleber De Souza Cunha100% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Simple CASC StationsDokument74 SeitenSimple CASC Stationssherief marouf100% (2)

- Anglo American - Belt Conveyor Design CriteriaDokument19 SeitenAnglo American - Belt Conveyor Design CriteriaIgor San Martín Peñaloza0% (1)

- Continuous Microbiological Environmental Monitoring For Process Understanding and Reduced Interventions in Aseptic ManufacturingDokument44 SeitenContinuous Microbiological Environmental Monitoring For Process Understanding and Reduced Interventions in Aseptic ManufacturingTorres Xia100% (1)

- School Calendar: Queensland State SchoolsDokument1 SeiteSchool Calendar: Queensland State Schoolsibnu.asad984Noch keine Bewertungen

- 2016 Timetabling CalendarDokument1 Seite2016 Timetabling Calendaribnu.asad984Noch keine Bewertungen

- 2016 Liturgical Calendar: Liturgy OfficeDokument8 Seiten2016 Liturgical Calendar: Liturgy Officeibnu.asad984Noch keine Bewertungen

- Recomm2015 2016Dokument2 SeitenRecomm2015 2016ibnu.asad984Noch keine Bewertungen

- 2016 Monthly CalendarDokument12 Seiten2016 Monthly Calendaribnu.asad984Noch keine Bewertungen

- 2016 Liturgical Calendar: Liturgy OfficeDokument8 Seiten2016 Liturgical Calendar: Liturgy Officeibnu.asad984Noch keine Bewertungen

- 2016 Training Materials CatalogDokument24 Seiten2016 Training Materials Catalogibnu.asad984Noch keine Bewertungen

- 13 BridgeDokument25 Seiten13 Bridgeibnu.asad984Noch keine Bewertungen

- February 2016: Sun Mon Tue Wed Thu Fri SatDokument1 SeiteFebruary 2016: Sun Mon Tue Wed Thu Fri SatWilly ChandraNoch keine Bewertungen

- Welded Excutive SummDokument36 SeitenWelded Excutive Summibnu.asad984Noch keine Bewertungen

- Welding Application Spring 2016Dokument10 SeitenWelding Application Spring 2016ibnu.asad984Noch keine Bewertungen

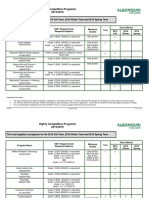

- Competitive Programs For CanadaDokument41 SeitenCompetitive Programs For Canadaferoz_bilalNoch keine Bewertungen

- Fab-Welding Supervisors and Inspector Dates and InformationDokument2 SeitenFab-Welding Supervisors and Inspector Dates and Informationibnu.asad984Noch keine Bewertungen

- 1221 Hot Gas and Extrusion Welding Jan 2016Dokument2 Seiten1221 Hot Gas and Extrusion Welding Jan 2016ibnu.asad984Noch keine Bewertungen

- Tws School CatalogDokument76 SeitenTws School Catalogibnu.asad984Noch keine Bewertungen

- Appendix C - Welding Specification For Fabrication of Piping SystemsDokument33 SeitenAppendix C - Welding Specification For Fabrication of Piping Systemsibnu.asad9840% (1)

- p24 Course Description Welding Technology Courseplan 2016Dokument3 Seitenp24 Course Description Welding Technology Courseplan 2016ibnu.asad984Noch keine Bewertungen

- Highly Competitive Programs Chart 2015-2016Dokument3 SeitenHighly Competitive Programs Chart 2015-2016ibnu.asad984Noch keine Bewertungen

- MC2034 Weld Rods - v4Dokument2 SeitenMC2034 Weld Rods - v4ibnu.asad984Noch keine Bewertungen

- 2015 Programs Book List PricesDokument13 Seiten2015 Programs Book List Pricesibnu.asad984Noch keine Bewertungen

- MC2034 Weld Rods - v4Dokument2 SeitenMC2034 Weld Rods - v4ibnu.asad984Noch keine Bewertungen

- CCC 2015 2016 Fee ChartDokument5 SeitenCCC 2015 2016 Fee Chartibnu.asad984Noch keine Bewertungen

- WeldingDokument4 SeitenWeldingibnu.asad984Noch keine Bewertungen

- 16 17 Dept Flow Charts v2 0Dokument17 Seiten16 17 Dept Flow Charts v2 0ibnu.asad984Noch keine Bewertungen

- AWS Weld Symbol ChartDokument1 SeiteAWS Weld Symbol ChartExsan OthmanNoch keine Bewertungen

- New Technologies 112515Dokument29 SeitenNew Technologies 112515ibnu.asad984Noch keine Bewertungen

- FIEA Events 2016 One Page FlyerDokument1 SeiteFIEA Events 2016 One Page Flyeribnu.asad984Noch keine Bewertungen

- h2020 wp1617 Fet - enDokument41 Seitenh2020 wp1617 Fet - enibnu.asad984Noch keine Bewertungen

- Gs 16 1 Distributed Ledger TechnologyDokument88 SeitenGs 16 1 Distributed Ledger Technologyibnu.asad984Noch keine Bewertungen

- 27nov12 PA Task Force On Child Protection ReportDokument445 Seiten27nov12 PA Task Force On Child Protection ReportDefendAChildNoch keine Bewertungen

- Perkalink 900Dokument2 SeitenPerkalink 900casual12100% (1)

- 4 - Mixing Equipments Used in Flocculation and CoagulationDokument27 Seiten4 - Mixing Equipments Used in Flocculation and Coagulationhadeer osmanNoch keine Bewertungen

- A-V300!1!6-L-GP General Purpose Potable Water Commercial Industrial Hi-Flo Series JuDokument2 SeitenA-V300!1!6-L-GP General Purpose Potable Water Commercial Industrial Hi-Flo Series JuwillgendemannNoch keine Bewertungen

- Tda12110h1 N300Dokument1 SeiteTda12110h1 N300rolandseNoch keine Bewertungen

- Tropical Fruit CHAPTER-3Dokument32 SeitenTropical Fruit CHAPTER-3Jeylan FekiNoch keine Bewertungen

- ReclosersDokument28 SeitenReclosersSteven BeharryNoch keine Bewertungen

- Seachem Laboratories, Inc. Safety Data SheetDokument10 SeitenSeachem Laboratories, Inc. Safety Data SheetJorge Restrepo HernandezNoch keine Bewertungen

- Texas Steering and Insurance DirectionDokument2 SeitenTexas Steering and Insurance DirectionDonnie WeltyNoch keine Bewertungen

- Bleeding in A NeonateDokument36 SeitenBleeding in A NeonateDrBibek AgarwalNoch keine Bewertungen

- Death Obituary Cause of Death Ookht PDFDokument4 SeitenDeath Obituary Cause of Death Ookht PDFMayerRhodes8Noch keine Bewertungen

- Powador 7700 - 7900 8600 - 9600: OriginalDokument52 SeitenPowador 7700 - 7900 8600 - 9600: Originalashraf-84Noch keine Bewertungen

- Bsbfia401 3Dokument2 SeitenBsbfia401 3nattyNoch keine Bewertungen

- Subhead-5 Pump Motors & Related WorksDokument24 SeitenSubhead-5 Pump Motors & Related Worksriyad mahmudNoch keine Bewertungen

- SPKT Thiet Ke Co Khi 1Dokument33 SeitenSPKT Thiet Ke Co Khi 1Chiến PhanNoch keine Bewertungen

- Week 4 (Theories)Dokument15 SeitenWeek 4 (Theories)Erica Velasco100% (1)

- Open Courses Myanmar Strategic English Week 4: U Yan Naing Se NyuntDokument24 SeitenOpen Courses Myanmar Strategic English Week 4: U Yan Naing Se NyuntYan Naing Soe NyuntNoch keine Bewertungen

- Mental Health & TravelDokument18 SeitenMental Health & TravelReyza HasnyNoch keine Bewertungen

- Polyken 4000 PrimerlessDokument2 SeitenPolyken 4000 PrimerlessKyaw Kyaw AungNoch keine Bewertungen

- Mrunal Handout 12 CSP20Dokument84 SeitenMrunal Handout 12 CSP20SREEKANTHNoch keine Bewertungen

- Aits 2324 Ot I Jeea TD Paper 2 OfflineDokument14 SeitenAits 2324 Ot I Jeea TD Paper 2 OfflineAshish SharmaNoch keine Bewertungen

- C50SCR PLC Complete ManualDokument286 SeitenC50SCR PLC Complete ManualthuanNoch keine Bewertungen

- Julie Trimarco: A Licensed Speech-Language PathologistDokument5 SeitenJulie Trimarco: A Licensed Speech-Language PathologistJulie TrimarcoNoch keine Bewertungen

- MPSI OverviewDokument15 SeitenMPSI OverviewZaqee AlvaNoch keine Bewertungen

- MLT IMLT Content Guideline 6-14Dokument4 SeitenMLT IMLT Content Guideline 6-14Arif ShaikhNoch keine Bewertungen